-

Posts

1,867 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Chuck Seiler

-

Hello Blair. Welcome to Model Ship World. I think you will find the CHAPERONE to be an interesting and challenging build, but not overwhelming. I built the Missouri River steamboat FAR WEST as my first scratch build many years ago. All the joys of model ship building without the pesky rigging. Looking forward to your build log.

-

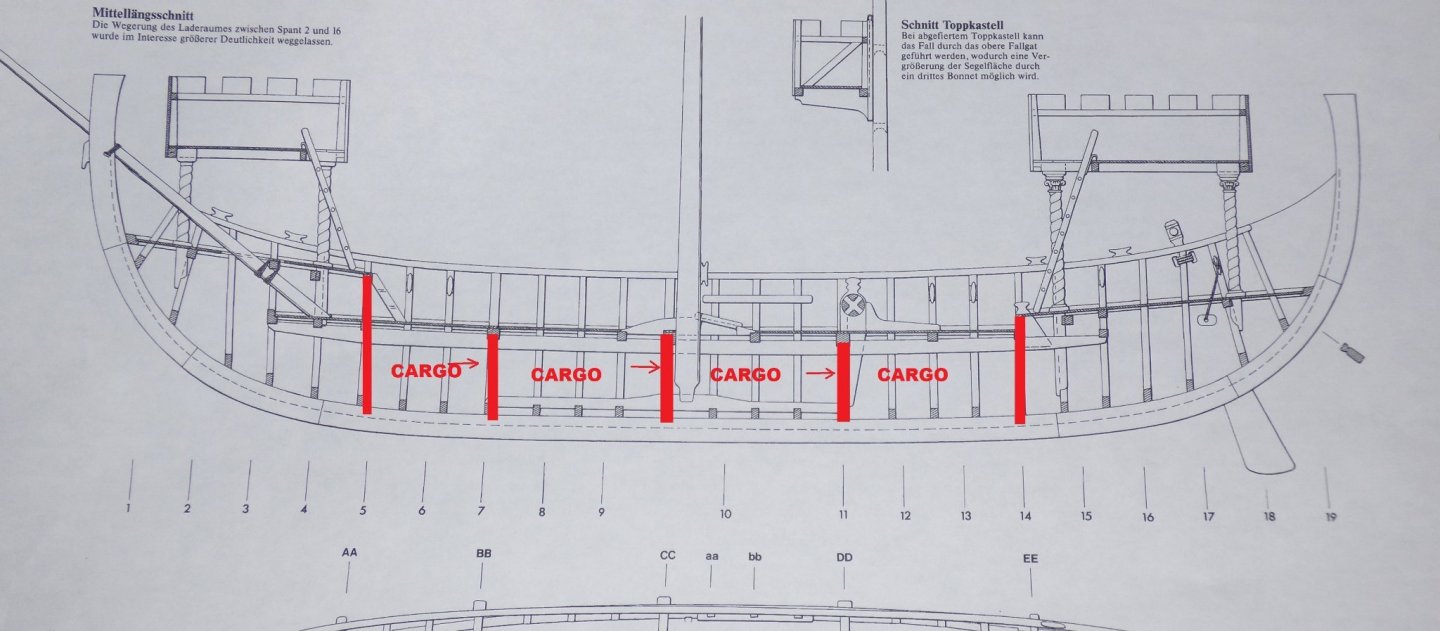

Steven, I agree with this conclusion. That is what I was trying to indicate in post 136, but it was very wordy and may have missed the point. Long story short: The frames that contained the thru beams were centrally located and provided stability. The cargo area could be accessed via removable deck planks and ran thru-beam frame to thru-beam frame. (In other words the area between thru deck frames formed sort of a compartment). Here is the best picture I could find to illustrate the removable planks. They include fingerholes and don't appear too water tight. Deck winch. Most of the ones I have seen, and the way depicted in Zimmerman, was that the hole/slot went all of the way through the windlass so the windlass bar could be used to stop/hold the windlass in place.

