-

Posts

902 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by giampieroricci

-

Congratulations to you, Greg, and to David for this wonderful model! So beautiful that I have already ordered the two volumes and hope they arrive soon, maybe one day I can emulate you!

-

EURYALUS 1803 by Peter6172 - 1:48

giampieroricci replied to Peter6172's topic in - Build logs for subjects built 1801 - 1850

One source of inspiration is surely the splendid Matiz model!... -

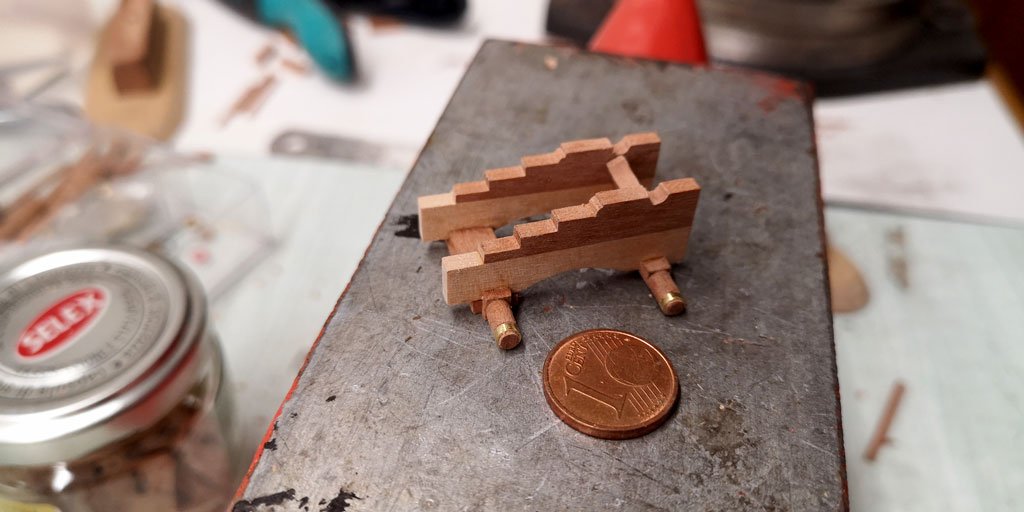

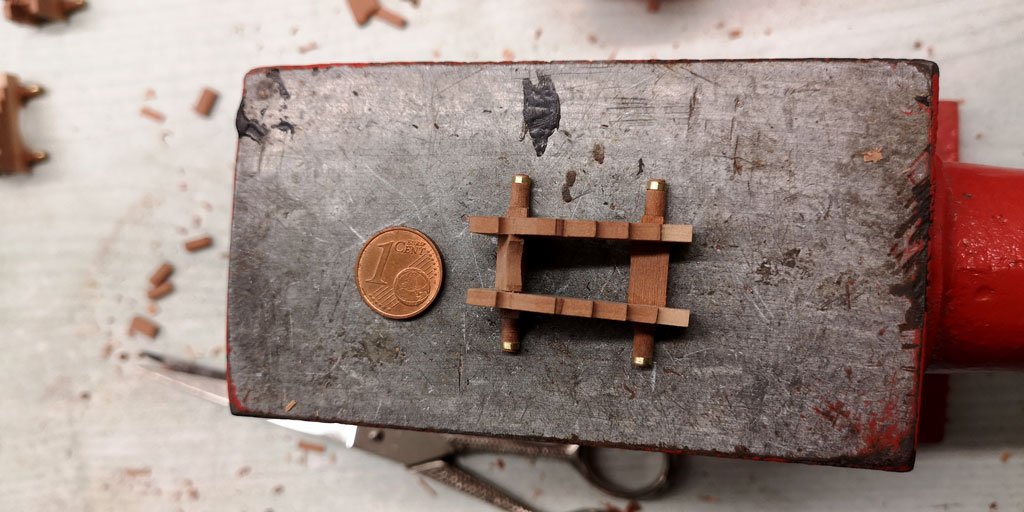

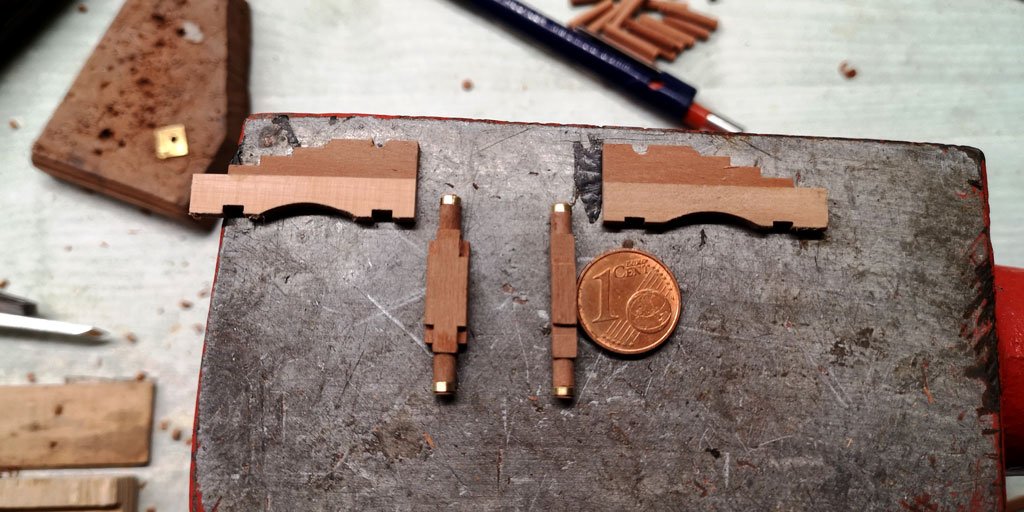

