-

Posts

964 -

Joined

-

Last visited

About CharlieZardoz

- Birthday 11/17/1978

Profile Information

-

Gender

Male

-

Location

Bushwick, New York

-

Interests

Model ships, wooden and plastic focus on US Navy and Star Trek universe. My ultimate goal is to scratch build the USS Congress, Minnesota, Cumberland and United States.

-

Scottish Guy reacted to a post in a topic:

For Beginners -- A Cautionary Tale

Scottish Guy reacted to a post in a topic:

For Beginners -- A Cautionary Tale

-

mtaylor reacted to a post in a topic:

Brig USS Enterprise 1799 info gathering

mtaylor reacted to a post in a topic:

Brig USS Enterprise 1799 info gathering

-

Canute reacted to a post in a topic:

Brig USS Enterprise 1799 info gathering

Canute reacted to a post in a topic:

Brig USS Enterprise 1799 info gathering

-

Marcus.K. reacted to a post in a topic:

Brig USS Enterprise 1799 info gathering

Marcus.K. reacted to a post in a topic:

Brig USS Enterprise 1799 info gathering

-

Marcus.K. reacted to a post in a topic:

Brig USS Enterprise 1799 info gathering

Marcus.K. reacted to a post in a topic:

Brig USS Enterprise 1799 info gathering

-

Brig USS Enterprise 1799 info gathering

CharlieZardoz replied to CharlieZardoz's topic in Nautical/Naval History

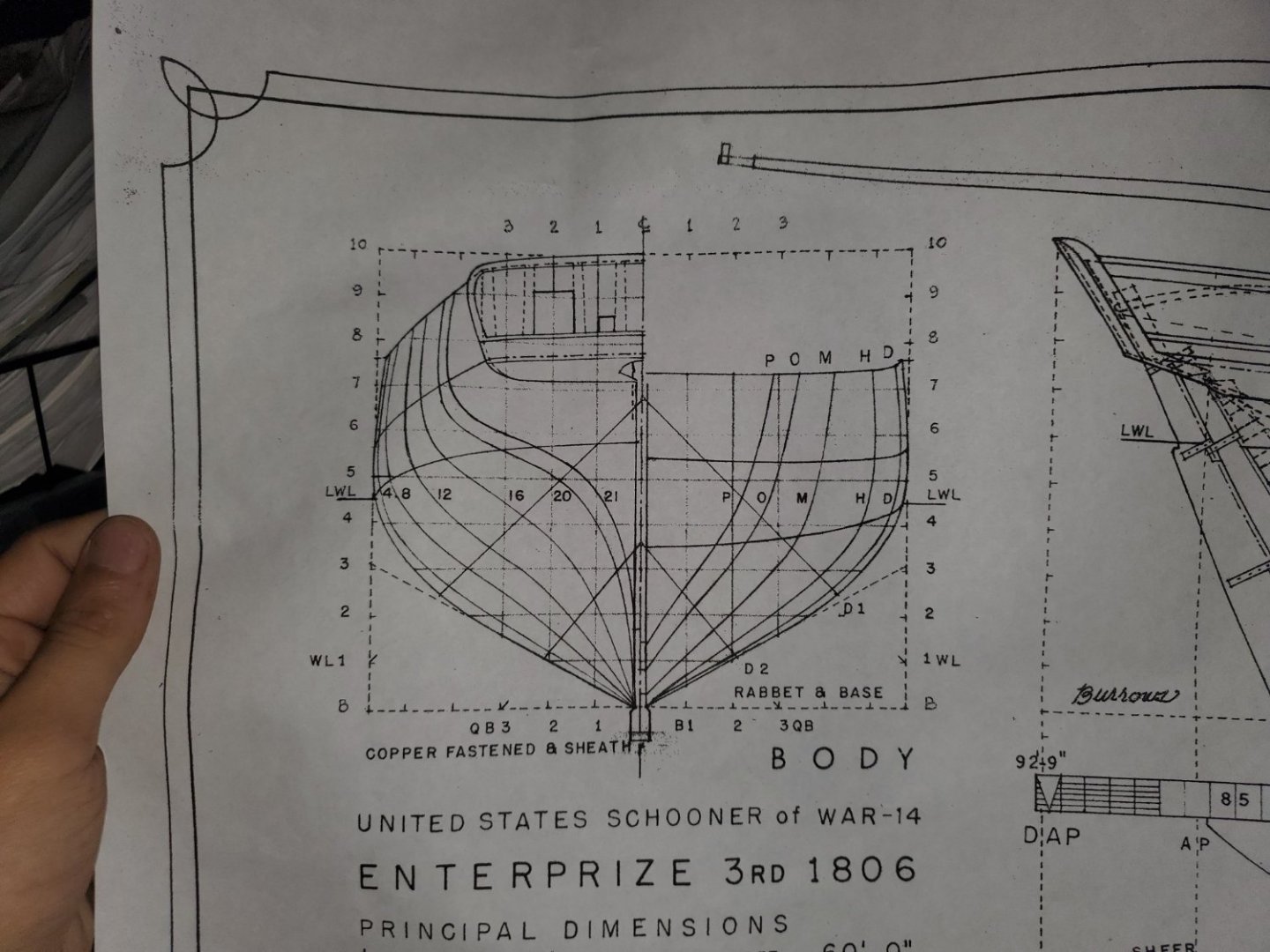

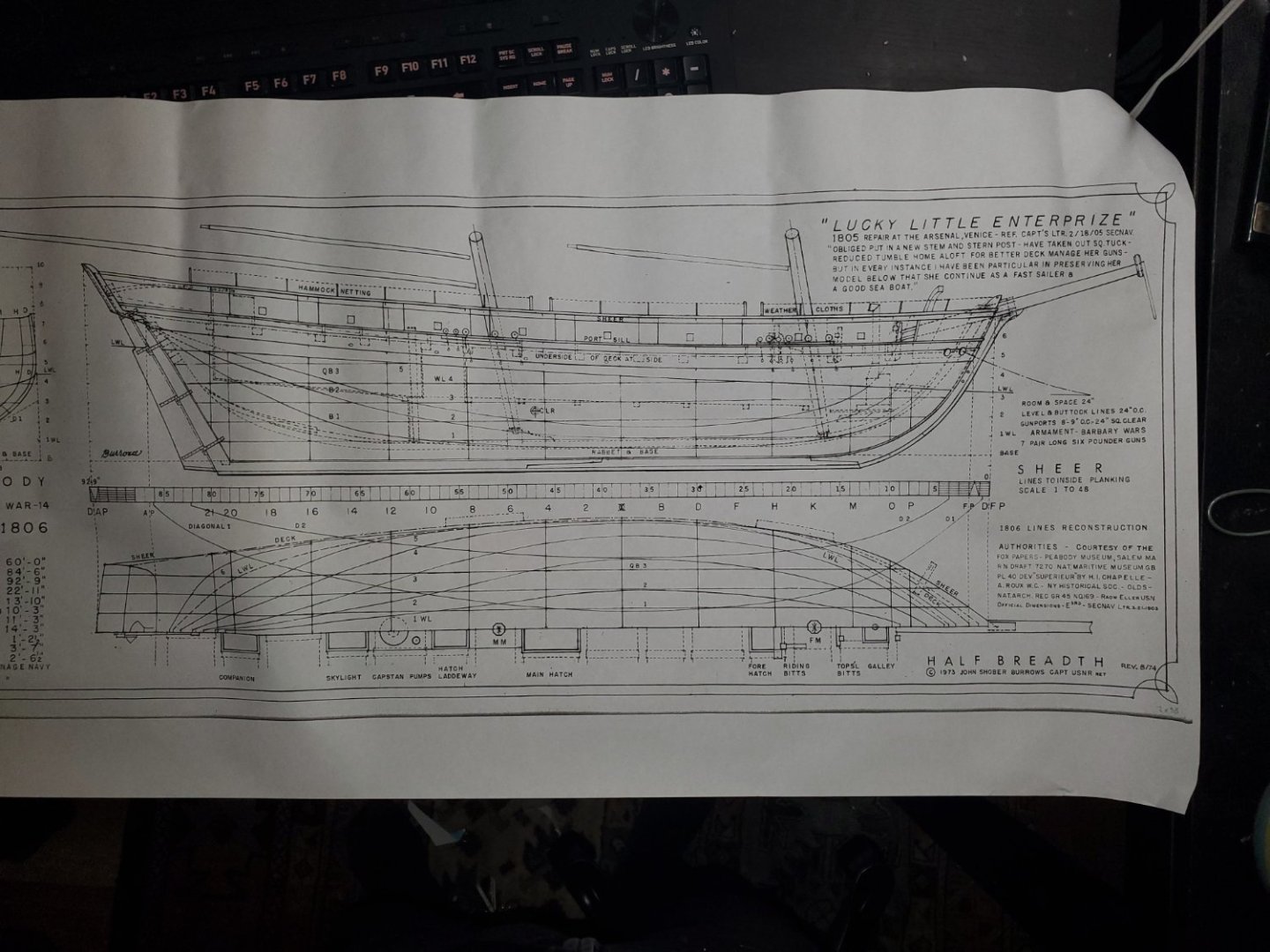

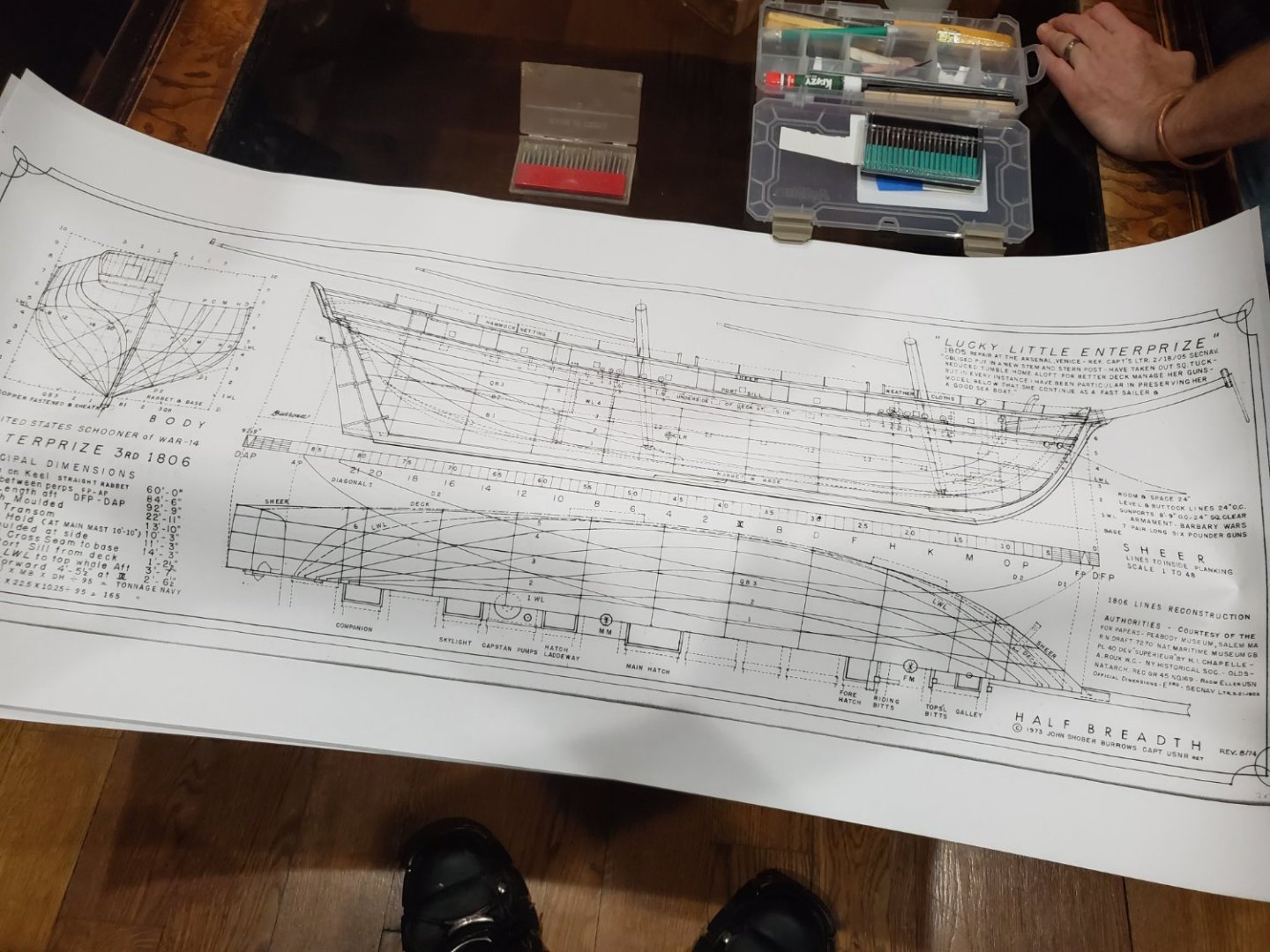

Hi so the story of the plans is this. I gave up trying to go to the museum to find them at mystic then it came to my attention that in our brooklyn boat group had a copy and our head of group Dan Pariser gave his copy to one of our group members and made me a photocopy. So these copies are the only available version of the plan I know that are able to be sourced and not even sure where and when Dan got it from. -

Archi reacted to a post in a topic:

Looking for plans or possible models of Magellan's ships.

Archi reacted to a post in a topic:

Looking for plans or possible models of Magellan's ships.

-

Canute reacted to a post in a topic:

Looking for plans or possible models of Magellan's ships.

Canute reacted to a post in a topic:

Looking for plans or possible models of Magellan's ships.

-

GrandpaPhil reacted to a post in a topic:

Looking for plans or possible models of Magellan's ships.

