-

Posts

541 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by FrankWouts

-

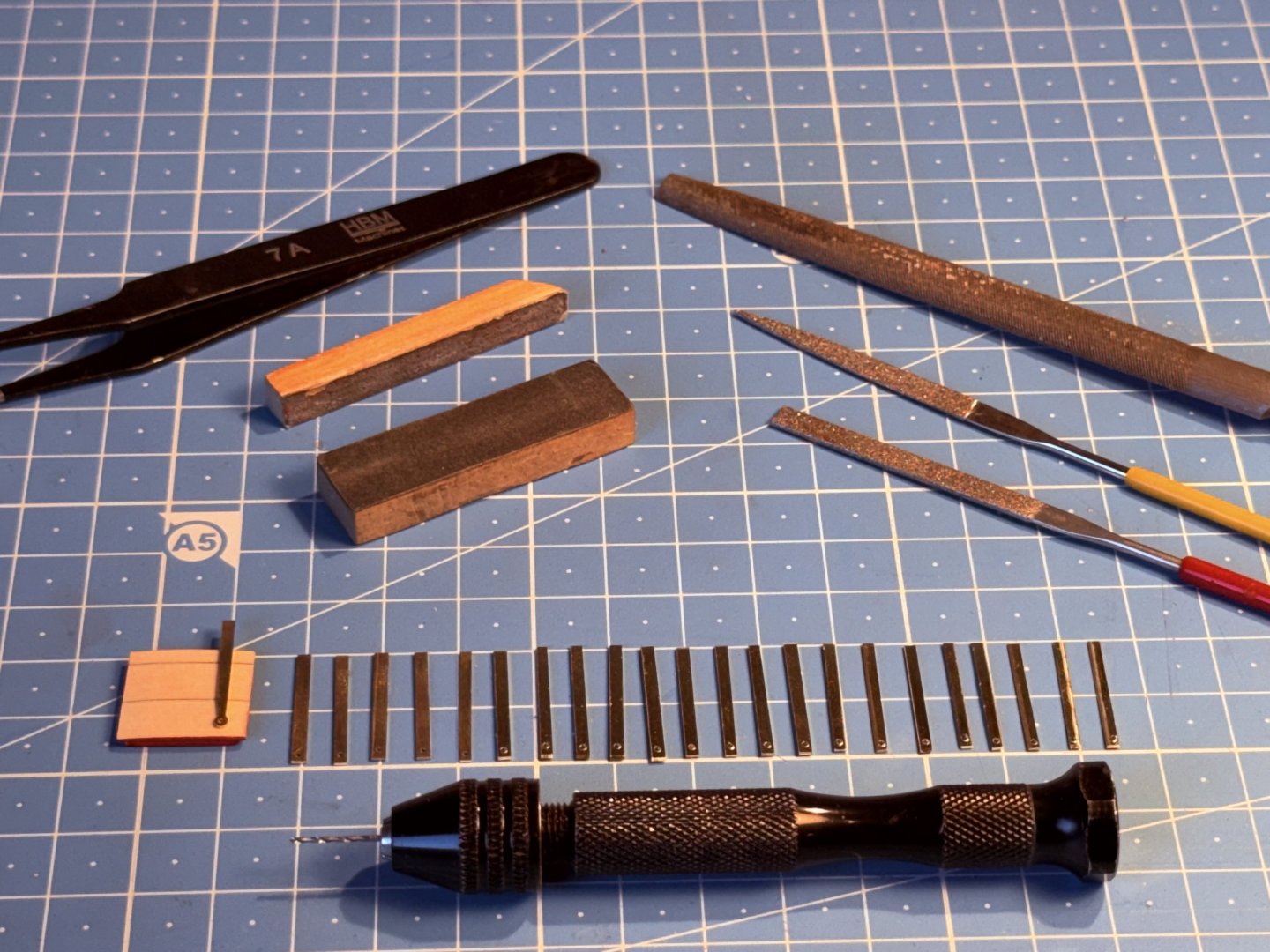

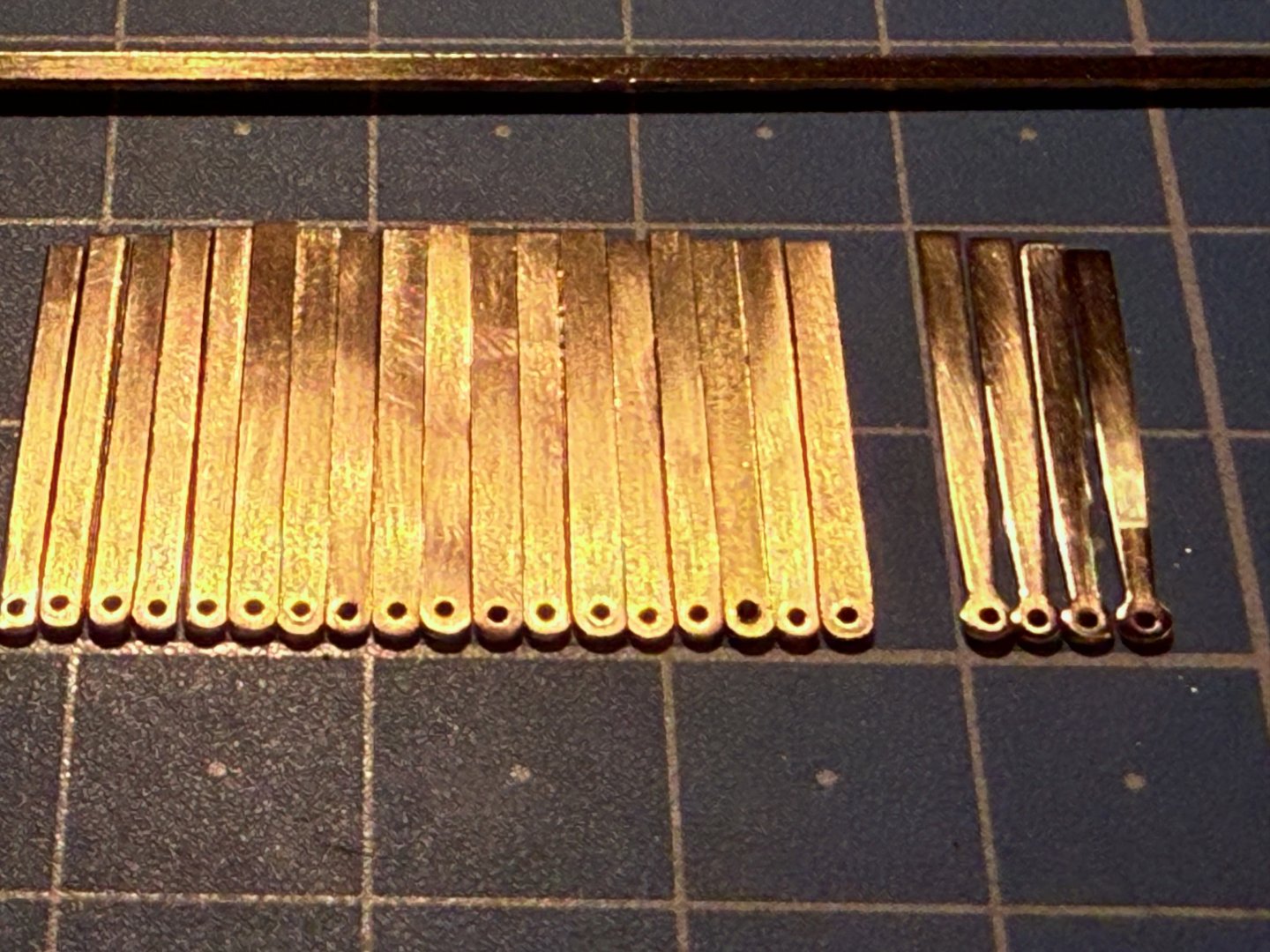

Today I made a start with the hinges for the gun hatches. With a strip of wood under a 20x40cm 0.4mm thick piece of brass it can be cut in strips of 1.6mm wide. Without the wood the brass slams hard under the saw and bends in an ugly way…the scratch piece of wood underneath it prevents that. After that cut the strips in the length of the hinges as found on the plans and reserve 4mm for the curled hinge piece. More tomorrow… Frank.

-

Hi, I need help. I have two questions: 1: It's not explained how to make the eyebolts that are drilled into the lid through the lid hinges' hole. Is there a tutorial how to make these and how big should they be made with the 28 gauge wire? Is it just a ring that let's the 24 gauge wire split ring go through with a little pin on it to be glued in the drilled hole in the port lid? 2: Where can I buy this Japanese saw like the one Chuck uses to saw his split rings that go on the cannon port lids? Thanks, Frank.

