-

Posts

10,594 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by ccoyle

-

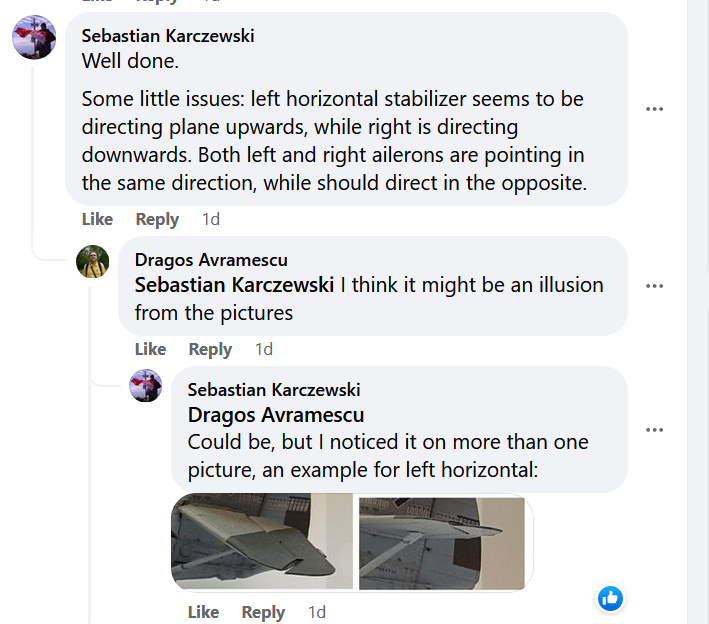

Thought you all might enjoy this little exchange that took place in a Facebook group after I shared some pictures there. Every group of modelers has "that guy" who is nit-picky to the nth degree: The best way to respond to such a character is to beat him to the punch. Here's my reply to him: In case anyone wonders, Mr. Karczewski's comments were the only negative ones posted, and no, I'm not bothered by them -- mainly just amused. 😉

-

On Hold - Nakajima Type KO 3 by CDW - Answer - 1:33 Scale - CARD

ccoyle replied to CDW's topic in Non-ship/categorised builds

http://www.answer.pl/en/laser-cut-components-for-aircraft/1955-nakajima-type-ko-3-laser-cut-frames.html?search_query=ko-3&results=255 Most publishers use some variation of the following code for laminating parts: ** = 1.0 mm card * = 0.5 mm card + = plain card stock (i.e. the part gets doubled) You can verify the thickness of your laminated parts by using calipers and comparing that measurement to the width of any slots that the parts must fit into. -

On Hold - Nakajima Type KO 3 by CDW - Answer - 1:33 Scale - CARD

ccoyle replied to CDW's topic in Non-ship/categorised builds

Yep, matte clear. One or two light coats. -

Technically, the word "FINISHED" (all caps) should be added to the build log title right after the subject name and builder's username, set off by <space>hyphen<space>. Titles can only be edited from post #1 in the build log. Here's an example: HMS Pinafore 1878 by Gilbert O'Sullivan - FINISHED - Opera Comique Models - 1/571 scale The word "Finished" (capitalized) should also be added as a tag. You can do this yourself if you feel up to the challenge, or have me do it for you. Cheers!

-

On Hold - Nakajima Type KO 3 by CDW - Answer - 1:33 Scale - CARD

ccoyle replied to CDW's topic in Non-ship/categorised builds

Yeah, card model instructions tend not to be much more than "glue part a to part b, etc., etc." -

