barkeater

NRG Member-

Posts

387 -

Joined

-

Last visited

About barkeater

- Birthday 02/18/1953

Contact Methods

-

MSN

barkeater@msn.com

Profile Information

-

Gender

Male

-

Location

Howell, NJ

-

Interests

I enjoy fly fishing and fly tying, bow hunting and reading historical fiction and historical non-fiction usually concerning the 1700's

Recent Profile Visitors

-

KARAVOKIRIS reacted to a post in a topic:

Carcass 1758 by barkeater - scale 1:48

KARAVOKIRIS reacted to a post in a topic:

Carcass 1758 by barkeater - scale 1:48

-

GrandpaPhil reacted to a post in a topic:

Carcass 1758 by barkeater - scale 1:48

GrandpaPhil reacted to a post in a topic:

Carcass 1758 by barkeater - scale 1:48

-

GrandpaPhil reacted to a post in a topic:

Carcass 1758 by barkeater - scale 1:48

GrandpaPhil reacted to a post in a topic:

Carcass 1758 by barkeater - scale 1:48

-

GrandpaPhil reacted to a post in a topic:

Carcass 1758 by barkeater - scale 1:48

GrandpaPhil reacted to a post in a topic:

Carcass 1758 by barkeater - scale 1:48

-

barkeater reacted to a post in a topic:

Block size calculations

barkeater reacted to a post in a topic:

Block size calculations

-

JacquesCousteau reacted to a post in a topic:

Carcass 1758 by barkeater - scale 1:48

JacquesCousteau reacted to a post in a topic:

Carcass 1758 by barkeater - scale 1:48

-

barkeater reacted to a post in a topic:

L'Invention 1799 by Greg Davis - Scale 1:48

barkeater reacted to a post in a topic:

L'Invention 1799 by Greg Davis - Scale 1:48

-

barkeater reacted to a post in a topic:

L'Invention 1799 by Greg Davis - Scale 1:48

barkeater reacted to a post in a topic:

L'Invention 1799 by Greg Davis - Scale 1:48

-

barkeater started following L'Invention 1799 by Greg Davis - Scale 1:48

-

yvesvidal reacted to a post in a topic:

Carcass 1758 by barkeater - scale 1:48

yvesvidal reacted to a post in a topic:

Carcass 1758 by barkeater - scale 1:48

-

davyboy reacted to a post in a topic:

Carcass 1758 by barkeater - scale 1:48

davyboy reacted to a post in a topic:

Carcass 1758 by barkeater - scale 1:48

-

davyboy reacted to a post in a topic:

Carcass 1758 by barkeater - scale 1:48

davyboy reacted to a post in a topic:

Carcass 1758 by barkeater - scale 1:48

-

AnobiumPunctatum reacted to a post in a topic:

Carcass 1758 by barkeater - scale 1:48

AnobiumPunctatum reacted to a post in a topic:

Carcass 1758 by barkeater - scale 1:48

-

Carcass 1758 by barkeater - scale 1:48

barkeater replied to barkeater's topic in - Build logs for subjects built 1751 - 1800

