-

Posts

304 -

Joined

-

Last visited

Contact Methods

-

Website URL

http://www.regulusastro.com/

Profile Information

-

Gender

Male

-

Location

Exeter, NH, USA

-

Interests

archery, model building, astronomy, photography, oil painting, drumming, cooking, family.

Recent Profile Visitors

-

GrandpaPhil reacted to a post in a topic:

Sopwith Camel by Mike Dowling - FINISHED - Model Airways - 1/16

GrandpaPhil reacted to a post in a topic:

Sopwith Camel by Mike Dowling - FINISHED - Model Airways - 1/16

-

GrandpaPhil reacted to a post in a topic:

Sopwith Camel by Mike Dowling - FINISHED - Model Airways - 1/16

GrandpaPhil reacted to a post in a topic:

Sopwith Camel by Mike Dowling - FINISHED - Model Airways - 1/16

-

Old Collingwood reacted to a post in a topic:

Sopwith Camel by Mike Dowling - FINISHED - Model Airways - 1/16

Old Collingwood reacted to a post in a topic:

Sopwith Camel by Mike Dowling - FINISHED - Model Airways - 1/16

-

Duanelaker reacted to a post in a topic:

Sopwith Camel by Mike Dowling - FINISHED - Model Airways - 1/16

Duanelaker reacted to a post in a topic:

Sopwith Camel by Mike Dowling - FINISHED - Model Airways - 1/16

-

Duanelaker reacted to a post in a topic:

Sopwith F.1 Camel by jablackwell - Model Airways - WOOD

Duanelaker reacted to a post in a topic:

Sopwith F.1 Camel by jablackwell - Model Airways - WOOD

-

Duanelaker reacted to a post in a topic:

Sopwith F.1 Camel by jablackwell - Model Airways - WOOD

Duanelaker reacted to a post in a topic:

Sopwith F.1 Camel by jablackwell - Model Airways - WOOD

-

Richvee reacted to a post in a topic:

Kate Cory by Richvee - FINISHED - Model Shipways - 1:64 - solid hull

Richvee reacted to a post in a topic:

Kate Cory by Richvee - FINISHED - Model Shipways - 1:64 - solid hull

-

Congratulations! Lovely build. Thanks for letting me follow along. ~john

- 109 replies

-

- model shipways

- kate cory

-

(and 1 more)

Tagged with:

-

jablackwell reacted to a post in a topic:

Kate Cory by Richvee - FINISHED - Model Shipways - 1:64 - solid hull

jablackwell reacted to a post in a topic:

Kate Cory by Richvee - FINISHED - Model Shipways - 1:64 - solid hull

-

jablackwell reacted to a post in a topic:

HMS Winchelsea - FINISHED - 1764 - by Chuck (1/4" scale)

jablackwell reacted to a post in a topic:

HMS Winchelsea - FINISHED - 1764 - by Chuck (1/4" scale)

-

jablackwell reacted to a post in a topic:

HMS Winchelsea - FINISHED - 1764 - by Chuck (1/4" scale)

jablackwell reacted to a post in a topic:

HMS Winchelsea - FINISHED - 1764 - by Chuck (1/4" scale)

-

CiscoH reacted to a post in a topic:

US Brig Syren by jablackwell - Model Shipways - first POB build

CiscoH reacted to a post in a topic:

US Brig Syren by jablackwell - Model Shipways - first POB build

-

jablackwell reacted to a post in a topic:

HMS Winchelsea - FINISHED - 1764 - by Chuck (1/4" scale)

jablackwell reacted to a post in a topic:

HMS Winchelsea - FINISHED - 1764 - by Chuck (1/4" scale)

-

Tom E reacted to a post in a topic:

US Brig Syren by jablackwell - Model Shipways - first POB build

Tom E reacted to a post in a topic:

US Brig Syren by jablackwell - Model Shipways - first POB build

-

jablackwell reacted to a post in a topic:

HMS Victory 1805 by Robert29 - FINISHED - Caldercraft - Scale 1:72

jablackwell reacted to a post in a topic:

HMS Victory 1805 by Robert29 - FINISHED - Caldercraft - Scale 1:72

-

jablackwell reacted to a post in a topic:

