-

Posts

1,499 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by archjofo

-

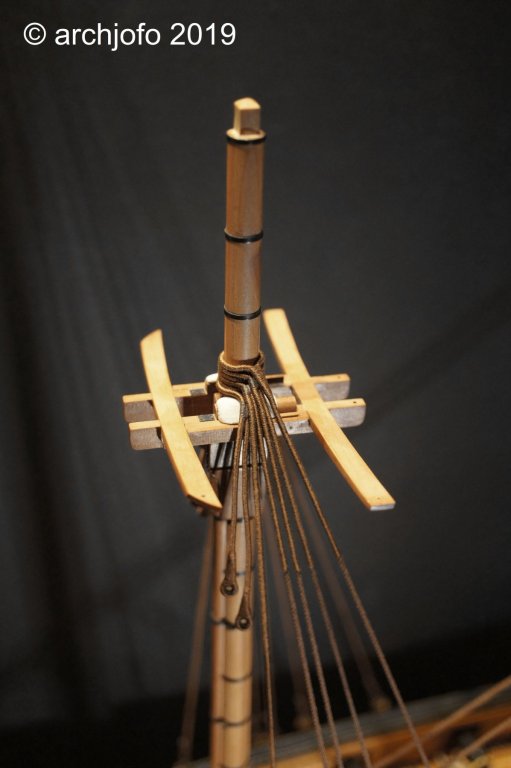

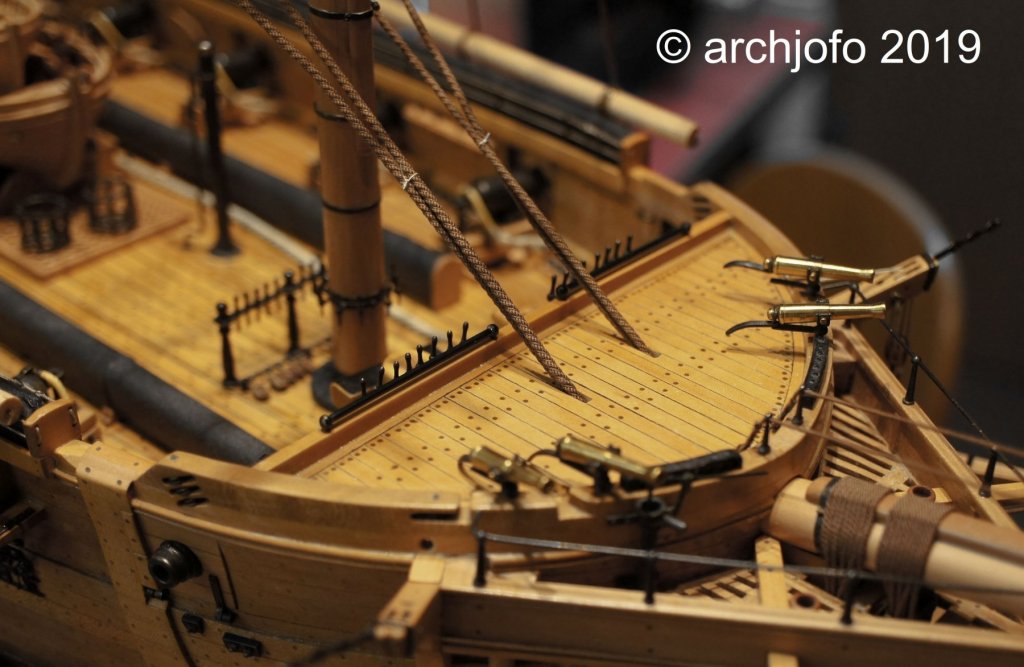

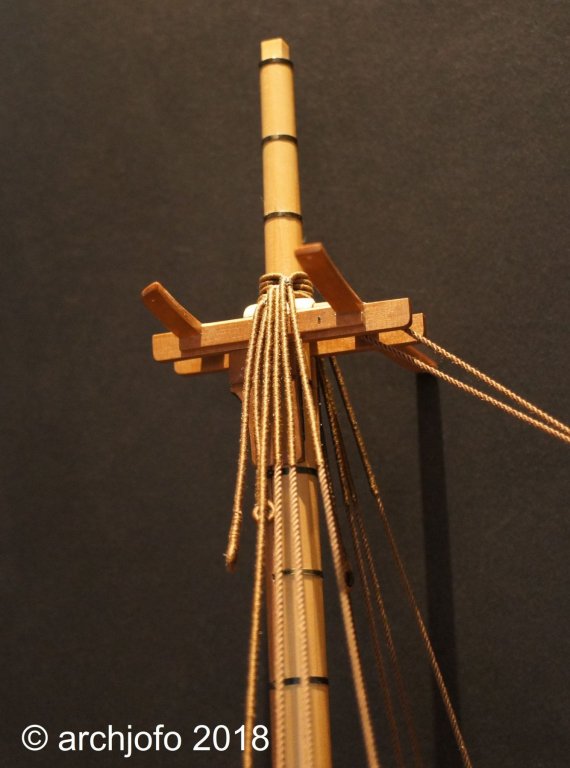

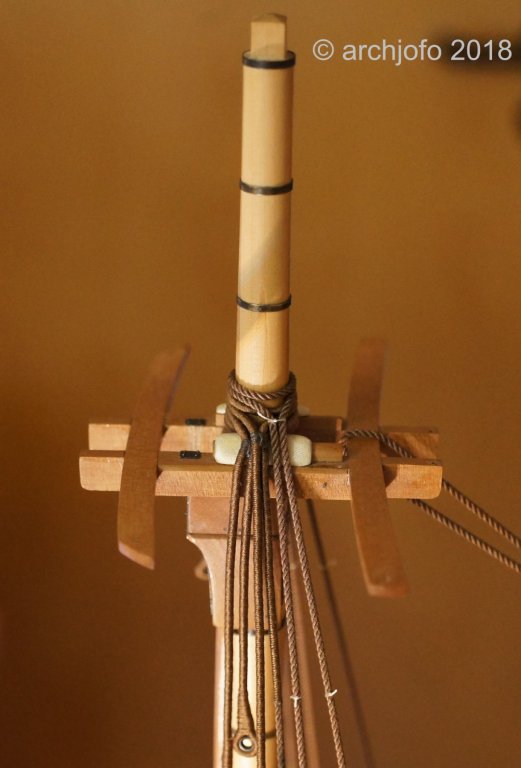

The shrouds of the La Creole for the mizzenmast had a diameter of 58 mm, which corresponds to a diameter of 1.2 mm on a scale of 1:48. The foremost shrouds were not served in this case. Thus I have set all shrouds so far. Here are a few pictures. Finally, a picture of the current state of construction.

-

@KORTES Fantastic pictures of an outstanding model. I am excited about your great work and congratulate you for your beautiful model.

- 306 replies

-

- schooner

- la jacinthe

-

(and 1 more)

Tagged with:

-

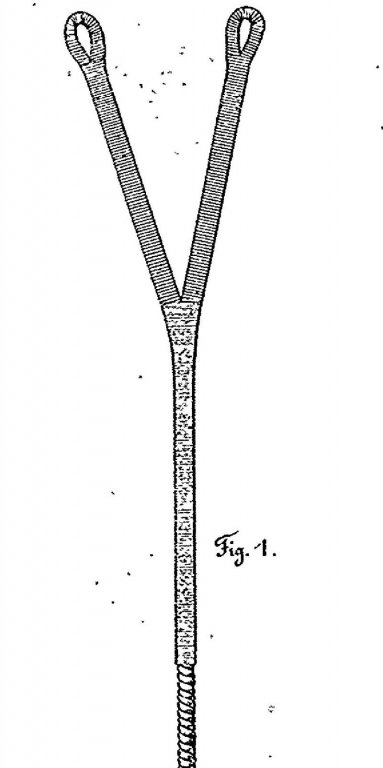

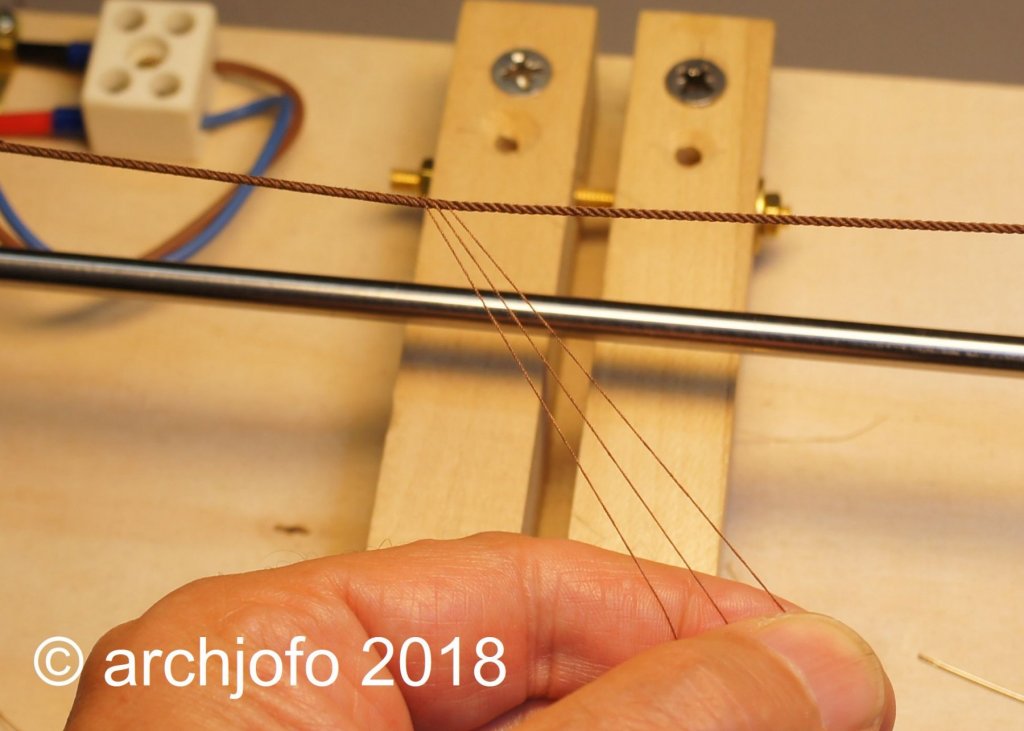

Before it goes on in the report I would not Forget to thank you for your nice comments an the many LIKES. After the little excursion to the bulwark I continued with the shrouds for the foremast. The foremast has 5 shrouds per side. Therefore, the last shrouds require a special design. These are placed together with a so-called horse-shoe-splice. "Every picture is worth a thousand words."

