-

Posts

2,654 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Glenn-UK

-

-

Hi Rich.

Many thanks for the view and kind comment. I'm leaving plating the stern post and keelson until I have finished plating the hull (both sides)

-

Hi Jerry

I'm pleased I'm getting near the end of completion of the copper plating, however I have it all to do again for the port side, so should be getting near completion when you return from your European holiday. Have a great time.

I more than ready for the next phase of the build but will press on with the copper plating to its conclusion.

-

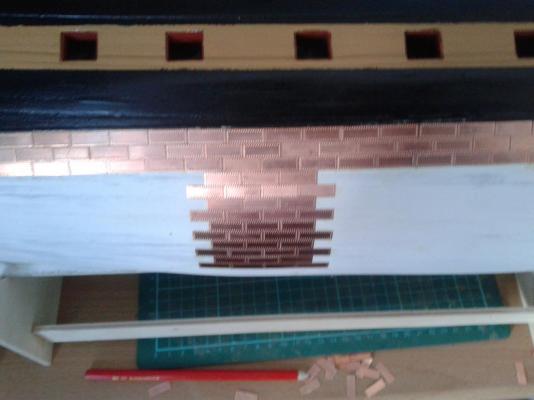

I love it when a plan comes together, the copper plates seems to be aligning as I continue with the infill at the keel.

Given my past history with measurements around the house with various DIY tasks I'm surprised and very pleased.

Will continue to build up from the keel as work continues on the infill.

- MarisStella.hr and canoe21

-

2

2

-

Good morning Rich and Jerry

Many thanks for your visit to my log and kind words. I really appreciate my work being compared with Lawrence as he is a true master of the art of model ship building.

Glenn

-

- MarisStella.hr, canoe21 and WackoWolf

-

3

3

-

Just found your build log, welcome to the HMS Victory build, there is a wealth of experience on this site from other HMS Victory builders, such as Shipyard Sid, Gil and Jerry which I have found to be invaluable as I progress with my build.

-

David

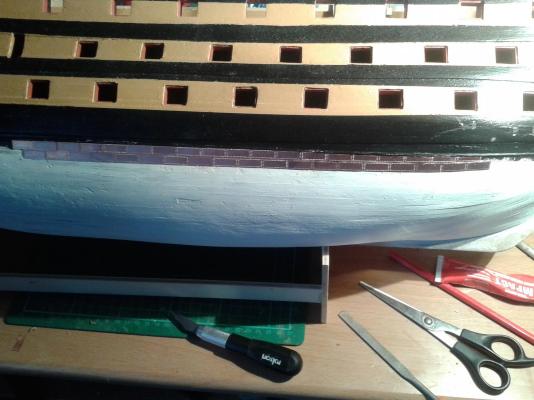

You were correct it has been a bit awkward today as I progress very slowly and carefully south toward the keel.

I have sorted out the copper plating line at stern post down to keel, so last row of plates will run true with the keel and should also be an exact plate width so no trimming or overlapping required (best laid plans of mice & men!). Also started sorting out the bow rows which will take a bit more time complete for the next three rows. I then plan to plate up a few rows from keel until I reach the completed plates at the bow. This in theory should just leave a few rows in the central area to complete.

No ship build work scheduled for tomorrow as the admiral has booked tickets to see a play in our local theatre. Build time may also slow down a bit as I understand there is a football (soccer for my Amercian friends) tournament starting later in the week in Brazil which will command some of my valuable time, but not to much hopefully as I have installed a tv in the workshop so I can multitask!

-

Many thanks David.

It is fiddley work cuting the end plates for stern post and bow but I'm taking time to check fit before I apply the glue. The bow has been more challenging than the stern and your pictures have helped me out. I'm also taking time to bend the plates before fitting as necessary. How is the barge build progressing? Will be interested to know where/how you fitted bulkhead 6.

-

Hi Jerry

The rigging looks amazing, what's happened to the long pointy thing?

-

Many thanks for your very kind comments. I will be very happy if my build turns out as good as yours look.

-

524 copper plates now fitted. I think I'm about 40% complete on the port side.

I think the Evostick instant glue, as recommended by Shipyard Ship has proven to be a sound choice, although I have found it necessary to use ca glue for the odd copper plate at stern and bow end.

My hat goes off to the builders, like Jerry, who used ca for fixing all the copper plates.

Here are some up to date pictures, I think I will replace one of the plates at the stern as I'm not totally happy with the fit.

-

-

As with all Victory build tasks what seems difficult in the beginning tends to get easier as we master the different techniques required for each stage. Your build is an excellent example of what can be achieved with dedication and hard work.