GrandpaPhil reacted to a post in a topic:

Looking for plans or possible models of Magellan's ships.

-

Harvey Golden reacted to a post in a topic:

Looking for plans or possible models of Magellan's ships.

Harvey Golden reacted to a post in a topic:

Looking for plans or possible models of Magellan's ships.

-

mtaylor reacted to a post in a topic:

Looking for plans or possible models of Magellan's ships.

mtaylor reacted to a post in a topic:

Looking for plans or possible models of Magellan's ships.

-

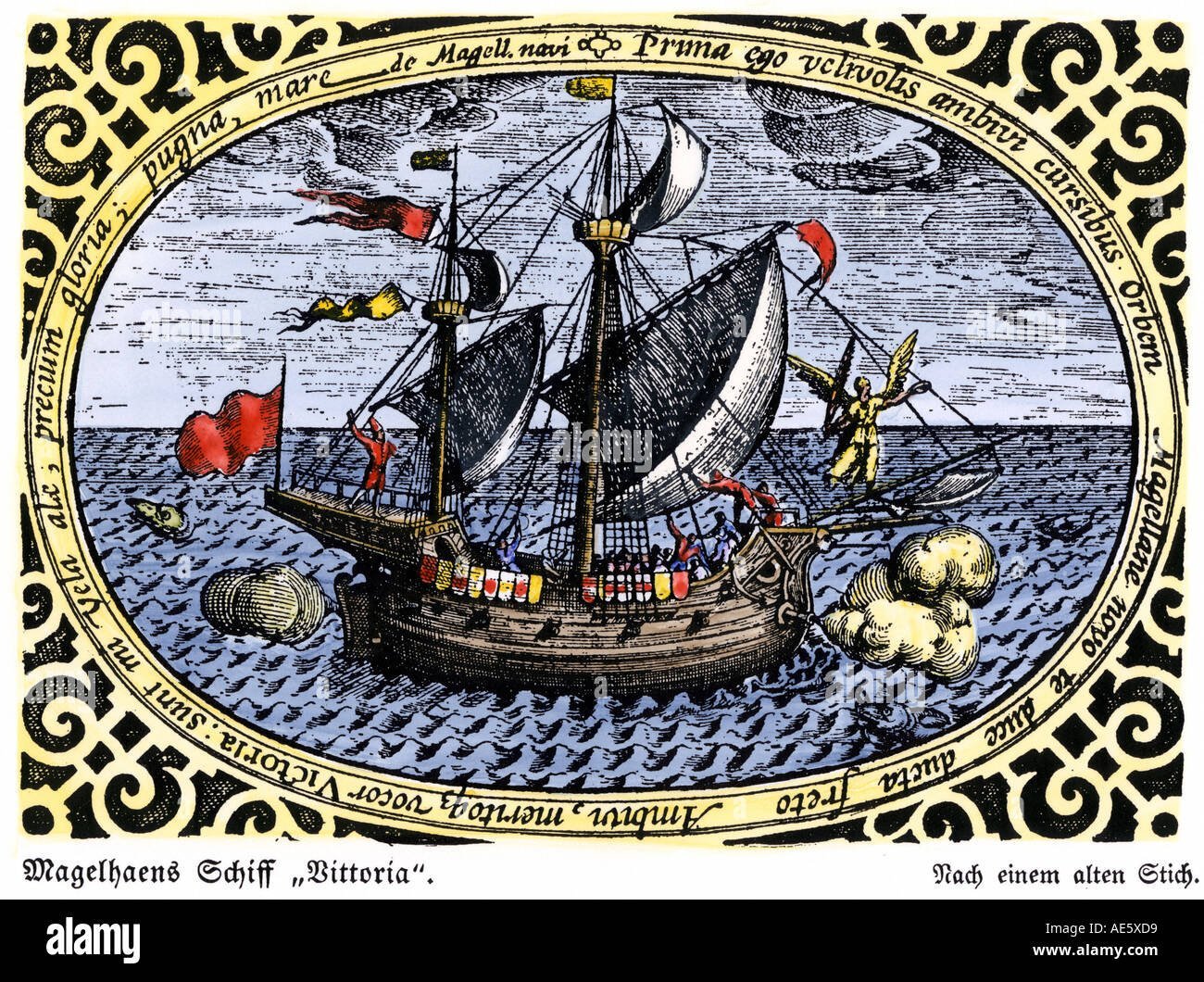

Looking for plans or possible models of Magellan's ships.