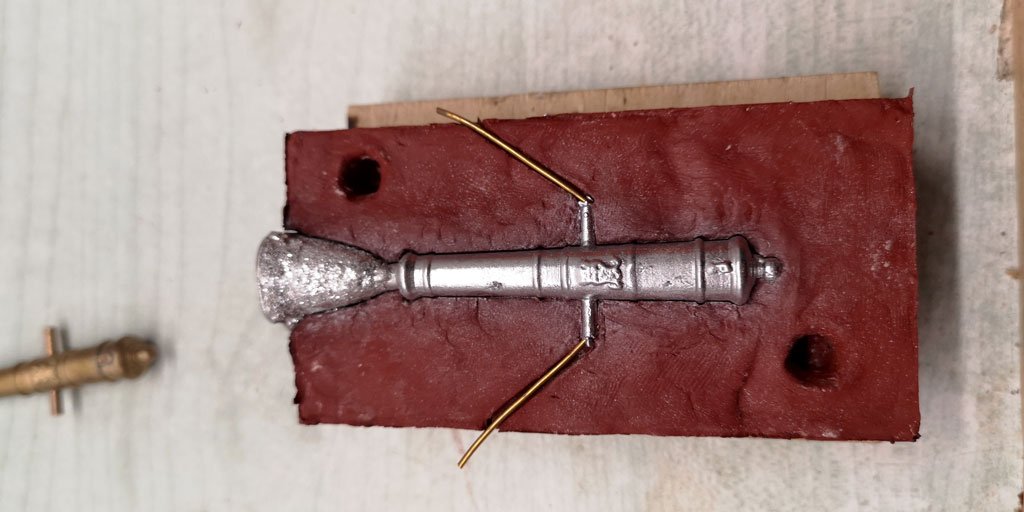

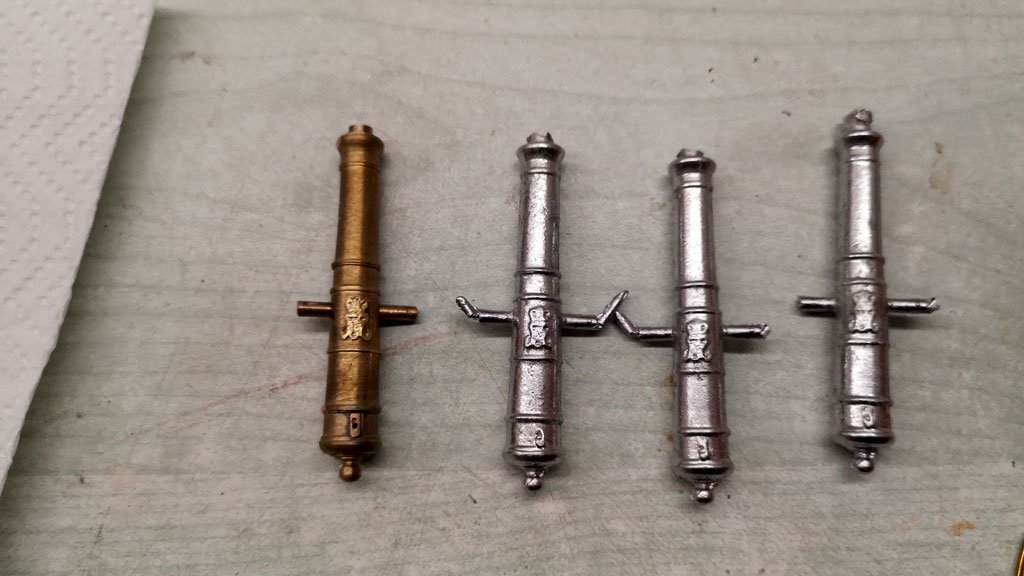

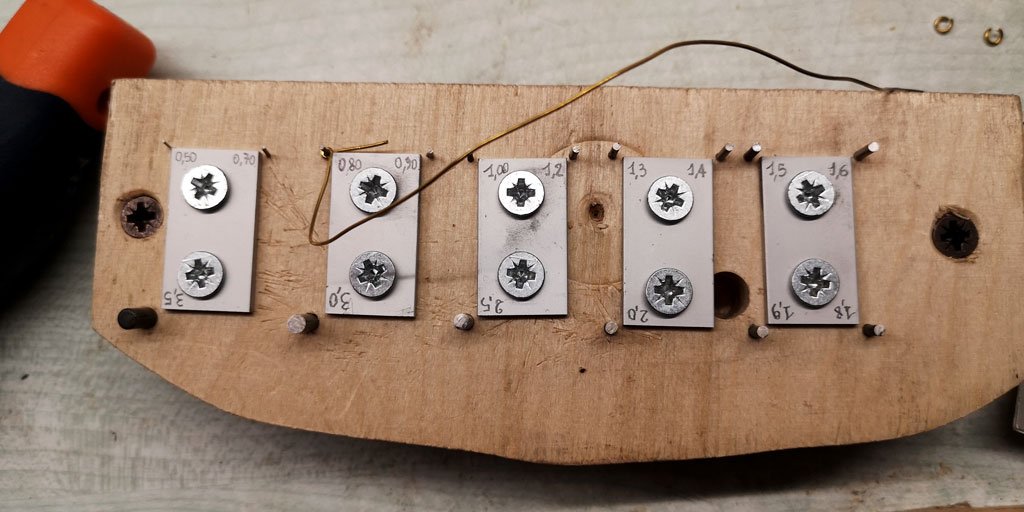

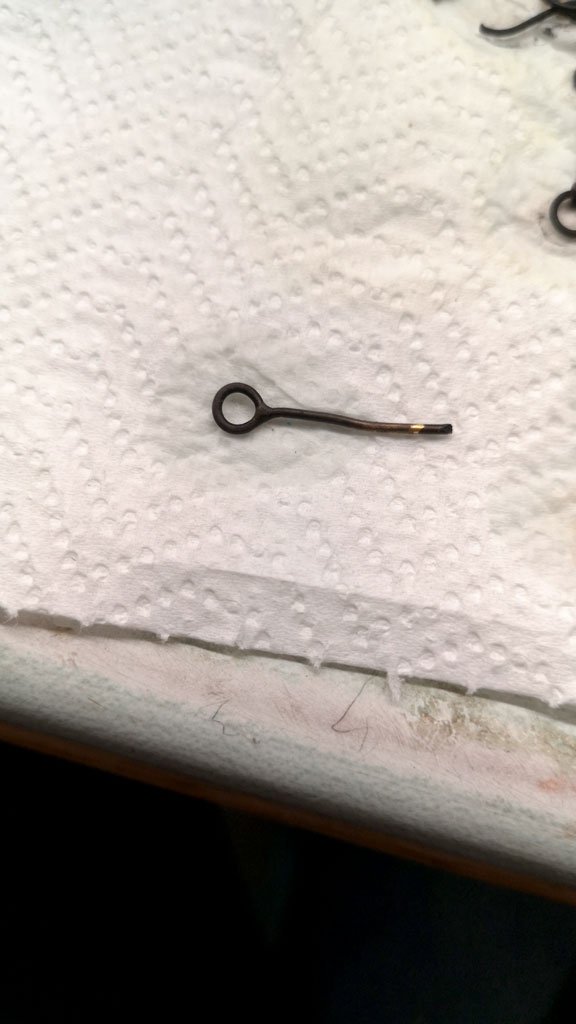

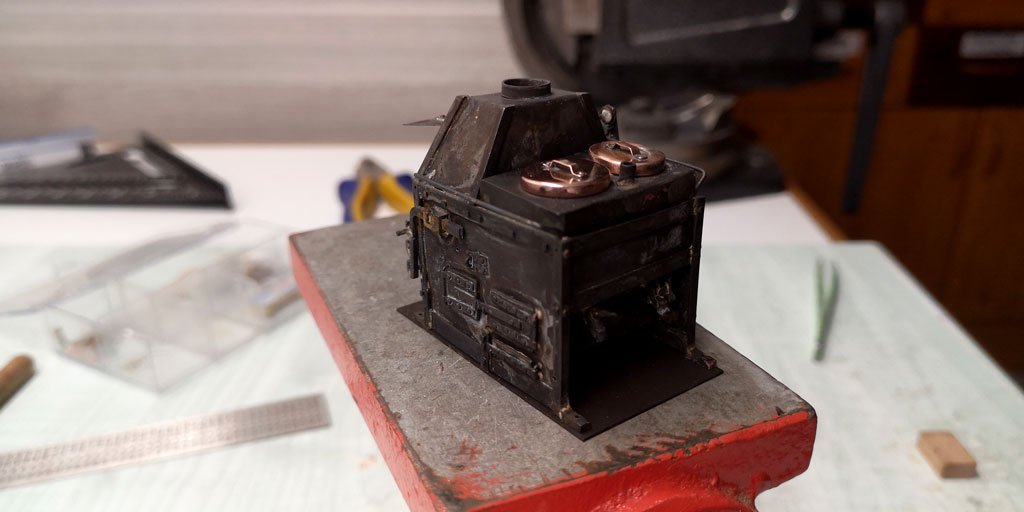

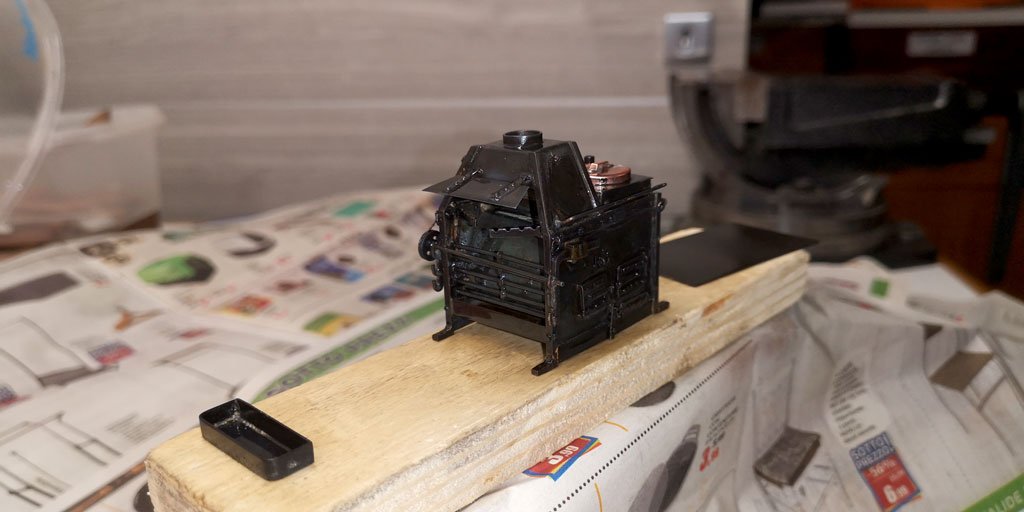

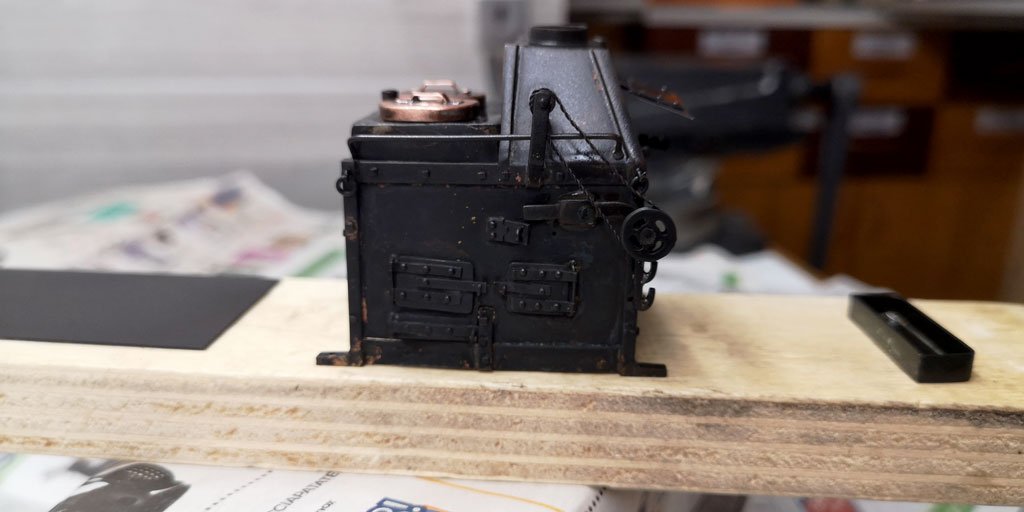

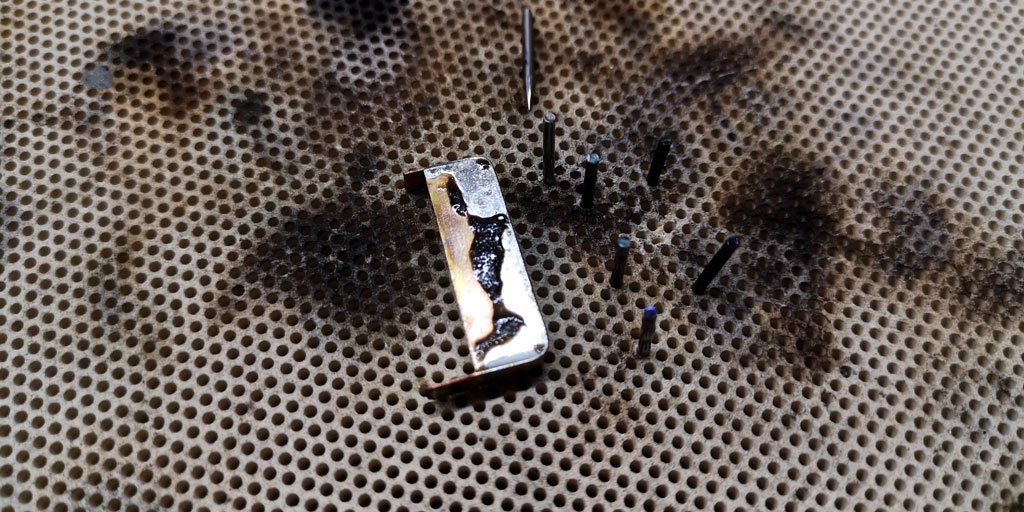

