-

Posts

1,038 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by No Idea

-

Byrnes 18" extended table saw table

No Idea replied to davec's topic in Modeling tools and Workshop Equipment

In that case I would magnetise the screws so that they stay onto the screwdriver. That should sort your problem. -

Byrnes 18" extended table saw table

No Idea replied to davec's topic in Modeling tools and Workshop Equipment

I too changed my saw to a 18" table and I support all of what you say. Another benefit is that you can use the cross cut sledge without having to remove the fence. Just slide it out of the way. To fit the belt cover - the screws only need loosening and the cover slides rearwards and comes off. So if you remove your cover firstly put all of the screws into their locations on the saw but only loosely. Then place the cover over the belt and push forward towards the front of the machine. This locates it onto the screws and then you can tighten them fully through the access holes. -

I think we need to use the machines that our pockets allow. wefalck's comments are spot on - however I have seen some great results using cheaper machines but the trade off is time and waste. Time is how long it takes to get it right and the cost of materials doing this is expensive. Afford what you can and maybe upgrade later

-

Jim Byrnes Thickness Sander Maintenance

No Idea replied to Billtoons's topic in Modeling tools and Workshop Equipment

Hi - This is a very simple machine with sealed bearings. The drum is driven by a belt straight off of the electric motor so I would start with that. Remove the belt guard and just make sure that everything spins freely. If either the drum or the motor doesn't that will be your problem. -

L'Amarante by marsalv - 1:36 - POF

No Idea replied to marsalv's topic in - Build logs for subjects built 1501 - 1750

marsalv that is such lovely work especially the way you have fitted the planks into the rebate on the wing transom. That is as I have found difficult to get right so that they look square but you have it spot on. Very brave too with the amount of frames removed - I'm glad I've seen you do it as this is what I want to do with my next build. Happy Xmas and a very happy new year -

Sandpaper Grit

No Idea replied to Malazan's topic in Painting, finishing and weathering products and techniques

First planking I use 120 grit which I think is rough enough for any model. Don't go any smoother for than that for the first planking as it gives a great key for the second planking. You are trying to get a shape and not a finish. Second planking - well thats a personal choice as it depends on how you want your model to look. Some modellers stop at 180 grit and others will go very fine to maybe 800 grit. Its really up to the builder and the finish they want or are going to apply. -

@vossiewulf Your knives are amazing and I think that knives like these are far superior to scalpels. They take commitment and skill though to make them effective - alas I don't have your skills and I have tried over a quite a period of time to learn. It's a skill I will never possess as I just don't have the patience. It's so easy just to load another blade into the handle.

-

Hi All I use something similar to these https://im3vet.co.uk/scalpel-blade-holder-round/ They are heavy in your hand and give great control using scalpel blades...........just my Pennys worth Mark

-

I think your approach to this build is fantastic with accuracy being foremost. The pictures are great too looking at the grain of the wood it's all just so in line with each piece. Lovely job and I hope that you are ok after your op. I'm looking forward to your updates.

- 91 replies

-

Hi Ah I see your problem now but I think it's easily sorted. You have the basis of a frame but it's the building of the parts that seem the issue. I too had this issue and threw all of my first frames away - so I get it. So - The joints and their angles are very important and it took me a while to work this out. Once I started assembling my frames over a frame drawing my efforts became far better. You are so close so don't be put off just keep going. If you do decide to change tack and use Underhill's methods then good luck my friend. I do think that it can be done but Gerard's plans are so precise that I stayed the course. My build is 1/24th which actually shows any defects in accuracy as much greater. If I can help in anyway just let me know Mark

-

Hi Jackson and welcome to MSW I have a simple story - many years ago I was in a stressful job and quite frankly it made me not the nicest of people to be around. My Uncle Ray who built model ships told me to chill out and build a ship. He suggested that a change of job and hobby would do me good. He suggested a kit and I bought it there and then - I also changed jobs. The rest is history. Probably the best advice I have ever had and it changed everything for me. I became absorbed in model ships and have been trying to better myself in this hobby ever since. If I'm not ship building I'm thinking about it - what more can I say apart from - cheers Ray