CharlieZardoz replied to J11's topic in Nautical/Naval History

Hello and greetings! I always find the idea of trying to reconstruct ships with little to no historical references daunting but also challenging. With some awareness of the history involved one can make an "interpretation" of such vessels as Magellons. The main thing to be mindful of is to be very aware of the exact time the ship was in service as there are subtle differences in ship design even of that time that one can notice decade to decade and be aware of or stumble over if not researched properly (see above about that stern tuck for example). The other is taking into account tonnage as a method of determining size and function. The only ship which seems to have had a reasonable attempt at reconstruction is Victoria and you can see examples of the ship below. 85 tons about 65 feet +/_ She strikes me as being a bit longer and more slender than a carrack like Santa Maria if I were to attempt a model of her I'd likely use alot of this material for reference. As for the others... that's really a challenge. These weren't naval vessels so there was no commissioned design but of a type one could assume larger ships looked closer to galleons while smaller ones looked more like caravels such as Nina. Personally I feel the more drab and unspectacular and weathered they looked the more close to reality they probably were. Exterior was covered in pitch and a modeler might want to add some subtle paint and detailing to avoid boredom but also these embellishments were likely not the case and its doubtful each had very little to distinguish themselves from the other. At any rate an interesting topic I wish you luck on. -

Brig USS Enterprise 1799 info gathering

CharlieZardoz replied to CharlieZardoz's topic in Nautical/Naval History

Well you know gunboats can always be altered and added as i suspect they were at times 👌😉 -