-

Cutty Sark by NenadM

archjofo replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

Fine work!- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

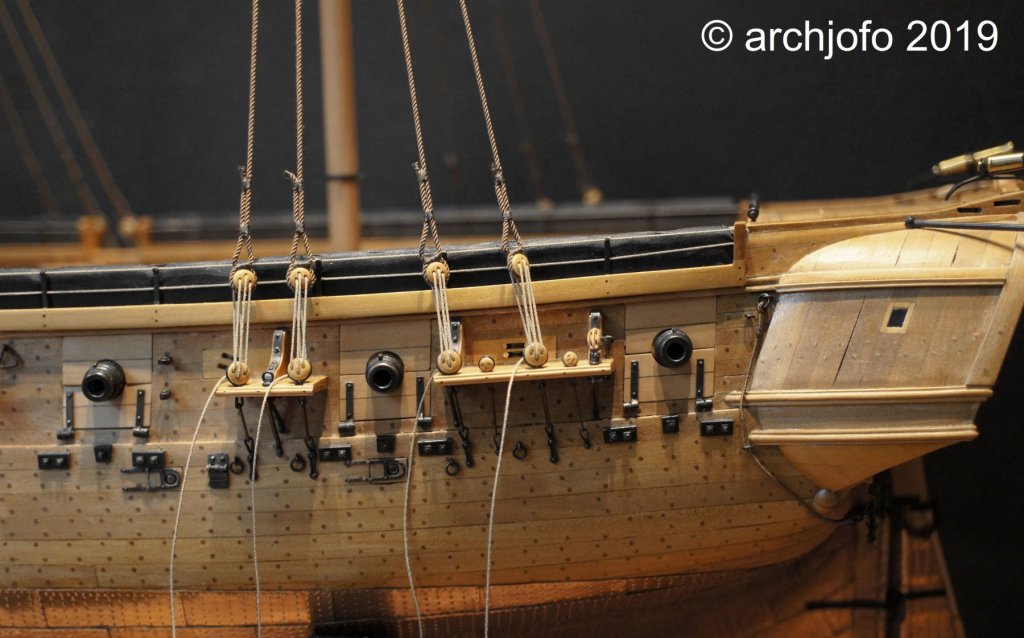

Hello, thank you for your interest and for the benevolent words. Also thanks at all for die many LIKES. Before I continue with the standing rigging, I have to add different details, because otherwise there is no accessibility. On the one hand it concerns the ship toilietts, on the other hand it concerns belayin pins and cleats. I hope you like the pictures.