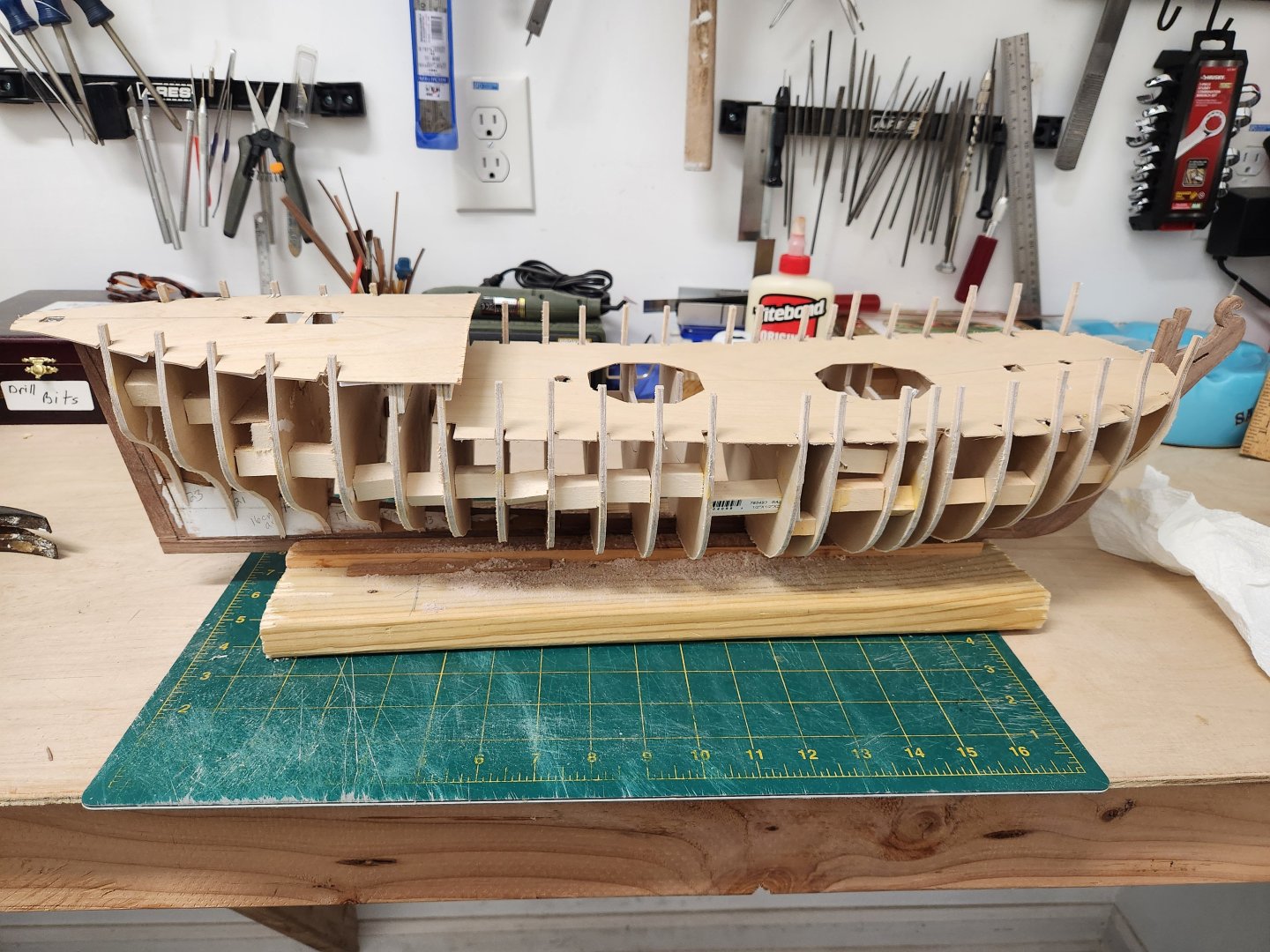

The bulkheads have been installed as well as the sub decks for both the main deck and quarterdecks. There is a foredeck, but this is open to the main deck along its aft portion. I will not do a subdeck but rather a single plank on beams. I found two slightly different sets of plans from the NMR. One has two masts while the other has three and the quarterdecks are different lengths. I went with the 3 masts as this is how she is depicted by John Cleverly the Younger on her Nordic expedition with the Racehorse. Next job is fairing. -

barkeater reacted to a post in a topic:

LA CREOLE/ LA GUADELOUPE by matiz - 1:48 - by Tiziano Mainardi from Boudriot plans

barkeater reacted to a post in a topic:

LA CREOLE/ LA GUADELOUPE by matiz - 1:48 - by Tiziano Mainardi from Boudriot plans

-

barkeater reacted to a post in a topic:

Planking calculator advice.

barkeater reacted to a post in a topic:

Planking calculator advice.

-

Ronald, Think of the hull as one big batten instead of dividing it up into multiple smaller battens. I plank from the keel up. Now, I know at the top planking at the bulwarks, if I've cut out my bulkheads correctly, I will have a true or correct run of the planks. The needed taper of planks in between the keel and the top plank can therefore be calculated. Using the entire hull gives me the advantage that I can correct any tapers that need to be made gradually rather than having to make larger or greater corrections in a briefer run. This is especially useful along the stern where you can have an area where you need to increase your widths and have another area where you need to taper. I don't mean to disparage other methods, but this method works best for me. Rich

-

I measure the run of each bulkhead once the first planking is done and pencil them in on the hull at their appropriate bulkhead. I then do a run of 10 planks and remeasure allowing me to adjust plank widths ahead of time repeating every 10 planks. This prevents me from running into trouble and having to use a drop a plank or stealer. I do trenails and plank lengths in scale. To help facilitate this I may add false bulkheads where needed to allow me to stay below 20 feet to a plank in scale. Rich