-

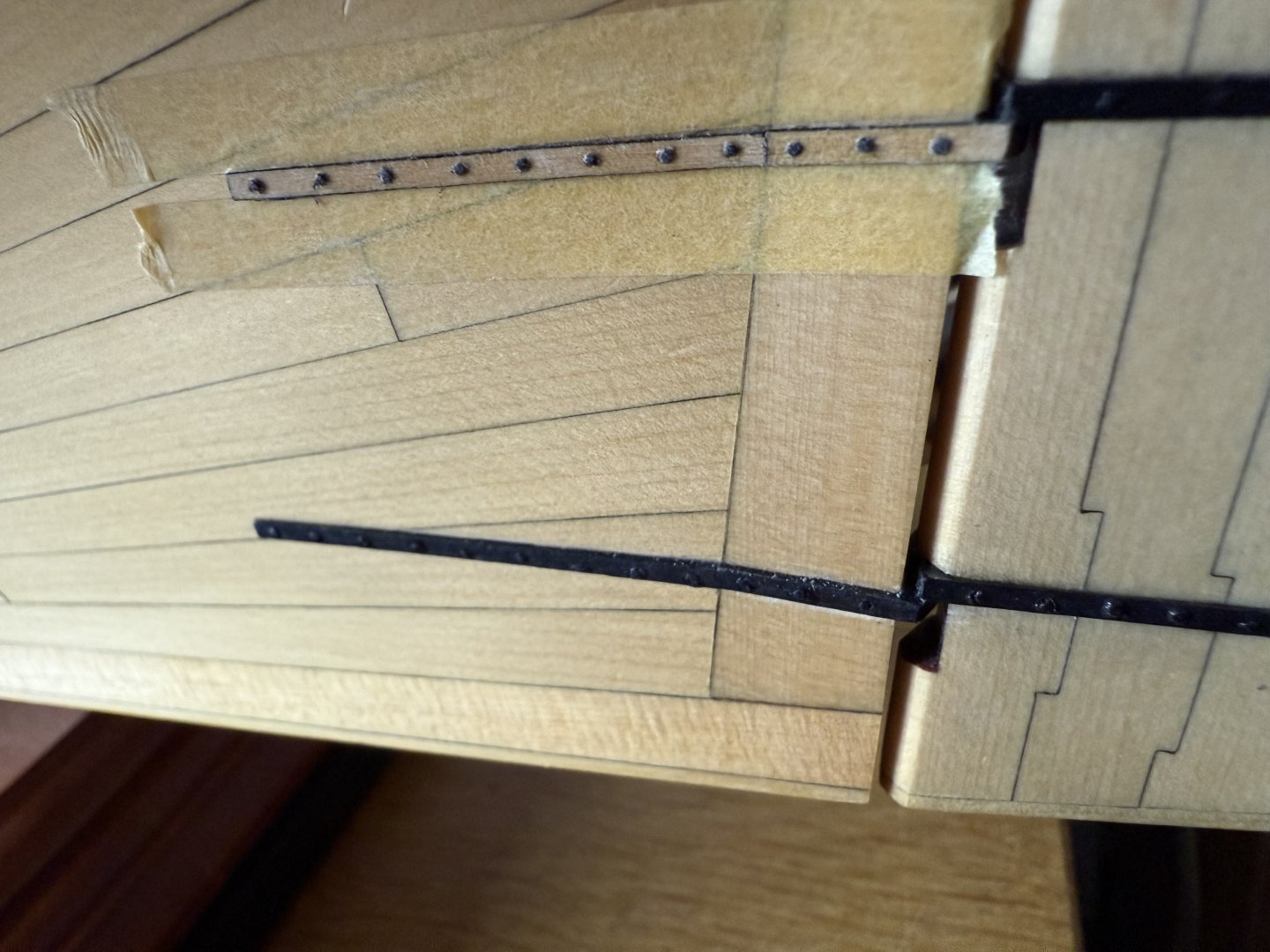

Thank you Steve, Yes I’m afraid I have that detail, fit & finish syndrome which slows me down a lot, but only then gives me full satisfaction. Lots of techniques and detail also is new to me, so I’m also very careful not to ruin Chuck’s lovely parts. Today, Sunday, I have some time to make some progress in chapter 5 again. I’m now at making the port lids fit… Frank.

-

Beautiful work Ronald! Your pear planking is not only near perfect, but also very warm and beautiful to the eye! I'm curious if you're going to paint the freezes or use the etched metal? I'm thinking of painting my freezes on Winchelsea too, but haven't got the nerves to do so till now... Ofcourse I could use the printed papers as a template and glue them on later when they're allright, but then I'll have two layers of paper, or I will have to remove the existing freezes. You could paint the freeze white over blue, spray or paint the bleu again using the etched metal as a template and then fill in the left behind white 'negative' forms with darkened (with brown?) yellow ochre, yellow ochre and lightened yellow ochre (with white?)? Frank.

