paul ron

Members-

Posts

292 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by paul ron

-

take a gear from a clock, mount it on a stick... pounce wheel.

-

Work area pictures only

paul ron replied to Johnny Mike's topic in Modeling tools and Workshop Equipment

-

Looking for ideas for work area

paul ron replied to Desertanimal's topic in Modeling tools and Workshop Equipment

find a door in the dumpster or get one at home depot for $60. you just need to build a base or just put it on a pair of horses. i like solid core doors over hollow ones, but either will do just fine. -

Dremel 4 inch table saw 588-2

paul ron replied to lynne's topic in Modeling tools and Workshop Equipment

hopefully someone here has this saw and can measure the pullies for you? you can get them in hardware stores or machine shops. contact dremel. btw amazon is world wide too. -

Dremel 4 inch table saw 588-2

paul ron replied to lynne's topic in Modeling tools and Workshop Equipment

-

Dremel 4 inch table saw 588-2

paul ron replied to lynne's topic in Modeling tools and Workshop Equipment

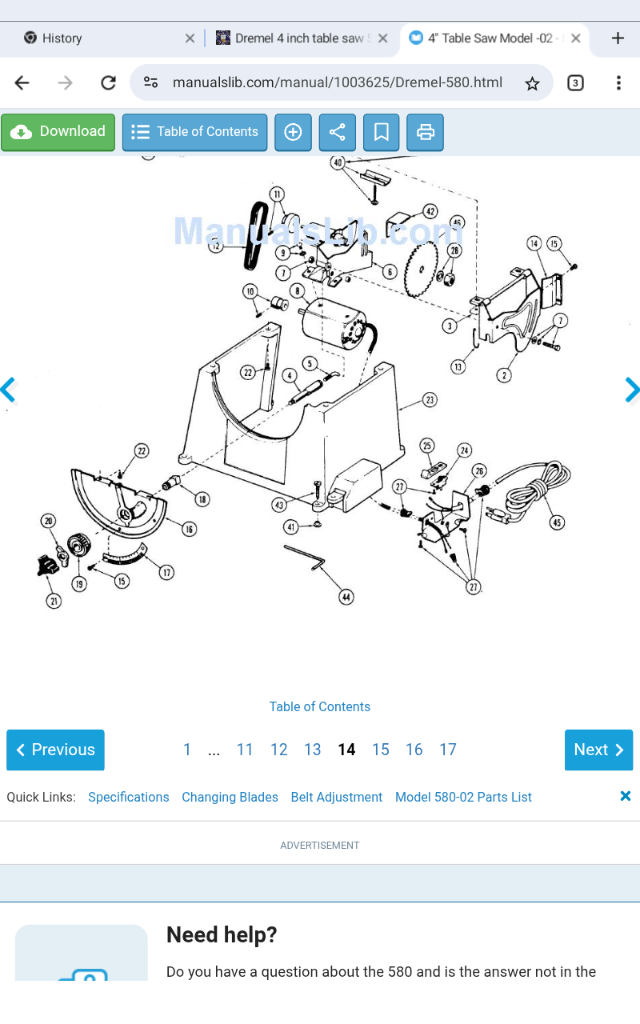

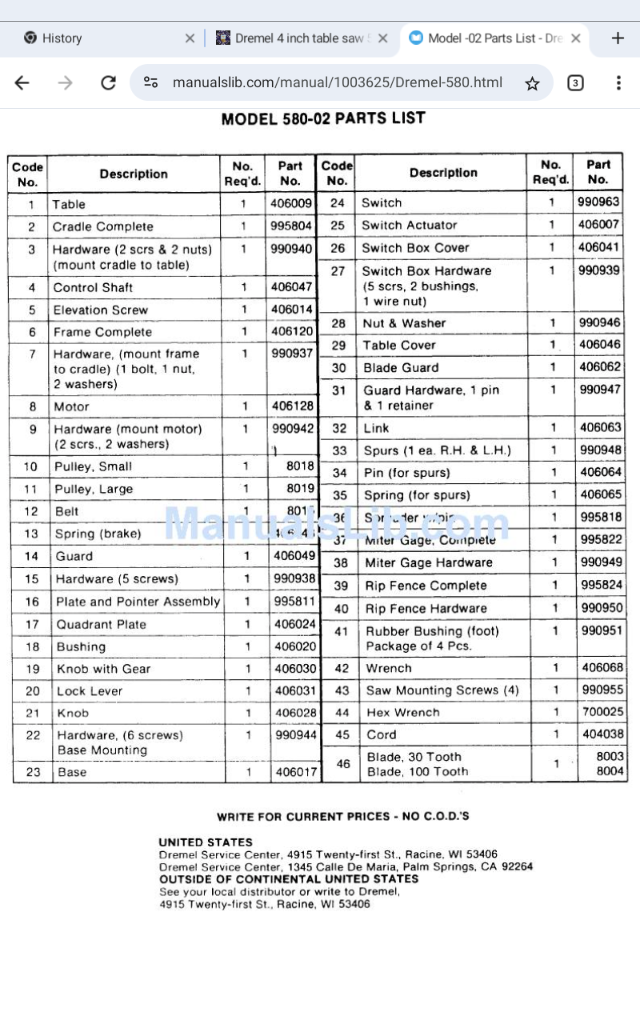

i took a screenshot of the parts list i the manual... https://www.manualslib.com/manual/1003625/Dremel-580.html?page=15#google_vignette seems there are 2 pullies available. perhaps a call or email to dremel to get the part? https://www.dremel.com/us/en/service-and-support/customer-support-services another way to go is try to figure out the size of the pully by measuring the belt slack. you may also put a multi pully so you can slip the belt for a different speed. btw the blade speed in the specs is about 9000rpm. the motor runs at 10,000rpm. -

Taig Lathe Motor Mount

paul ron replied to kgstakes's topic in Modeling tools and Workshop Equipment

im not familiar with these small lathes. i do have experiance on metal lathes, comercial machines, and wood lathes. are you working metal? an oil drip pan under the lathe and an oil feeder may be worth looking into. do you intend to do threading? there are special toolings and accessories needed for that. perhaps asking others here for literature and check out you tube videos to see how to properly and safely use your tools. videos... https://duckduckgo.com/?q=taig+desktop+metal+lathe best thing to do is use it, follow instructions, get plenty of practice. -

Taig Lathe Motor Mount

paul ron replied to kgstakes's topic in Modeling tools and Workshop Equipment

its not unusual to diy mount a tool's motor using a hinge. the weight of the motor should be enough to tension the tool to the drive belt... if not, you can use bungies or other additional methods to tension the mount. there is no additional stresses to worry about as long as its all aligned properly. -

