-

Posts

1,499 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by archjofo

-

Hello Michael, Paul, @deadbrotherbear, and @aviaamator, thank you for your interest and the nice comment. Also thanks to all for the LIKES. Here is a little update: I had completely forgotten the coppering of the mizzen mast in the upper area as protection for the jaw of the gaff. I remembered how I made the leather for the gaff. Another detail for the mizzen mast is a fitting for the topping lifts of the davits.

-

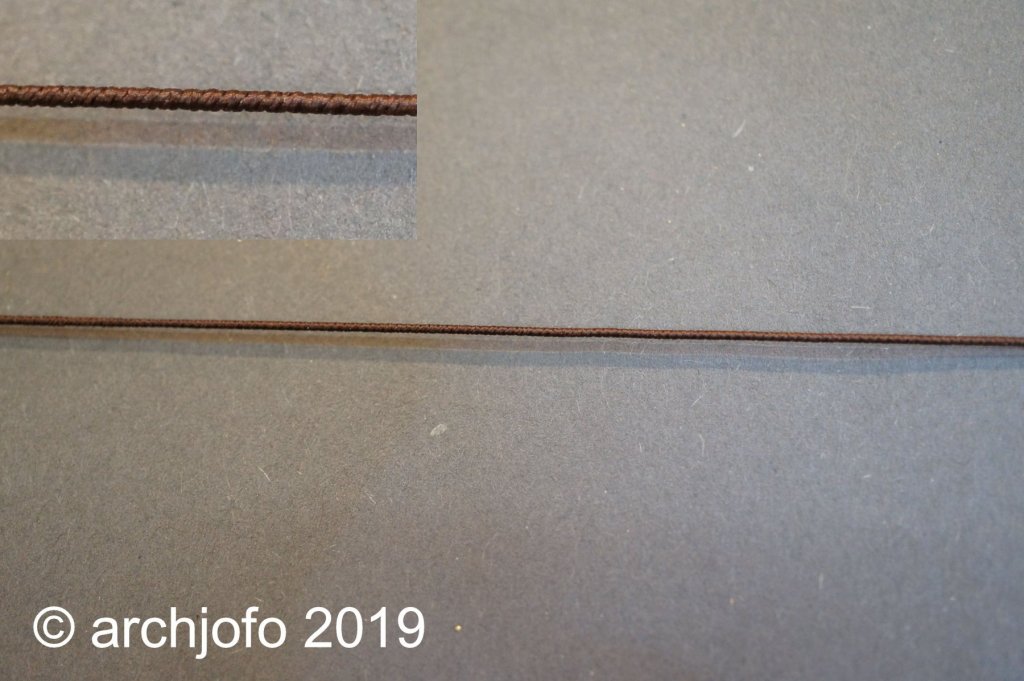

Hello, thin leather about 0.15 - 0.2 mm is not available. So you have to make thin leather even thinner. For this I have built a primitive device, as can be seen in the following picture. For example, the bobstays are served with leather. The thin leather, about 0.2 mm thick, can easily be glued around a rope after splitting, as shown in the next picture. The jaw of the gaff was lined on the inside with leather.

-

Hello Doris, the letters for the nameplate look fantastic again. Simply admirably beautiful!

- 1,035 replies

-

- royal katherine

- ship of the line

-

(and 1 more)

Tagged with:

-

Hi Alex, again you have a masterpiece created! Congratulations to this magnificent model ship!

-

Hello, today I tried serving with a thin rope. This rope has a diameter of 0.45 mm. It works just fine with the device. But the macro shot shows that the yarn is too thick in relation to the rope. For my model in 1:48 scale this is certainly not relevant. However, it might be interesting for smaller scales. @druxey The worming of ropes probably requires too much effort on a scale of 1:48. Has anyone practiced that?

-

@ Jorge Diaz O Thank you for your interest and your nice comment. But with assistance here in the forum that was not too difficult. Therefore, thanks also to the others, who helped with suggestions. In addition to a thicker dew Ø 1.6 mm, I have also served a thinner dew Ø 0.9 mm. Now the rigging can begin ... oh, I have to clarify the questions about the material and the coloring before.

