-

Posts

2,644 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by thibaultron

-

-

I have not abandoned this build, just had many things get in the way. I have to go out of town, but will restart in Nov.

I sold my Atlas lathe, and to clear a path to get it out of the back of the shop, I had to fill up the area in front of my workbench. It took 2 days about a week apart to get it out and loaded onto the buyer's truck.

I bought his small 7X10 Harbor Freight (really 7X8 they exaggerate the size) metal lathe, so I will at least be able to make ship model parts. I need to do a bit of work on it, though, to bring it up to what I concider reasonable shape. It is almost new, but needs a lot of tweaking. I may also buy a second bed and extend it for making masts and spars. The extension would not be useful for metal work, but good enough for wood working.

-

I would personally avoid Constructo at all costs. Amati I don't know about. Artesania Latina has a reputation of not packing all the parts, or packing some from other kits, and horrible instructions. I had a Billings kit and was distressed with all the plastic parts it had. Model Shipways has a good reputation.

-

-

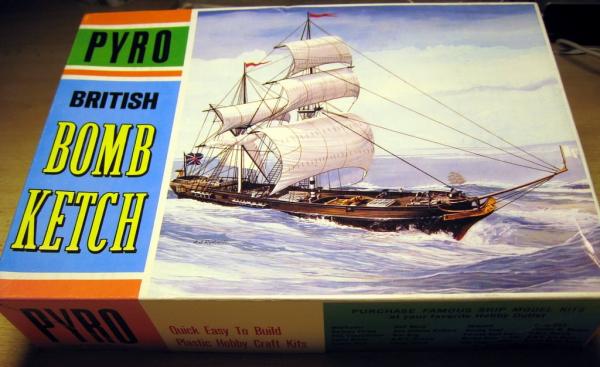

Darn. I like the Pyro kit. It and the Dutch Yacht were my favorites when I was a teen (that was just about the time the dinosaurs went extinct).

- Canute, CharlieZardoz and mtaylor

-

3

3

-

- GuntherMT, Canute, CharlieZardoz and 4 others

-

7

7

-

Does anyone know if the old Marine Models kit for the bomb ketch is based on an actual ship? I think it was labeled as HMS Lion.

-

I have several kits, all from respected US companies, the dowels in all of them are mostly useless.

- thomaslambo and Canute

-

2

2

-

t the following site they have a converson chart for Floquil to other manfg. paints. This site says Vallejo Ivory matches the Floquil Antique White.

-

I looked up on the Web, and got the following information for the color values for Floquils Antique White:

Name # Antique White

Product # F110085

HTML # F1E8D6

CMYK # 5, 7, 15, 0

RGB # 241, 232, 214This may be useful to someone. A paint store may be able to get you a swatch to use as a comparison for mixing your own.

-

-

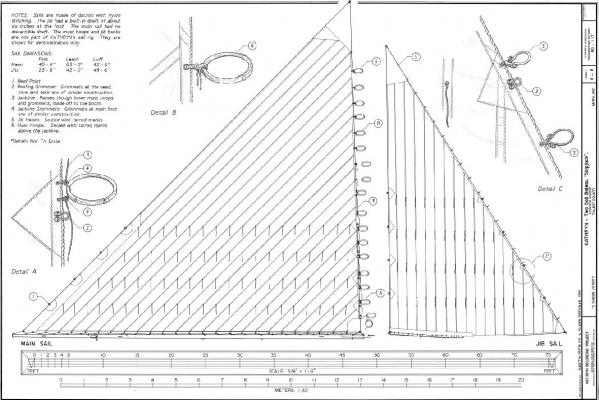

The post #14 in the thread "Furling a boom-footed forestaysail" on this forum has interesting information on how a main sail would be attached to the mast hoops, on a boat with a steeply raked mast, which the skipjacks have. The above thread has much more information on this.

They have a large rake on their masts, and the foot is basically immovably attached to the boom. The sail would jam, if directly the leading edge was laced to the hoops. So they have a rope running between the lower hoops and the sail hanks. This rope was loosened when the sail is lowered, allowing the leading edge to slide back.

