-

Posts

1,027 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by alde

-

-

Thanks for the help. The brass strip supplied in the kit is 3/32" x 1/64" and would be bent on the larger dimension. I think you guys are right about cutting it from a brass sheet. The radius would probably be around 10" give or take.

-

Can anyone recommend a method of making a large radius edge bend of brass strip? I'm making a sheet metal guard to go on top of the railings at the bow, around the anchors on my Glad Tidings.

-

HM Cutter Cheerful 1806 by Erik W - 1:48 scale

alde replied to Erik W's topic in - Build logs for subjects built 1801 - 1850

"Pretty well"? I think it looks fantastic. Mine is a complete hack job in comparison. -

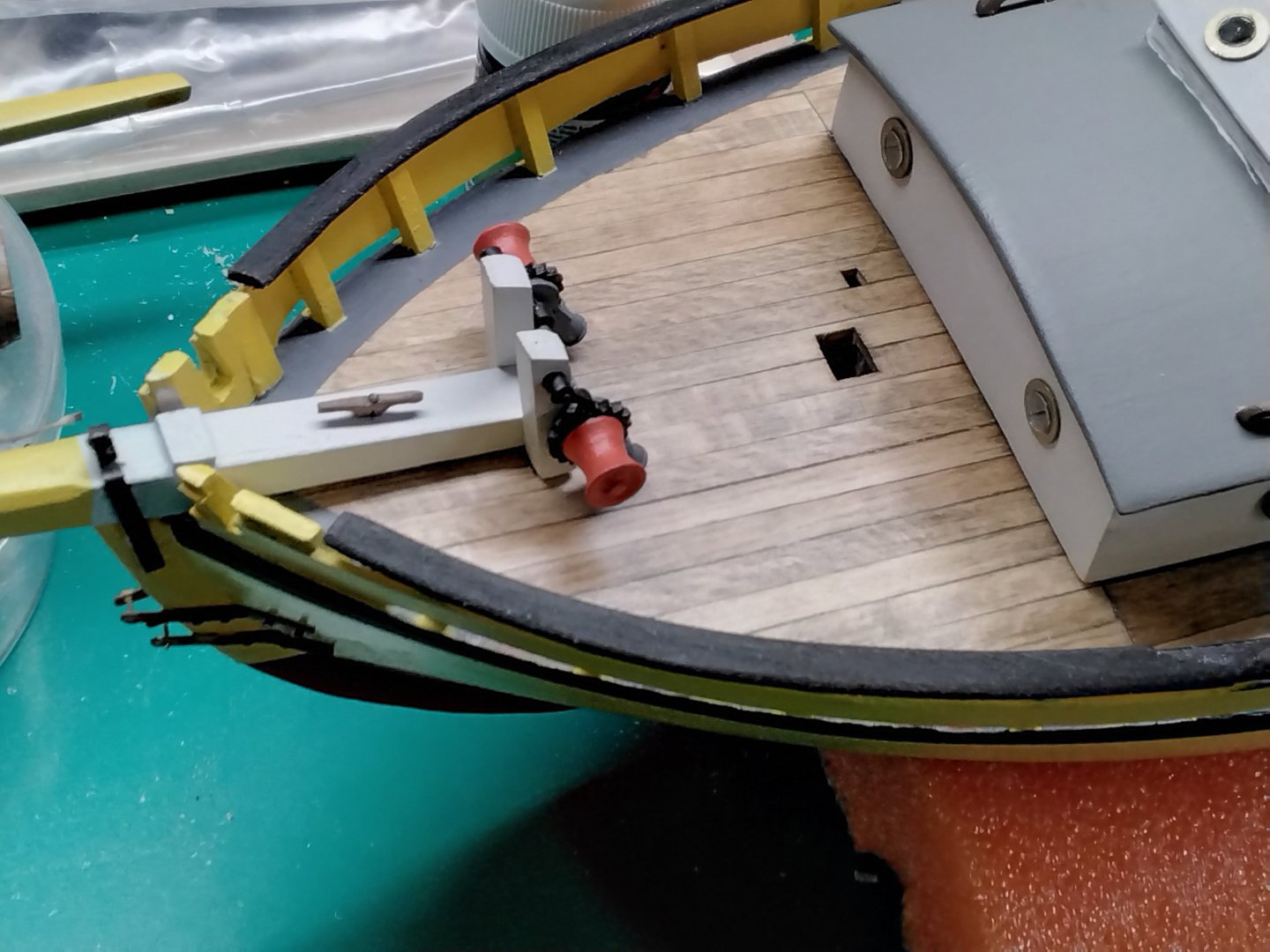

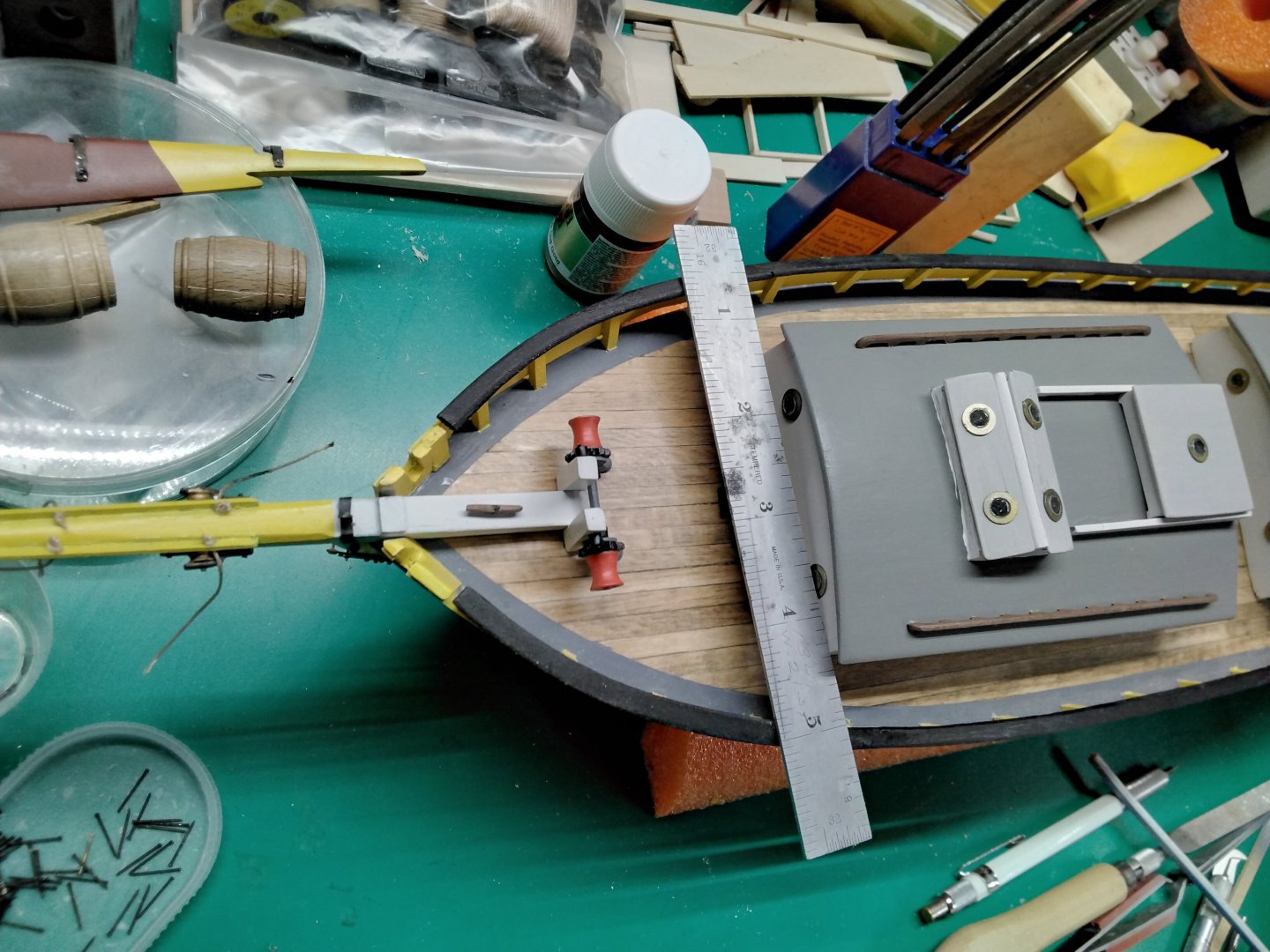