Decals for draft markings

paul ron replied to g8rfan's topic in Painting, finishing and weathering products and techniques

the rub ons are hard to find in typesets or sizes let alone color. ive had pretty good results with the water slide. the paper is semi transparent so i trace the lettering off the plans using pen n ink. it would be great to find the rub ons we need. im all for the easy way out whenever i can. i hope everyone posts their sources here? -

Gold solder for brass

paul ron replied to Richard Braithwaite's topic in Metal Work, Soldering and Metal Fittings

a pen torch would be more than adaquate for such a small piece. but it seems by the conversation here, color is more important than heat. yes, silver solder would be fine, but some of the color matching sugestions are like killing mosquetos with a hammer. at the scale and size of the piece, the weld would appear insignificant. an eopxy fix would be more than sufficient but it's just too simple a solution. -

Gold solder for brass

paul ron replied to Richard Braithwaite's topic in Metal Work, Soldering and Metal Fittings

you do realize there are brass low temp brazing rods available? https://www.amazon.com/GEOYLE-Brass-Brazing-Rods/dp/B0C7P15LC9?th=1 -

Decals for draft markings

paul ron replied to g8rfan's topic in Painting, finishing and weathering products and techniques

do you have a link to where you got your rub on letters? -

Decals for draft markings

paul ron replied to g8rfan's topic in Painting, finishing and weathering products and techniques

oh u need white. that creates a different problem. ive made waterslide decals using my caligraphy pens n inks, i needed gold type. i coated the decals with clear satin acrilic spray before soaking in water to preserve the ink from running. perhaps try doing this using white acrilic paint on the print side of the paper? -

Decals for draft markings

paul ron replied to g8rfan's topic in Painting, finishing and weathering products and techniques

have you considered using water slide decal paper than you can print your own via an ink jet or laser printer? https://www.amazon.com/water-slide-decals/s?k=water+slide+decals -

Grommets for 1930 Pond Yacht Sails

paul ron replied to Kimberly's topic in Masting, rigging and sails

https://www.amazon.com/Diameter-Eyelet-Colors-Clothes-Making/dp/B0CM3R4NWQ/ref=sr_1_17?dib=eyJ2IjoiMSJ9.uutbGviZ3Xg8GlX5As_CaaMToYaSzKqOIPuhhggJLDjg9G79SaGl9sJ1dN4eZZNz6EIfcEJIXNXD-usPMCurDioiJM8Agj9AMnfTTAg9Lqa5CIaF_ea4M1drf53_RabEFkAb-K8t5K0IedsY7vCfd6qjNXV-S7LCElSadUaNr61CCGN_y9heNeX9KRqs1ocARl_aCAl-77SIYJt1h-SWPmv1Oz5VF7EIdfvxafbEickO3YcPttbNEQ5EE4ROWHgE2xTM2B6Fb8azHqTV7Rmf5Nhkf5x7OYnclaEFRYCTFWE.SWjrxCHUlZgjnbPKh1VjBFmdzzvuq69NAF6GubOeCUg&dib_tag=se&keywords=small%2Beyelets&qid=1750424228&sr=8-17&th=1 -

