-

Posts

7,748 -

Joined

-

Last visited

About CDW

- Birthday 04/16/1954

Profile Information

-

Gender

Male

-

Location

Tampa, Florida

-

Interests

Scale model building of all types; American and world history; science; religious studies; flight; grandchildren; travel; antique car and motorcycle restoration

-

yvesvidal reacted to a post in a topic:

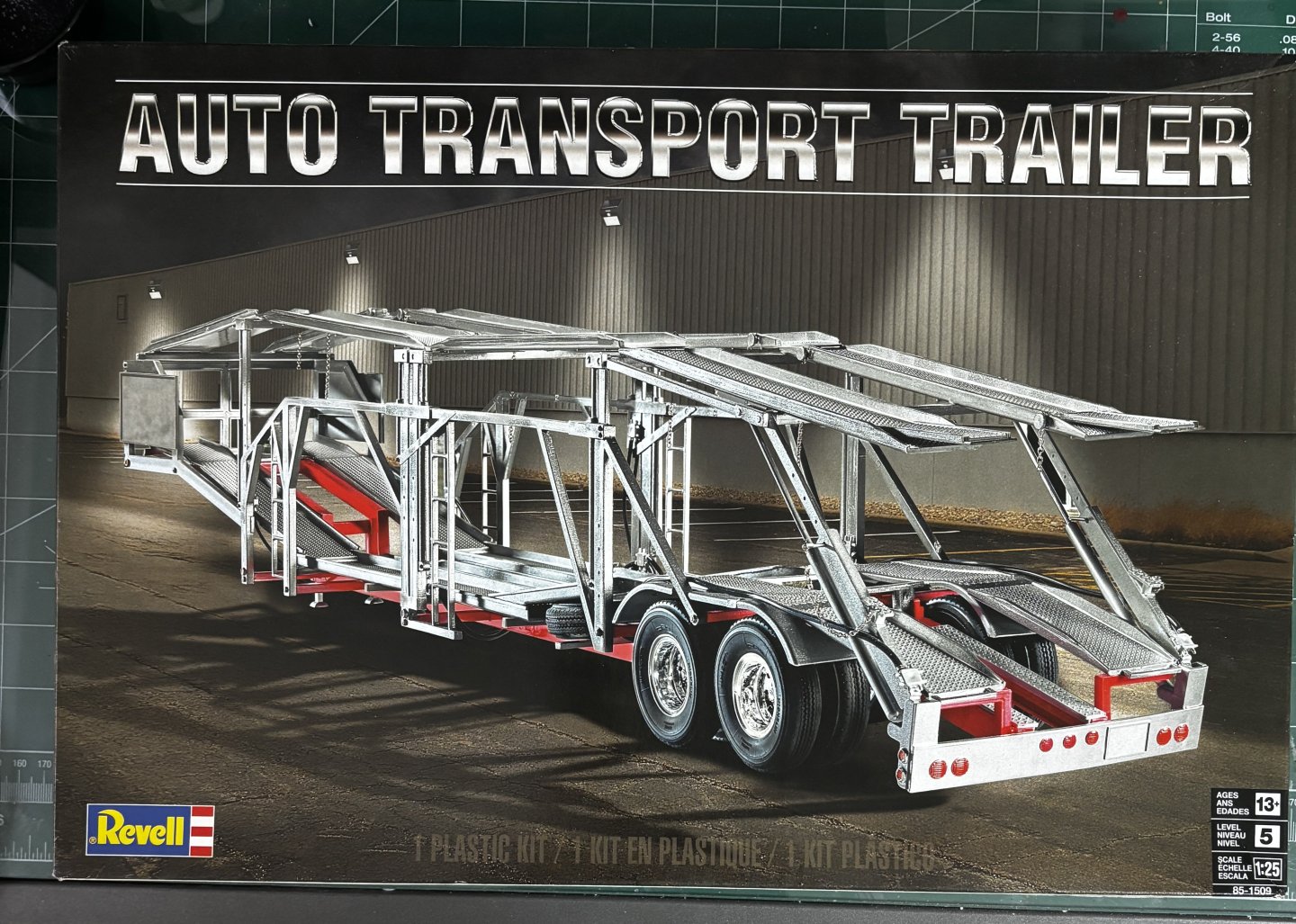

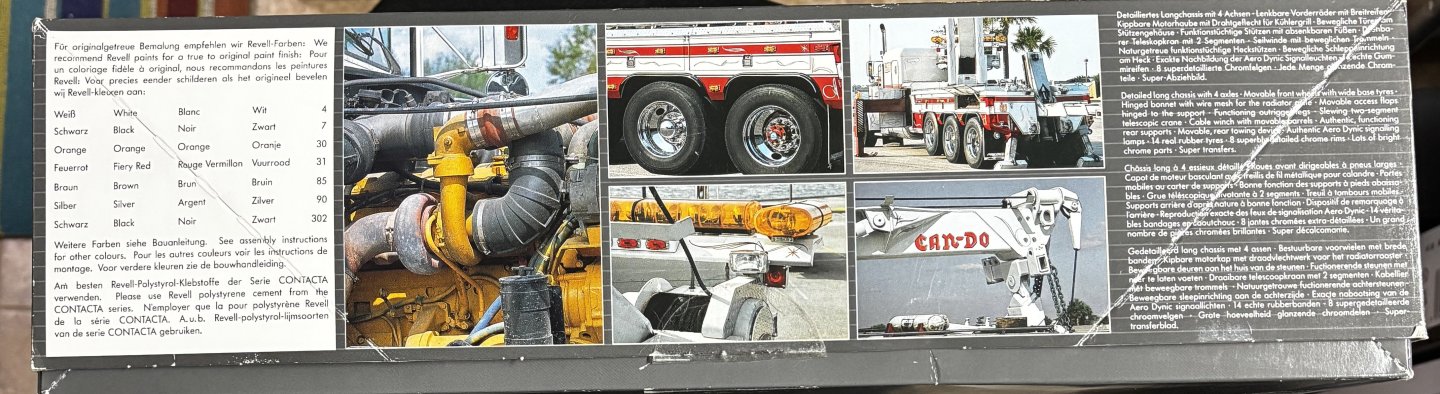

Auto Transport Trailer by CDW - Revell - 1:25 Scale

yvesvidal reacted to a post in a topic:

Auto Transport Trailer by CDW - Revell - 1:25 Scale

-

gsdpic reacted to a post in a topic:

Auto Transport Trailer by CDW - Revell - 1:25 Scale

gsdpic reacted to a post in a topic:

Auto Transport Trailer by CDW - Revell - 1:25 Scale

-

Canute reacted to a post in a topic:

Auto Transport Trailer by CDW - Revell - 1:25 Scale

Canute reacted to a post in a topic:

Auto Transport Trailer by CDW - Revell - 1:25 Scale

-

GrandpaPhil reacted to a post in a topic:

Auto Transport Trailer by CDW - Revell - 1:25 Scale

GrandpaPhil reacted to a post in a topic:

Auto Transport Trailer by CDW - Revell - 1:25 Scale

-

Ryland Craze reacted to a post in a topic:

Auto Transport Trailer by CDW - Revell - 1:25 Scale

Ryland Craze reacted to a post in a topic:

Auto Transport Trailer by CDW - Revell - 1:25 Scale

-

ccoyle reacted to a post in a topic:

Auto Transport Trailer by CDW - Revell - 1:25 Scale

ccoyle reacted to a post in a topic:

Auto Transport Trailer by CDW - Revell - 1:25 Scale

-

CDW started following Auto Transport Trailer by CDW - Revell - 1:25 Scale

-

-

GrandpaPhil reacted to a post in a topic:

USS Hornet by CDW - Merit International - 1:200 - PLASTIC - Scale Aircraft Carrier

GrandpaPhil reacted to a post in a topic:

USS Hornet by CDW - Merit International - 1:200 - PLASTIC - Scale Aircraft Carrier

-

Frecap reacted to a post in a topic:

HMS Bellona by yvesvidal - FINISHED - CAF Model - 1:48

Frecap reacted to a post in a topic:

HMS Bellona by yvesvidal - FINISHED - CAF Model - 1:48

-

Old Collingwood reacted to a post in a topic:

White Freightliner DD by CDW - AMT - 1:25 Scale - PLASTIC

Old Collingwood reacted to a post in a topic:

White Freightliner DD by CDW - AMT - 1:25 Scale - PLASTIC

-

GrandpaPhil reacted to a post in a topic:

White Freightliner DD by CDW - AMT - 1:25 Scale - PLASTIC

GrandpaPhil reacted to a post in a topic:

White Freightliner DD by CDW - AMT - 1:25 Scale - PLASTIC

-

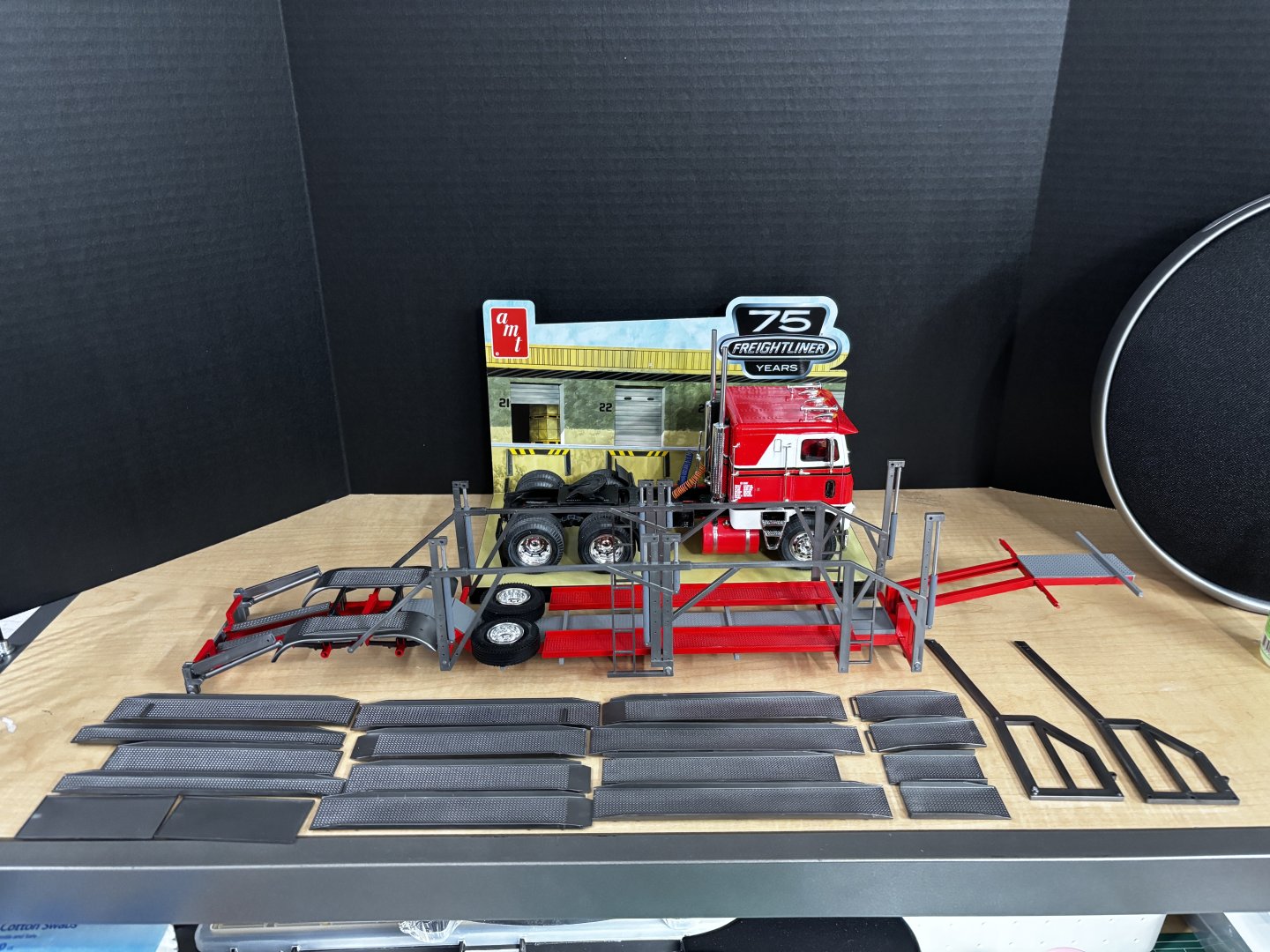

White Freightliner DD by CDW - AMT - 1:25 Scale - PLASTIC

CDW replied to CDW's topic in Non-ship/categorised builds

This might be the right load for the Freightliner. Besides, up to eight car models can fit on the trailer, freeing up the shelf space the truck-trailer combo would require. -

CDW reacted to a post in a topic:

White Freightliner DD by CDW - AMT - 1:25 Scale - PLASTIC

CDW reacted to a post in a topic:

White Freightliner DD by CDW - AMT - 1:25 Scale - PLASTIC

-

CDW reacted to a post in a topic:

White Freightliner DD by CDW - AMT - 1:25 Scale - PLASTIC

CDW reacted to a post in a topic:

White Freightliner DD by CDW - AMT - 1:25 Scale - PLASTIC

-

CDW reacted to a post in a topic:

White Freightliner DD by CDW - AMT - 1:25 Scale - PLASTIC

CDW reacted to a post in a topic:

White Freightliner DD by CDW - AMT - 1:25 Scale - PLASTIC

-

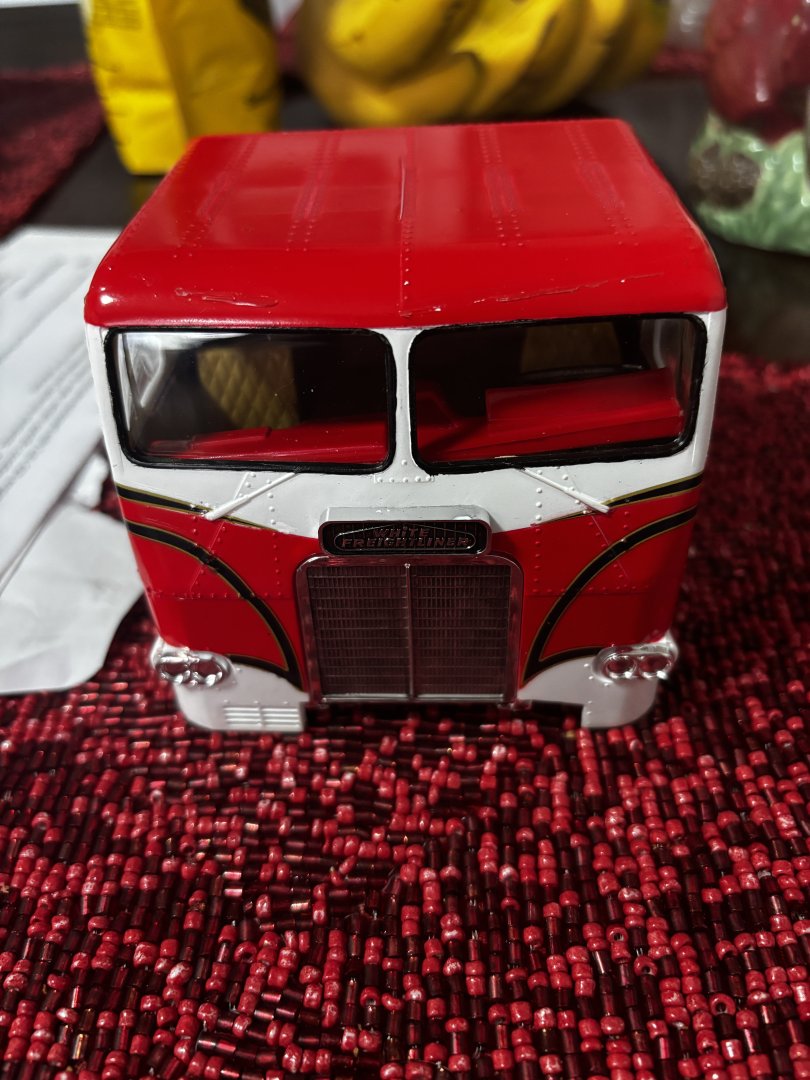

White Freightliner DD by CDW - AMT - 1:25 Scale - PLASTIC

CDW replied to CDW's topic in Non-ship/categorised builds

Gonna call this finished. Could have spent more time and effort but wanted to get my feet wet with a first ever big rig build for me. Learned a lot with is kit and look forward to more similar kits in the future. Thanks for following along and for all your likes and comments. -

White Freightliner DD by CDW - AMT - 1:25 Scale - PLASTIC

CDW replied to CDW's topic in Non-ship/categorised builds

-

CDW reacted to a post in a topic:

White Freightliner DD by CDW - AMT - 1:25 Scale - PLASTIC

CDW reacted to a post in a topic:

White Freightliner DD by CDW - AMT - 1:25 Scale - PLASTIC

-

White Freightliner DD by CDW - AMT - 1:25 Scale - PLASTIC

CDW replied to CDW's topic in Non-ship/categorised builds

-

White Freightliner DD by CDW - AMT - 1:25 Scale - PLASTIC

CDW replied to CDW's topic in Non-ship/categorised builds

Horns, cab running lights, visor added. Baby moon hub covers on rear hubs. 68 Firebird sits along side for size comparison. -

White Freightliner DD by CDW - AMT - 1:25 Scale - PLASTIC

CDW replied to CDW's topic in Non-ship/categorised builds

-

White Freightliner DD by CDW - AMT - 1:25 Scale - PLASTIC

CDW replied to CDW's topic in Non-ship/categorised builds

I’ll do something with tire weathering at the end when I’m sure handling of the model is almost finished. i still need to drill location holes in the cab to install all the bits. That will take some time. More wreathing in general as well. -

White Freightliner DD by CDW - AMT - 1:25 Scale - PLASTIC

CDW replied to CDW's topic in Non-ship/categorised builds

turning attention to the exhaust stacks. Remember, this is an old tool kit. As such, many parts need TLC to make them fit. The exhaust stack supports are no exception. Careful fitting to make sure they line up properly with the cab and the exhaust pipe is required. My exhaust stacks had big, ugly dink marks in the pipes rising above the heat shields, plus they were solid plastic, not hollow as they should be. I just cut them off and replaced with plastruct tubing, then painted the tubing with AK Super Chrome. The stacks will get attached later after the glue on the supports sets up well. -

White Freightliner DD by CDW - AMT - 1:25 Scale - PLASTIC

CDW replied to CDW's topic in Non-ship/categorised builds

-

CDW reacted to a post in a topic:

White Freightliner DD by CDW - AMT - 1:25 Scale - PLASTIC

CDW reacted to a post in a topic:

White Freightliner DD by CDW - AMT - 1:25 Scale - PLASTIC

-

CDW reacted to a post in a topic:

White Freightliner DD by CDW - AMT - 1:25 Scale - PLASTIC

CDW reacted to a post in a topic:

White Freightliner DD by CDW - AMT - 1:25 Scale - PLASTIC

-

White Freightliner DD by CDW - AMT - 1:25 Scale - PLASTIC

CDW replied to CDW's topic in Non-ship/categorised builds

-

White Freightliner DD by CDW - AMT - 1:25 Scale - PLASTIC

CDW replied to CDW's topic in Non-ship/categorised builds

The Freightliner is a very old kit. As such, there are multiple well documented fit issues that I didn’t read about soon enough. One of those issues is the fit of the interior tub inside the cab. It’s one of many but one that seems most difficult to correct without building a new interior from scratch. I’m going to make it work but as such it will be a 10-footer. One of those models that will look okay sitting on the shelf 10 feet away. Nevertheless, I am having fun with it. Some progress photos. -

CDW reacted to a post in a topic:

White Freightliner DD by CDW - AMT - 1:25 Scale - PLASTIC

CDW reacted to a post in a topic:

White Freightliner DD by CDW - AMT - 1:25 Scale - PLASTIC

-

CDW reacted to a post in a topic:

White Freightliner DD by CDW - AMT - 1:25 Scale - PLASTIC

CDW reacted to a post in a topic:

White Freightliner DD by CDW - AMT - 1:25 Scale - PLASTIC

-

CDW reacted to a post in a topic:

White Freightliner DD by CDW - AMT - 1:25 Scale - PLASTIC

CDW reacted to a post in a topic:

White Freightliner DD by CDW - AMT - 1:25 Scale - PLASTIC

-

White Freightliner DD by CDW - AMT - 1:25 Scale - PLASTIC

CDW replied to CDW's topic in Non-ship/categorised builds

I haven't seen Highway Through Hell (AFAIK) but I have watched some awesome recovery vehicle videos on YouTube. Some where there were two of these same type of large wreckers used to recover and haul away big rig wrecks. Those men operating the wreckers are highly skilled at what they do. it must cost a small fortune to have a vehicle recovered like that. Takes hours sometimes. -

CDW reacted to a post in a topic:

White Freightliner DD by CDW - AMT - 1:25 Scale - PLASTIC

CDW reacted to a post in a topic:

White Freightliner DD by CDW - AMT - 1:25 Scale - PLASTIC

-

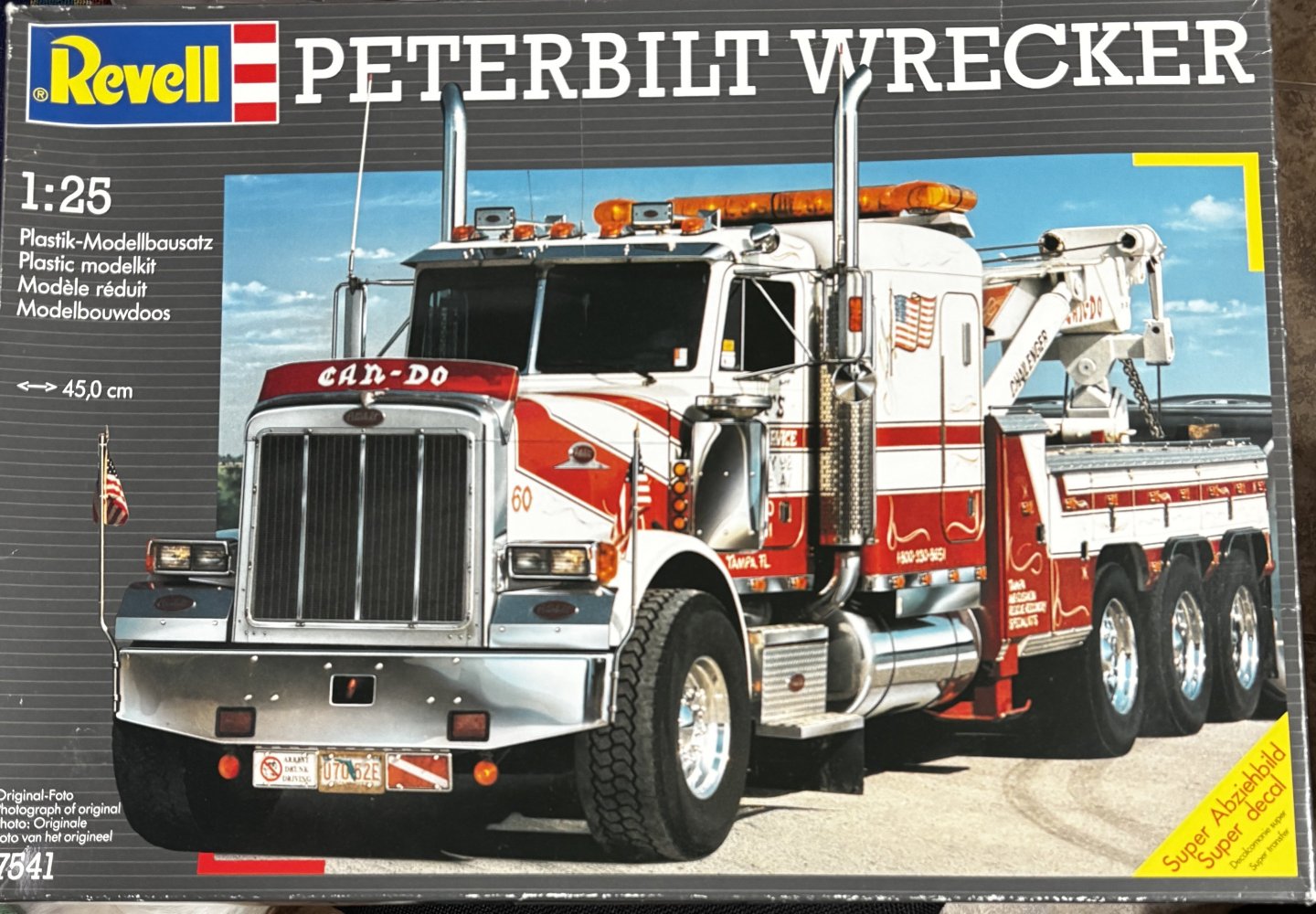

White Freightliner DD by CDW - AMT - 1:25 Scale - PLASTIC

CDW replied to CDW's topic in Non-ship/categorised builds

The kit has three big chrome trees -

White Freightliner DD by CDW - AMT - 1:25 Scale - PLASTIC

CDW replied to CDW's topic in Non-ship/categorised builds

I recently acquired this kit. If you attend a swap meet and see one for sale, grab it. Truly outstanding kit. The model is based on a wrecker that operates from my hometown in Tampa, Fl.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.jpg.7e80607770d9078b2f0b470e8c9c33ac.jpg)