-

Posts

1,694 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by JesseLee

-

- 607 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

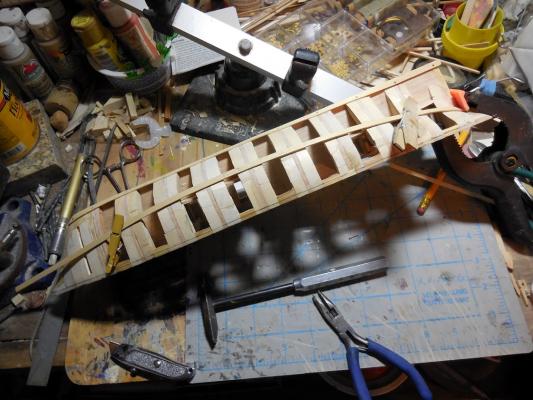

Continuing the first planking layer. A lot more wedges to fill on this hull than I've one in the past. Not sure if I will get all of these planks exactly right. The instructions are small 3 1/2 x 5 1/2 in. pics on a fold-out page. The whole first planking layer is covered in 2 or 3 of these pics.

- 607 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

Finally back to the planking. Making good progress in spite of Murphy showing up & reminding me he his still brutally enforcing his law!

- 607 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

- 607 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

What do you do when your razor edge hobby knife slips & stabs deep into your finger? First move your hand away from the model & all that precious wood so the blood drips on the rug instead. A Dr. visit for a few stitches would take too long & prevent any more progress on the build this afternoon (not to mention take away money for supplies) so squeeze like crazy till it stops bleeding, sterilize the area & grab the super glue. Works like a charm! All sealed up & ready to get back to the ship!

- 607 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

After removing some planks, deeply cutting my finger & some precise sanding it's looking much better now.

- 607 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

LOL, my wife has a hundred pair of shoes too! This is why I love working with wood. You can easily take away, add to, shape, re-shape, etc. It can be fixed if you have the will to do it. it's a great material to work with!

- 607 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

- 607 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

Glenn, I think I missed that too. It's ok, I have a lot of time on my hands & it's not the 1st time I've had to go back to redo something like this. This cold snap moving through is not good for someone with lyme so today I feel like I've been in a plane crash. Haven't felt good enough to do much work but did decide to make some templates to see how different each side is. Since my problem is aft I made templates for the last 3 sections it that area. The 1st one is pretty close, the 2nd shows a little more gap on one side & the 3rd one is so off it wont even fit over the other side.

- 607 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

A little irritated with myself. I spent a whole day the other day measuring all over to make sure I had everything right. Somehow I missed the stern area & have one side 1 1/2 -2 mm off from the other. Of course this throws off the plank spacing on each side so I will tear them off, sand the side down to the right spot & re-plank.

- 607 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

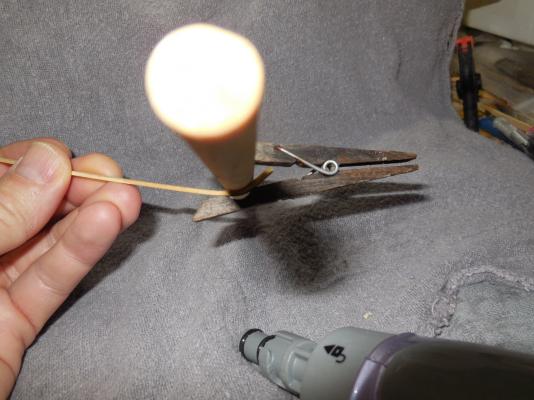

Went looking in the bathroom cabinets & found several extra curling irons not being used. (They all worked so I'm wondering what my wifes reasoning is for buying the new ones she & my daughter are using now - I will never understand women, lol ) Anyway I decided I would take them & use for additional plank bending tools. I got 3 different size curves & a straight one. Should come in handy in the days to come.

- 607 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

- 607 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

Sailor, It depends on how much you are familiar with modeling I guess. If you have built before you can figure it out. It may be hard to get a few things accurate mainly the right angle at the stern for the transom. The instructions seem to be made for modelers who have some experience in ship building.

- 607 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

Getting better results now. I heated a cup of water in the microwave till almost boiling & soaked the end of the strip for about 20-30 min. first then used the steamer & the wood is bending way better & farther now without breaking.

- 607 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

Works on average bends but on the real sharp bends I still got wood breaks & cracks. Trying a longer soak first for the one on the other side......

- 607 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

- 607 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

Yes, that bend is pretty sharp. It is easy to break even the softer woods at that much of a bend

- 607 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

I have an old unfinished ship( supposed to be the Mayflower) that I picked up in an antique store a few years ago. I thought it would be simple to restore & finish it until I actually got it home & got to looking at it better. A lot has to be redone. I've been messing with it off & on for a few years. Don't know if I will ever be able to finish it! Good luck on this project. Can't wait to see what you do with it!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.