-

Posts

1,694 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by JesseLee

-

Began cutting the timber heads. It takes 54 of these so this step will take some time & a lot of sawdust. Seeing the sawdust there I thought I'd show all the various colors I have saved up on this build. Being sick leaves you with a lot of left over medicine containers. They have worked well for sawdust containers!

- 607 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

Sanded everything down. Added more planking to the inside side of the transom. looks more like it should now. Once some paint is added it wont show on the outside. While I was at it I evened up the bulwark tops at the bow too.

- 607 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

As the transom top edge is made higher the bulwarks also had to be added on to a little also where they joined the transom. I took an extra strip of wood from the first hull planking & sawed it in half lengthwise. This made 2 strips almost exactly the right size to fit the top of the bulwarks. Added all this on

- 607 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

- 607 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

Looking good! Cant wait to see how this planking looks when finished.

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

-

Gluing the water-ways on when I noticed another problem. I didn't get the transom on at the right height as the side-by-side of the model & photo shows. This one has me temporarily stumped.

- 607 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

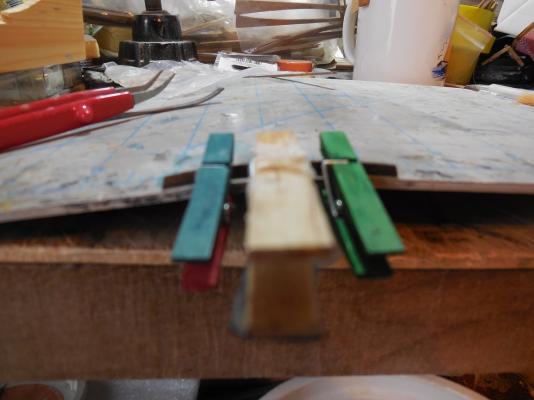

It took one more round of steaming & clamping overnight to get them to the final curve I needed because the wood resisted the bending. Taking these several steps at a time prevented any cracking & splitting. Now these parts are ready for when I get to them which is coming up soon.

- 607 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

After soaking clamped the parts with clothespins to pull down on them while steaming them. Used a hair straightener to heat dry to hold the new shape.

- 607 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

Was going to dry fit the stern waterway & saw that due to a lack of real instructions I did not get the correct curve on the stern & transom area. I was not going to re-do the whole end of the ship so since the parts that will fit here are pre-fab I've got to get them bent to match the curve I have. Dropped the stern waterway, transom step gunwale & stern gunwale pre-fab parts in water for a good long overnight soaking since they are all African walnut & do not bend well at all.

- 607 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

The wood looks nice like it is. Not going to worry about any kind of coppering. What would be the best way to show slight weathering (not too much- just a thin wash) all over the ship so that it looks more realistically used some instead of brand spanking new the first day she was launched?

- 607 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

Thank you Frank. guillemot, would any light greenish color do if I don't have chrome oxide green? Just as a very light watered down wash? Steve, I got the idea from one of the many discussions here on MSW somewhwere

- 607 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

I actually got the idea here on MSW somewhere

- 607 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

Just realized I left 2 pics out that should have come befire the last one showing the marking of the waterline & masking it for painting.

- 607 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

I was trying to read up on weathering ship models last night. Found a lot of discussion but not real instructions on exactly how to do it.

- 607 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

I used satin varnish- 3 coats, lightly steel wooled

- 607 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

Just caught this. Love the weathering & even the barnacles! Never seen a model done like this. Great job!

- 389 replies

-

- supply

- caldercraft

-

(and 1 more)

Tagged with:

-

Still feeling rough but working a little bit during this down time. Well, it was not an easy decision but historical accuracy won out. Don't know if I will leave the bottom like it is or if I will pain it too. Looks ok like it is.....

- 607 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

Yes, they haven't been added on yet. This is just a dry fitting ahead of time to see how everything fits together. Look at how much space there is from the inside edge of the crosstree & the mast pieces on each side. Shouldn't they touch?

- 607 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

- 607 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

I saw someone else square the mast. I looks better that way. The crosstrees from the kit seem to be spaced too far apart & have too long of a space for the mast doubling, but without any real plans I don't know if they are right or not.

- 607 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

Interesting. It shows her copper plated. I think like you from all the talk & reading that she most likely wasn't. Since I don't have materials for copper plating I may not go that way. Not sure if copper paint over wood planks would look right.

- 607 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.