-

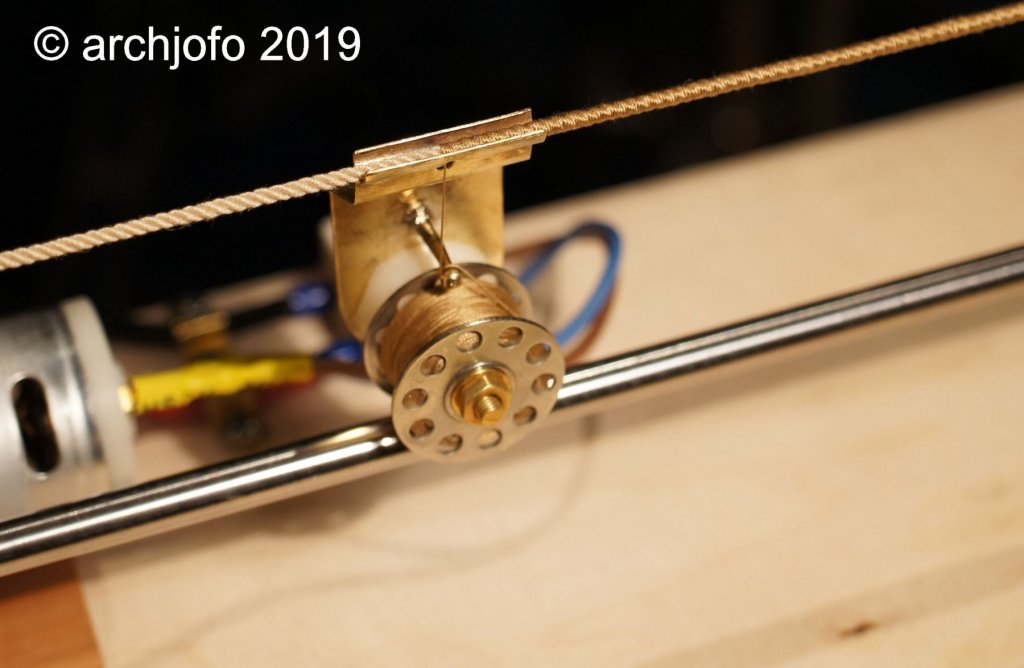

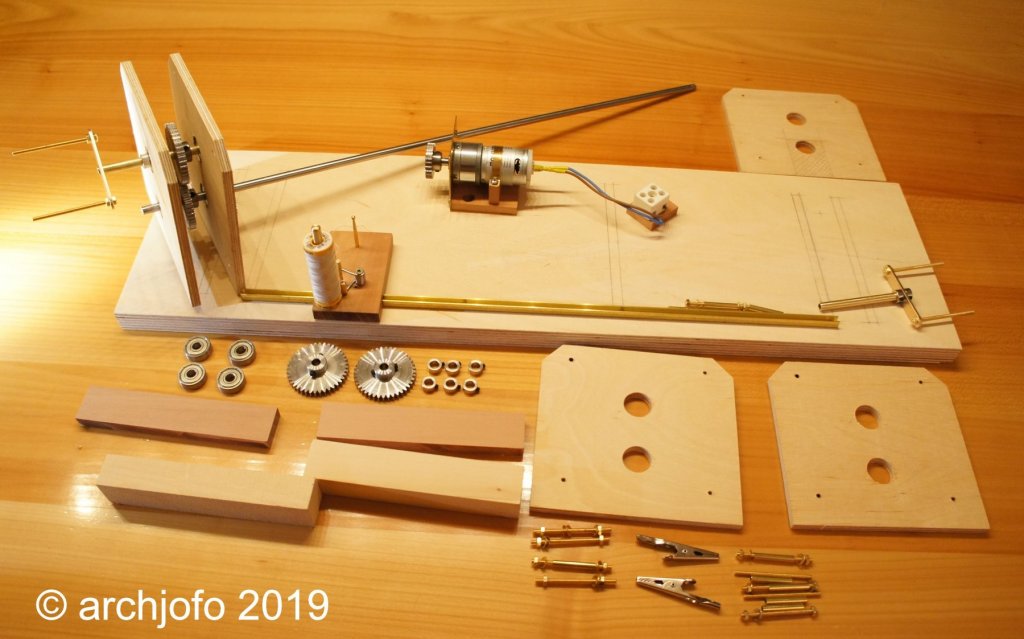

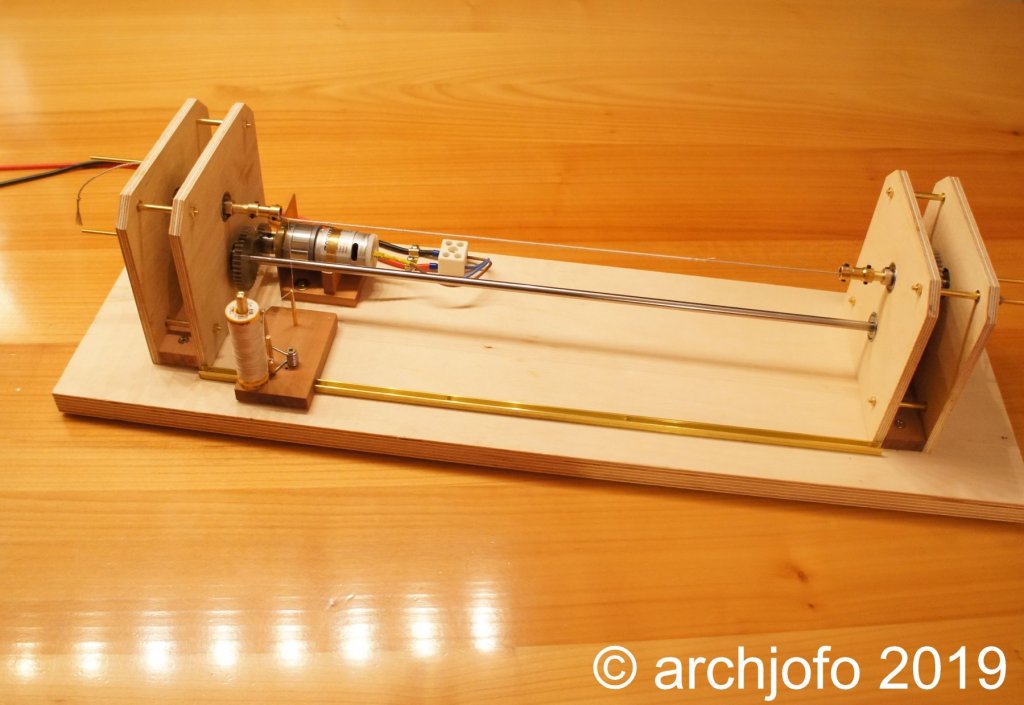

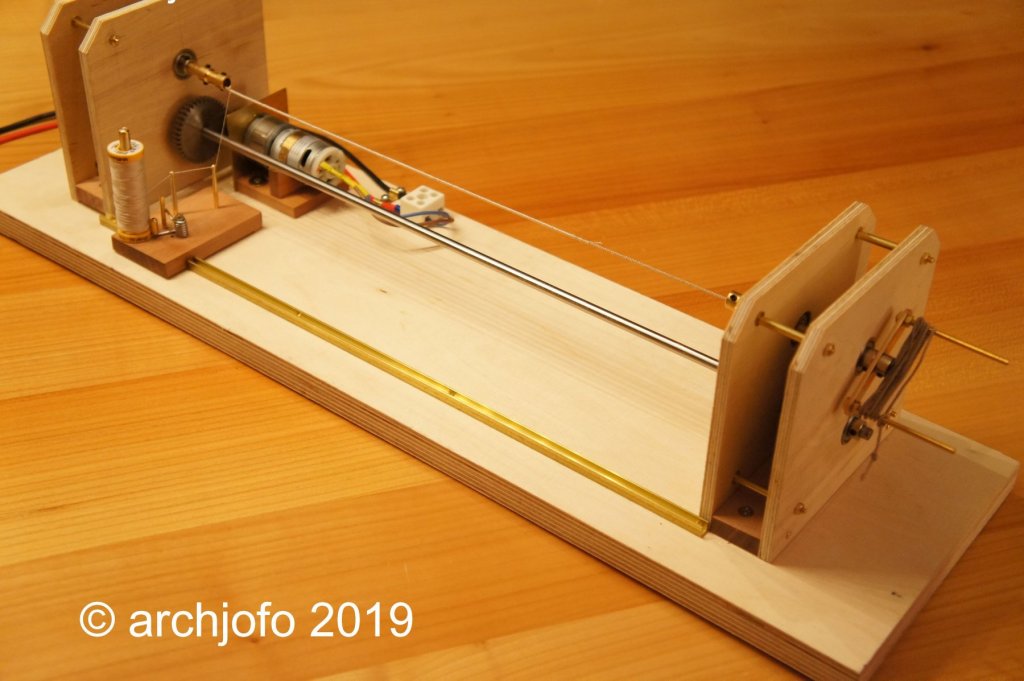

Inspired by previous discussion on serving of ropes, especially with regard to an automated thread guide, I tried to implement them according to the examples from the Internet for my rope serving machine. Actually, a simple device that receives the propulsion through the juxtaposition of the thread, and thus moves on independently. Very important here is the adjustment of the tension for the thread, which is pulled by the rotating rope from the spool. A short video sequence shows this process very impressively: LINK A very special thanks to @Dziadeczek for your suggestion. The serving of the ropes is now, more or less, automatic and, above all, very even. Up soon …

-

@ Michael mott Hi Michael, yes, the carriage with the spool has to be moved by hand. But that works pretty well. Nevertheless, I still try to optimize. I already admired your machine. This is a very nice device. @wefalck Hi Eberhard, your considerations for a rope serving machine are also very interesting. The control of the thread tension with the index finger is very promising. @Dziadeczek Hi Dziadeczek, that is of course a very interesting hint. I´ll try that, if the serving will be tight.

