-

Posts

1,309 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by TBlack

-

SS Vinal Haven by TBlack - FINISHED

TBlack replied to TBlack's topic in - Build logs for subjects built 1851 - 1900

Mark, These are terrible pictures because my camera is quite rudimentory, but perhaps you can get the idea. The eagle is 3 dimensional and probably about 12 mm beak to tail feathers in profile and 10 mm at its widest. Tom- 326 replies

-

- vinal haven

- steam ship

-

(and 1 more)

Tagged with:

-

SS Vinal Haven by TBlack - FINISHED

TBlack replied to TBlack's topic in - Build logs for subjects built 1851 - 1900

Michael, I didn't have any yew (BTW, nice looking piece of wood), so I substituted cherry. I'll get back to you on the eagle charms, another good idea, but lots to look at and I'm not buying gold @ $250/charm. Cap'n Bob, thanks for looking in. Tom- 326 replies

-

- vinal haven

- steam ship

-

(and 1 more)

Tagged with:

-

SS Vinal Haven by TBlack - FINISHED

TBlack replied to TBlack's topic in - Build logs for subjects built 1851 - 1900

I made pretty good progress on the Amanda, and finished the Titanic for my grandson, so I got to try out Michael's suggestion. Duck soup! Very simple, very elegant solution: It needs cleaning up and painted flat black, and it's done! I'm delighted. Michael, you've gotten me through this process and also your help on the pilot house windows. There's just one more sticky wicket: the eagle on top of the pilot house. Any ideas? Tom- 326 replies

-

- vinal haven

- steam ship

-

(and 1 more)

Tagged with:

-

I'm with Augie, I think it looks pretty good, too! Tom

- 382 replies

-

- stadacona

- sylvan scale models

-

(and 1 more)

Tagged with:

-

Andy, Have you tried this product? Tom http://www.testors.com/product/136637/3527C/_/Non-Toxic_Cement_Liquid_Cement

- 382 replies

-

- stadacona

- sylvan scale models

-

(and 1 more)

Tagged with:

-

SS Vinal Haven by TBlack - FINISHED

TBlack replied to TBlack's topic in - Build logs for subjects built 1851 - 1900

Bob, I can't wait to see what the whole thing looks like either, but I've got to get this stack right, as it's a pretty prominent feature on the model. Also, I'm working on 2 other boats, one for my grandson and the other a restoration of a clipper ship (im getting paid for the latter, o I really need to be working on it). Tom- 326 replies

-

- vinal haven

- steam ship

-

(and 1 more)

Tagged with:

-

SS Vinal Haven by TBlack - FINISHED

TBlack replied to TBlack's topic in - Build logs for subjects built 1851 - 1900

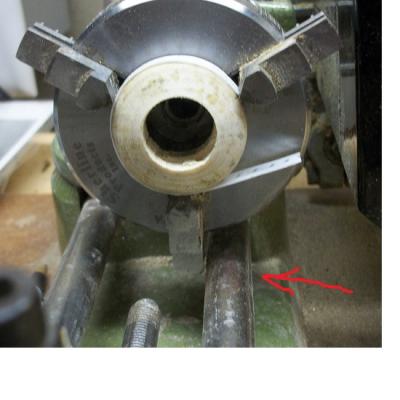

You just gave me an idea! What I can do is drill the 5/8" hole part way through my "yew piece". Lock the piece in position on the drill press; switch out drills to say 1/4" drill; drill through the yew piece; insert screw and tighten; mount that in the lathe; finish off the lip in the yew piece; reposition at the drill press and finish drilling out the 5/8" hole. Voila! I'l give it a try, thanks. But just because you can do it doesn't mean I can. Tom- 326 replies

-

- vinal haven

- steam ship

-

(and 1 more)

Tagged with:

-

SS Vinal Haven by TBlack - FINISHED

TBlack replied to TBlack's topic in - Build logs for subjects built 1851 - 1900

Michael, That looks fabulous, and you make it look so easy! Only one problem. I can't put the yew piece in my lathe to create the sloped edge My lathe doesn't have the clearance necessary to handle a piece of that diameter. See picture: Tom- 326 replies

