-

Posts

829 -

Joined

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Cap'n Rat Fink

-

-

-

Thanks Mario,

Woody Joe doesn't do direct sales anyway. I recommend ordering from my friend Kazunori Morikawa at Zootoyz.jp. His site is in english and service is very good and prices are reasonable. Here's a direct link to the Woody Joe ship model kits: http://www.zootoyz.jp/contents/en-us/d67_Woody_JOE_Wooden_Sailing_Ship_Model.html. The Yakatabune kit is about halfway down the first page.

Clare

Hey Thanks Clare! You are a gentleman and a Scholar!

Mario

-

Looks great Clare! Went to their site. How do you even order something when you can't read their language?

Mario

- mtaylor, Canute, Landlocked123 and 1 other

-

4

4

-

-

-

Heal well Alan.

Nowadays you have a table saw like Sawstop with it's special safty feature. But with that safety feature comes a hefty price. Which a lot of wood workers can afford. There are also just as nice quality TS like Laguna out there too. But do not come with the Sawstop safety feature.

But as you say respecting your hand or power tools is the best and safest thing anyone can do. Even a Sawstop can be dangerous if not respected. My friend who is in his 70's has owned mid=grade TS throught the years and has always repected his tools. He has never even had a scratch. I'm in my mid 50's and he has been cutting as long as I have been alive. What a safety record. he has always told me spend that little more time on setting up your tools for cutting. Have a good clean and clear work area. Keep your tools in good working condition. Always keep safety in mine, and have safety equipment(AND USE IT). In the long run it will payoff.

So heal well Alan. My right hand index finger has nerve damage, and that was just from a xacto blade slip 3 yrs back. Nothing since. So even the littlest of blades can be mean.

mario

- thibaultron, Canute and mtaylor

-

3

3

-

-

FRIENDS,

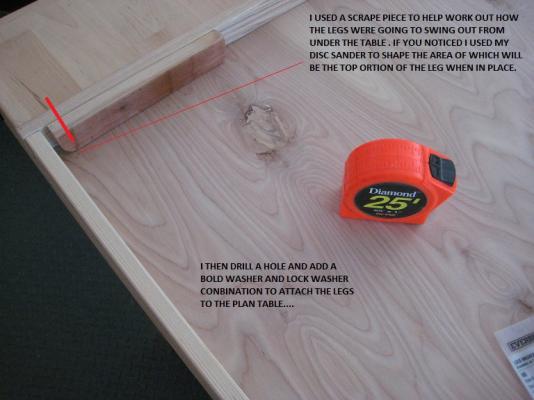

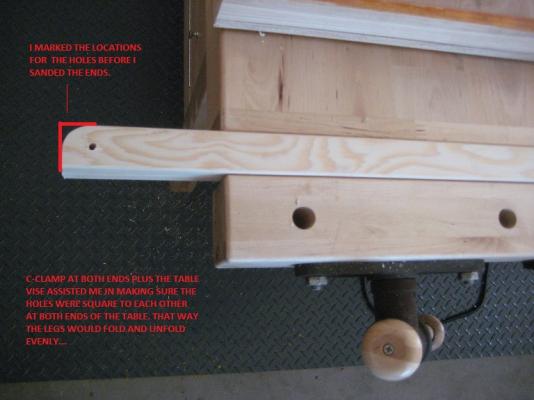

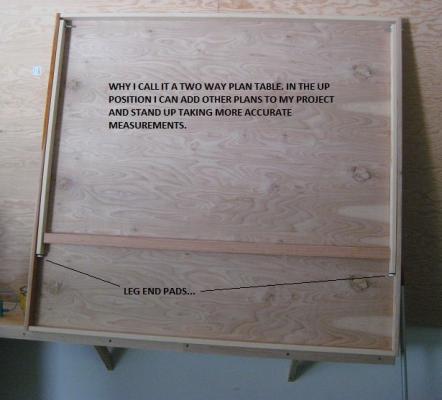

Well as my adventures in getting my shop together. One big issue with me as is with others. Is an area for your model to be built. But you also need an area for your plans. I have seen others will have their plans under glass and their model on top. Others build a drawer and they slide the drawer open, then close it to get close to their project to work on. Some have them pinned on the walls. So this was one big issue I really had to think things out. So I had so many ideas running through my head. Until finally I found one that would work for me.I JUST NEED A DEDICATED AREA FOR MY PLANS FOR RESEARCH, INTERPRETING, ECT.

1. I needed something I did not have to worry about fitting my model and plans in the same area. But still had them close enough so all I had to do was turn and there they are.

2. At the end of the day roll them back up and put them away. When I’d rather leave them out.

3. When I take measurements from my plans I much more preferred to be standing and have the plans basically on the wall. I just think I take better measurements rather then stooping over plans that are flat on a table.