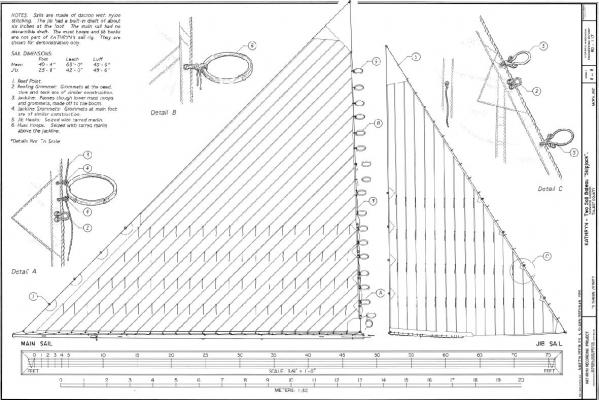

This is a drawing of the sails of the skipjack Kathryn. Notice details A and B.

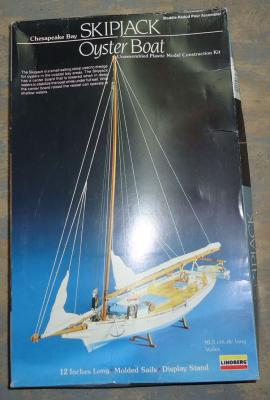

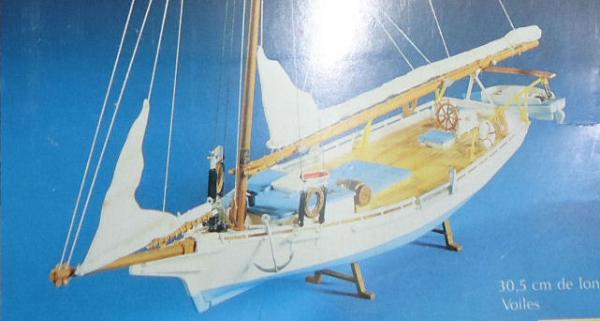

And here is a picture from the top of the box of Pyro's skipjack model showing the sail being lowered. When I started on my model, I thought that they had not cast the sail correctly. I'm used to modern sailboats.

-

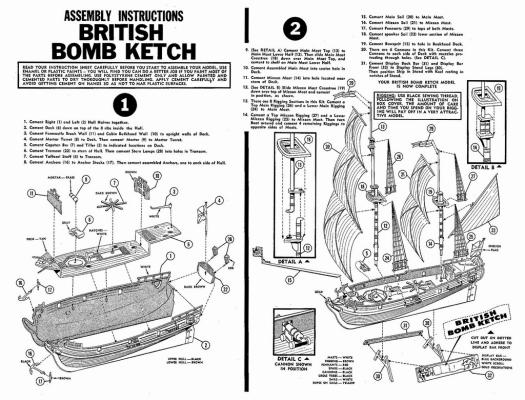

Part 22

I guess I owe Pyro an apology. At the beginning of this build, I commented that the casting they made for the furled, or as it turns out being furled, main sail was incorrect. I think I used a stronger comment. Because I'm used to modern sailboats, I said that they had cast the angle of the leading edge, in the wrong direction, as it angled away from the mast.

They had it right!

After reading the thread "Furling a boom-footed forestaysail" on this forum, post #14 described how the sail is attached to the hoops.

The foot of the mainsail is laced to the boom in such a fashion that it cannot side forward as the sail is lowered. With the steep rake of the mast, the leading edge would jam as the sail was lowered. I have not worked up the geometry for this, I'll take their word for it.

To solve this problem, the lower part of the sail is not directly laced to the mast hoops. Instead there is a rope that runs between the sail hanks and the hoops. I'm not explaining this well but the drawing that will follow should clear it up.

As the sail is lowered this rope is loosened and the leading edge can pull away from the hoops, letting it slide back.

Detail A shows how the lower part of the sail is attached to the hoops by a rope running between them and the hoops. Detail B shows the upper hoops laced directly to the sail.