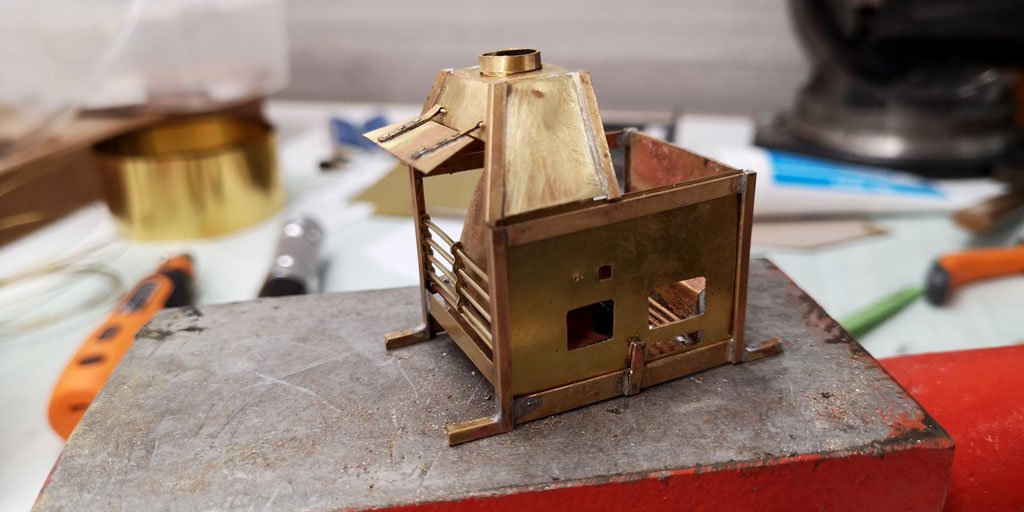

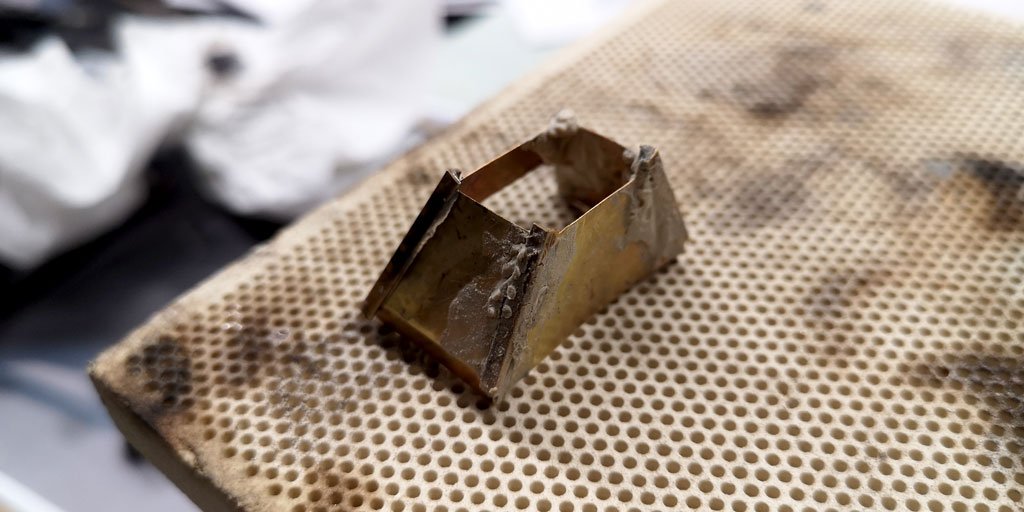

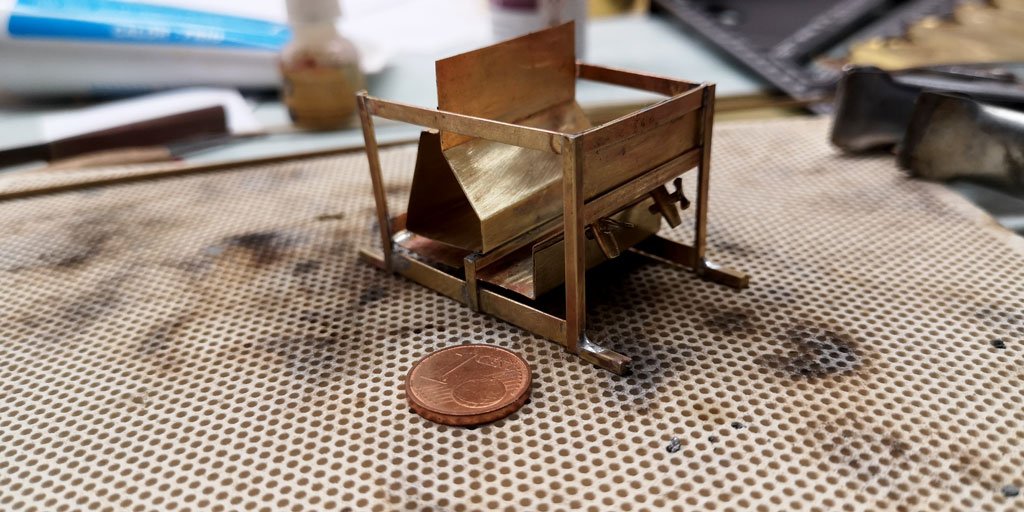

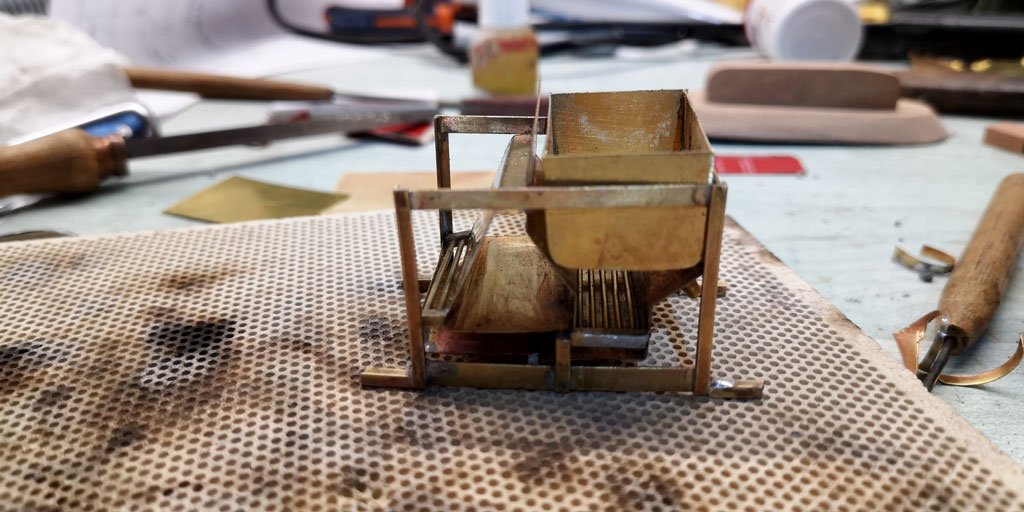

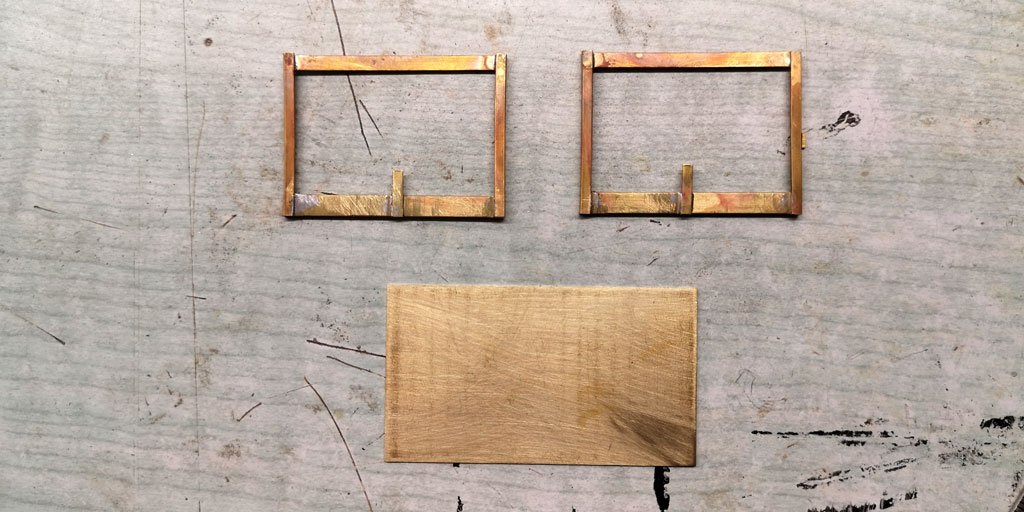

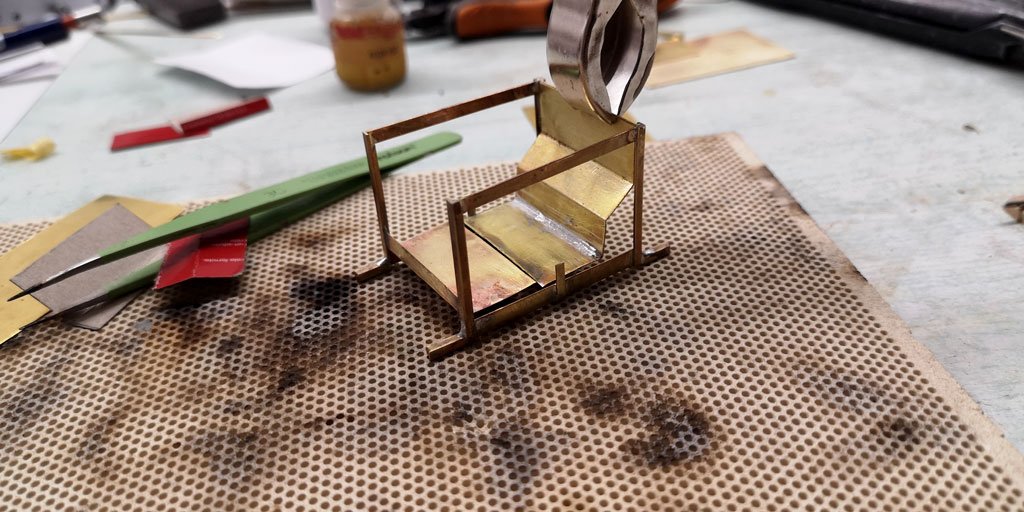

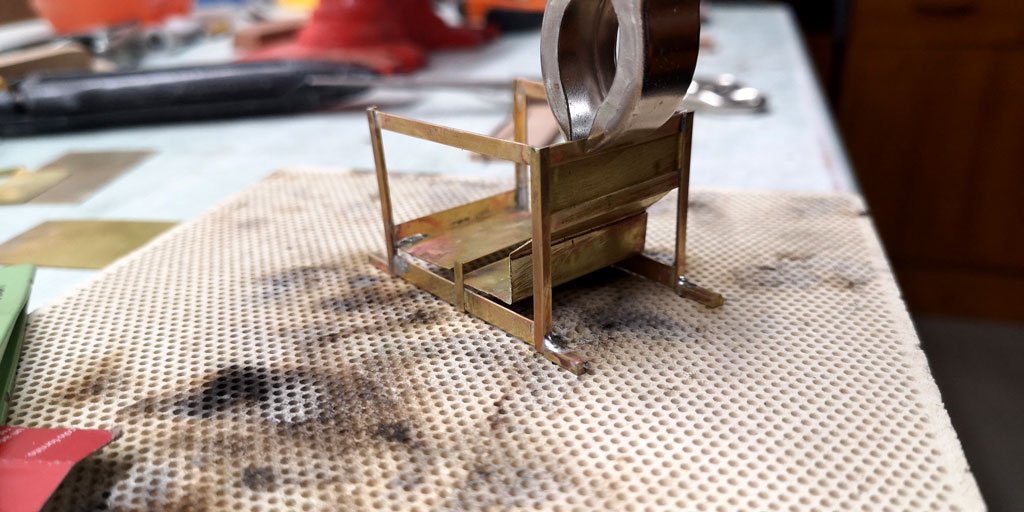