-

- vinal haven

- steam ship

-

(and 1 more)

Tagged with:

-

SS Vinal Haven by TBlack - FINISHED

TBlack replied to TBlack's topic in - Build logs for subjects built 1851 - 1900

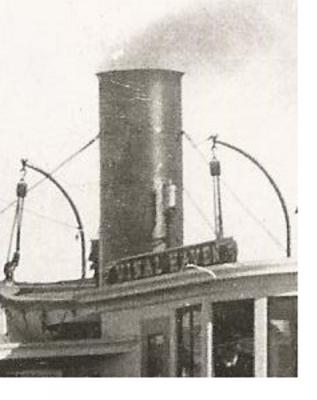

Michael & John, OK, here's another photo with more evidence. I'm hoping you can see the detail. The rings, truly, must be quite thin as they don't seem to stand out at all from this angle. I'm thinking I could use a strip of paper to accomplish the task. Also, to John's point, where the strip is strengthening the guy wires/stays, all you can see is a shiny band; there is another shiny band lower down which would validate John's observation about a second band. Finally, it looks like the top doesn't have a band around it, but rather is flared. I have no way to do that with my tools. My alternative is to put the stack back in the lathe and apply a round file to the band that rings the top. If that ends up looking hokey, then I'll just have to live with a straight stack. Tom- 326 replies

-

- vinal haven

- steam ship

-

(and 1 more)

Tagged with:

-

SS Vinal Haven by TBlack - FINISHED

TBlack replied to TBlack's topic in - Build logs for subjects built 1851 - 1900

John, You may be right. It would be easy enough to add another one. I'll have to look at my other photos. The lower of the two rings takes the four stays. So the addition of a third ring would be just for structural integrity? Tom- 326 replies

-

- vinal haven

- steam ship

-

(and 1 more)

Tagged with:

-

Andy, Your Peggy looks like a dingy by comparison. I just finished building a resin kit of the Titanic for my grandson, and, while the assembly wasn't difficult, like your model, there was a lot of detailed painting which consumed most of my time. Good luck with this beast! Tom PS I just looked at the linked page for your RR club; it doesn't look like they're going to need your ship for a while, so at least you have time to spend on the build.

- 382 replies

-

- stadacona

- sylvan scale models

-

(and 1 more)

Tagged with:

-

SS Vinal Haven by TBlack - FINISHED

TBlack replied to TBlack's topic in - Build logs for subjects built 1851 - 1900

Michael, Bob, New up-date. I figured if my first attempt at rings in wood were a bust, why not stick my neck out a little and see if I could get them down to proper size. If I ruined them, no loss. Anyway, I chucked the tube in the lathe and applied file and sandpaper and got the rings down to less than .5 mm without damage (I think that's less than an inch at 1:48?). Also, I replaced the brass skirt with a styrene one. Take a look: I'm a lot happier with this arrangement. And, Bob, I'll check out Special Shapes in any event; thanks for the tip. Tom- 326 replies

-

- vinal haven

- steam ship

-

(and 1 more)

Tagged with:

-

SS Vinal Haven by TBlack - FINISHED

TBlack replied to TBlack's topic in - Build logs for subjects built 1851 - 1900

Michael, Why does life have to be so complicated? Tom- 326 replies

-

- vinal haven

- steam ship

-

(and 1 more)

Tagged with:

-

SS Vinal Haven by TBlack - FINISHED

TBlack replied to TBlack's topic in - Build logs for subjects built 1851 - 1900

Popeye, Thanks for the support. I actually think the rings look fine, standalone; they don't look grossly over-sized. I was just comparing them to the picture. Michael, As I was reading your suggestions, I remembered that Longridge, in his book on the building of Victory, mentions using square wire in its construction. So I googled "square wire" and it turns out that jewelers use it all the time. It's available, in copper, all the way up to 8 guage. Does anybody know what the dimension of 8 guage is? Tom- 326 replies

-

- vinal haven

- steam ship

-

(and 1 more)

Tagged with:

-

SS Vinal Haven by TBlack - FINISHED

TBlack replied to TBlack's topic in - Build logs for subjects built 1851 - 1900

I've been struggling with building the funnel for this craft. Here's what it supposed to look like: And here's what I've come up with so far: I started with a 5/8"brass tube; fabricated a wooden plug to establish the slope of the skirt and drilled the center out to 5/8". The skirt in the picture is brass which started out something like this reject: I'm still not happy with the result, as the edges of the skirt get wobbly with all the handling. I'm going to try fabricating it out of sheet styrene. The other issue is the rings around the top. I wanted to make them out of brass strip, What's available commercially (that I've been able to find) is strip of the right thickness, but 1/4" wide. I have no way of cutting the 1/4" down to, say, .5 mm. So, first I tried styrene strip of the right size, but there is no adhesive that I could find that will bond plastic to brass. My fallback was wood. What you see in the picture is apple wood and epoxy. It's good and solid, but it's too thick compared to the rings around the stack in the first picture. I'm hoping that Michael Mott, who drops by this log occasionally, will have some recommendations on how I can "tool up" to be able to cut brass to small dimensions. Tom- 326 replies

-

- vinal haven

- steam ship

-

(and 1 more)

Tagged with:

-

Whoa!, Cap't, a lot of progress between entry #106 and #121. I'm looking through those beautifully clear windows and seeing mahogany trim inside. I had a terrible time with my pilot house at 1:48, and you're working at 1:96! (maybe your fingers are smaller than mine?) Very nice work. Tom

-

Casey's comment is spot-on. That's a wonderful paint job; it looks like fiberglass. How do you do it? Tom

- 209 replies

-

- muscongus bay lobster smack

- midwest products

-

(and 1 more)

Tagged with:

-

SS Vinal Haven by TBlack - FINISHED

TBlack replied to TBlack's topic in - Build logs for subjects built 1851 - 1900

Andy, you have never failed me! Tom- 326 replies

-

- vinal haven

- steam ship

-

(and 1 more)

Tagged with:

-

Michael, I know I'm coming late to this party, but my thinking is like John's vis a vis the cabin top. Although I understand your attraction to "pinstripe" decking; it is attractive. That binacle and compass are truly outstanding. It's good that you put dimensions in the log entries from time to time, otherwise we get to thinking it's life-sized. I've seen for a while now that you know how to talk to brass, and apparently it answers you back! Tom

- 2,215 replies

-

SS Vinal Haven by TBlack - FINISHED

TBlack replied to TBlack's topic in - Build logs for subjects built 1851 - 1900

I decided to take Andy's suggestion and buy some pre-cast dentils from an outfit in Calif. rather than try to make my own. They are made of styrene and come in 2" strips. They're close enough, and I certainly can't make anything smaller. They needed some adjustment along the top, but married to a single bead moulding along the bottom, and the whole assembly looks OK. It's not an exact replica of the prototype, but I can't get that detailed with the tools I have. To make the single bead molding, I cut the profile in a razor blade secured to the tool post of my lathe, using both the large Dremel cut-off wheel and the small Dremel cut-off wheel. The thickness of the larger wheel is just the right width for the moulding (2mm), and the thinner wheel is as small as I can get to cut the bead. It's the profile on the right. Sorry for the bluriness. So the final product still needs to be smoothed out where the joints occur and all painted. Sorry for the lack of close-ups, but my camera doesn't do it very well.- 326 replies

-

- vinal haven

- steam ship

-

(and 1 more)

Tagged with:

-

Dan, A beautiful effort. The finish, the deck hardware immaculate! What particularly catches my eye is the cutwater and the upholstery. Very clean! Tom

-

Pete, Great progress. Wonderful looking, both of them. But actually, I LOVE the sawhorses! Tom

- 209 replies

-

- muscongus bay lobster smack

- midwest products

-

(and 1 more)

Tagged with:

-

Bob, Nicely done. I especially like your approach to the windows with the tape, although I would be severely challenged to get the tape in the right place and lined up properly. Looking great so far! Tom

-

Pete, Nice pictures that capture the graceful, classic lines of this beauty! You're doing her great justice. Tom

- 209 replies

-

- muscongus bay lobster smack

- midwest products

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.