-

I Have an Itch to Scratch

barkeater replied to SaltyScot's topic in Modeling tools and Workshop Equipment

Mark, As Jim said, you can purchase milled lumber which is actually easier than milling your own for the planking or deck. The exception would be if you want to include exotic woods such as yellow heart or ebony where milled pieces can't be obtained. The one machine I would find tough to replace by other means is a scroll saw for cutting odd shapes. I have a table saw and a thickness planner. I find the thickness planner very useful for making sure the stock I personally milled is uniform. I also have a mini lathe. I don't have a drill press. Welcome to scratch building. It's a lot of fun and it opens up a lot more opportunities as to what you can build. Rich -

What scale? I've used the liquid glass product before, and it works well as long as your openings are not too big. I work in 1/48 scale. If your window is divided into multiple panes, it makes it easier. I've used thread to make panes in the frame. Also, the liquid glass is semi opaque. Lastly, I have bought mica chips which I'm going to try on my current build but have no experience with yet. Rich

-

Carcass 1758 by barkeater - scale 1:48

barkeater replied to barkeater's topic in - Build logs for subjects built 1751 - 1800

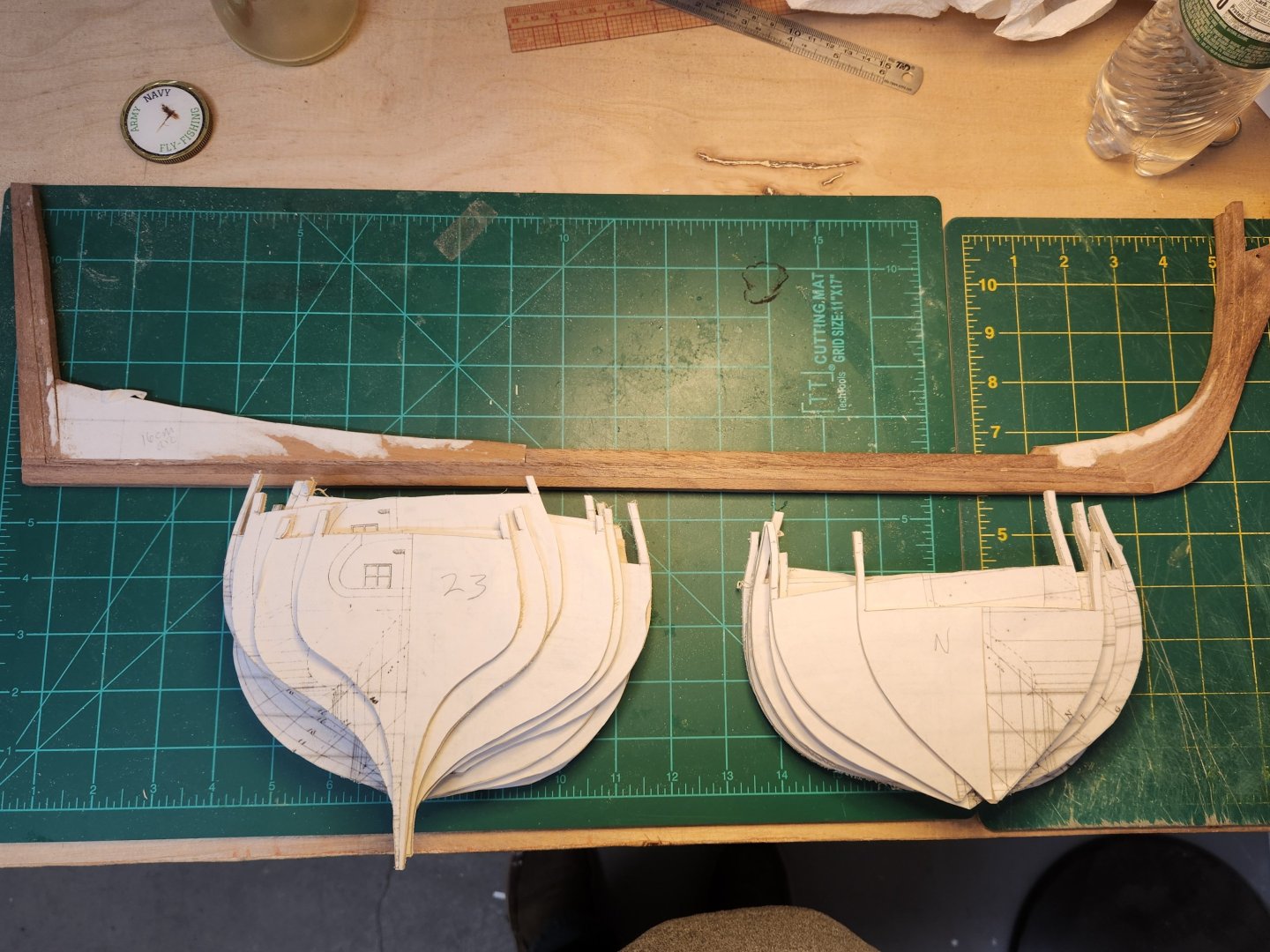

Rabbet line is done, and bulkheads have been cut out. I will trim them to fit the keel assembly as I go. Also next up framing out the stern assembly. Rich -

barkeater reacted to a post in a topic:

need references to do some model repairs in Northern Virginia/DC/Maryland area

barkeater reacted to a post in a topic:

need references to do some model repairs in Northern Virginia/DC/Maryland area

-

Mohogany plank bending

barkeater replied to Bontie's topic in Building, Framing, Planking and plating a ships hull and deck

I use room temperature water, but I would think 20 minutes should do it for 2mm. Mahogany tends to be a bit brittle. Don't overly force it. With a tight bend you may need to partially bend it and repeat your water bath before bending more. Rich -

