-

Posts

1,197 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Stuntflyer

-

Is that the same as Dick's Sporting Goods found here? http://www.dickssportinggoods.com/products/athletic-apparel.jsp There are a few close by. If yes, I will visit but leave the wallet home!

- 109 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

David - Thanks for the tip. The closest Bass Pro store is 3 1/2 hrs away in Harrisburg, PA. They say that there will be one "coming soon" in Bridgeport, CT and that is only 45 min from me. I will go there after they open.

- 109 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

Thanks guys, your kind words keep me going. I have made and destroyed several seizings in an effort to understand and do what Chuck has explained to me. Here is the end result. . . I formed the eye at the bottom of the block by making an overhand knot around a looped piece of rope and sliding the knot down over a pin and pulling it tight. I applied a few thinned coats of white glue to stiffen the eye and once it was dry I removed it from the pin. I tied the rope around the block with another knot and glued that. I wrapped the loose ends (forming a double wrap) of the rope around the boom and tied it off at the bottom of the boom with an another overhand knot. Looking at the photos of Chuck's build it's hard to tell if he tied the final knot on top of the boom which would make it a single wrap, I think. The double wrap is small and looks clean so I went with it.

- 109 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

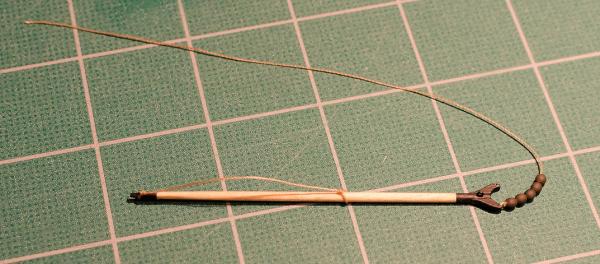

With the mast repaired and re-glued into the hull my next project will be the boom and gaff. I shaped and painted the two parts without any problem but had no idea how to do the seized block and rigging that went along. I posted the topic on "Masting, Rigging and Sails" found here . .http://modelshipworld.com/index.php?/topic/7277-stropping-and-seizing/#entry215601. Some great tips and how-to's came out of that post but I needed more information. I talked with Chuck who also gave me a number of great tips and how-to's as well as explaining that I was over thinking the process. His opinion was that "The scale is too small to do it the way it would be done on the actual ship". Needles to say I had to do a number of trial runs before I was satisfied with the results. I will pass on the tips as I post new photos. The gaff rigging was made from one piece of rope. Measuring off the plans the length of rope is approx 48mm. I seized the loop around the gaff in the middle first. The second loop was then seized for the peak of the gaff. I moved that seizing to approx 48mm of the first seizing and pulled the loop tight to the peak of the gaff. When I first did the seizings I thought they looked too large so I removed 1 strand from the tan rope to make it thinner. The thickness went from .015 to .010 and to me it looks more realistic. As Chuck said "Its just very tricky and there are no silver bullets." BTW; the black color is very dark, not what you see in the photo.

- 109 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

I second David B. Looking very good!

- 132 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

Lextin - Your photos and explanation on seizing help a lot. I still need to see how to seize the block to the boom and create an eye on the bottom end of the strop.

-

Jerry, I understand what you are saying about "As for making the strop grommet". Just can't open the jpg file.

-

Any videos or drawings on how to do all this?

-

Hello, I am building the 18th Century Longboat http://modelshipworld.com/index.php?/topic/4930-18th-century-longboat-by-stuntflyer-mike-model-shipways/page-3 Can anyone show me how to strop a block with an eye on the bottom of the block and seized to the boom on top of the block as in the photo below. The photo is from Chucks log. Thanks very much, Mike

-

Thanks Rich, much appreciated. Your Constitution looks awesome! Do you have photos here of the Aluminum long boat?

- 109 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

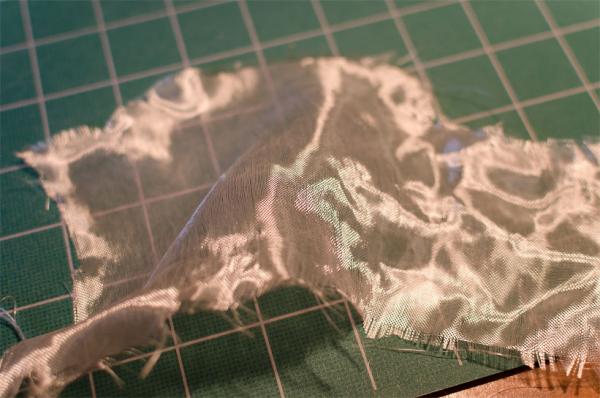

David - your idea sounds really good but I wanted to try something I used to do on the airplanes to strengthen glued wing joints. When doing aerobatics with 90 degree pullouts at 60 mph, 10-15g stresses on the airplane are common. 1. First step was to glue the mast together with epoxy glue. 2. Use 1/2oz or 3/4oz fiberglass cloth, I chose 3/4 oz, to strengthen joint. 0.0015 thick. 3. Attach the cloth to the mast by spraying the cloth with spray adhesive and wrapping the cloth around the mast just once. 4. Here is a photo of the wrapped and glued cloth. At this point the joint is stronger but still not strong enough. 5. Apply 4 to 5 thin CA applications lightly sanded between coats. After the first application the mast is super strong without any flex at the joint. The additional applications will fill the weave of the cloth. 6. Finished mast repair

- 109 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

I'm trying to fix it now. It broke at the bottom sheave hole which is a weak spot. Will take pics of what I hope will be a working solution. Definitely don't want to make another one. But, I will if I have to.

- 109 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

- 109 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

- 109 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

Chuck, Sorry for so many questions. Being my first build I really want to do things right. Should I seize the block/horse and Mast block/hook the same way? Is there a link showing the way that you would do the seizing? Thanks, Mike

- 162 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

Thanks! As always very helpful.

- 162 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

Chuck, do you normally ca the seizing between a block and the "horse", for example? When I do, it turns the tan line dark brown and it just looks too dark. Thanks, Mike

- 162 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

Mike, I know what you are saying but I don't see where the problem is. The gap between planks and the false keel is normal and won't have a negative effect on the final shape of the hull. By the "joint would be smooth" I'm guessing that you mean like on the Pinnace where the bulkheads flow into the keel. Again, I don't see where the problem is. Only 3 planks after the garboard are needed to get to all the bulkheads. Those 3 planks can easily be sanded into a smooth contour.

-

Longboat 1:48 scale 1/4"=1ft Here is a good link on oars. . . https://sites.google.com/site/shipwrightsfaq/smf-qoars

- 132 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

Mike, Page 4 of Chucks manual explains how to bend planks 90 degrees so they fit against the false keel. There are 3 after the garboard plank that need this type of bending. He also explains about beveling the edges where necessary to get a tight fit between the planks. I don't know if your using boxwood makes this impossible to do. With basswood it's quite easy. If it would be helpful for you to see photos of the process, I would be happy to post a few. Mike

-

Thanks guys! Pops. . . Your coming along nicely and fast too. You will be where I am in no time. David B. . .Do you have any build logs I can follow?

- 109 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.