-

Posts

1,028 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by alde

-

First I want to say how glad I am that I removed the old planking. The new is far from perfect but way better. I'm still working on the stern which has had its own issues. I think I finally got it figured out after 3 times. I was hoping for an opinion from you guys though. After so many do overs the planking on the stern has gotten thin. I really don't want to rip it out and start over. Would it be appropriate to paint the stern planks and if so what would be an acceptable color? When I look at my pictures ompaired to some other builds I realize what a wood butcher I am. It's getting better though.

-

When I was a kid I was walking across the carpeted living room. I felt a sharp pain on the bottom of my foot and started dancing on one leg. As i was hopping in pain my mom with a perfectly straight face said "oh, you found my earing". The entire stud was stuck straight in. We all had a good laugh about it later but I didn't think it was very funny at the time.

-

I want to sign aboard this one.

- 145 replies

-

- model shipways

- charles w. morgan

-

(and 1 more)

Tagged with:

-

Now that would be fantastic. The CWM needs around 7 I think. It would be a huge improvement over the blocks of wood that come in the kit.

- 216 replies

-

- masterkorabel

- ships

-

(and 3 more)

Tagged with:

-

Fantastic Chuck. Do you profile the boxwood shear strip before or after its applied to the hull? I would think it might be easier on the hull if your careful not to scratch the hull or protect it with tape.

- 421 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

It's great that your shipyard move is about done. I'm looking forward to seeing some progress and especially your carvings.

-

Using a moulding scraper tool?

alde replied to alde's topic in Modeling tools and Workshop Equipment

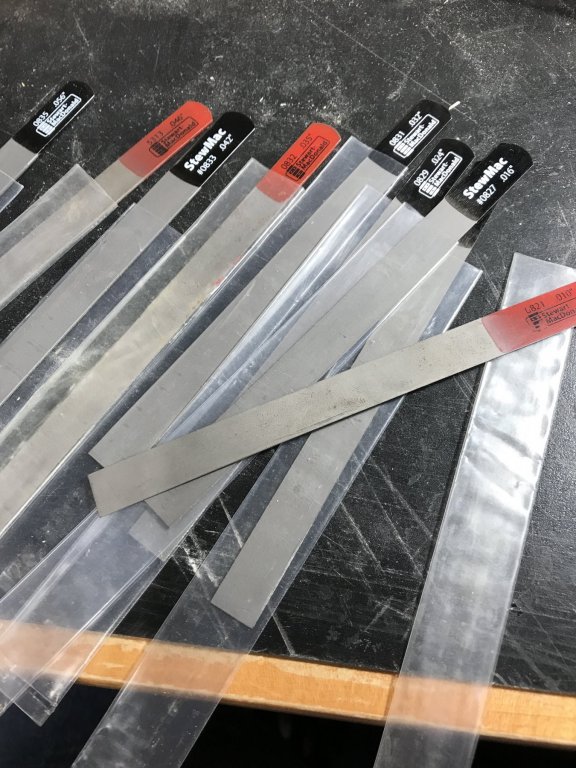

I dug out my guitar but slotting files for the heck of it. My smallest is .010” and the largest is .056”. They should work just fine if the metal is softened first. Here are a couple of pictures. The cutting surface is on the edge. -

Using a moulding scraper tool?

alde replied to alde's topic in Modeling tools and Workshop Equipment

A cheaper alternative that may work is guitar nut slotting files. I didn't think of it until your post but I have a full set and they go pretty small. -

The planking I'm using the second time around is 1/32" thick. The sheets of boxwood I just got from you will be used to finish the job.

- 421 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Yes, that's about right. The pictures on my log are before I ripped off all the planking though. The ones you see were straight planks that were forced into place. I am now re-planking with spiled planks and it looks much better. I was not happy with it before.

- 421 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thank you very much Chuck. That clears things up quite a bit for me. On my Halifax I have been spileing, fitting, soaking and clamping the wet plank to the hull until it's dry. Then I do a bit more fitting then glue with titebond and clamp again. The formed planks still have a bit of spring to them but clamp easily with very little additional bending. This is my first time really spileing planks so I'm still trying to learn as much as I can. Your willingness to share your knowledge is very much appreciated.

- 421 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Chuck, your hull looks amazing. A couple of questions if you don't mind. First, the lower shear strake fits perfectly snug against the plank under it. Is this strictly because the shear plank is perfectly spiled? Does it have to be forced at all? Also, how to you clamp the planks in place? I have seen several different clamping methods but your seems to really work well. With the planks that I have spiled I can get them to lay down pretty well against the frames but it's a challenge to get them to snug up tight against the previous plank.

- 421 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Great job Rusty and nice save on the dolphin.

- 120 replies

-

- queen anne barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Using a moulding scraper tool?

alde replied to alde's topic in Modeling tools and Workshop Equipment

I’ll try that. -

Using a moulding scraper tool?

alde replied to alde's topic in Modeling tools and Workshop Equipment

Yes they are. I think they are too big for most ship modeling applications. Now that I did it its really easy to make your own. I think I remember seeing Chuck make a scraper from brass. I'm going to try that next time. That way it can be done with files with more control. -

Using a moulding scraper tool?

alde replied to alde's topic in Modeling tools and Workshop Equipment

Thank you all for your help and great suggestions. I just finished making 2 moulding strips out of Swiss Pear and have them soaking in water to be bent to shape. The home made tool cut really well as you can see from the shavings in the picture. The diamond cutter had no trouble cutting the blade using the fastest speed on the Dremel tool. -

Using a moulding scraper tool?

alde replied to alde's topic in Modeling tools and Workshop Equipment

I made a scraper from a blade using a small diamond cutter on my Dremel tool and it worked very well. The boxwood strip is just 1/16” wide. It’s hard to see the profile in the picture but it looks pretty nice. -

Using a moulding scraper tool?

alde replied to alde's topic in Modeling tools and Workshop Equipment

Absolutely beautiful Druxey. A true work of art. I'm going to try making my own scraper tomorrow. The factory made ones I have are the wrong size for my application and they do drift. I'll be carving my own decorations (very simple compaired to yours) and your work is an inspiration for sure. -

Using a moulding scraper tool?

alde replied to alde's topic in Modeling tools and Workshop Equipment

I was for sure applying pressure. Probably too much.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.