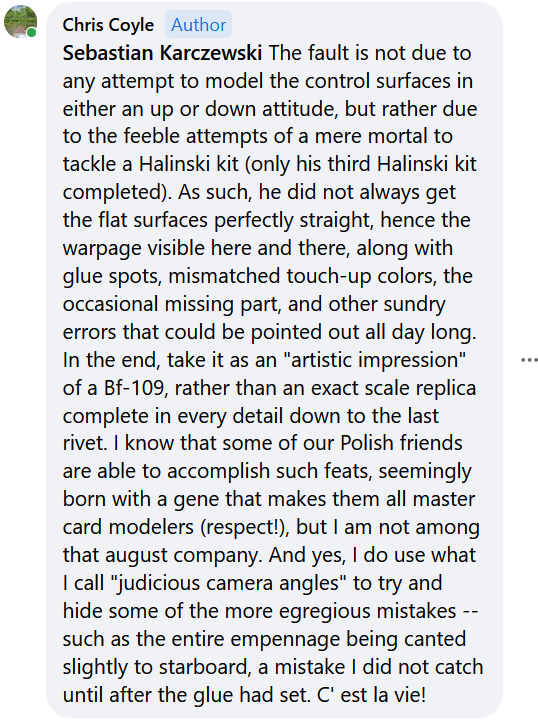

Okay, the Messerschmitt is done, so it's back to USS England. As you know, I bought some after-market resin parts from Darius Lipinski. Some of these are parts whose card counterparts are already on the model; some would probably be too difficult to remove from the model without damaging it and, in exchange, their resin replacements would probably not be a noticeable upgrade. Other parts are definitely worth an attempt at replacement. The gun directors are one such part. Here's the card director, after careful removal from the model, and its resin counterpart after painting: And the new part in place: More cosmetic surgery to follow . . .

-

Now you're doomed -- you're just gonna have to get Oregon to go along with it.

- 166 replies

-

- Maine

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

On Hold - Nakajima Type KO 3 by CDW - Answer - 1:33 Scale - CARD

ccoyle replied to CDW's topic in Non-ship/categorised builds

Good luck, Craig! I'll be following along with interest. -

More like a "journeyman class," but I appreciate the accolade! I think one of the biggest take-aways from this build for me personally is that I now feel less intimidated by Halinski kits, having completed three of them. I have to qualify that statement with the observation that Halinski kits tended to get even more complex after the 2007 publication date of this kit. Some of the newer ones that I have in my stash (e.g. Fw-190D-9, Ki-61) make this one look rather tame. And Card Army, whose chief artist, Marcin Dworzecki, did the artwork on many of the Halinski kits, has ratcheted up the detail on card kits to an even higher degree, if you can believe it. When I look at the Card Army kits and coolly assess my skills against what would be required to build one of them, I have to realistically conclude that they are really only suitable for a very tiny minority of modelers.

-

The kits come with templates for cutting the glazing from the modeler's choice of material. In this instance, I used a molded after-market canopy. Such canopies are usually kit-specific, meaning that a canopy for one kit may not fit a kit from another publisher, even if it's the same subject. However, in my experience, even the fit with the intended kit (i.e. a Halinski canopy with a Halinski kit) can be problematic and depends greatly on the skill of the builder in getting the cockpit dimensions just right; get the dimensions off a millimeter here and there and all sorts of fit trouble follows. I have had to 'fudge' the fits on more than one molded canopy.

-

MRAP ATV by CDW - FINISHED - Rye Field - 1:35 Scale

ccoyle replied to CDW's topic in Non-ship/categorised builds

Very interesting piece -- well done! -

I think that it's safe to say that a model of a U-boot or other submarine, having a relative paucity of structure compared to a surface combatant, really depends on the painting and weathering skills of a modeler in order to bring it to life. This you have done in spades, Greg!

-

Yep, beneath the grating is definitely not correct, as the beam would largely block the open grate and thus defeat the purpose of placing a grate there in the first place.

- 82 replies

-

- Fly

- Victory Models

-

(and 2 more)

Tagged with:

-

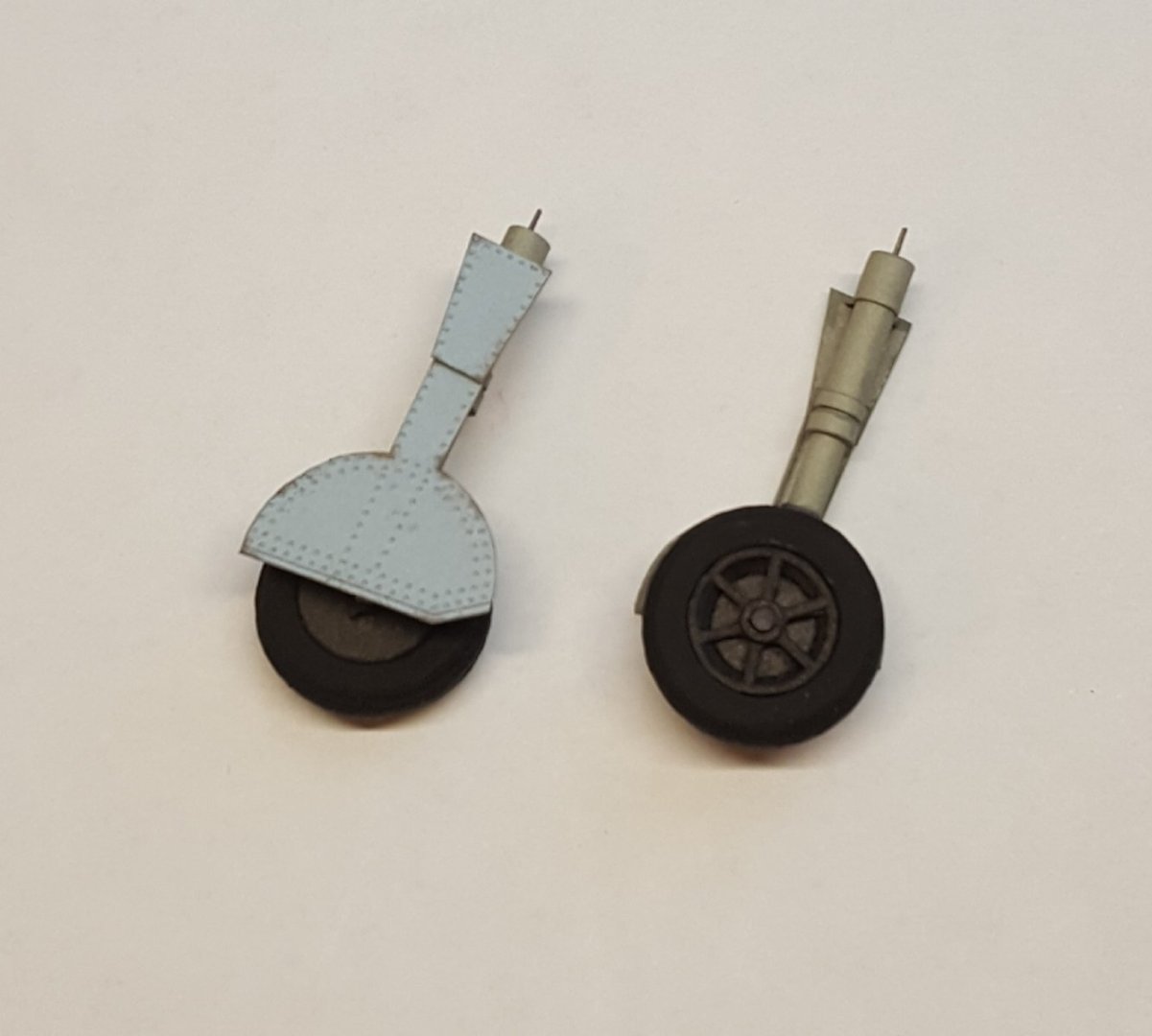

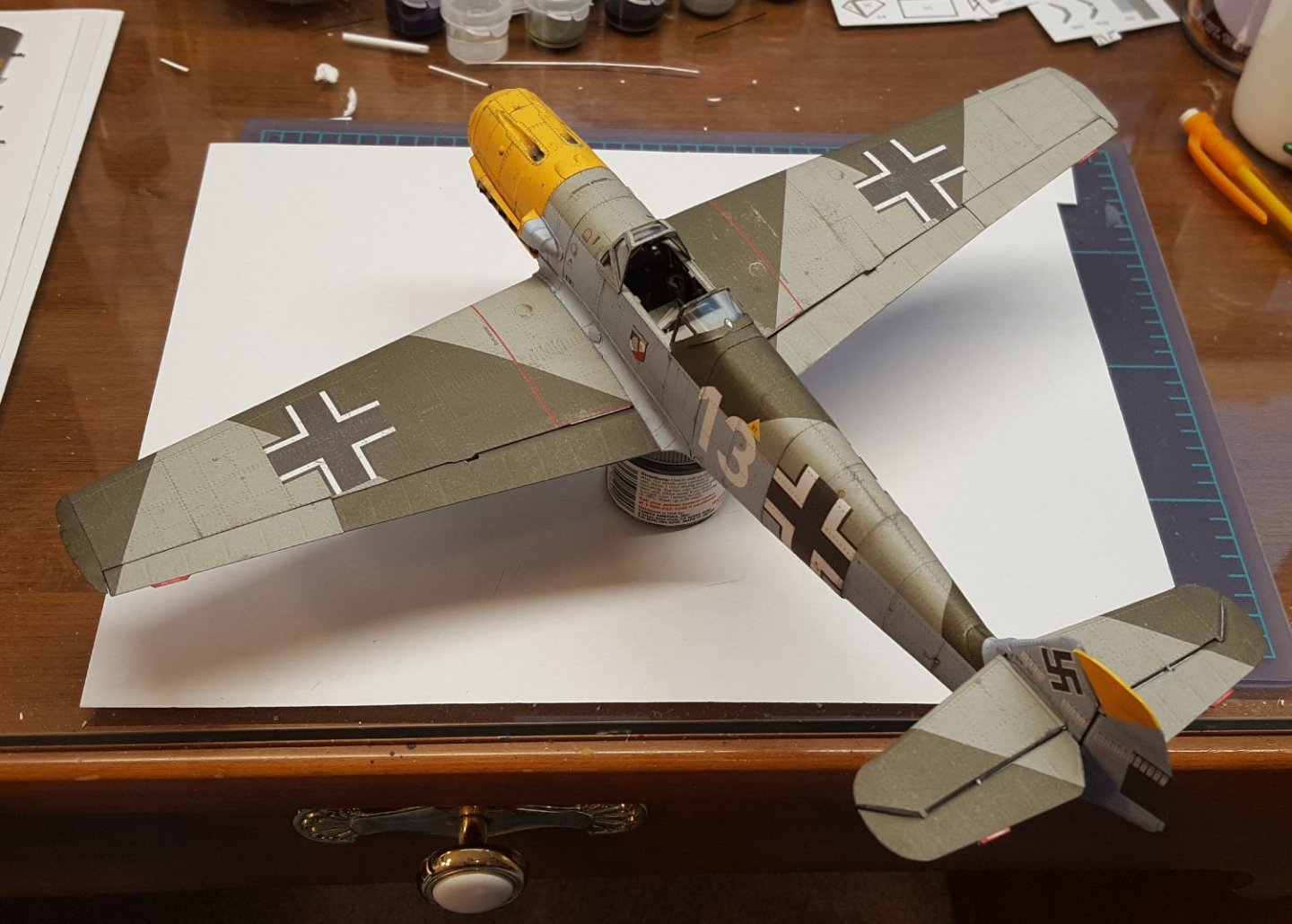

The Big Reveal! So, one day shy of two months from the beginning of construction on this project (though it felt like longer), the Bf-109E-4 is complete. The final bits of construction consisted of small parts that needed to wait until the final stage in order to avoid getting knocked off repeatedly: tail wheel, antenna masts, gun barrels, aileron counterweights, pitot tube, and canopy. All in all, a challenging project without too many issues, though I did find some post facto construction errors and did wind up with a few tiny "mystery parts" left over. Enjoy the pictures!

-

So, I recently decided to suffer the injustice of high postage costs from Poland and ordered a batch of kits. The VERY NEXT DAY I learned that Kartonowa Kolekcja, my favorite publisher, just published a new kit. It's a Nieuport 16c.1, complete with Le Prieur rockets. The Nieuport 16 was an updated Nieuport 11, so this kit amounts to a repaint and slight modification of the older release. I was hoping that the next kit might be a SPAD, Albatros, Swordfish, or Fokker DVII repaint, but no joy. Still, this kit is a nice addition to the KK catalog

-

Welcome, Zac! I actually think a well-motivated beginner might be able to pull off the Endurance. Having no guns and being square-rigged on only one mast, it lacks some of the elements that can make a first build particularly difficult. The photo-based instructions should also be very helpful. Be sure to create a build log when you get started, and you should be able to get lots of advice along the way. Cheers!

-

Great! I'd be interested to see pictures of that kit when it arrives. The only photos I've seen of the printed parts were taken it what appeared to be poor lighting. I went ahead and pulled the trigger on the two Answer kits I spoke of earlier, the Nimrod and the Nieuport 28 -- they're both incredibly nice-looking biplanes -- I couldn't resist (don't tell the missus)! I also added a Stearman PT-17 Kaydet to the order and laser-cut frames for all three kits, plus resin wheels for the Nimrod and some frames for a Fiat G.50 Freccia I have in the stash (the desert camo on that kit matches the livery of my CR.42 Falco).

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.