US Brig Syren by jablackwell - Model Shipways - first POB build

jablackwell reacted to a post in a topic:

US Brig Syren by jablackwell - Model Shipways - first POB build

-

An update, since it has been a long while. As many of us have noticed, the world is in a bit of chaos right now. My job and life surrounding my family and job have been really... "wild"... and unpredictable. I am still working (good), teaching astronomy and physics (good, too) and almost all remote (also good). I got back to the Syren build this week, which has me excited and happy. It offers some respite from the world's craziness. Right now I am continuing with the boxwood planking above the wales. I've decided to finish off one side first, perfect my methods then work on the other side... maybe the second side will be more presentable! Ha! So that places me some place in the early stages of chapter 5 on the build. One...plank...at...a...time 😉 ~john

- 90 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

jablackwell changed their profile photo

-

jablackwell reacted to a post in a topic:

Kate Cory by Richvee - FINISHED - Model Shipways - 1:64 - solid hull

jablackwell reacted to a post in a topic:

Kate Cory by Richvee - FINISHED - Model Shipways - 1:64 - solid hull

-

jablackwell reacted to a post in a topic:

Kate Cory by Richvee - FINISHED - Model Shipways - 1:64 - solid hull

jablackwell reacted to a post in a topic:

Kate Cory by Richvee - FINISHED - Model Shipways - 1:64 - solid hull

-

Your K Cory is looking absolutely lovely - good solid work there. A case will really be a nice touch, as mentioned above. Oh, and I really like your whaleboat color work. Good job there. Such fun! ~john

- 109 replies

-

- model shipways

- kate cory

-

(and 1 more)

Tagged with:

-

Jesse - it has been a real pleasure watching you work through the build: those flags are gorgeous. Nice work all around. You have given this old guy the urge to get to the shop and resume work on the Syren which has been an idle build for about a year. Congratulations! ~john

- 1,306 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Fabulous work! I've enjoyed the journey! ~john

- 449 replies

-

- sultana

- model shipways

-

(and 2 more)

Tagged with:

-

I am definitely going to pull up a seat to watch your build. I have heard all sorts of good things about this version of the CS, and hope to accomplish this some time in the future. Happy building! 😃 ~john

- 27 replies

-

- cutty sark

- artesania latina

-

(and 1 more)

Tagged with:

-

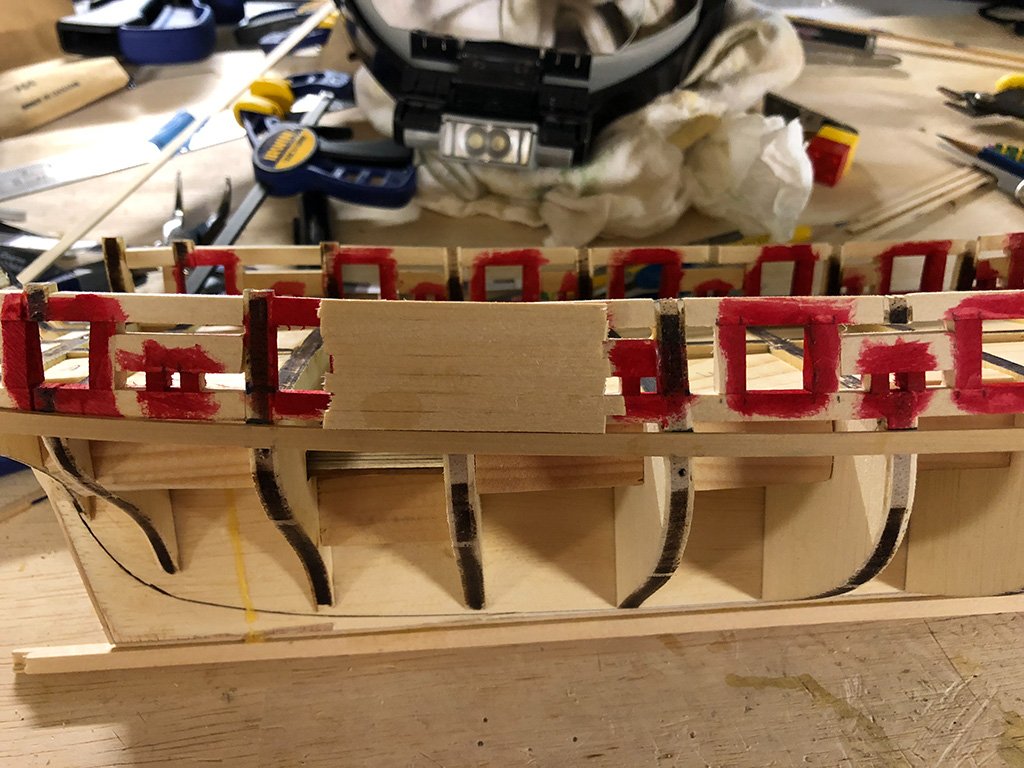

All, Still working on the Syren - I haven't given up, honest! I hope y'all have had a marvelous season and enjoyed the holidays. With some of that luscious time off, I got back to planking the ship. It's slow going, but I am enjoying the pace, taking my time and slowly seeing it all come together. Some images of the current progress. The boxwood has been making this a real pleasure: ~john

- 90 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Awesome work on that netting: I am taking notes! Nicely done, Jesse! ~john

