-

Posts

1,694 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by JesseLee

-

Glued on rubbing strake on one side. Got to the other side & even though I had already steamed & shaped it the other one broke in 2 places. Got mad at first but noticed it broke at angles along the grain which should be easy to hide when glued & it was. Then added on the stern rubbing strake reinforcements & the fenders.

- 607 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

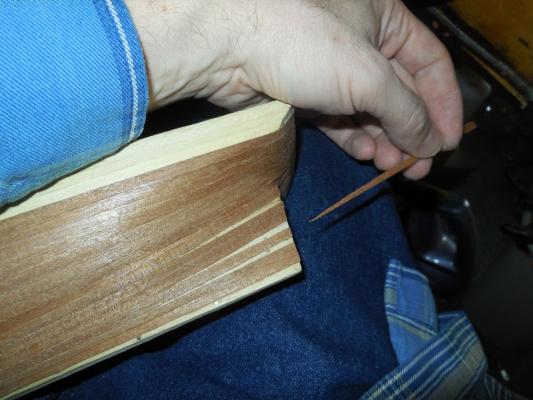

Scarf joints were still a lighter color after sanding sawdust down on them so I added a little stain along the joint with a toothpick & lightly sanded & they look much better now.

- 607 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

- 607 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

Scarf joints weren't as tight as I thought they were but I was prepared for this. I had some sawdust from these pieces ready. Packed it around the joints while the glue was still wet. Cleaned them off after the glue set & lightly sanded them.

- 607 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

- 607 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

Steve, yes, I want to blend them in better when I glue them. They are not as snug fitting as it looks in the pics. Keith is probably right that they will most likely disappear when glued.

- 607 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

I noticed that anywhere that had been glued looked lighter at the glue spots or lines. Thought I'd try to blend these areas in better. Got out some stain & a toothpick. Carefully added stain only on the lighter glue areas with the sharp end of the toothpick. Let dry good & very lightly hit with a sanding stick & it looks much better. This is how I will probably hide those seams too.

- 607 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

Last night while dry fitting the stem broke along the grain. Glued it back overnight & smoothed the glued edge down

- 607 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

- 607 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

- 607 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

The laser cutting on the stem & keel parts was not good. No matter how I tried to cut the parts out it was impossible to get them out without ends & edges with chunks wood out in places. I glued small wedges of wood in the broken out places & packed sawdust mixed with glue around it. When dry filed & sanded each one into shape. Hoping that there wont be any big color difference in these spots when finished.

- 607 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

- 607 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

Because of the bad edges of the wood planks in the kit there were quite a few very thin gaps between the planks. I fixed this by cutting thin slivers from the scraps from the planking & gluing them in the gaps.

- 607 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

- 607 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

- 607 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

Thought I would try Keith's tip. I used scrap pieces of planking to space where the other planks will fit. Pre-drew lines where the plank will lay. Glued plank at the stem. When it was dry I wet the plank on both sides then used an old hair straighteners outside edge to steam & dry the plank into shape. It works very well. Thanks for the tip Keith!

- 607 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

Thanks for the tip Keith, I'll have to try that

- 607 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

Finished making my stand. Painted it black & sealed it. Used a trick I figured out a long time ago. To prevent wood rubbing on wood I cut strips of the soft fuzzy side of Velcro strips. Glue them on where the hull will rest on the stand & add a few pieces under the stand. This helps with any unevenness with the bottom of the stand & also prevents rubbing or scratching between the stand & whatever you have it sitting on.

- 607 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

Began the outer planking. Started with the outer planking on the transoms then on to the hull. A little frustrated that the outer planking strips supplied in this kit have a lot of rough & uneven edges. Very difficult to line up without showing small gaps. I tried to see if I could sand straighter edges but the strips are too thin & I just break them when I attempted this, so making the beat of it & shoving them as tight as I can beside each other as I glue them.

- 607 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

Started working on a stand for the model. Decided to make a cradle type holder instead of the pedestal type stand.

- 607 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

- 607 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.