-

Posts

1,197 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Stuntflyer

-

Locker and cockpit details completed. The hinges were made as Chuck suggests in his build log using card stock and 28 gauge wire. I know that the contemporary model calls for a red cockpit but it ended up not looking very authentic when painted on such a broad surface using a brush. I was trying to get a even coverage but it didn't work out. I decided to do the cockpit area over again. The instructions say that using stain here is okay.

- 109 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

Hi Augie, I have been following your build logs since I joined MSW recently. Your work is simply beautiful and I hope that I can achieve 1/2 of what you have been able to do in the years to come. Now that my Longboat is ready for some metal work, I have a question regarding your Blacken-it procedure. You wrote: "They are then soaked in a bath of 50% 'Blacken-it'. ." Can you tell me what the bath consists of? Thanks, Mike

- 2,191 replies

-

- confederacy

- Model Shipways

-

(and 1 more)

Tagged with:

-

More interior details completed. I ended up braking a thwart while trying to get it under the cap rail. Fitting them close to the inner hull width means that one has to bend them slightly and they can break easily. Raising one end up so it touches the cap rail makes it easier to insert the other end. I'm still working on the wider thwart for the mast and need to paint the filler piece at the bow red.

- 109 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

Mike, I use lint free 100% cotton cheese cloth to apply the Wipe-On Poly. The Min Wax Wipe-On poly in the satin finish works great. On stained wood it will soak in so use a dry area of the cloth to wipe off the excess and let it dry overnight.

- 137 replies

-

- finished

- model shipways

-

(and 1 more)

Tagged with:

-

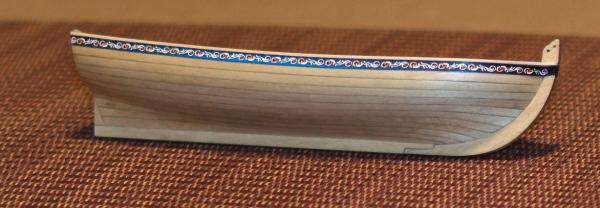

Molding strip under friezes and some interior details completed. The red paint is much smoother than it appears here. I applied 4 coats thinned just a little bit with water. Used 1/64" and 1/32" shims to get the floor spacing as close to the plan as I could. The front platform required a lot of sanding and fitting to place it low enough thereby making room for the risers which I have yet to work on.

- 109 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

David and Chuck, thanks! much appreciated. Chuck, you said in the Longboat Instruction Manual ". . take your time and treat each plank as a small milestone", which I think is great advice. I am trying to do this with each step regardless of how simple it may seem.

- 109 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

First two friezes finished. Used Krylon Workable Fixatif 1306 to protect them and 3M Super 77 Spray Adhesive. If you happen to get some of the adhesive on the out side there is a great product called UnStik (see below) that will easily remove any excess without harming the frieze or the planking. I used it for many years when I was in the picture frame business. You can even use it on glossy photos.

- 109 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

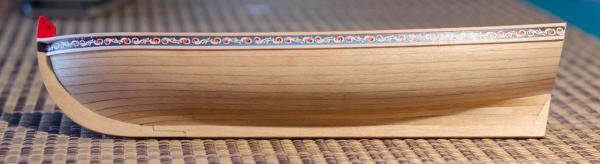

Got the cap rail sanded and shaped today. Average width is around 0.100 inch except where it flares slightly at the bow.

- 109 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

Decided to fix the shear plank by redoing the planking once more. I realize that I could have left things as they where but I need planking experience anyway. After sanding the hull with 400 sandpaper to a near sheen I applied the stain, 1 part Golden Oak to 3 Parts Natural and a coat of Wipe-On-Poly. After removing the bulkhead centers I thinned the bulkhead tops to 3/64". 3/64" + 1/32" plank + 1/64" overhang will give a 3/32" cap rail. I stained the hull inside as well. I then added the cap rail which is now ready for sanding.

- 109 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

Thanks! That explains it perfectly.

- 162 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

If the cap rail width is 3/32" can the depth of the bulkhead at its upper most point be slightly under 3/32" or should its edge line up with the edge of the cap rail?. Hope this makes more sense.

- 162 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

Hello Chuck, Can the bulkheads be slightly recessed where they meet the cap rail or are they supposed to be flush with the cap rail edge? Thanks, Mike

- 162 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

Hello Chuck, Are the sheave holes for the ball truck the same 69 or 70 drill you recommended for the mast?

- 162 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

Thanks, I see what you are saying.

-

Looking at Model Shipways period ships 19th century, are there any in particular that have larger parts like dead eyes, blocks, canons, etc? I have read somewhere were some ships are easier to build than others because of this.

-

Dremel sounds like a good way to go. Perhaps a little bulky and hard to get close to the hull when drilling so I ordered this from Ebay. Dremel 225-01 36" Flexible Flex Shaft Rotary Tool Attachment. http://cgi.ebay.com/ws/eBayISAPI.dll?ViewItem&item=370943910461&ssPageName=ADME:L:OC:US:3160

- 137 replies

-

- finished

- model shipways

-

(and 1 more)

Tagged with:

-

Mike, I'm getting ready to treenail the Longboat. Did you drill the treenail holes by hand or use power? I have bits from Drill City and they tend to screw in if I try doing it by hand.

- 137 replies

-

- finished

- model shipways

-

(and 1 more)

Tagged with:

-

Chuck, I would like to treenail the hull and paint below the waterline. After the Wipe-On-Poly Should I apply primer before applying the Badger acrylic water base Antique White? Do you think the treenails would be visible under the paint? Mike

- 162 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

Mike, add one more "well done!" from me. I did some tests with stain and found that lightly applying the stain onto the basswood using gauze, as suggested, works quite well. Before staining I finish sanded the wood with 400 TRI-MITE sandpaper. The trick to getting the stain on evenly (at least for me) was to candle the test pieces, making sure that the wood was sanded consistent in sheen thereby showing no low spots. Hope this helps. Mike

- 137 replies

-

- finished

- model shipways

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.