-

Posts

1,028 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by alde

-

Using a moulding scraper tool?

alde replied to alde's topic in Modeling tools and Workshop Equipment

Thanks Chazz. I'll try your tips when I get back to the shop tomorrow morning. -

I have been trying to shape some moulding strips for my Halifax using a scraping tool as shown in some books and I have seen builders here use. I have tried using both boxwood and pear but just get a mess. It just feathers and won't form a clean shape. What am I doing wrong?

-

She's looking up to your usual high standards Bob. The gun rigging looks great.

- 359 replies

-

- prince de neufchatel

- model shipways

-

(and 1 more)

Tagged with:

-

Nice planking job. Chucks Cheerful sure makes for a beautiful model.

- 574 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thank you Ken. That helps me a lot. I tried edge bending the planks and it looked ok but just wasn’t right. I’m really glad I removed it and have a another shot st doing it right.

- 122 replies

-

- independence

- privateer

-

(and 1 more)

Tagged with:

-

Ken, you mentioned that you edge bent the lower wale. Did you also edge bend the planking between the wales? I edge bent the planks between the wales on my Halifax and found it could have been better. I had to remove all the planking because it was not positioned properly. Now I have a chance to do a better job. The spacing is even from bow to stern like yours. Your hull looks very similar to Halifax. By the way your Independence is looking great.

- 122 replies

-

- independence

- privateer

-

(and 1 more)

Tagged with:

-

A first build to be proud of for sure. Very nice.

- 37 replies

-

- pickle

- caldercraft

-

(and 1 more)

Tagged with:

-

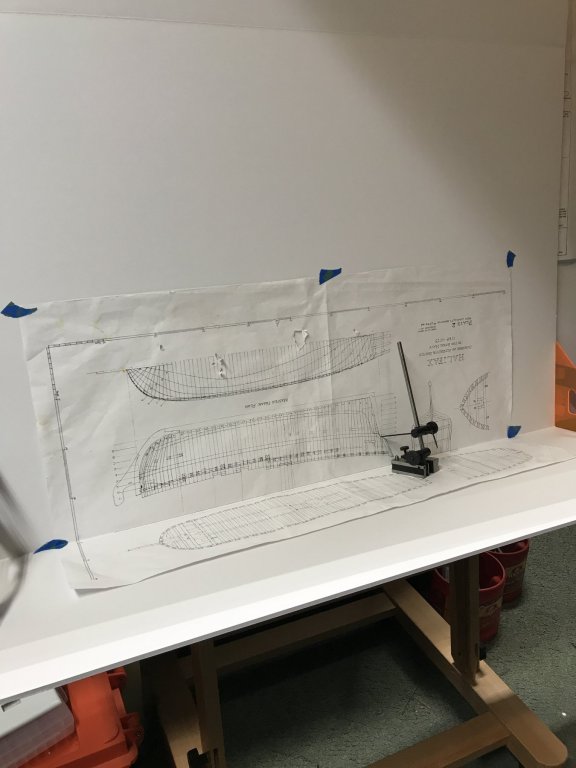

Here is the method I’m going to use to get accurate elevations from the plans. I picked up a tri-fold foam board and used plastic drafting angles to fix it at 90 deg. Then I folded the plan on the top surface of the building board. Now accurate dimensions can be taken and transferred right to the hull. I wish I had done this the first go around.

-

I went ahead and did it. I ripped off the planking to the wales. I could have faked it and made it look OK but it just would not have been right. This time I'll think a few moves ahead before I redo it and lay it out correctly. I know I would never be happy with it the way it was. It will probably take a couple of days before it's cleaned up enough to lay in some planks. It was a tough decision but I know I'll be glad I did it.

-

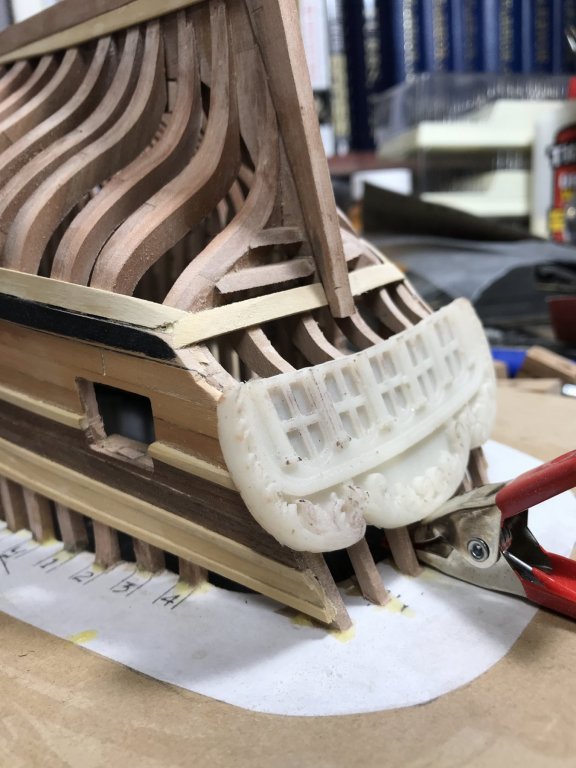

I told you guys about my problem with starting the planking too far from the keel or maybe using planks that are too wide. In any case my biggest problem is the stern. The picture shows where the casting should go but the as you can see the planking is much too high. The way I see it there are two things I can do. First is redo the planking by ripping it all off and starting over. The second is to build my own stern decorations and windows with elongated windows or more empty space between the windows and carvings. Do you guys see any other choices or have any suggestions?

-

Sometimes it’s hard to redo something you have put so much work into but it’s always worth it in the end. Your tops are looking really nice.

- 1,135 replies

-

- model shipways

- syren

-

(and 2 more)

Tagged with:

-

Your doing a fine job on a very interesting ship.

- 421 replies

-

- caldercraft

- granado

-

(and 1 more)

Tagged with:

-

J3 Piper Cub by Steve 12345 - FINISHED - 1/4 scale

alde replied to Steve 12345's topic in Non-ship/categorised builds

Beautiful Piper Cub. Thanks for posting your pictures. -

I appreciate that Mark. I think the camera hides some of the flaws. I think I should be able to compensate for starting the planking too far from the keel with no problems. The only thing that may cause trouble is where the bowsprite exists the hull. Everything else should be fine. I think I'll build some of the internal structure before I cut it loose. I really don't want it to fall apart though it seems pretty strong.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.