With these few pictures I try to explain how I do my welding. The parts must be well cleaned and kept in contact. With a brush I spread the flux all over the part to be soldered. With a flame soldering iron I heat everything around until the flux starts to boil. Now it is time to apply some of the solder, which is a silver-based rod. Care must be taken to protect soldering joints already made with a heat-insulating paste

-

MONTAÑES by Amalio

giampieroricci replied to Amalio's topic in - Build logs for subjects built 1751 - 1800

what precision and what cleanliness!!! you are one of the best modellers I know! Unmatched! One question: will you leave the rudder hinges in brass or use burnisher? (How I love those planes of yours!!!) -

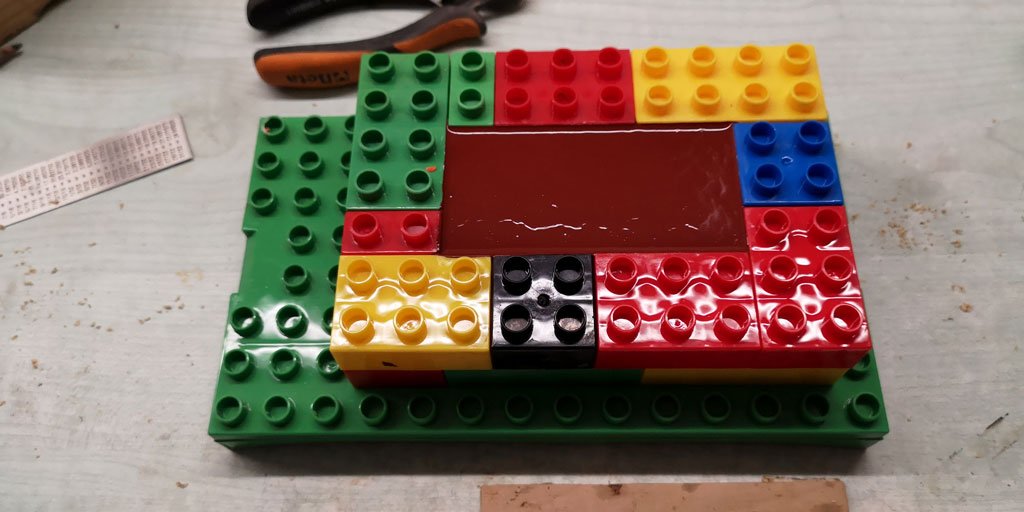

hello Kevin and thank you for your appreciation. As you can also see from the last photo, I am using a heat-absorbing paste to protect the soldering done previously and I must say that it works very well! I simply cut the sheet metal with a pair of scissors as the thickness is very thin (0.25 mm). You can't see it in the photo but I use a wooden counterform for assembly.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.