-

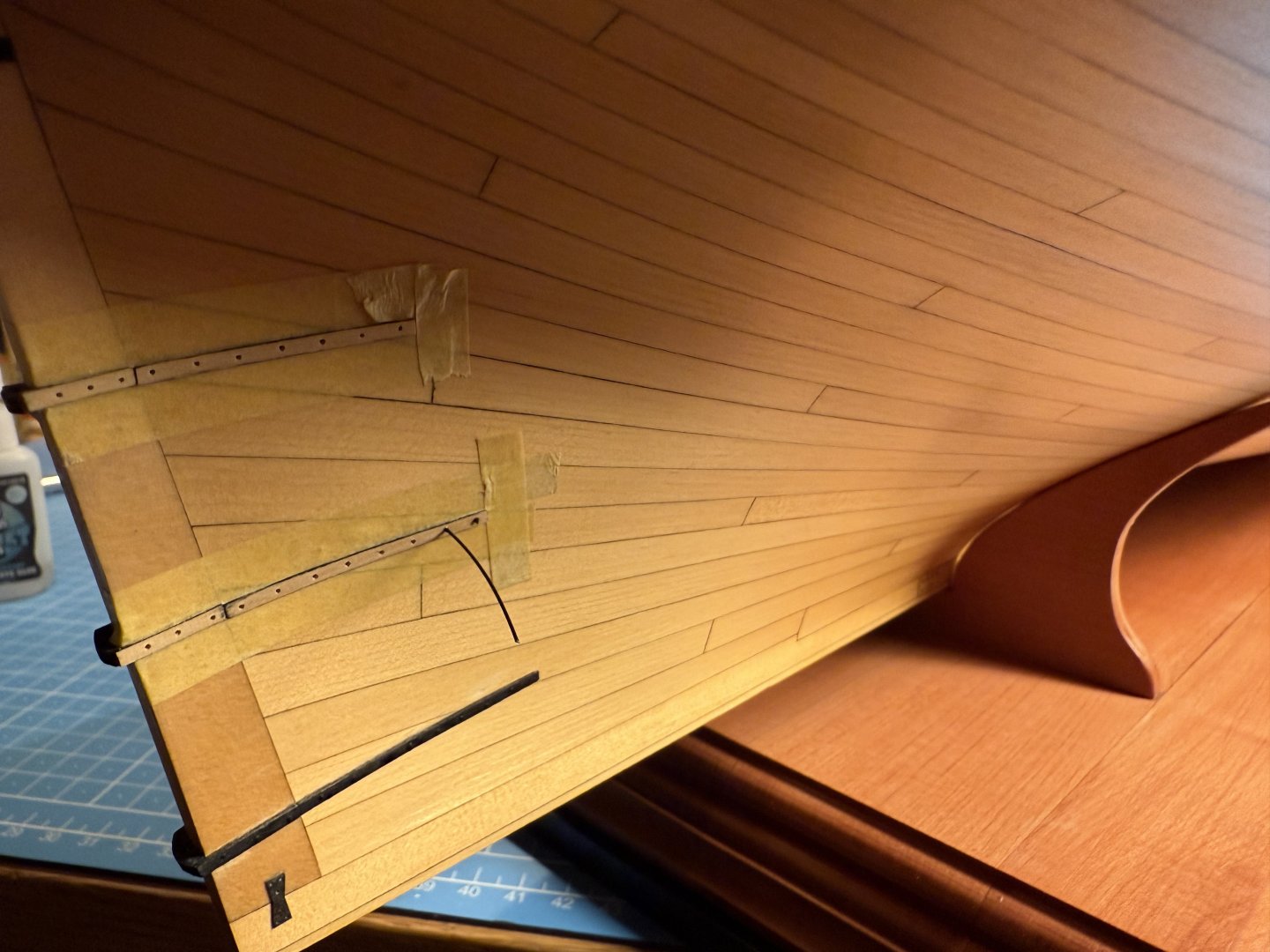

Thank you all for the kind words, these are really appreciated and inspiring! I’ve been busy making my stand fit to the hull and put some WOP on it. The lowest edge had some ugly spots so I decided to paint it very dark brown, almost black to cover that up. With a last layer of WOP this will look very natural I hope. Also I finally put the glass behind the windows on the sides of the quarter galleries. The rudder section is not yet finished as you can see ofcourse. Frank.

-

Can it still be bought without the complete wood package, as earlier provided as by hobbymil.eu also? That would make a big difference in custom duties. I see they offer it still on their website: https://www.hobbymill.eu/products/wood-packages/cutter-cheerful-1806 Thanks, Frank.

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.