-

Kingship and Maritime Power in 10th‐Century England, by Matthew Firth and Erin Sebo—has been published in the International Journal of Nautical Archeology. You have to be a member of an institution to access the article and I fear the "San Diego Mental Hospital" doesn't qualify. An article I read that summarizes it states that English naval tradition goes back to before Alfred...there was a battle with the Vikings in 851. Alfred had a couple battles but the article suggests his ships weree not all that great. Comparison of 'burial ships' over the years suggests "Similarities in burial configuration and in ship design across these regions demonstrate ongoing cultural contact, resulting in comparable technological innovations in warship design between England and Scandinavia, and common cultural attitudes to the importance and prestige of sea-power." If you build below average ships and your neighbor, a seafaring group of hardies, builds better ships, you copy those. So, while England may have had its own shipbuilding traditions, I contend they were influenced by the Scandinavians LONG before 1066. I agree, ship design was not the same in 1250 as it was in 950 and a nef is not a knarr, but I suspect there is much carry over.

-

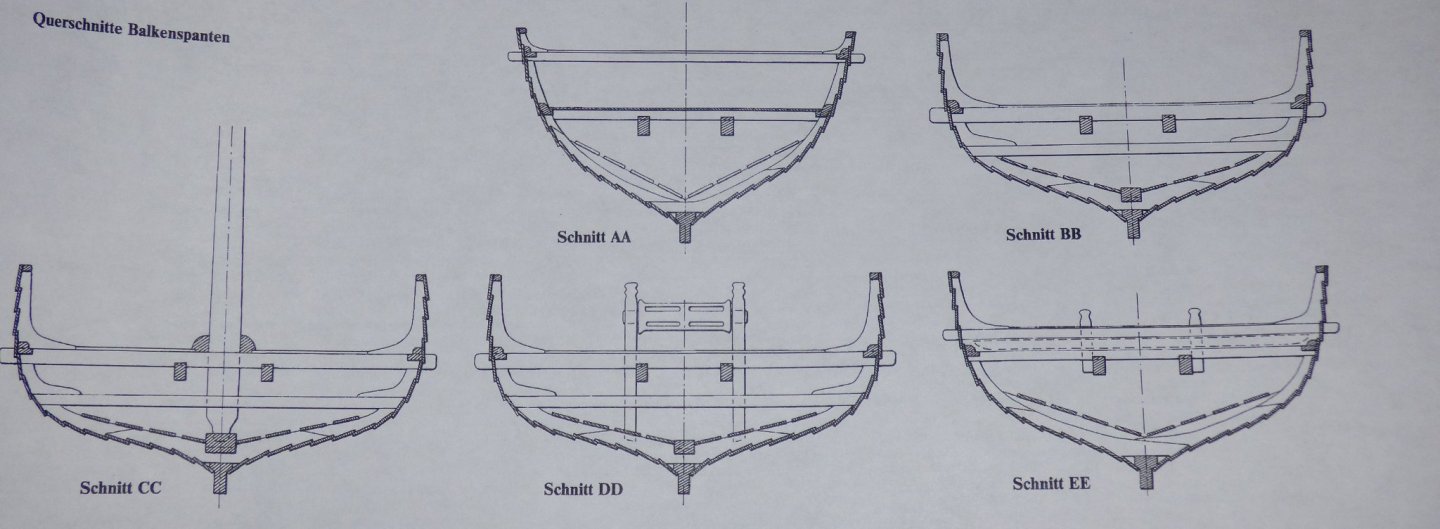

I agree. These are similar to the thru beams in cross sections AA and EE of the Zimmerman plans.

-

The thru beams appear to be notched(?) so that a ledge the depth of the deck plank runs end to end on each side. While the deck planks COULD be secured to the top of the thru beam, they would have to be nailed. Un-nailed planks would easily move. By using the ledged thru beam, the deck planks would snugly fit into place without the need for nails...just a finger hole to lift one up. As for the lower beam? My thought is that it provided more transverse structural stability required for the increased weight of cargo. On the other hand, maybe the first person to make a nef model did it that way and everybody else followed along. ...on the third hand... I want to say that I remember seeing the removable deck planks used with the Viking longships. I can't remember if I saw it in a video of the SEAHORSE replica or HARALD FAIRHAIR. The arrangement was similar and you would just pull up the deck planks to get access to gear stored below.

-

Here is a model I have seen with a hatch. I have mixed emotions about the hatch. (1) I am not wild about loose deck planks and the hatch solves that. but (2) I am not sure how easily cargo passes thru the thru beam frames with the double beam. Perhaps one of Steven's crew can explore this.

