-

Posts

538 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by SGraham

-

Andy, I'll just add a little to David's explanation. The frames intersect with the false keel at right angles, right? The outside edges of the frames are square in shape. The planking has to curve nicely with the shape of the hull. It can't do that if it's attached to squared-off frame ends. You'd end up with big ugly lumps under the planking. The contour of the hull sides doesn'trun parallel with the false keel. If it did, the boat would be shaped like a box. That's why you have to sand the outside edges of the frames so that their angle matches the curve of the hull at that point. Look at post #21 in my build log. That's where I'm trying to follow the same directions David gave you. Use a flexible stick so it can bend around 3-4 frames at a time. I'll answer your question about the directions later--gotta run and teach a class. Steve

- 55 replies

-

- corel

- shenandoah

-

(and 1 more)

Tagged with:

-

Hi Andy, I'm really glad to see you got your build log up and running. I'll definitely be following along. If we can get one more member to post a Shenandoah log, we'll have a fleet. The false keel in my kit was warped too. I have a luthier's bending iron. It's basically an aluminum pipe that gets hot. I didn't get the keel wet or anything. I just held it up to the iron where the keel was curved and applied pressure in the opposite direction of the warp. It didn't take long at all for it to straighten out. You could probably get the same effect with a curling iron set on high and clamped to your workbench. I've bent relatively thick pieces of wood before with a propane torch clamped to the bench, blowing into a length of copper pipe. I've also seen people use a soldering iron with steel wool wraped around the tip, stuffed inside a copper pipe. When you drop water onto the pipe and it dances right off, then it's hot enough to bend. Hope this helps. Steve

- 55 replies

-

- corel

- shenandoah

-

(and 1 more)

Tagged with:

-

HALF MOON by jct - FINISHED - Corel

SGraham replied to jct's topic in - Kit build logs for subjects built from 1501 - 1750

Great idea! -

HALF MOON by jct - FINISHED - Corel

SGraham replied to jct's topic in - Kit build logs for subjects built from 1501 - 1750

J, That planking looks really smooth. Did you follow the tutorials? I like the shade of white you concocted. You got a nice clean line. What color will the keel be? Steve -

Hey Andy, sound like we're in the same boat--no pun intended. When Model Expo had this kit on sale, it seemed like too good a deal to pass up for a project to learn on. Are you going to post a build log? I'd love to watch how your build progresses. Thanks J. +1 for the look of tung oil on walnut. My plan is to plank the hull in basswood (please note, that's my plan. My plans on this build seem to be working somewhere in the 15 - 20% range). I'm going to go with the paint scheme suggested in the instructions: white from keel up to the waterline, gray from the waterline to the wale, bright from the wale to the rail cap, gray inside the bulwarks. I'm going to try tapering the thickness of the outer bulwark planking from top to bottom so it's not such a pronounced step down in thickness when it hits the hull planking--even though there will be waling in between.

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

-

Thanks David. I rubbed them down to 400 grit, sealed them with a coat of tung oil and buffed them out with steel wool. Steve

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

-

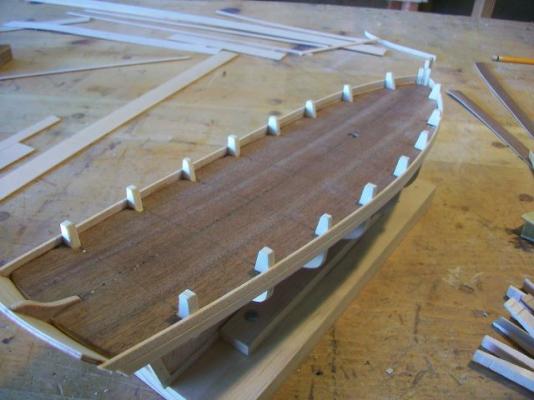

I'm waiting for Dressel's "Planking Techniques" book to arrive in the mail before I start on the garboards. So, while I'm waiting, I decided to plank the topsides in the walnut supplied with the kit right over the maple planking I installed earlier. One side of the ship is uniformly dark and the other has more variation. The planks were a lot of fun to install. I found a dental bit that makes holes the right size for treenails. Actually, I had to make the diameter of the bit a little smaller by running it against the edge of a metal file. I haven't made any holes in the planking yet--only on scraps. I'm not sure what to fill the holes with that would look good against the dark walnut planking. Suggestions? Being new to this, I had been wondering how one goes about handling the stem rabbet on a double-planked hull. The first layer of planking had already been glued into the rabbet. How would I make room for another layer of planks? The old Dikar kit that I built back in 80's had you finish planking the hull and then cut a slot for the stem to fit into. It was very hard to do and looked pretty bad. I really like the look of the plank ends resting cleanly in the stem rabbet. As it turns out, it was quite easy to cut a new slot in the first layer of planking. It literally took only a few seconds. You old hands know this already, but I included this for any other newbie like me who might have been wondering the same thing. Just cut it like you did the first one in the false keel, except this time you're cutting it into the first layer of planking. I also planked the insides of the bulwarks and made waterways. I cut the waterways out of maple and used an oscillating spindle sander to get the curve right on the inside. I gave these and the insides of the bulwarks a coat of gray, because I need the contrast in order to install the false frame tops (54 of them total) and then to cut scuppers in between the frame tops. I'm not looking forward to that part of the build, but it has to be done. Actually, a day cutting scuppers beats a lot of other activities that I can think of. If you look closely on the last photo, you can see the little pencil tick marks where the frame tops will go. A few strokes of a file exposes enough wood for a good glue joint. Steve

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

-

Jesse, That transom looks great, very symmetrical. I'm enjoying watching the Maid take shape. Steve