4. But I also needed to have them laid flat to see if my new part fleshly made matches the plans.

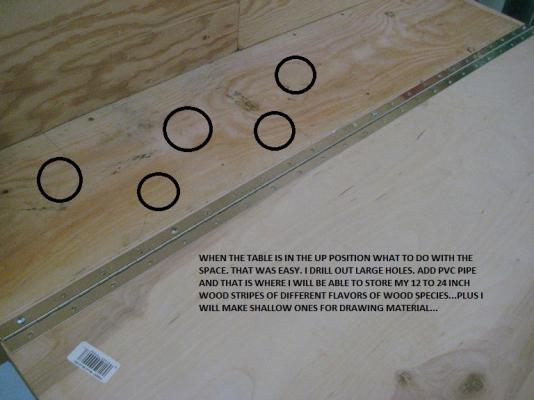

5. And one really big issue. Leaving my plans out. But not in the way when doing other things around the house.6. I also hate to waste space. I like to use every bit.

There are other reasons but too many to mention. But I hope you get my drift….

So I came up with my “TWO-SIDED PLAN TABLE” or “TWO-WAY”

When the table is down I can also pin a 3rd plan to the wall. No more switching from plan to plan most will be dsplayed for my use.... So my shop is getting there.MARIO

-

-

Looks good Greg,

If you mean by lining it, you penciling in the planks and staining the floor. Yes that would be a good idea. That would make it easier. Just don't get any stain where the glue goes. It does not adhere to good with stain.

Mario

-

BTW, I've had your build log permanently open in my browser for the past 3 weeks!

Oh Boy! 3 weeks! Ok Greg just remember that was only my third boat model ever. Just as long as you don't hold anything against me. Lol. Midwest Models are fun and they are great kits to cut your teeth with. There have been several builds here on this boat and by far are a lot better then mine.

Hopefully I will get my act together soon and start having fun again building models like you. So keep up the good work. Your attention to detail is great.

Mario

-

Hi Greg,

This is a common problem with bulkhead kits. Like the keel is warped, slots too long or too short, the list goes on. When I built this model I bought it on ebay(used). Some parts were broke so I had to scratch a few pieces.

If it were me I would take down the material from the keel to meet the bulkheads. My thinking is I'm deal with one piece instead of several pieces. Since the camber looks good to you on the bulkheads. the other reason is if it were me, is the bulkheads are really the only material that is going to rest on the keel. Your deck will be resting on the bulkheads. And you would want the camber as smooth as possible. What I mean is run a long plank ergo a batten across all the bulkheads once in place to make sure you have a nice smooth run of the deck plank. You don't want any dips or hills from stem to stern. Plus a couple of those bulkheads are for your cabin roof.

Just search Muscongus Lobster Smack by teleman and you can look at my build log

have fun

Mario

-

Just a beautiful build Buck. You are a very good craftsman.

Mario

-

Richard,

i am in the process of finishing my garage shop. I had cabinets and lowers placed in there the garage. they are set at 36". but I have workbenches at 34 inches. So those are the 2 heights I want. it works well for standing or sitting on a stool or an adjustable chair. But I also considered my height of 6 foot.

Mario

-

Hey Zambocknee,

The multi-color clamps are on sale fight now at harbor Freight. 6 for 99 cents.

Mario

-

-

Zamboknee,

Just click on my Steam Launch under my signature and you see what I did. It was basically the situation you have.

Mario

-

-

Thanks Guys,

Haven't seen this build in a while. You can find free plans on this model at modelshipbuilder.com under Projects. wq3296 I have several vintage model from Big Daddy. I'm saving them for my little boy who wants to build them. According to what I see they are very expensive to buy originals. But I bought them when I was kid to have fun. So boy is going to build them to have fun too.

Thanks for your kind words Guys. Have a great day.

Mario

-

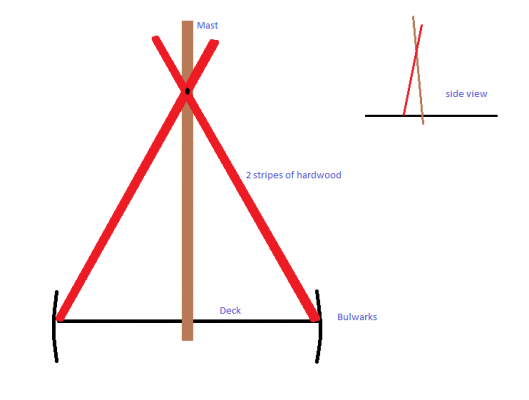

Guys I use a simple little jig. I use two straight strips of hardwood with a small screw and nut. I position the mast and the rack of the mast. I wedge the bottom of the jig where the deck meets the bulwarks. Then I wedge the cross hairs up against the mast. It works well for me while I rig the mast. Once done I just remove and my mast is right where I wanted it. I do not have a picture of this procedure of mine, but here is a quick drawing.

- GLakie, cristikc, thibaultron and 2 others

-

5

5

-

-

You can go here on my build log and see what I did. nails and rubberbands.

mario

-

Stephan,

Why don't you get a few scraps together and test paint it. But I'm thinking you won't be seeing any black. On my BWL I left the deck natural.

She is coming along nicely.

Mario

-

KUFO SECO

in Modeling tools and Workshop Equipment

Posted

Hello All,

I have a small shop. Been Looking at dust collectors. Does anyone of this brand......KUFO SECO.

Looking at their 2hp dust collector 110/220. Not going into a high end price since this will be in a garage. Its gotta mobile. I do not want a fixed unit. If you have another brand you think is great please let me know.

Thanks again

Mario