- 1,306 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

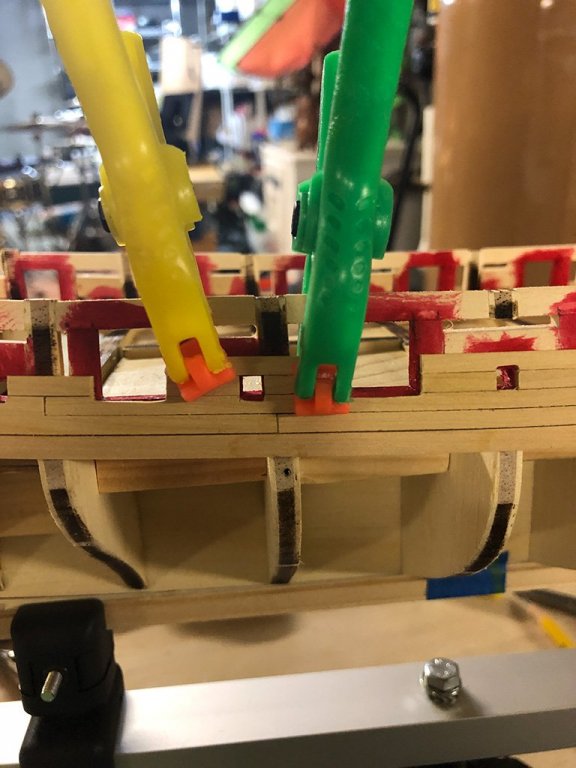

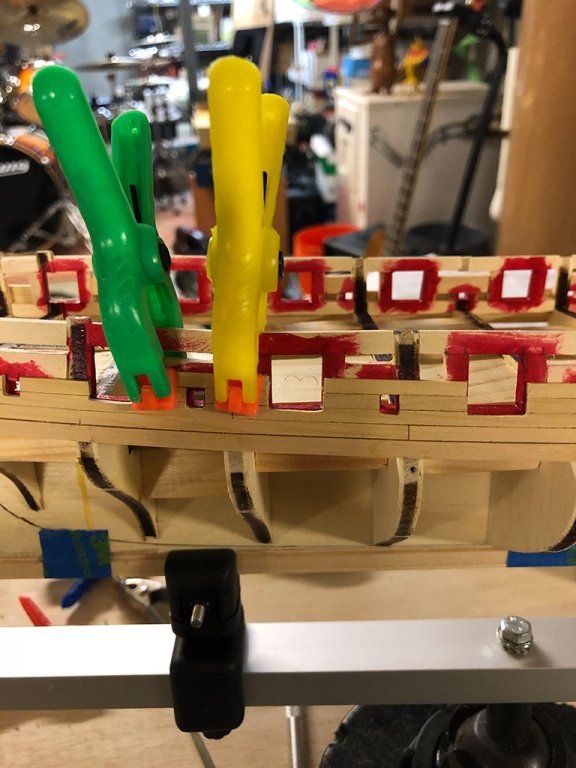

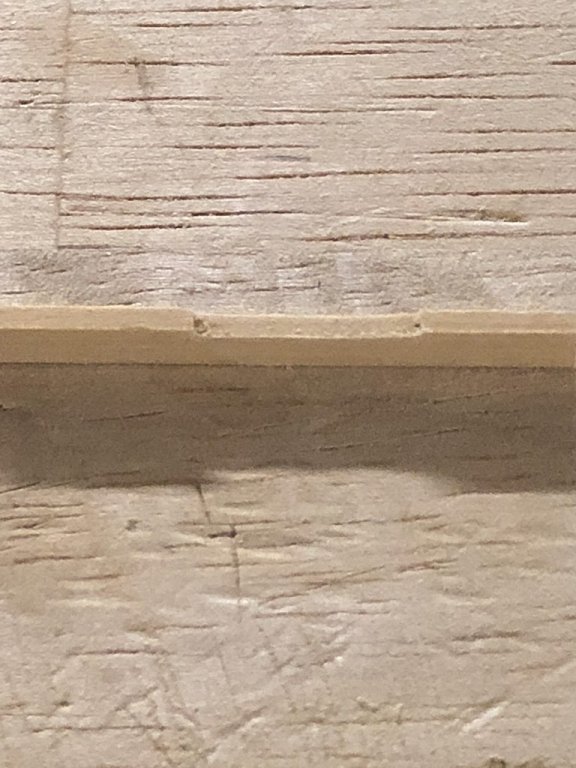

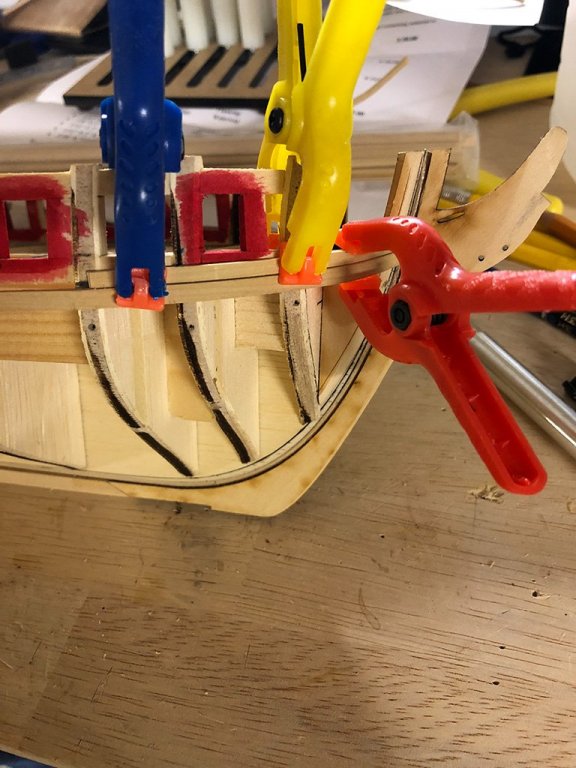

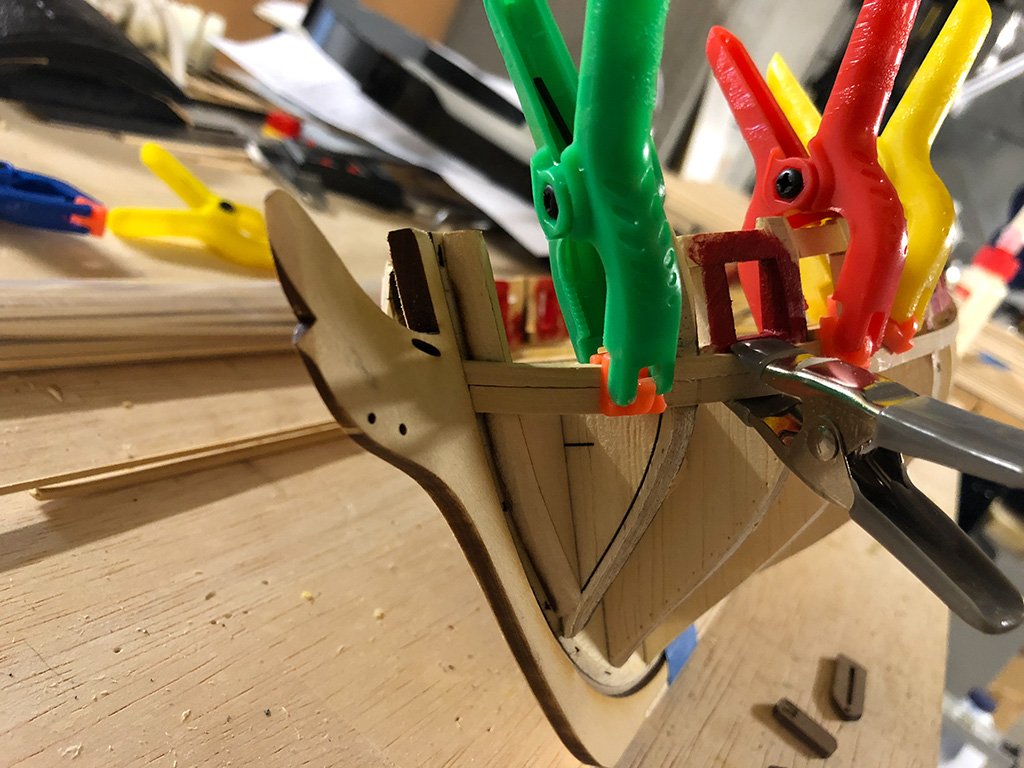

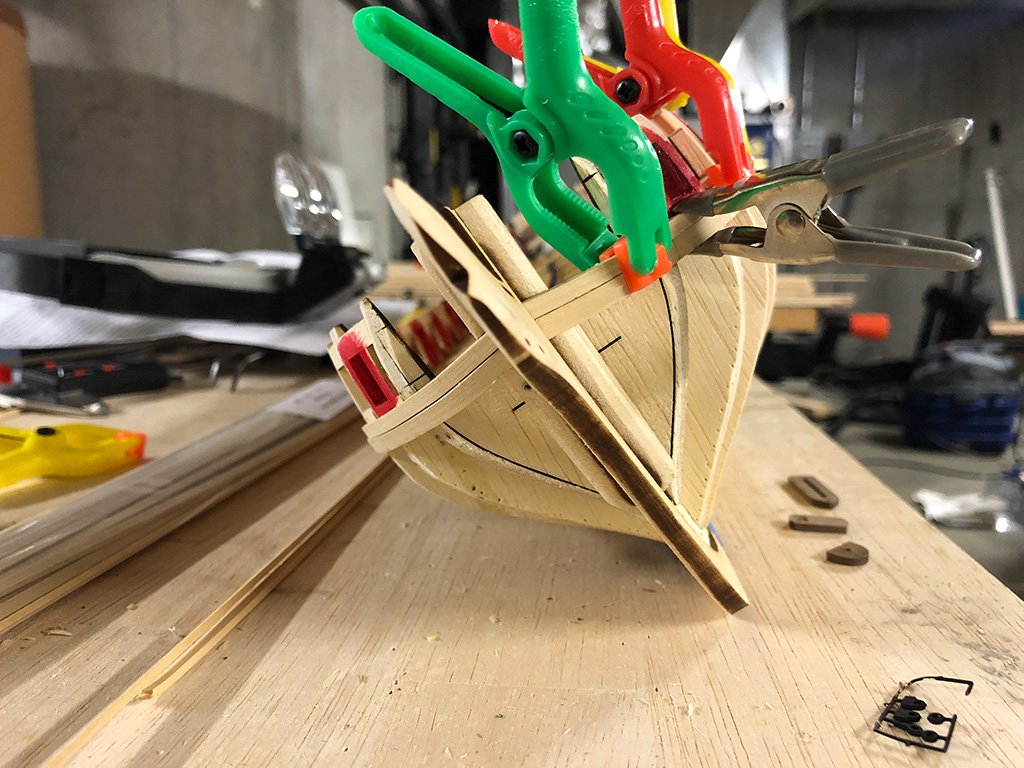

Yep - a teacher - astrophysics during the school year and researcher during the summer months. It's good work, and allows for some interesting off-time hobbies. Been working the planks up to the port openings. I have some images here to show how I am handling the cutting of the notches into the planks. I am using a small saw to notch the planks first, to the depth of the needed notch, then I use a #11 blade to remove most of the wood, then a small file to finish it off. It looks pretty good. It was a trial and error type thing at first, with a couple of horribly failed attempts. I am sure there are better methods, but this one is working for me thus far ;-) The colorful clamps were a bargain at the Dollar Store... they are poorly made, but do just right for this work. ~john