So Pyro’s casting with the lower part of the sail pulled away from the mast, as it is being lowered, is correct.

The jib has only a partial boom, so this is not a problem. It is hanked directly to the stay.

Learn something new every day.

-

I can't help you with AutoCAD, but I did do a step by step for CADing a simple boat for the builder in the below build: America Schooner POF by Walter Biles

The procces used may help you.

-

I used a type similar to the one in your link, almost constantly. It is one of the older round florescent bulb types. The only problems I have with it are that it tends to sway back and forth when first positioned, or when I hit it with my hand or a tool. This is a frequent occurance, and a pain.

On the other hand my over the eyes types have a much closer focal distance, so that I have to either be holding the parts close to my eyes, or be bent over it.

The desk mounted lighted one allows me to do most of the modeling in a comfortable position. My eyes require magnification for any small work, and the shakiness of my hands makes holding parts some times challenging.

-

-

-

-

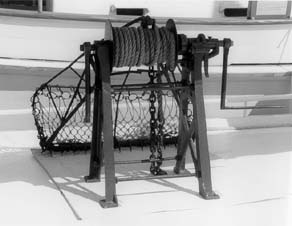

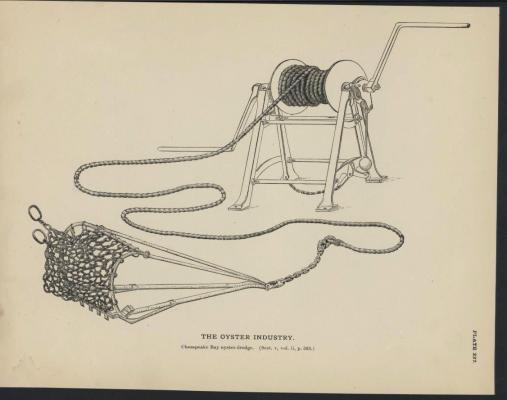

I think the winders on these sunk wells were a little shorter, see the Fisheries drawing I posted earlier. The crank handle would be much closer to the deck than the one I drew and you provided the pictures for. If you look the dredge itself is narrower.

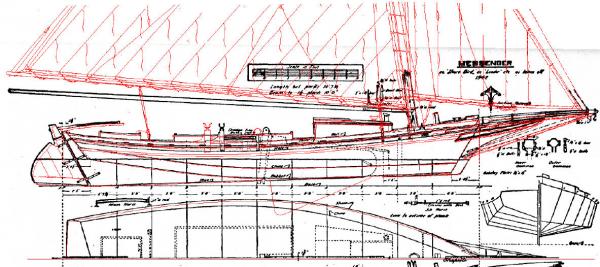

I have the Midwest skipjack kit. In reading Chappelle's Small Boat book, I found drawings of the skipjack "Messenger" that almost exactly match the Midwest kit. So close that it is a matter of less than inches. I think Midwest based their kit on these plans. This skipjack was one of the type used for "Oyster Pirating", dredging the oyster tonging beds at night, illegally. This boat has the sunken well, and a narrow roller for the dredge, like in the drawing.

Below is the drawing with the two plans overlaid. The black is the Messenger, the red the Midwest skipjack.

-

-

Thank you for the pictures!! Now I can correct my drawings! I have been trying for a long time to find more information on them. Wonderful pictures of the skipjack. I'd probably would have spent the whole time listening to the captain too.

Do you remember the approximate height of the winch?

-

- Omega1234, mikegerber, KevinR and 2 others

-

5

5

-

If you are going to build the As Built version. Look at my build. I have a section on the hand dredges at this time. The Chesapeake Maritime Museum, may also have one on display. They at least have a photo of one that I used as a basis for mine. If you go there, please take a few pictures of it for me.