-

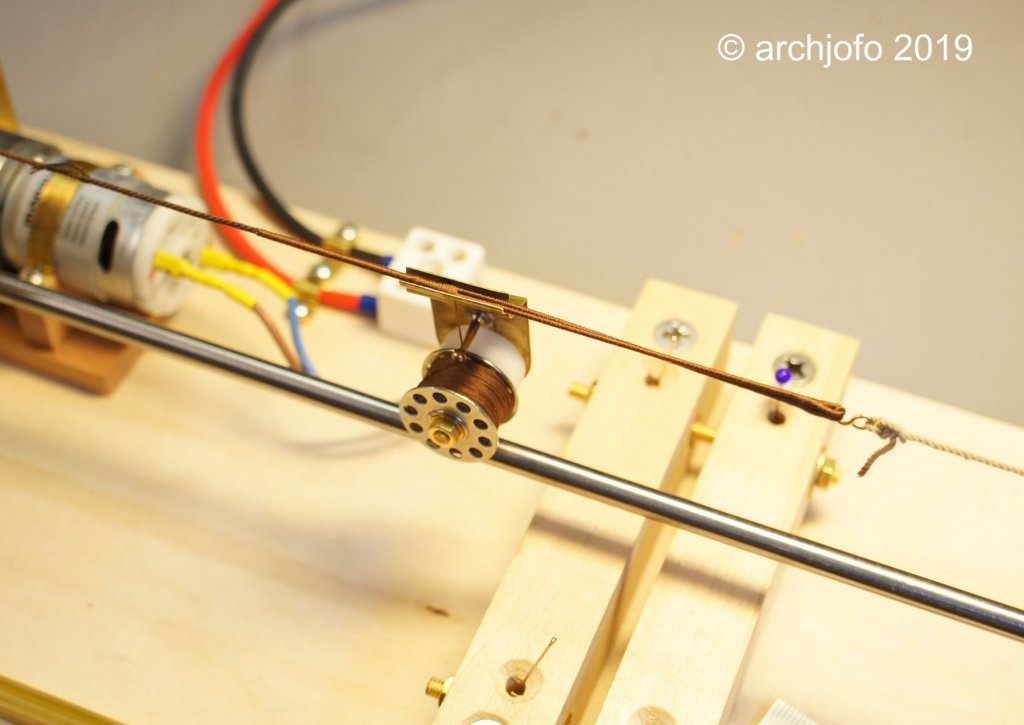

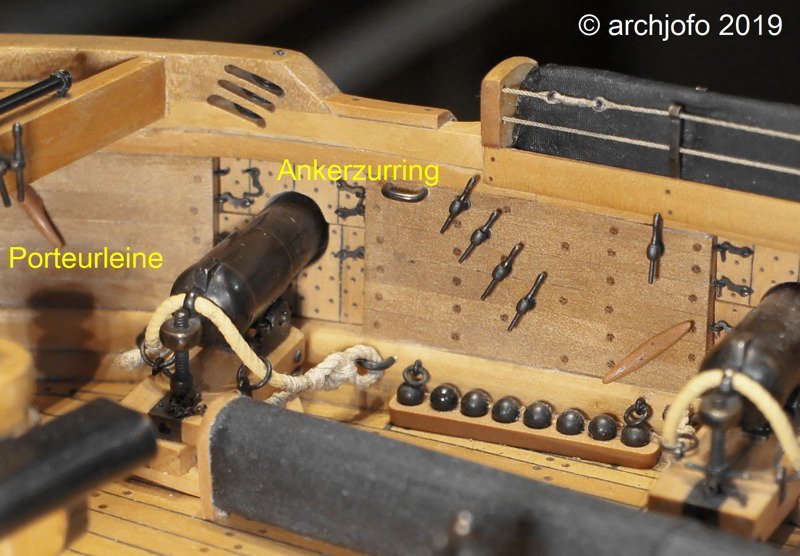

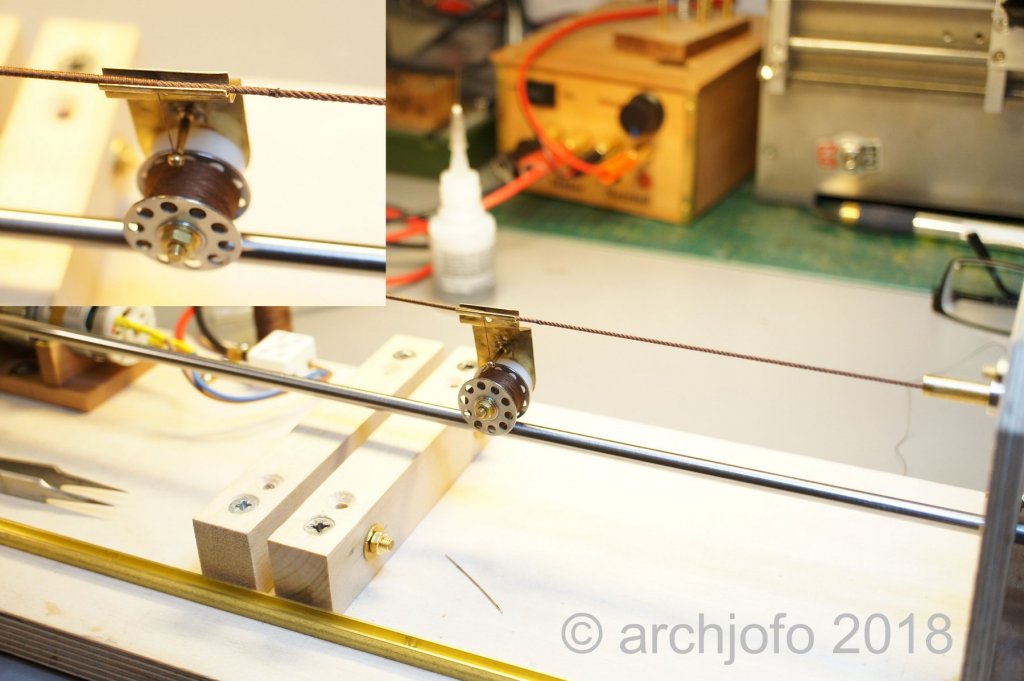

Hello @druxey first of all, thanks for your attention and all other for the LIKES. In between, I always need a change in model building to maintain the motivation. So far I have used a purchased anchor cable that was a bit too thick. Now I've tried to make a better anchor cable with my rope making machine. The anchor cable is made as a cable laid rope. In the original cable had a diameter of 107 mm, which corresponds to a scale of 1:48 exactly 2.2 mm. This consists of 3 x 3 standed right handed ropes laid up left handed. I think that the new anchor cable is much better than the purchased one.

-

The beautiful carvings give the model a high quality look. By the way, an interesting technique for the stand.

-

Hi Rob, I have just seen your progress from your rigging. Impressively beautiful pictures!

- 1,208 replies

-

- great republic

- clipper

-

(and 1 more)

Tagged with:

-

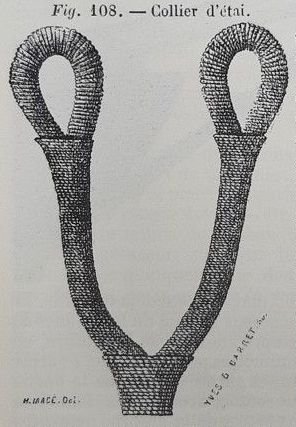

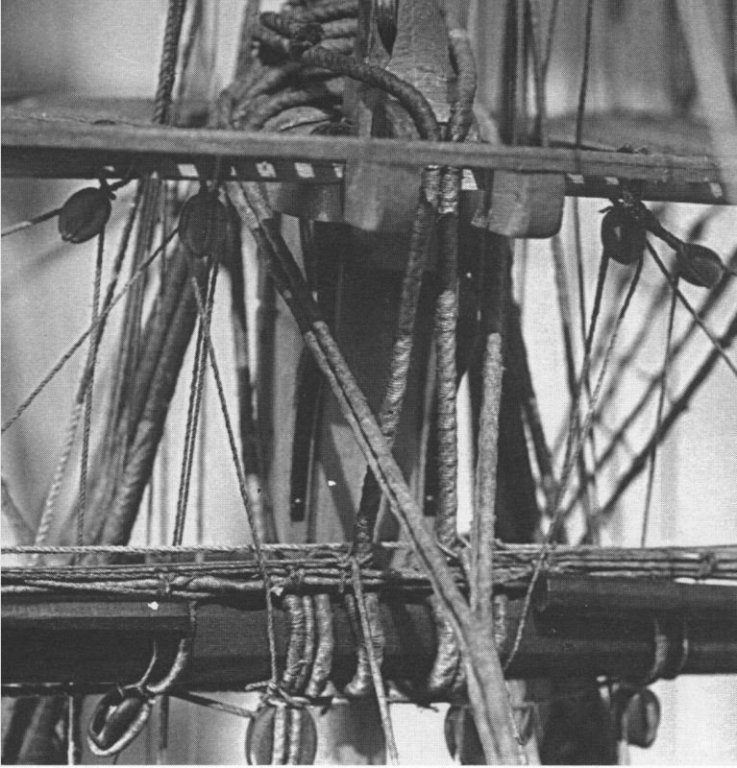

Hello, Thank you for your interest and the LIKES. Here I show the continuation of the work for the mainstay and the main preventer stay (Grand ètai et faux ètai grand mât). First of all historical drawings for the execution of the detial can be seen. Quelle: Manuel du Gabier 1875 Quelle: Takelung und Ankerkunde – Freiher von Sterneck 1873 Afterward you will see the realization for the model.

-

Hello, many thanks for the comments and the LIKES ! It Always makes me happy. In the meantime I have completed the shrouds of the mainmast so far. They are lashed tight only when the stays are installed. The time I prepare the mainstay and the main preventer stay. The stays were all cable laid and it is wormed, as can be seen. Quelle: Musée de la Marine Paris – La Crèole Source: Musée de la Marine Paris – La Crèole Around 1830 the stay mouse disappeared. The stays split into two parts which each had an eye for a lashing. Source: Atlas du Genie maritime The mainstay and main preventer stay penetrated the foredeck and was fastened under it with strong eye bolts. These had iron counter-plates on the outside of the hull. Source: Musée de la Marine Paris – La Crèole Source: Musée de la Marine Paris – La Crèo

-

Hi Ed! Wonderful model! Congratulations and many thanks for sharing.

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Hello Eberhard, that is very fine model making.In this scale with this precision to produce the details, deserves all respect.

-

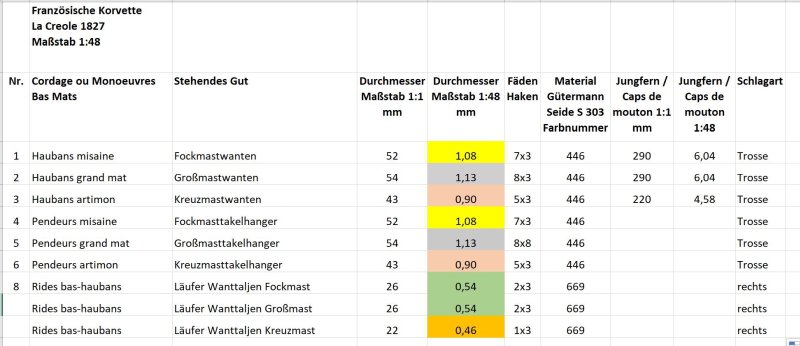

Hello friends, thanks a lot for the nice comments and the LIKES. On my rope walk I made the shrouds as hawser laid rope. The dimensions for the shrouds I take from Information from the monograph by J. Bourdriot and made a list. The first shrouds on the main mast are set. It is important that the distance between the dead eyes is usually 2 x distance dead eyes.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.