Brig USS Enterprise 1799 info gathering

CharlieZardoz replied to CharlieZardoz's topic in Nautical/Naval History

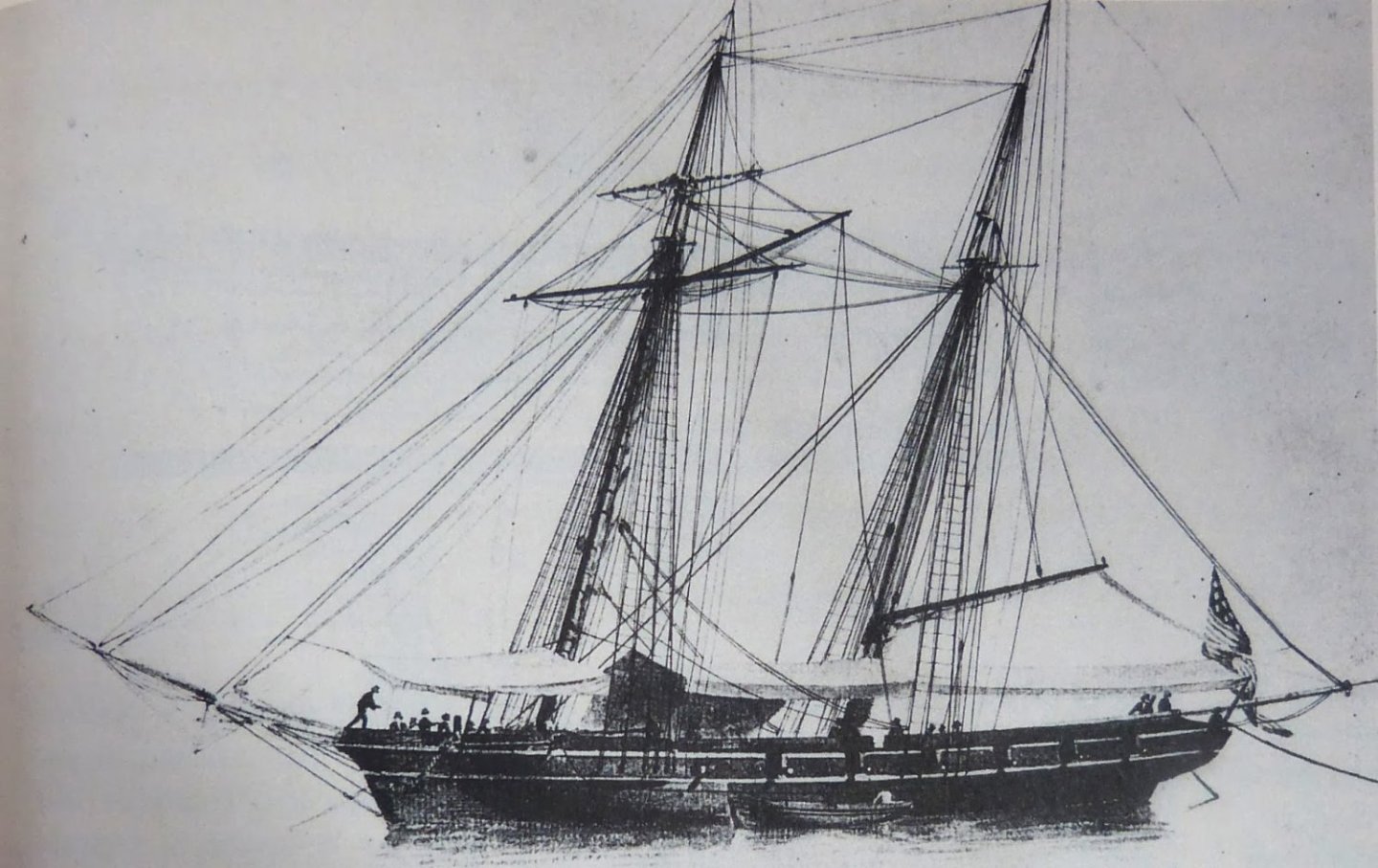

Yes thank you! You can see in that diagram how the Superior had lower bulwarks more typical to other Baltimore clipper style ships and how Burrows obviously used these lines as a basis. One could extrapolate that by the time.of her sinking Enterprize may have looked somewhat more like the Boxer class which was her replacement and that class of ship being a modernized version of the original Enterprize at least in style and function. -

Brig USS Enterprise 1799 info gathering

CharlieZardoz replied to CharlieZardoz's topic in Nautical/Naval History

I believe we mean this one yes? Also keep in mind Enterprize (with a z) had several rebuilds and hard to pin down exactly what she looked like at each turn. At some point she had a poop deck but not like the one from the constructo kit. That's poop circa 1776 not 1805 it was likely similar to what the cruiser class or frolic/peacock had and likely removed before 1812. The reason why the constructo/dikar kit looks like it does it because Vixen was ordered to be a ship of similar lines and displacement to the Enterprize however in truth she was a downscaled Syren and not at all the same type of ship. -

CharlieZardoz reacted to a post in a topic:

Brig USS Enterprise 1799 info gathering

CharlieZardoz reacted to a post in a topic:

Brig USS Enterprise 1799 info gathering

-

Brig USS Enterprise 1799 info gathering

CharlieZardoz replied to CharlieZardoz's topic in Nautical/Naval History

Hi yall. As the proprietor of this forum post I shall endeavour to answer. So the only real holy grail worth pursuing is this plan that was made by John Burrows supposedly under the supervision of Howard Chapelle ? It is basically a very well designed plan located at the music Seaport museum and there are actually 2 versions the 1799 and the 1805 version w the minute alterations. What you see here is not the vixen or anything looking like th constructo kit. It's a variation of the Baltimore clipper La superior which came from the same yard/builder or somesuch. It shows a far more shallow design but also high bulwarks like for a naval brig with heavier cannon. Did not have a bowsprit at least not in the early days and while this plan is conjectur it follows the design of the ship as depicted on the corne paintings of the battle at tripoli. As far as I'm concerned this is what Enterprize looked like pretty much. -

CharlieZardoz reacted to a post in a topic:

American sailing warships with no plans or records

CharlieZardoz reacted to a post in a topic:

American sailing warships with no plans or records

-

CharlieZardoz reacted to a post in a topic:

Hampton Roads Naval Museum video: The loss of the USS Cumberland.

CharlieZardoz reacted to a post in a topic:

Hampton Roads Naval Museum video: The loss of the USS Cumberland.

-

CharlieZardoz reacted to a post in a topic:

Final possible sightings of the US Sloop of War Wasp, 1814-5.

CharlieZardoz reacted to a post in a topic:

Final possible sightings of the US Sloop of War Wasp, 1814-5.

-

CharlieZardoz reacted to a post in a topic:

American sailing warships with no plans or records

CharlieZardoz reacted to a post in a topic:

American sailing warships with no plans or records

-

phebe started following CharlieZardoz

-

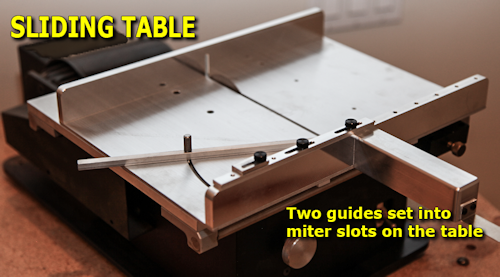

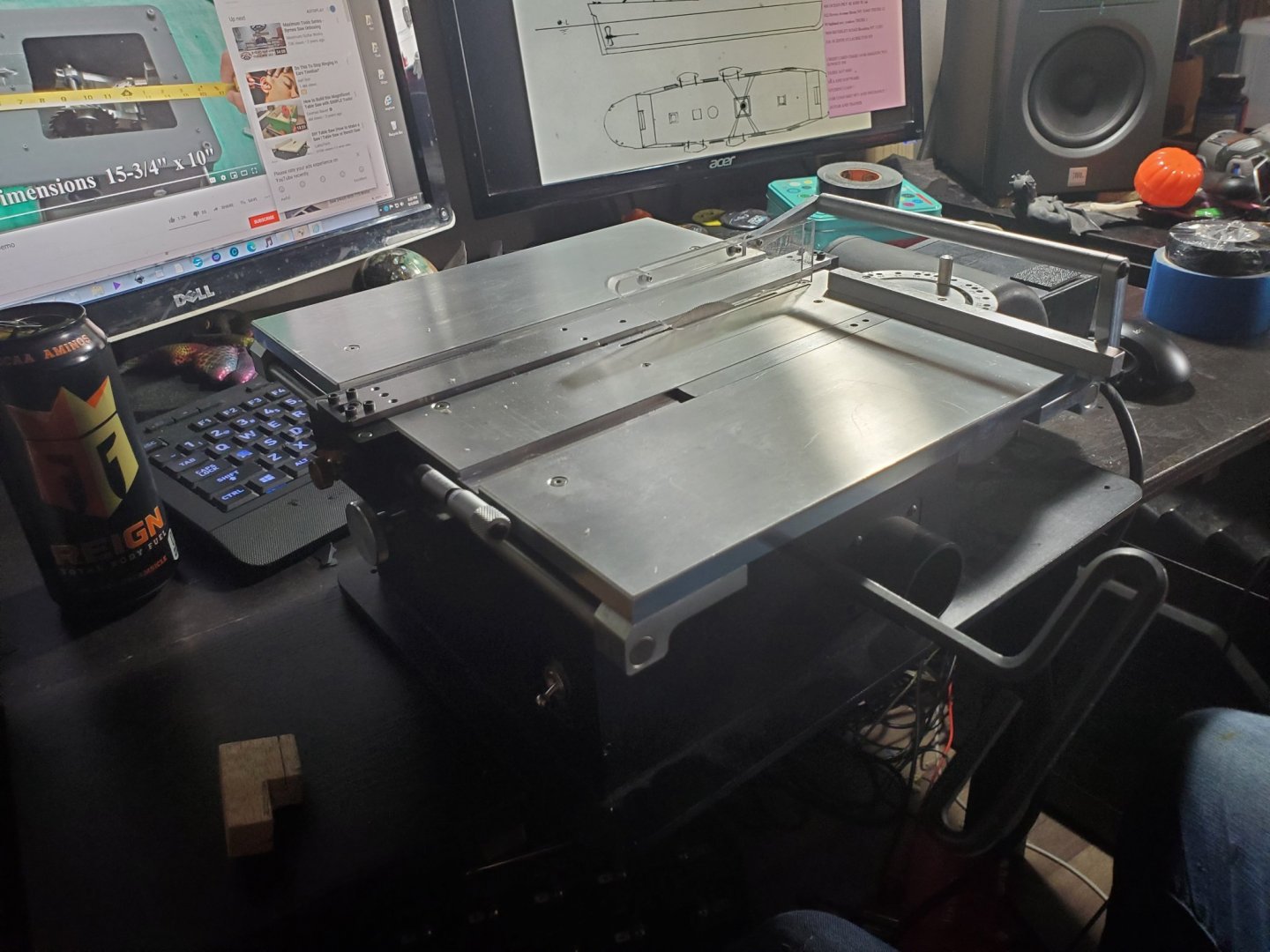

Hi everyone just an update, here it is a 1 mm strip! This one was made of basswood but if I was able to do basswood this precise, harder woods should be even easier. I followed the advice of 3/8" by 1mm and then cut the strip. I wouldn't say I'm great at it yet but I have the means now to keep at it and practice. Thank you all for assistance in helping me understand to usage of the machine. What a smooth cut! 😊

-

Lou I have many sizes and types of milled wood already. So let's say I use a 3" by 1/8" wood piece and want to make several strips so yeah the method you mentioned sounds what I assumed to be. And what was said about the blades its simply a matter of practice and I am unsure how to make something so precise as a 1mm cut. Like what sort of push stick is used for something that tiny?

-

Hi all! So I now have a Byrnes saw and have very little idea on how to use it. Yay! The ultimate goal is to make fine precise wood strips 1mm by 1mm thick so the question is what is the process needed to get to such a specific and small wood strip? Like how should the machine be set up for something so small and precise? I'm open to suggestions and words of wisdom and experience resources to watch or read if i need a sliding tray, ive already ordered a calibre. Ill add pics of what I currently have (blades and otherwise) shortly.