- 607 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

Thanks J. I also started planking up from the bottom of the bulwarks up but found that my top strake was uneven. I've looked around at people's builds here and have decided that I really like the look of an even, symmetrical strake just below the handrail. Maybe any unevenness at the bottom of the bulwarks can be hidden under the waling? Anyways, I'm starting the planking over. I take it that ripping out and starting over is not uncommon in ship modeling. Steve

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

-

Thanks David. That's great information. I found and ordered Dressel's book. You're right, they are available for very little money. I want to work at this until I really get the art of planking down. Can't wait to give it a read. Steve

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

-

Hi David, Thanks so much for the reply and for the kind comments. My shop is all geared to bigger work. The fine, intricate work you all do on this site simply amazes me. Do you have any ships finished or under way here? Your thoughts about beginning with a long strake make sense and coincide with what I learned from experience. The maple planking would have looked good, but I had a hard time getting a good clean edge on it, as I had to cut the planks with a knife. My table saw is kind of big for such a fine task. I've got a little Craftsman 8" freebie that needs restoring before it can be used but I don't want to put the boatbuilding down. As far as the garboard goes, I can resaw some basswood and don't think I'll have as hard a time cutting my planks out as I did with the maple. I'm going to try to follow Charles Davis' instructions in The Built-Up Ship Model, which I'm sure will be a bit harder than they seem. Do you have insights to share on garboard strakes? Steve

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

-

J, Did you plank the topsides from the deck level up or from the rail level down? Steve

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

-

Hi J, I first tried shorter lengths but found it hard to establish a clean, fair curve. Maybe one long plank to start with to set the pattern and then shorter planks on the rest? How's the Half Moon coming along? Steve

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

-

Hi J, Thanks for the response. I'm planning on using basswood planks the same thickness as the maple ones. Everything below the bulwarks is getting painted, so I'm not concerned about wood matching. As far as bending goes, I'm just going to have to see. I've got a heavy duty bending iron that bends the maple planks very quickly even when they're dry. So, I'm thinking that if I soak the basswood well before bending I'll be OK. Planking is about as hard as I remember--even the topsides which are supposed to be easy. I'm not happy with the look of the planks on the bulwarks and am going to cover them on the outside with the walnut planks supplied with the kit. Steve

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

-

All right, so I've got the bulwarks planked and the frame tops cut out and filled. I think I got a little too enthusiastic rounding off the edges of the planks. Oh well. I'll try to sand them down a bit after I install some false frames to the insides of the bulwarks for strength. If they don't look better after sanding, they just might get filled and painted...or I could double plank the model. The frame tops were a lot easier to cut out than I thought they would be. This boat building is downright absorbing. Steve

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

-

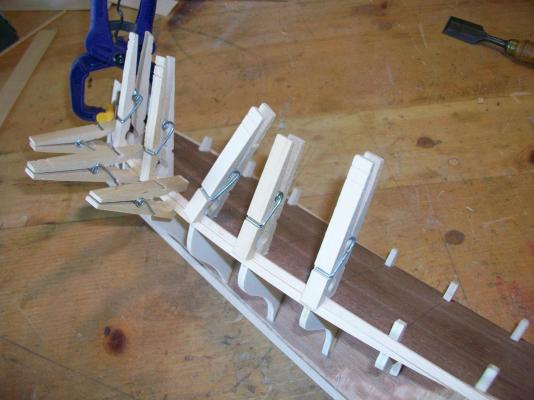

So here's what I decided to do. I'm throwing away the plywood bulwarks (if anybody wants them, let me know). I'm using one layer of maple planking only--on the outside of the frames. I'm gluing the lowest bulwark plank to the frames. This is the plank at the level of the sub decking. The plank that lies above that one will be edge glued to the one below it. I'll still use the frame tops as a form, but the planks won't be glued to the frame tops. I'll stop the bead of glue when it gets near the frame top, and then start it up again when I'm past the frame. This way, all of the bulwark planks will be edge glued together, and the frame tops should be easy enough to cut out and remove. The false frame tops that I'll add later should provide plenty of strength--sort of like a nicely jointed guitar top with lateral bracing underneath it. In the first picture you can see my see-through stem rabbet. And in the last photo I thought I'd show the clothes pins I was using as clamps. I had them clamping sideways and vertically on and between every frame. When I picked up the hull, all of the sideways pins let go at the same time, flying over the workbench. It was a most impressive clothes pin broadside. I don't think I could repeat the maneuver if I tried. Here are the first two planks on each side. Steve

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

-

I've begun planking the bulwarks. Ever since the planking on my Roger B. Taney came out looking so badly back in 1982, I've been reluctant to try it again. Of course, I didn't have MSW available to me back then. The kit came with a pair of plywood bulwarks complete with tabs and slots to help you fix them to the sides of the ship. Since I've decided to try single-planking this hull, I thought the plywood bulwarks might cause a problem. The plywood is the same thickness as the hull planking. Once you've got the plywood installed, you have to cover it inside and out with planks. This means that the bulwarks will be thicker and sticking out further than the rest of the hull planking. If I was double-planking the hull, then the second layer of hull planking would make up the deficit in thickness. Also, the instructions from Corel state that the plywood bulwarks should be glued to the frame tops. After they are dry, the frame tops should be cut away from the bulwarks, down to the level of the sub decking. Then, after the planking is applied inside and out, false frame tops are to be glued onto the inside of the bulwarks. On the real craft, the bulwarks are planked on the outside only, and the frame tops are visible from the inside of the bulwarks. I've been thinking about how to build the bulwarks without using the plywood. Here are the plywood bulwarks. Steve

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

-

I took a look at your build log. It looks like your fix worked very well. That's one nice thing about wood. It's pretty forgiving. I'm looking forward to seeing the Scottish Maid progress. And your boys looked like they were thoroughly intent on helping with the build. They'll remember that. Steve

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.