- 90 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

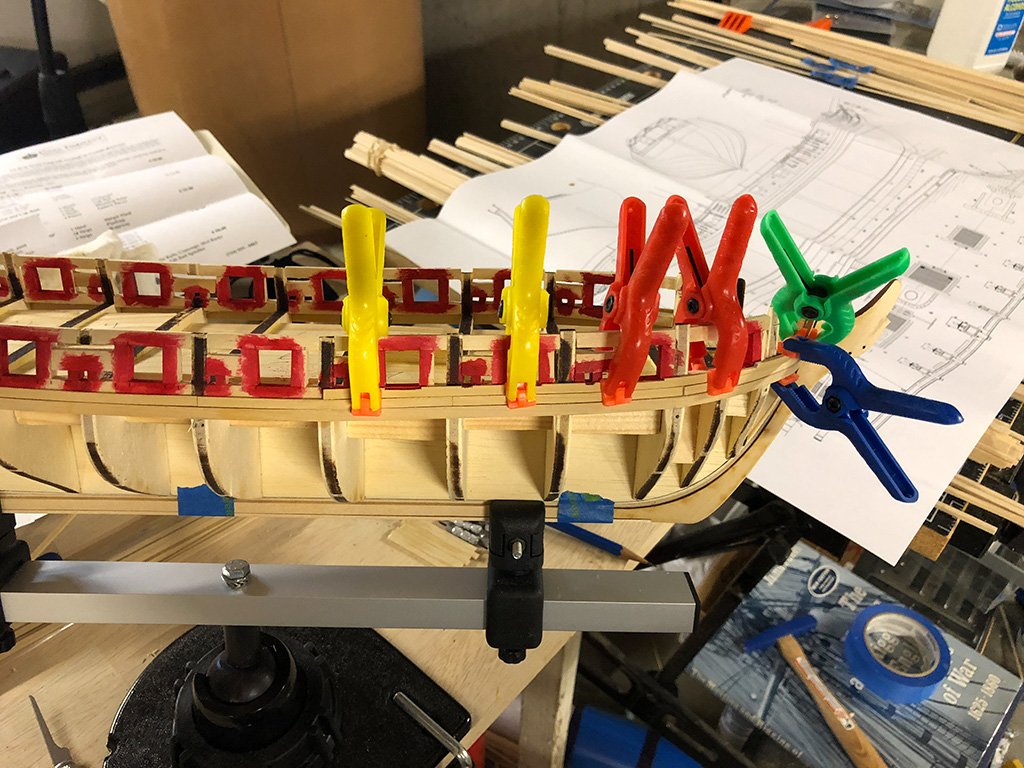

Some free time has evolved into my schedule - namely, school is over! 3 X Huzzah! I've been working on the upper planking with the boxwood, and it is moving along nicely. Made a "wall of planks" to use as a test for the total height above the wales, and it looks to be just about spot on. So far, so good. Using PVA, and going slowly to allow things to set overnight. Some pics of the process.....

- 90 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Patrick: no worries! I am doing well to remember my name on most days ;-) All: Yep I have TONS of binder clips.... best thing ever for frame clamping, as long as there is a bulkhead in place to attach the clamp to. Their price is right. ~john

- 90 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

I am using a little peg stand that I built for a plank bender. The pegs align with the curve at the bow, and have some adjustment. Works well enough, but not as precise. The clamps are there to hold the plank onto the bulkheads long enough for the wood glue to set. I will be looking into additional plank bending methods (heat, etc) when the planks get to be needing bi-directional curvature, as it does towards the stern. I have a surface mount solder station that might just blow hot enough air, so I will be giving that a try some time soon on some scrap. ~john

- 90 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.