-

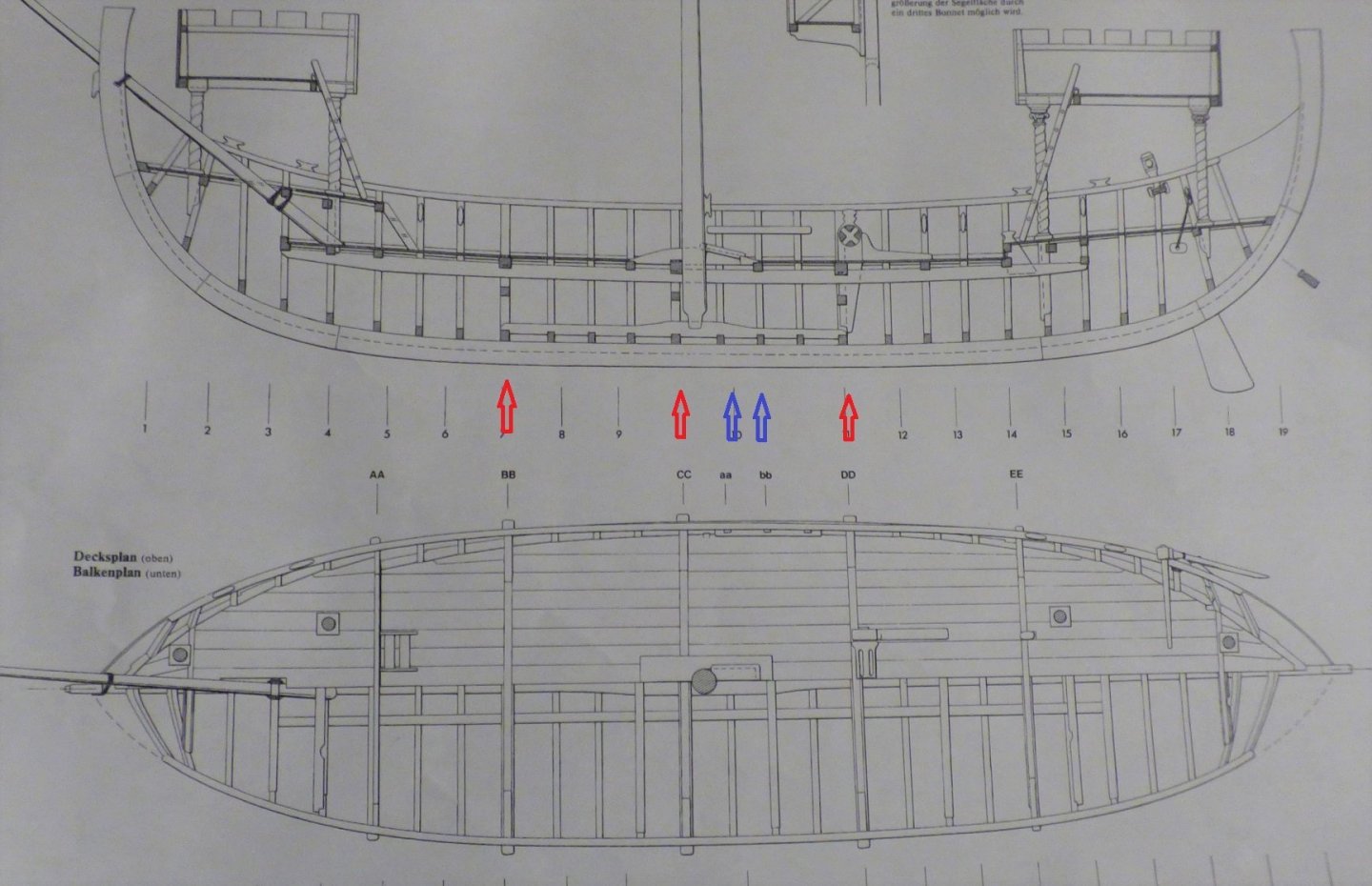

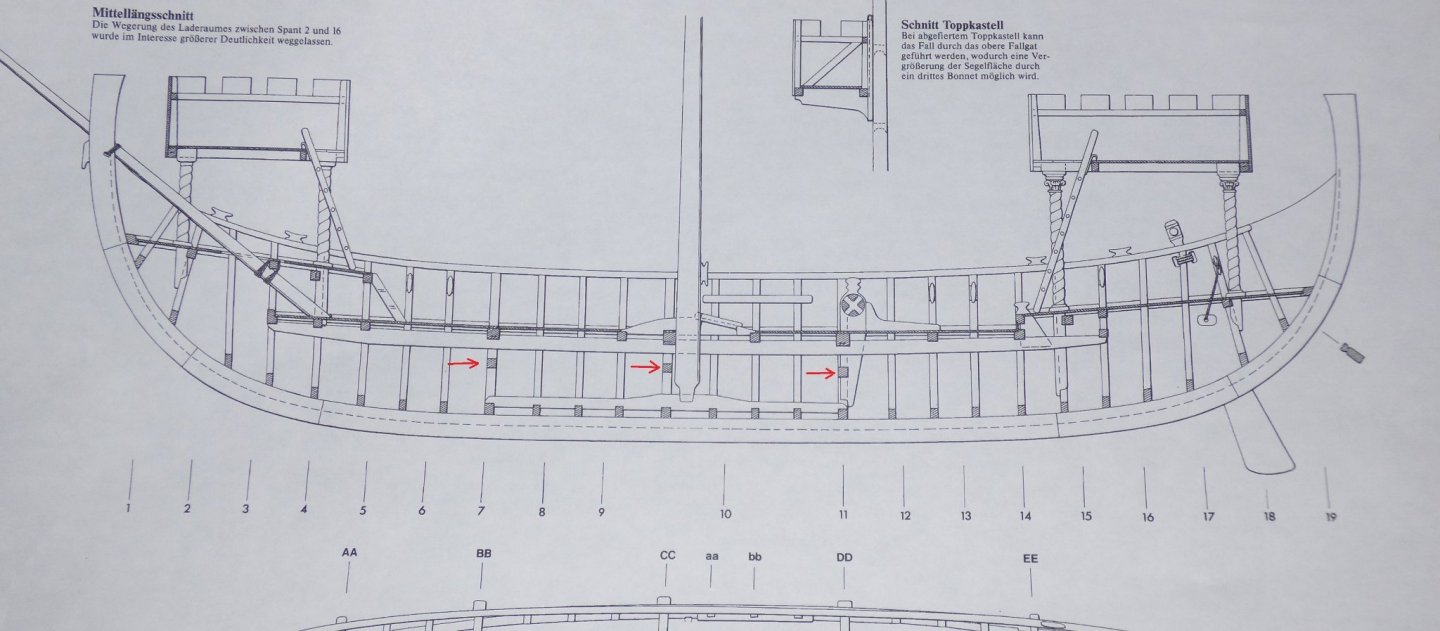

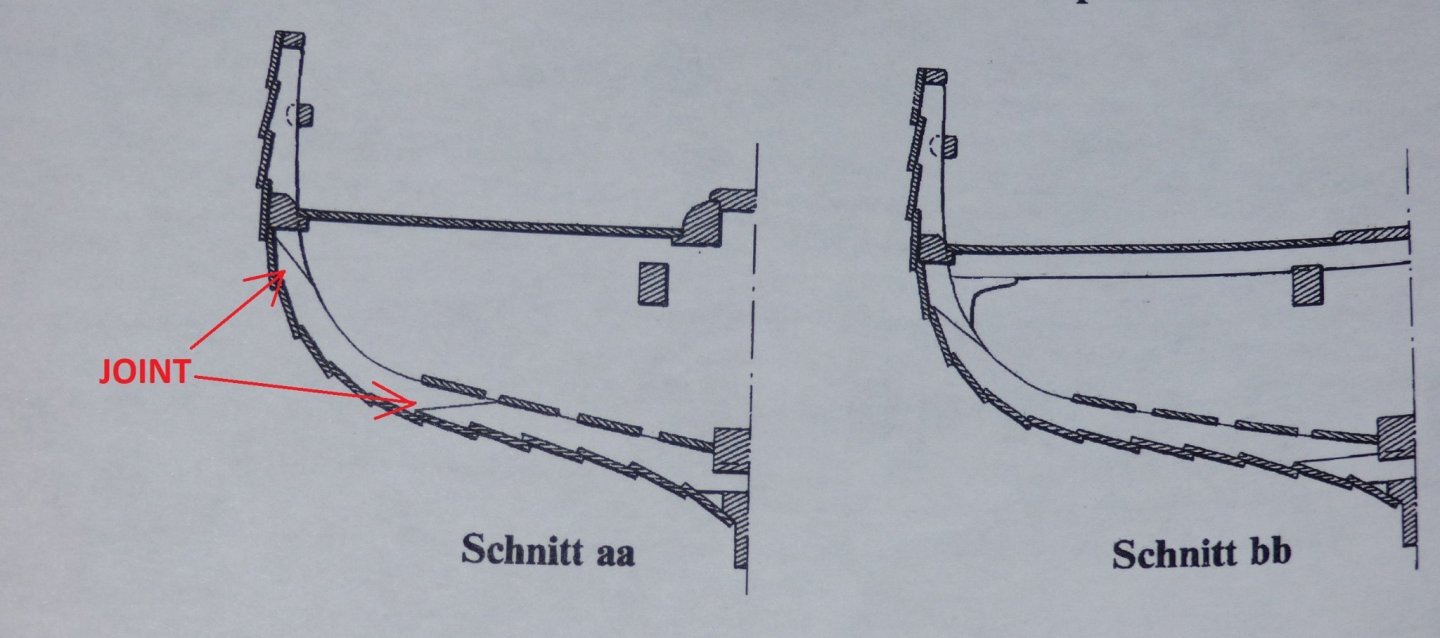

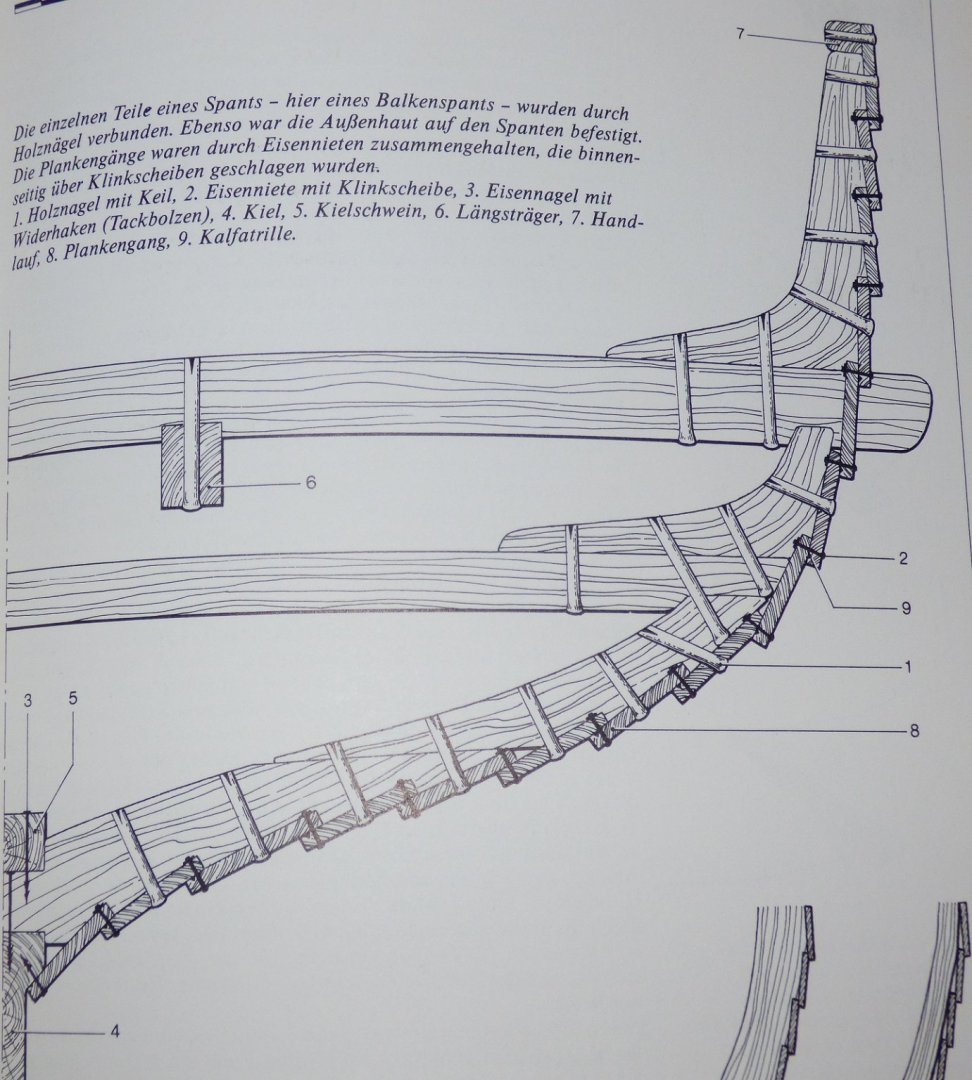

Werner Zimmermaqn, in his NEF DER CINQUE PORTS appears to harken back to the knarr and longship construction as a basis for the nef. The text is in German, so I am not sure, but the way it is presented it appears he is of the same mind set as Steven. Here is the framing for his generic nef. I call attention to BB CC and DD which are where the thru beams on the main deck are located. (Red arrows). Also aa and bb which are non-thru beams (blue arrows). We will see cross sections of these later. Notice that some of the non-thru beam frames have deck beams and some do not. In ALL cases only the thru beams are seen above the planking. Here is a closer view. Note the thru beam frames have a beam lower down in the hull while the others do not. Cross sections of the thru beam frames. Cross section of 2 of the non-thru beam frames. It appears knees are only used to support the frames when used over a beam. The rest of the frame uses angled joints and are