-

-

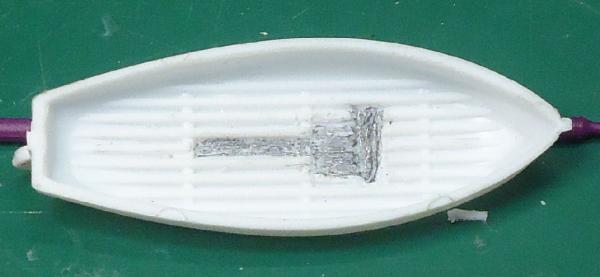

Part 21

Using a chisel blade and a regular blade I spent some time hollowing out this area.

For the engine block I removed the center and the two next slats. For the shaft I just removed the center one. For the flywheel, I cut out an additional slat on each side.

The chisel blade was just the right size to remove the center three slats for the engine. I cut vertical cut stops where the holes would end, and worked back and forth from the ends and center, to remove the slats. Unfortunately while doing this, I damaged one of the slats beside the engine area. I will see how it looks with a little paint, later. Hopefully it will not be too noticeable. This would be Really hard to replace.

For the shaft, the chisel was far too wide, so I had to attack it from the sides. Not fun.

I was going to recess the flywheel hole more so I could retain more of it. Luckily while I was doing this I flipped the hull over. That is when I saw that I was just about to cut all the way thru. I had not noticed the plastic getting translucent as I was cutting from the top! I managed to get the flywheel hole only about .010 deeper than the engine area.

You can see the flywheel area from the bottom. It is the slightly darker area by the bow. Those slats were cast deep.

I went back and cleaned up the area, by scrapping with both blades.

I colored in the cutout, roughly, with a pencil to make it more visible. After taking the picture, I thought, “Dummy ,I wonder how well the paint will stick to the pencil graphite!!!” I cleaned it out as best I could with the eraser and window cleaner and a cotton swab. I’ll go back later with paint thinner to see if I can get out more.

I discovered while doing the hollowing out that my hands seem to shake concirably more than they did 40 years ago! J

To see how things were going to look I set the engine in the hull, and the deck on top. Yes, I didn’t get the deck back all the way, but I had enough trouble just getting everything to stay in place. It was sort of like those toys where you have to get all the BBs into the holes.

The flywheel is not installed in these shots. To simulate the center hub, I’m going to use a regular pin. The head will be positioned so it is a little away from the center web, and I will add a little glue to fill in the area. But, right now I don’t have a regular pin. I’ll finish this in the future. I also decided not to drill the lightning holes in the flywheel. I do not feel like making another one, if I mess it up, the first was hard enough.

I’ll work on the flywheel this week, and post it. It may be a couple weeks after that before I post any more. I will be helping a disabled friend to pack up to move.

- GuntherMT, KevinR, captainbob and 1 other

-

4

4

Carrie Price by thibaultron – Lindberg/Pyro – PLASTIC – 1:64 - Small - Skipjack

in - Kit build logs for subjects built from 1851 - 1900

Posted · Edited by thibaultron

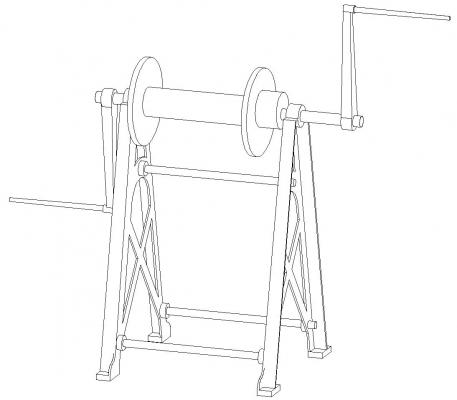

No building has gotten done, I'm away from home, but I have been able to do a better drawing of the dredge winches.

Thanks to another member, I have some pictures of one in a Chesapeake Bay museum. This was the same one I based the old drawing on, but with a small photo to work from.

Here is the old drawing.

An overall of the new drawing, with the better photos.

The drawing itself.

The next task is doing a 3D drawing, then draw it in SketchUp, a 3D modeling CAD program.

The crank handles are, I think, overly long. Compared to the old picture they are about half again as long. I think they extended the handles so that the museum could bolt them to the display (see the pictures).