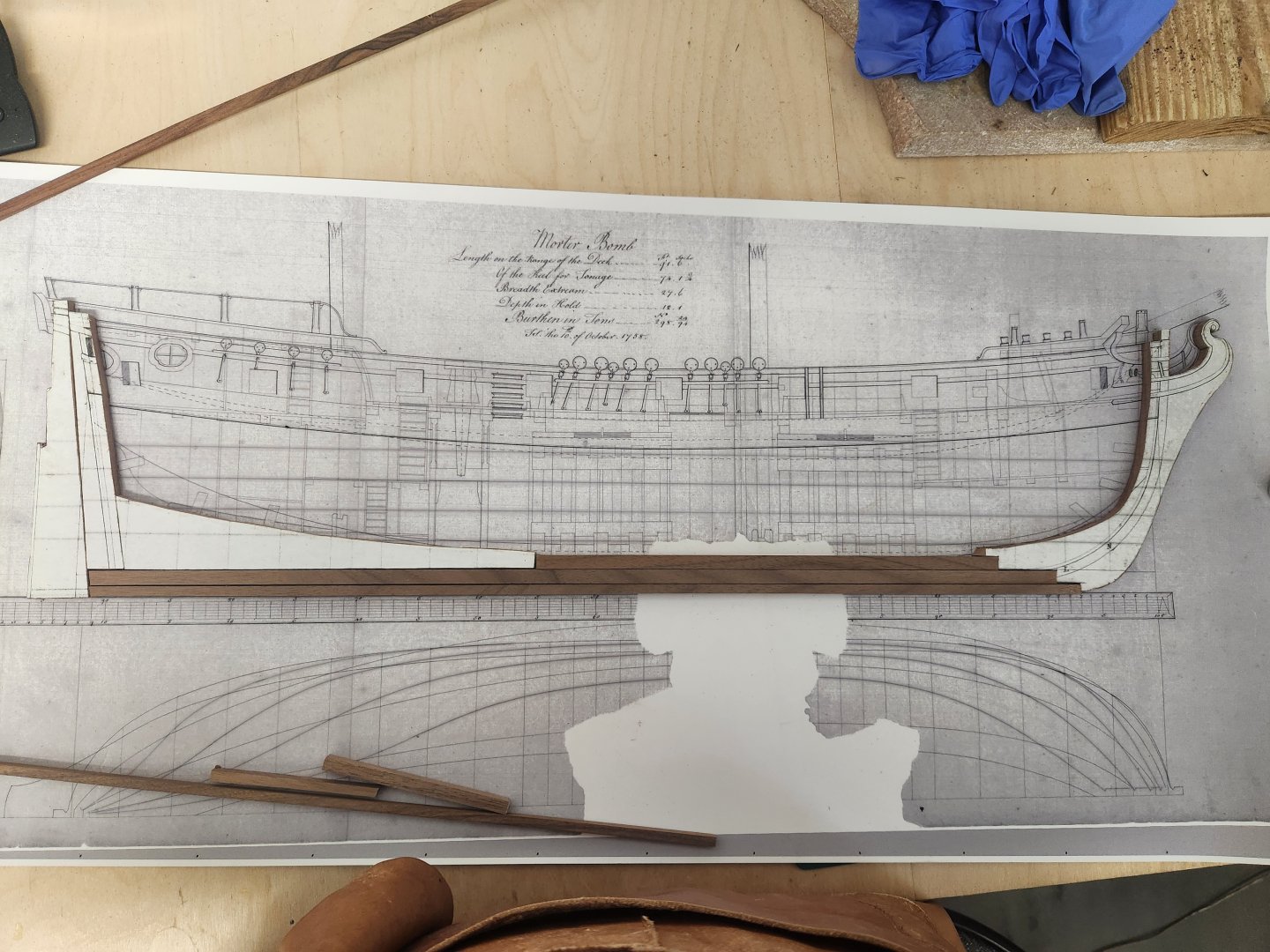

The Carcass bomb vessel saw action in the Seven Years War as well as the American Revolution. Horatio Nelson served on her as a midshipman during the arctic exploration of 1773. The build will be double plank on bulkhead. Plans are from the National Maritime Museum. It will be as originally commissioned with mortars which were removed for the arctic exploration. Rich

-

barkeater reacted to a post in a topic:

Anybody know how to attach this block to the gaff boom? (HM Sherbourne Vanguard)

barkeater reacted to a post in a topic:

Anybody know how to attach this block to the gaff boom? (HM Sherbourne Vanguard)

-

barkeater reacted to a post in a topic:

Bending small (approx 5x15 mm) plywood pieces?

barkeater reacted to a post in a topic:

Bending small (approx 5x15 mm) plywood pieces?

-

The Mossy Shipyard by Bryan Woods - 1:1

barkeater replied to Bryan Woods's topic in Non-ship/categorised builds

Congratulation. I redid part of a barn two years ago for my workshop and love it. Rich -

Question re: Rigging Multiple Blocks at One Location

barkeater replied to GGibson's topic in Masting, rigging and sails

Gregg, I noticed in your drawing that there isn't a yard arm cleat. I don't know where you are on your build, but these help your lines from slipping when under tension. They are a lot easier to do before the yard is hung. They are easy to fabricate, I first drill the cleat for the trenail. Then I glue it in place and drill into the yard itself then insert a glue coated trenail. They varied over time and country of origin. The ones I did would be from 1660 to 1815 according to James Lees "The Masting and Rigging of English Ships of War Rich -

Question re: Rigging Multiple Blocks at One Location

barkeater replied to GGibson's topic in Masting, rigging and sails