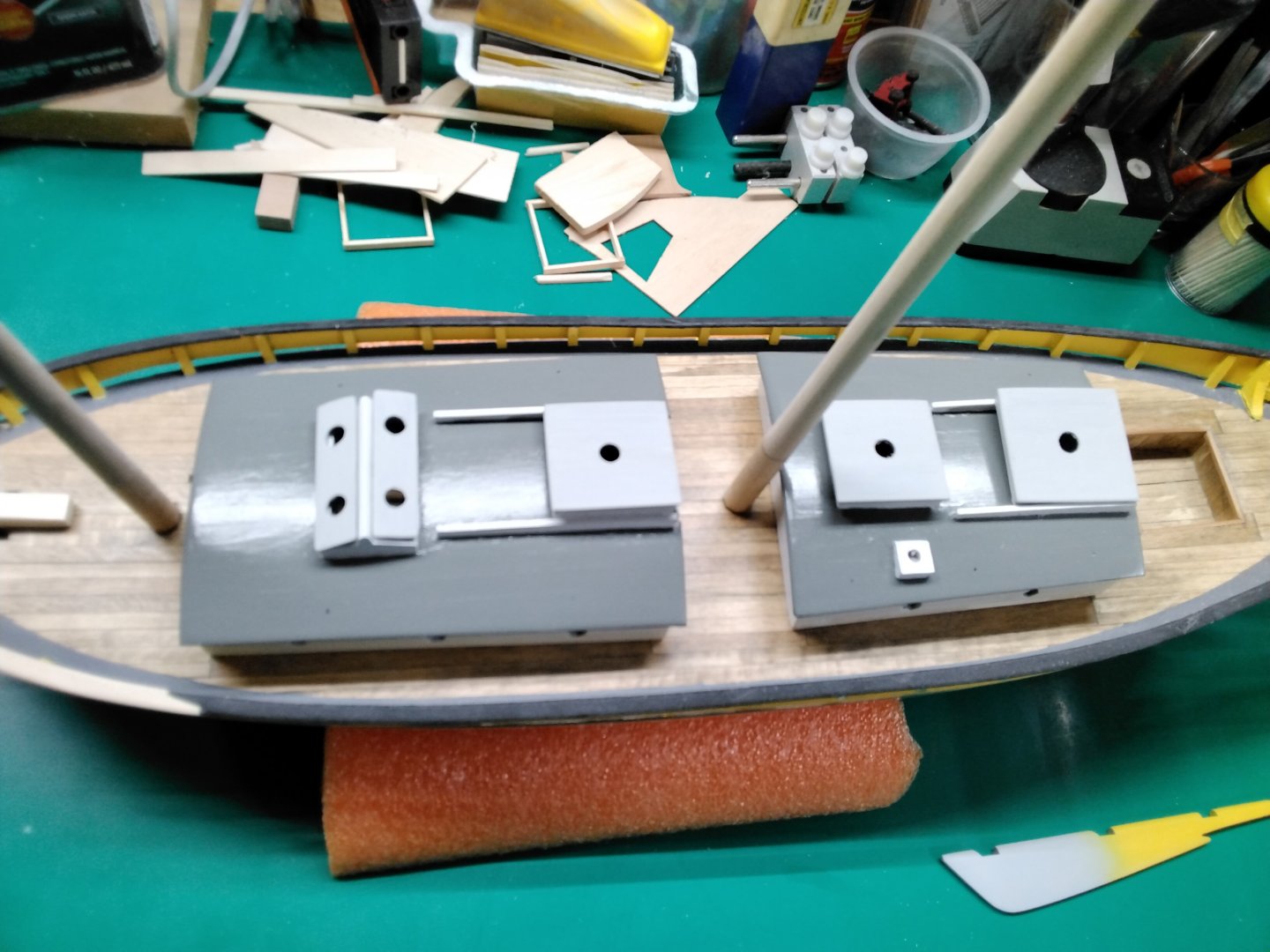

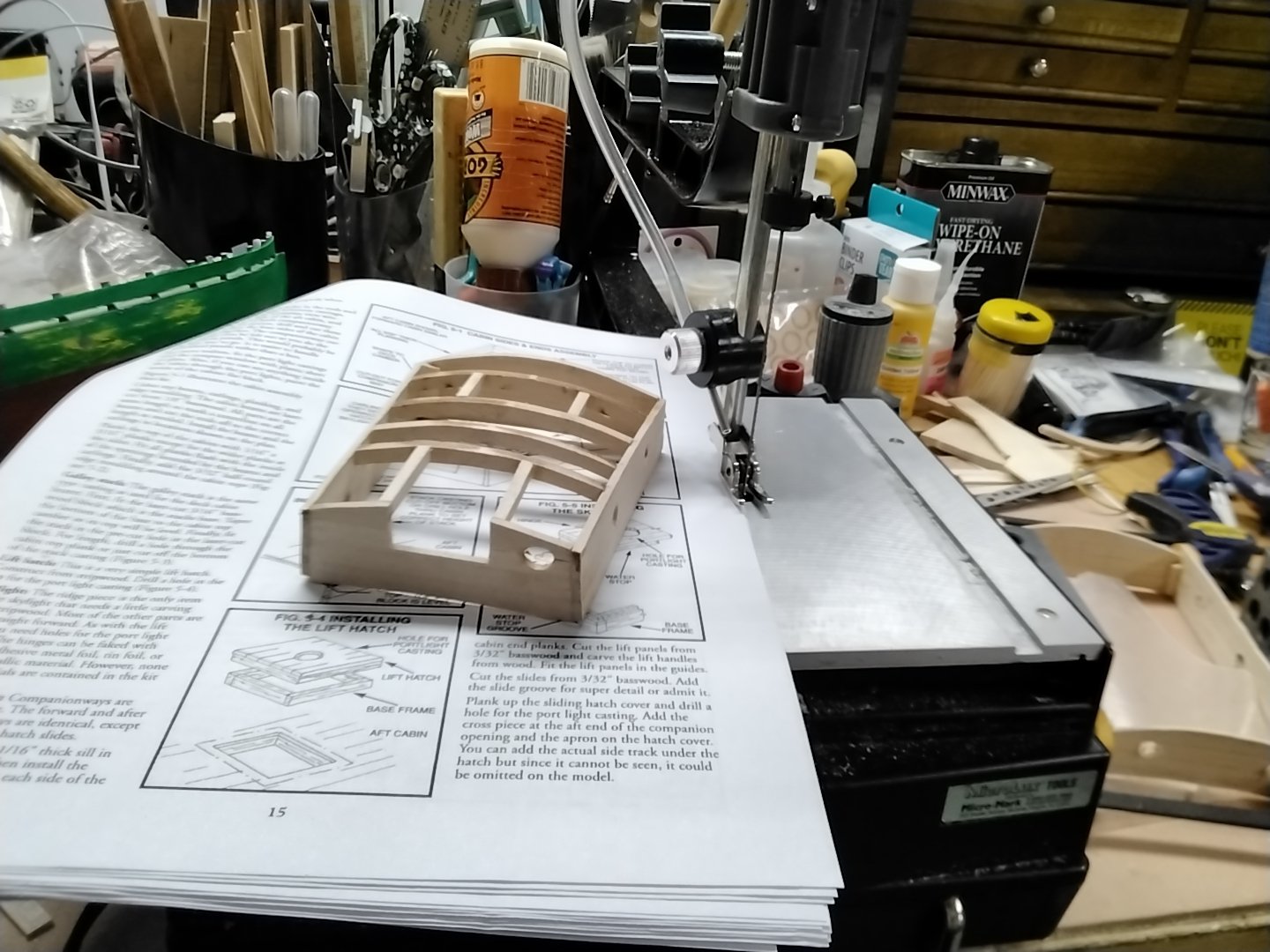

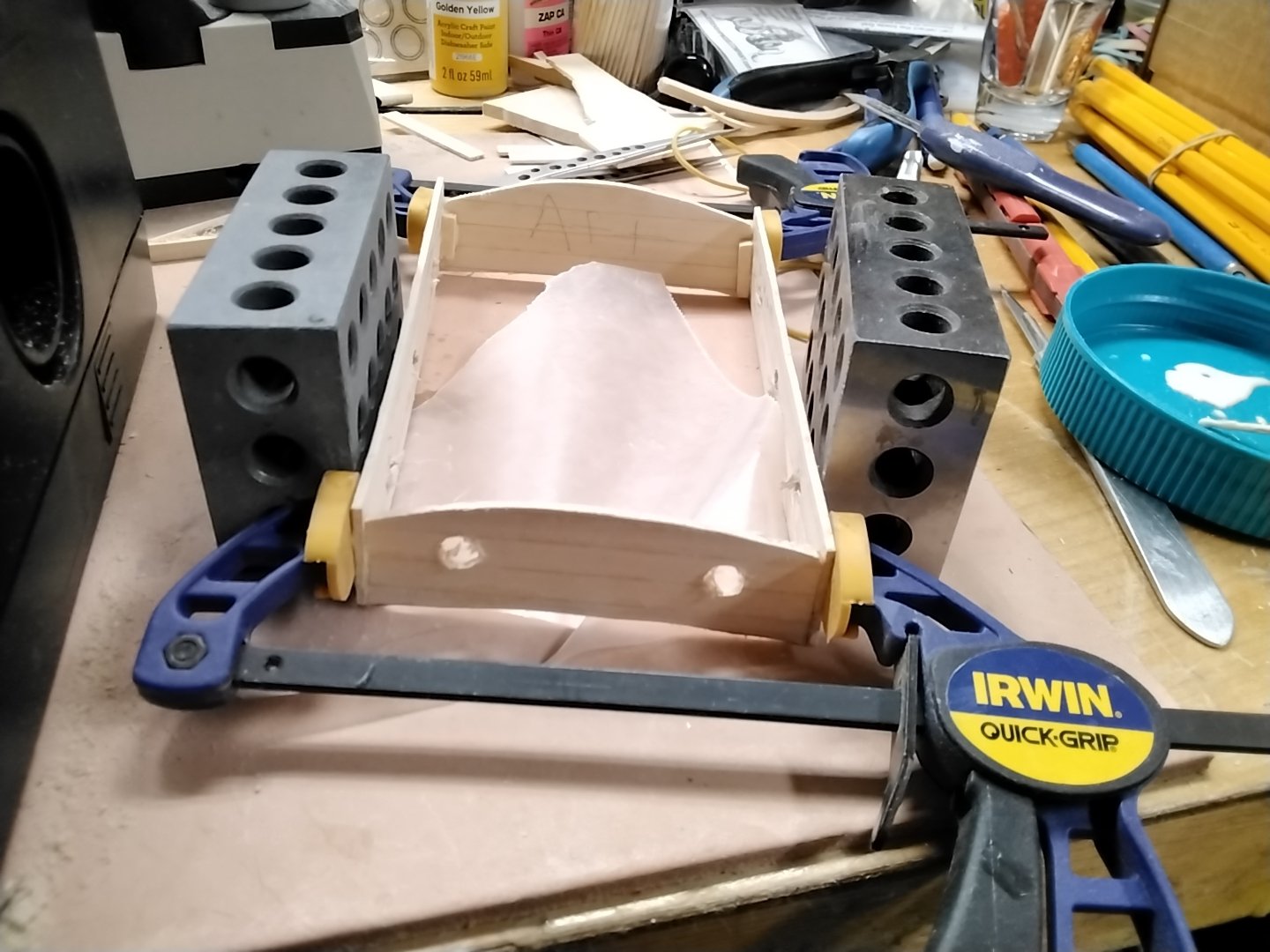

I just wanted to post a couple of proof of life pictures. I planed the spars to a tappered hex then sanded them round. It was really easy and I'll do it that way from now on. It was my first time using a plane. I still need to learn how to sharpen the blade. The cabins are just placed on and not glued. My next challenge is the metal work. It's another thing I've never done before. I have soldered PE and other small parts but I've never really made parts. I'm looking forward to trying it.

-

I have a question for you guys. The kit provides dowels for the masts but they need to be tapered. The instructions suggest planning them to square then octagonal . I have a nice Stanley plane