-

Hi What's the issue you are having as I think the pictures of your frames look very good? They follow the plans nicely and the final finished shape is not needed at this stage as that will be sanded once they are all in. I think that translating the plans that you have into an Underhill system may prove difficult. I know of another builder who has tried this on this model and ran into some difficult problems. Your skills are more than enough so maybe just keep at the frames as they are? If you don't have a copy - Adrian Sorrolla's book gives a step by step tutorial on how to assemble the frames on this ship. I followed his instruction pretty much to the letter and it helped me complete them Mark

-

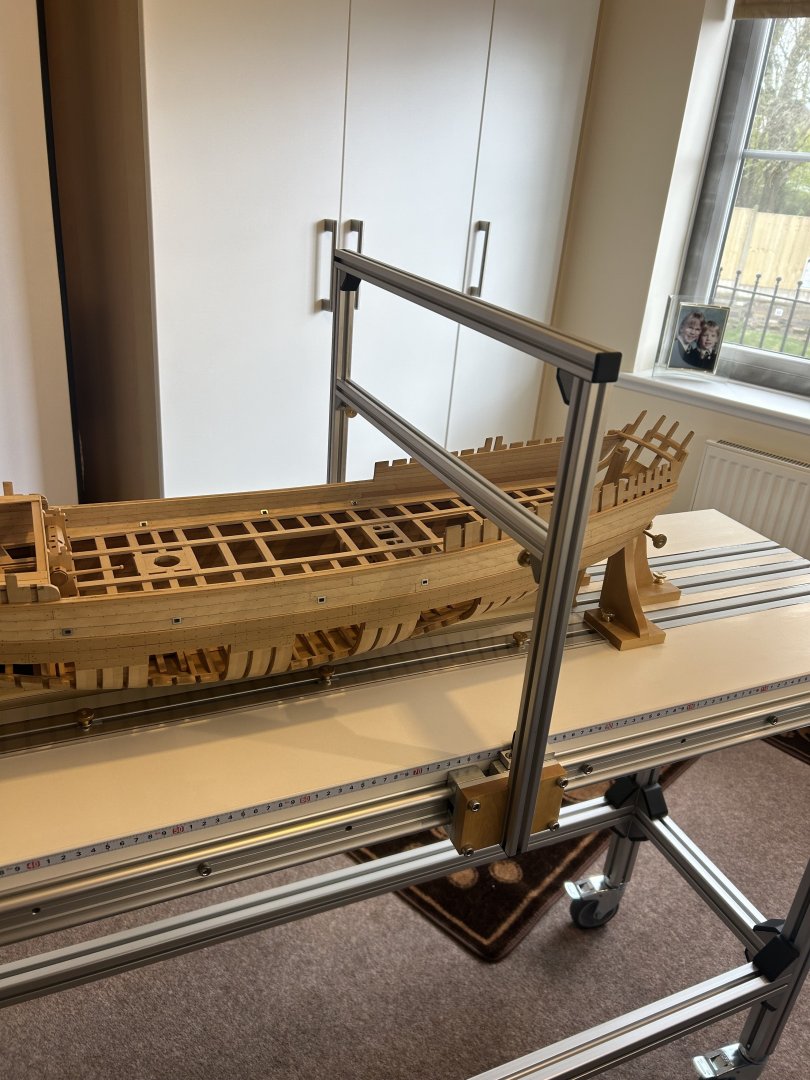

Gantry style building board dimensions advice

No Idea replied to davec's topic in Modeling tools and Workshop Equipment

This is my building table and I can let you know the dimensions when I get home sometime next week I’ve not actually had a chance to use it yet as my workshop has been completely taken over but that’s about to change 👍 -

The Foredom drill press is a very well made tool and its accuracy is fantastic. I bought one hoping it would justify the price and they certainly do. I also recommend the Starrett pin vices they are very good indeed and are well worth the money. They will last you a lifetime and then some. The comments about the drill bits are spot on - I buy cheap HSS jobber bits from RS in the UK and they last ages. They are also slightly flexible which helps when drilling in an awkward place say inside the hull with a 0.3mm bit.

-

Lovely work I used to worry about all of the little scratches and marks but I have found that as the ship progresses they disappear into the detail. When I cut my rabbets I did them too shallow - when I build me next ship I will have an actual plank ready to help me cut to the right depth. Keep the updates coming!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.