Easier would be to do each block on their own line going round the yard twice then lashing the afferent and efferent portions tight to grip the yard. If you do the two-block idea one line with the third used to tie it all together it becomes more complicated. Especially tying in that third line while keeping the other two tight to the yard. For looks you want all blocks to have the same length, and this is a lot easier to do doing one at a time. Added to this, you want your port to match your starboard. Easier to get it exact if you match up port and starboard blocks one at a time. If you really want to put 2 on 1 use a clove hitch and do the third separate. Rich -

Whats the best book on rigging for a beginner?

barkeater replied to Stuka's topic in Masting, rigging and sails

Well, not a lot of Petersson fans out there. In 1/64th scale you are not going to be able to copy exactly how the rigging was done. Be aware that some of the knots at that scale cannot be seen or identified with the naked eye. Rich -

Whats the best book on rigging for a beginner?

barkeater replied to Stuka's topic in Masting, rigging and sails

Try, Lennarth Petersson "Rigging period ship models" Rich -

I install all sections of the masts and platforms prior to adding the shrouds. Even if you tied in the shroud just distally, you still have to have the platforms in place as your lines need to go outside of the crosstrees and bolsters. Plus, you attach the shrouds in a specific order. The order could get messed up if hanging free for any length of time. You have to leave enough room to fit in the heel of the topmast or topgallant and this is tight. Easier to fit the lines one at a time rather than all at once and still keeping them looking neat and in correct order. Also, the topmast and topgallant have to a fit tightly together and adjustment with shrouds in place may make it more difficult. You want to get your masts all aligned midline and with the correct angle. I feel for me this is easier to set this up all at once and glue it rather than doing it in stages. Rich

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.jpg.d84ec4dad1d7791e855dca06210ab6f3.thumb.jpg.f45209242e851d4409eca1a09293165b.jpg)