a simple amazon search found this.... https://www.amazon.com/small-eyelets/s?k=small+eyelets are these small enough? https://www.amazon.com/Diameter-Eyelet-Colors-Clothes-Making/dp/B0CM3R4NWQ/ref=sr_1_17?dib=eyJ2IjoiMSJ9.uutbGviZ3Xg8GlX5As_CaaMToYaSzKqOIPuhhggJLDjg9G79SaGl9sJ1dN4eZZNz6EIfcEJIXNXD-usPMCurDioiJM8Agj9AMnfTTAg9Lqa5CIaF_ea4M1drf53_RabEFkAb-K8t5K0IedsY7vCfd6qjNXV-S7LCElSadUaNr61CCGN_y9heNeX9KRqs1ocARl_aCAl-77SIYJt1h-SWPmv1Oz5VF7EIdfvxafbEickO3YcPttbNEQ5EE4ROWHgE2xTM2B6Fb8azHqTV7Rmf5Nhkf5x7OYnclaEFRYCTFWE.SWjrxCHUlZgjnbPKh1VjBFmdzzvuq69NAF6GubOeCUg&dib_tag=se&keywords=small%2Beyelets&qid=1750424228&sr=8-17&th=1 https://www.amazon.com/GORGECRAFT-Quicklet-Grommets-Backing-Eyelets/dp/B0D2MGBT6T/ref=sr_1_10?dib=eyJ2IjoiMSJ9.uutbGviZ3Xg8GlX5As_CaaMToYaSzKqOIPuhhggJLDjg9G79SaGl9sJ1dN4eZZNz6EIfcEJIXNXD-usPMCurDioiJM8Agj9AMnfTTAg9Lqa5CIaF_ea4M1drf53_RabEFkAb-K8t5K0IedsY7vCfd6qjNXV-S7LCElSadUaNr61CCGN_y9heNeX9KRqs1ocARl_aCAl-77SIYJt1h-SWPmv1Oz5VF7EIdfvxafbEickO3YcPttbNEQ5EE4ROWHgE2xTM2B6Fb8azHqTV7Rmf5Nhkf5x7OYnclaEFRYCTFWE.SWjrxCHUlZgjnbPKh1VjBFmdzzvuq69NAF6GubOeCUg&dib_tag=se&keywords=small%2Beyelets&qid=1750424228&sr=8-10&th=1 https://www.amazon.com/Grommets-Eyelets-Backing-Grommet-Project/dp/B0DC6F3FXS/ref=sr_1_7?dib=eyJ2IjoiMSJ9.uutbGviZ3Xg8GlX5As_CaaMToYaSzKqOIPuhhggJLDjg9G79SaGl9sJ1dN4eZZNz6EIfcEJIXNXD-usPMCurDioiJM8Agj9AMnfTTAg9Lqa5CIaF_ea4M1drf53_RabEFkAb-K8t5K0IedsY7vCfd6qjNXV-S7LCElSadUaNr61CCGN_y9heNeX9KRqs1ocARl_aCAl-77SIYJt1h-SWPmv1Oz5VF7EIdfvxafbEickO3YcPttbNEQ5EE4ROWHgE2xTM2B6Fb8azHqTV7Rmf5Nhkf5x7OYnclaEFRYCTFWE.SWjrxCHUlZgjnbPKh1VjBFmdzzvuq69NAF6GubOeCUg&dib_tag=se&keywords=small+eyelets&qid=1750424228&sr=8-7

-

Gold solder for brass

paul ron replied to Richard Braithwaite's topic in Metal Work, Soldering and Metal Fittings

how about brazing brass using brass rods? for brazing small parts, you dont need a torch. i use a mini butane torch. the brass rod comes in all gages, even wire form. flux is important. here is a nice article how to braze... https://weldingproperty.com/how-to-braze-brass/ -

i love zona razor saws and bought each one, even the one that has a few replaceable blades in the kit... that key hole blade is amazing! tpi depends on what you're cutting.

-

Bulwark Posts

paul ron replied to Jackie's topic in Building, Framing, Planking and plating a ships hull and deck

when you fabricated the posts, why werent they all made the same size or follow the plans more accurately? the dremel may be the best answer to take them down. but after making them all even with the shortest ones, will they then all be too short? how about removing them and redo it correctly? it wouldnt be too hard to take m off if sanding is knocking them off.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.