-

Posts

1,500 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by archjofo

-

Hello thanks in Advance for the nice comments and the LIKES. To be continued: Other tackle elements for the bowsprit were manufactured and installed. There are then later fixed different stays. I show step by step how to dress a strop with genuine leather. First step: Second step: Third step: Fourth step:

-

I love these details. Unfortunately, only the chimney can be seen on my corvette.

- 306 replies

-

- schooner

- la jacinthe

-

(and 1 more)

Tagged with:

-

@KORTES This is model building at a high level. Fantastic performance!

- 306 replies

-

- schooner

- la jacinthe

-

(and 1 more)

Tagged with:

-

Hello Ed, very fine and beautiful detail work.

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

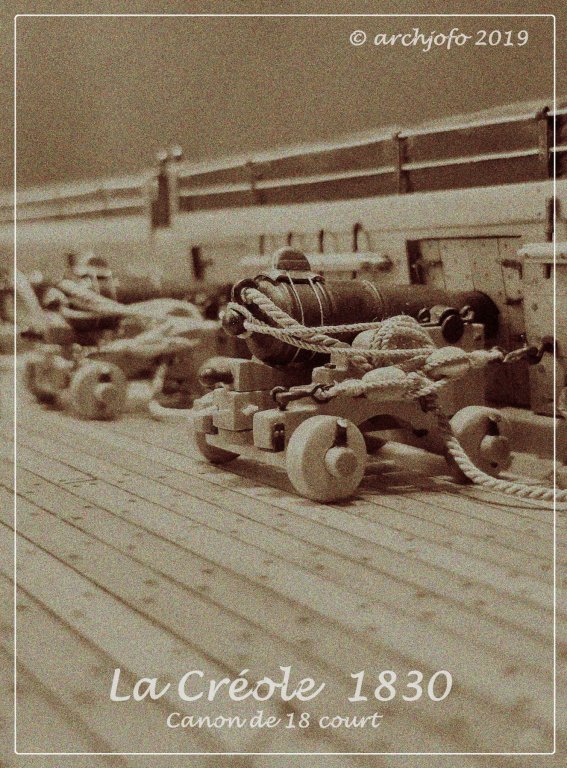

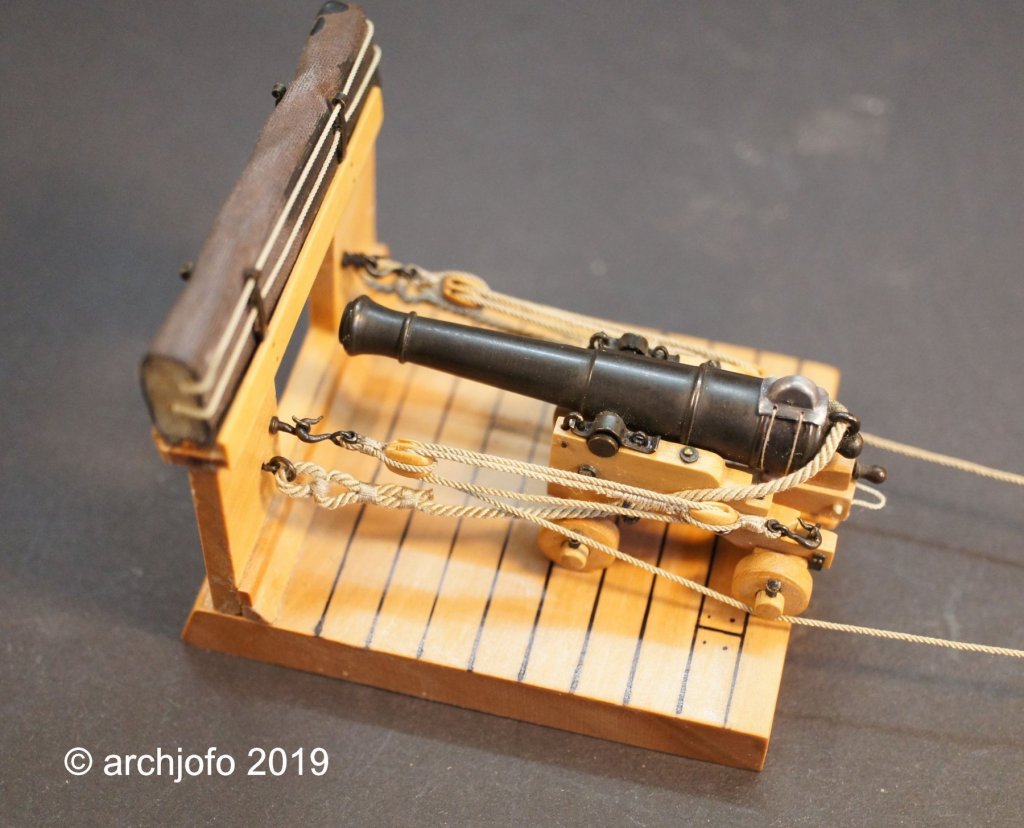

Hello, thank you for the interest! Just wanted to see what the 18-pounders of La Créole look like in the style of a historic postcard. In this context, a small note: The four 18-pounders, which were set up as part of the original equipment on the La Créole in 1829, were actually a bit dated at this time. This type of cannon was based on a system from 1786. Later, in 1837, these 18-pounders were replaced by 30 pounders of the Paixhans system.

-

Hello, thank you for the interest and the LIKES. This is how the gun looks full rigged on the model ship. It's pretty tricky to install the cannon on the deck. I replace the unsightly ropes in the hammock cranes with new, darker ones. I bought the previous ropes. But now I can make the ropes myself with my ropewalk.

-

This is a totally clean and great performance.

- 306 replies

-

- schooner

- la jacinthe

-

(and 1 more)

Tagged with:

-

Fantastic detail! I have a penchant for the French ships of the 19th century. And the La Jacinthe is a wonderful example of the elegance of these sailing ships.

- 306 replies

-

- schooner

- la jacinthe

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.