probably bolted together. From my viewing of the Harald Fairhair replica build, the frames are added after the plank shell is in place (added to as it rises). My interpretation is that the thru beam frames provide increased transverse structural strength due to the thru beam and the secondary beam lower down. This is the area used to store cargo. Some or all of the deck planks between AA and BB, BB and CC, CC and DD, and DD to EE were removable. More detail on frame.

-

Personally, I have mixed feelings on the nails. Treenails can be overdone and can 'smallpoxify' a model, but these are nails and are very prominent on a light colored hull. I didn't like the idea at first, but after looking at Chris Coyle's cog (a cacophony of cogs) a couple of times, it grew on me. Patrick, I have experimented with pencil and it is still an option but the dots tend to be too large for my taste. I think with that many dots it needs to be subtle. A REALLY sharp pencil or very fine mechanical pencil might work, but I keep breaking off the tips. I am currently experimenting with #80 drill bits, pins and the finger-jabby things they use for glucose testing. Once the holes are in place, I rub a #2 pencil over the holes then wipe it down with a slightly damp cloth. That has the effect of liquifying the graphite and pushing it into the holes while wiping it off the wood. I may need to try using alcohol instead of water to avoid raising the wood grain. Still, that's alot of dots.

-

Looking good. Be careful, this is when it is the most delicate and vulnerable. When do you put all the 'nail dots' in? Shouldn't be more than 3 or 4 thousand. Would that be a bandersnach of nef nails?

-

Excellent!! I was thinking about using VERY thin copper wire for nails in my Sea of Galilee boat. I will look into it. Many thanks.

-

Won't that stain the wood?

-

I was hoping Louis da Fly, Druxey or AnobiumPunctatum would weigh in on this. They are more knowledgeable than I on this subject. "Collective noun" would be 'medieval ship'. As I understand it, NEF is an archaic French word for "ship" and encompasses the various northern European permutations of ships between the viking longship and knarr, and the cog, including roundships and hulcs. The nef that LdF is working on (and that I have on the back burner) is roughly based on the knarr (viking cargo ship) and was used in southern England (Cinque Ports) and northern France in the 12th thru early 14th centuries. This is not unusual, since the English nobility of that period were from Normandy and the Normans were transplanted Vikings. While no nefs have been found, there is much speculation based on artwork and wrecks of knarrs from a century or so before.

-

HEY!!! You told me that alcohol was used for ungluing parts!!! Anywho, pulling up a chair and bowl of popcorn.

- 505 replies

-

- vanguard models

- Sphinx

-

(and 1 more)

Tagged with:

-

Mark, Welcome to MSW and as mentioned in your WINCHELSEA build log, welcome to the Middle Ages.

-

I am not aware of plans of Winchelsea Nef in the National Archives...but then again there is alot I don't know. I know of the plans in the book NORMANNENSCHIFFE by Jochen von Furchs and the generic nef in the book by Zimmerman. Steven (Louie da Fly) is taking a different approach. I look forward to your build log. Welcome to the middle ages.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.