-

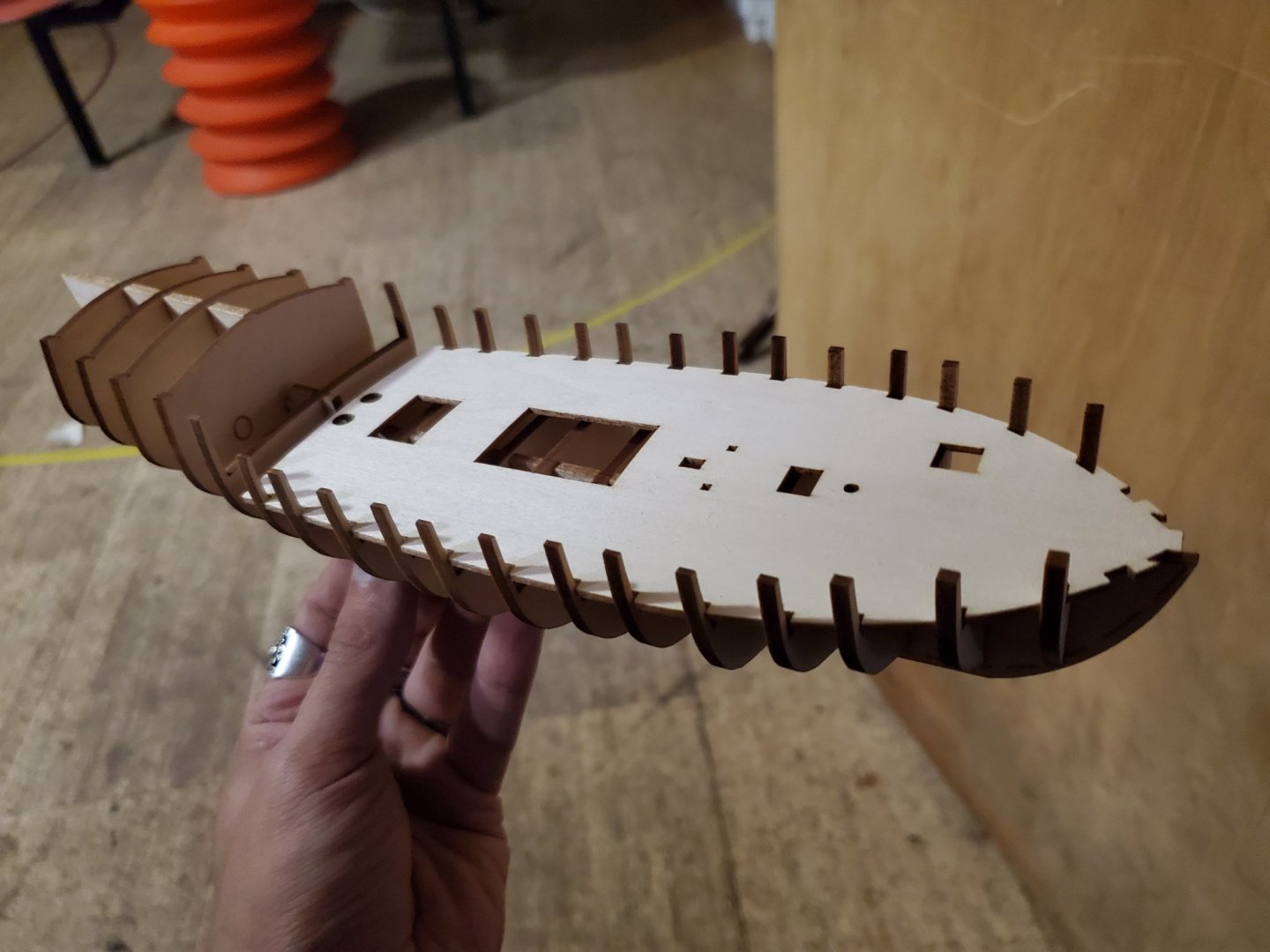

Hi all, this week has been about reorganizing my work space with the new tools provided. Part of this has been building a shelf for my various hulls. While I haven't posted this I actually spend alot of time making frames for various ships, modifying plans etc. The process is easy and in time while i plan to build them all my current environment doesn't give me alot of time and space for detail work as of yet. Hulls from bottom to top are 30 ton revenue cutter Active (in the box) Sultana Halifax Armed virginia sloop (just made based of ms purchased plans) 50 ton cutter (Monroe) And 70 ton (Vigilant) On the top marine model privateer which will probably become an Eagle class revenue cutter (in Chappelle's book the unidentified 75 footer of 1798). I also have 2 frames on table the constructo Enterprise (aka Vixen) and Dikar Lawrence which i will also add to the lot at some point. Overall this will be a much better space for crafts when time allows. New laptop also helps me create laser programs for ship parts on the go! 😉

- 362 replies

-

- active

- revenue cutter

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.