-

Hello Dave

I wasted 250+ plates with my false start and as they were quite cheap thought I would stock up just in case.

How is the barge build progressing?

-

Hello Tim

The copper plates are supplied with the kit, but replacement plates (of different styles) can be ordered from Cornwall Model Boats, I have ordered 500 additional plates, to cover my false start and to ensure I have a got a good spares level. Ordered them on Monday and they arrived in post on Wednesday.

Check out CMB web site for more information.

Hope this helps.

Glenn

-

-

-

It didn't take too long to remove the copper plates and excess glue and then to repaint as necessary.

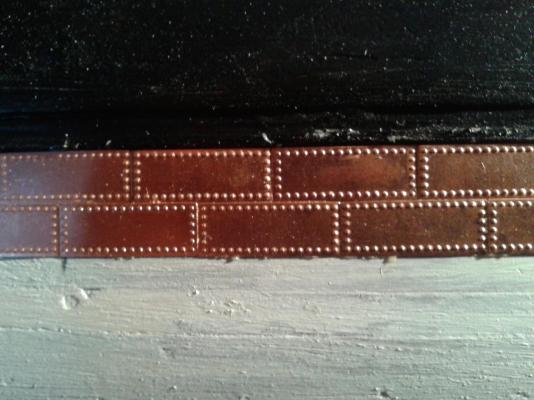

Started coppering again tonight, using the my lighted magnifying glass to check each plate. I'm very happy with the installation this time around.

It has worked out fitting time is 2 minutes per plate at the moment, which includes the shaping time of some of the tiles, this time will reduce quite a bit when I'm not having to cut the plates.

I plan to finish the first two rows completely before moving down to the next 2 rows this time and when complete move on to the next 2 rows etc.

The last tile on the 2nd row does look slightly out of alignment on the photos, but this is an optical illusion as it correct in real life.

-

Hello Jerry

I echo David's comments, that is one cracking photo, it really shows your all hard on you excellent build.

-

Hello David

I'm sure once you have built the small boats and experimented with some positions you will pick the best solution as always.

-

Thanks for you're comments, I glad I discovered the error of my ways at such an early stage and will soon have everything back to how it should be.

I should use the magnifying light more but its very old and not very user friendly so I tend to use it as a last resort. I think maybe I need to see if I can get the spring loaded adjustable arms to move in a coordinated manner. At the moment they have a mind of there own and will not cooperate with me when I need to adjust the postion.

-

On the face of it my copper tiling looks ok, and when I came back tonight from a family day out I started to fill in the gaps, as shown in in the first photo.

I used my light with built in magnifying glass to help check the cut tile fitting. But this also highlighted some issued with the installation of some of the basic tiles, some were not butted up to the adjacent tiles and some where overlapping the adjacent tiles. This is shown the in the next three photos. The excess glue is from removed tiles, which is explained later on.

To the naked eye it would probably be ok so I decided to continue with the installation of the next few tiles but soon realised there was going to be an alignment issue which was not going to easy to correct.

I have therefore taken the decision to rip of the tiles and start again, taking much more time to ensure I get the first two layers neat and tidy, using the light / magnifying glass to confirm the correct installation of the tiles.

Thankfully the tiles have been coming off without too much effort and removing the excess glue has not been a problem. I will complete removing the tiles tomorrow and will start again, with less haste. Will also order some more copper tiles from CMB!

-

First 200 copper tiles are now fitted, took 30 minutes to fit the last 50 tiles, so maybe it will not take as long as I first thought to complete.

Will start again on Monday as we are away tomorrow for the day. The first task will be to fill in the gaps as per Dave's (Shipyard Sid's) recommendation.

A couple more pictures of my progress.

-

Started the fitting the copper tiles today, 152 fitted in first session. I'm using Evostick instant which is a very good glue for this application, as advised by Shipyard Sid. It is very easy to roll off any excess glue once the tiles are fitted.

When working along a line I'm spreading the glue for 5 copper tiles, generally taking about 2 minutes to spread and fit 5 tiles.

I don't think this task is going as bad as I feared, yes it will take plenty of time to complete, but I'm finding it strangely therapeutic.

Sorry about the poor quality of the photos.

- CaptainSteve and Rich.F

-

2

2

HMS Victory by Glenn-UK - Caldercraft - 1/72

in - Kit build logs for subjects built from 1751 - 1800

Posted

Hello Lawrence

Many thanks for your visit to my to and your kind comments. I think CA is better in terms of getting the plates to adhere to the hull around the curves, and I have used for sitting some of the plates. The Evostick glue, which is readily available in the UK, works fine for the majority of the plates, and is easy to clean of plates and fingers.

I'm really impressed with your build.