that I never used before so I decided to try it on a cut off first. It went really well. I was able to plane it down to a tapered octagonal then sand it round. When I tried it on the actual mast dowel the first 3 sides went perfectly. The forth side wanted to grab and tear out. Is this because the blade is dull? It was giving me nice curly shavings when it seemed to cut well. BTW, I will be using this method from now on. I think I need to make some kind of fixture to hold the parts though. Is that what is called a shooting board? Thanks, Albert

-

HM Cutter Cheerful 1806 by Erik W - 1:48 scale

alde replied to Erik W's topic in - Build logs for subjects built 1801 - 1850

Erik, she looks fantastic. I'm really looking forward to watching her go vertical. I'm a little apprehensive about doing the masts and rigging on my Glad Tidings. I'll watch your masting and rigging with great interest. -

Wow, that is really attractive.

- 201 replies

-

- Oyster Sharpie

- first scratch build

-

(and 1 more)

Tagged with:

-

Will the Medway Longboat kit ever be made available again?

alde replied to alde's topic in Wood ship model kits

Thanks for the heads up. I appreciate it. -

She looks great. I love the shape of the hull. It looks fast.

- 51 replies

-

- Model Shipways

- Baltimore Clipper

-

(and 1 more)

Tagged with:

-

Will the Medway Longboat kit ever be made available again?

alde replied to alde's topic in Wood ship model kits

Thanks for the reply, Chuck. I can't imagine the time it takes for you to keep up. I'm in absolutely no rush but am happy to know that it will eventually be available. I'm looking forward to seeing what you develop in the future. -

Glenn, I know I'm really late to the party but have to tell you how much I appreciate you sharing so much detail of your amazing build of Cheerful. She's absolutely beautiful and an inspiration. I purchased the set from Chuck a few weeks ago but I see I'm far from ready for it. Luckily I have a couple of kits to practice on before I take Cheerful on. When I do, your detailed build will be an excellent guide. Thank you for taking the time to share your work process.

- 778 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

HM Cutter Cheerful 1806 by Erik W - 1:48 scale

alde replied to Erik W's topic in - Build logs for subjects built 1801 - 1850

The small details sure matter. Your work looks great.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.