-

First of all, many thanks for the greetings for the New Year and I hope that your interest in my report will continue in the New Year as well. Steve, thank you very much for your nice comment. Before I start with the shrouds, I still need a device for serving ropes. First of all, I drew a plan to get the material and parts. The first attempts with the rope serving machine were very successful. In order to be able to control the tension on the thread better, I have to think of a supplement for the device.

-

Hello Doris, it is phenomenal how you manage all this and, above all, in a quality that is admirable. I wish you and your family a happy new year.

- 1,035 replies

-

- royal katherine

- ship of the line

-

(and 1 more)

Tagged with:

-

Hello, as mentioned earlier, polyester is not an option for the ropes of my French corvette. That's why I kept coming up with information about the durability of silk on the internet, partly from scientific papers by conservators of museums. Ultimately, I can conclude for me that no specific time can be made to the durability of silk, it depends on many factors (environment, location, light conditions, processing, etc.). In any case, the silk rigging will outlive my existence for a long time. The difference between ropes made of linen and silk ropes is clearly visible in the next two pictures. The ropes made of silk therefore look smoother and cleaner. The rope made of linen is a little rough. If I make the ropes of silk, I can choose between 180 colors, for example at Gütermann. The right brown for the standing good will already be there.

-

In the meantime my attempts continued on the ropewalk. The following pictures show the last results. For these ropes, which have different diameters of 0.8 mm to 1.5 mm, I used linen yarn from Bockens NeL 60/2 or 120/2. I am so satisfied with the result. It is important to improve one or the other, but this will come with the further exercise and the associated experience. Ultimately, I'm still working on the color and the conservation of the ropes and the final decision, which material should be used for the cordage of my corvette. After the ropes made of linen yarn did not look too bad in the meantime, I tend to be more interested in this material at the moment.

-

@maturin This is an extremely interesting contribution about rigging of contemporary ship models. Can you tell me something about the use of silk to make ropes and how long does it last? Are there historical examples of silk rigging and how old are they? What is your recommendation for using silk for ropes?

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.