-

Posts

10,520 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by ccoyle

-

Great job on a sharp-looking ship!

- 146 replies

-

- Harriet Lane

- Model Shipways

-

(and 1 more)

Tagged with:

-

Bristol Beaufort by AJohnson - FINISHED - Airfix - 1:72

ccoyle replied to AJohnson's topic in Non-ship/categorised builds

Nice work, Andrew! -

I will answer those questions for you, since I'm the one who moved your topic. As you admitted, it is not a ship model, so the build log sections were not the right place. I admit that I wrestled with where to move your project -- it's one of those projects we get from time to time that doesn't fit neatly into one of our established sub-forums. It then becomes a judgment call about where to place it. If I'd left it in the build logs area, I'm sure some members would have wondered why a non-model was in that area. You can see the dilemma. The reason why we have that non-ship sub-forum "at all" is because members asked for it, and as you can see it is a popular feature at our forum. And your build log is no more "buried" in that area than in any other part of our site. I use the "all unread content since my last visit" feature and your topic came right up. The reason why I marked your project as finished is because it did appear to be finished, and it is not uncommon for members to not mark their projects finished when they are done with them. Again, it's a judgment call.

-

Oh, Mike, Mike, Mike . . . if I were to share more of the work of the True Masters of this medium (a group that does not yet include me), we'd all quit and take up knitting. 😂 Anyways, I have hung the rudder. I canted it a bit to starboard -- that creates the visual illusion that the vertical stabilizer isn't quite so crooked.

-

The vertical stabilizer has been added. It has a substantial amount of substructure, as can also be seen for the rudder. Unhappily for me, the stabilizer is noticeably crooked -- a fact I failed to notice until after the glue had well and truly set. This will subsequently require the judicious use of flattering camera angles.

-

Shoot a pm to MSW member greenstone. He works for the company.

-

Nice work, Nils! Pilot schooners make handsome projects.

- 180 replies

-

- pilot boat

- Elbe 5

-

(and 3 more)

Tagged with:

-

I always use a fresh #11 blade for the task. I do the job freehand, and I don't try to cut all the way through the card on the first pass -- score the cut first, then cut through on the second pass. On the curved section I use a jigsaw-like motion using only the tip of the blade and pushing the blade forward instead of drawing it back. I should add that although I have been using the Evergreen Canopy Glue for most of this build, I did not use it for seating the channels, since that task requires more working time to get everything seated properly. I used Aleen's Clear for the job.

-

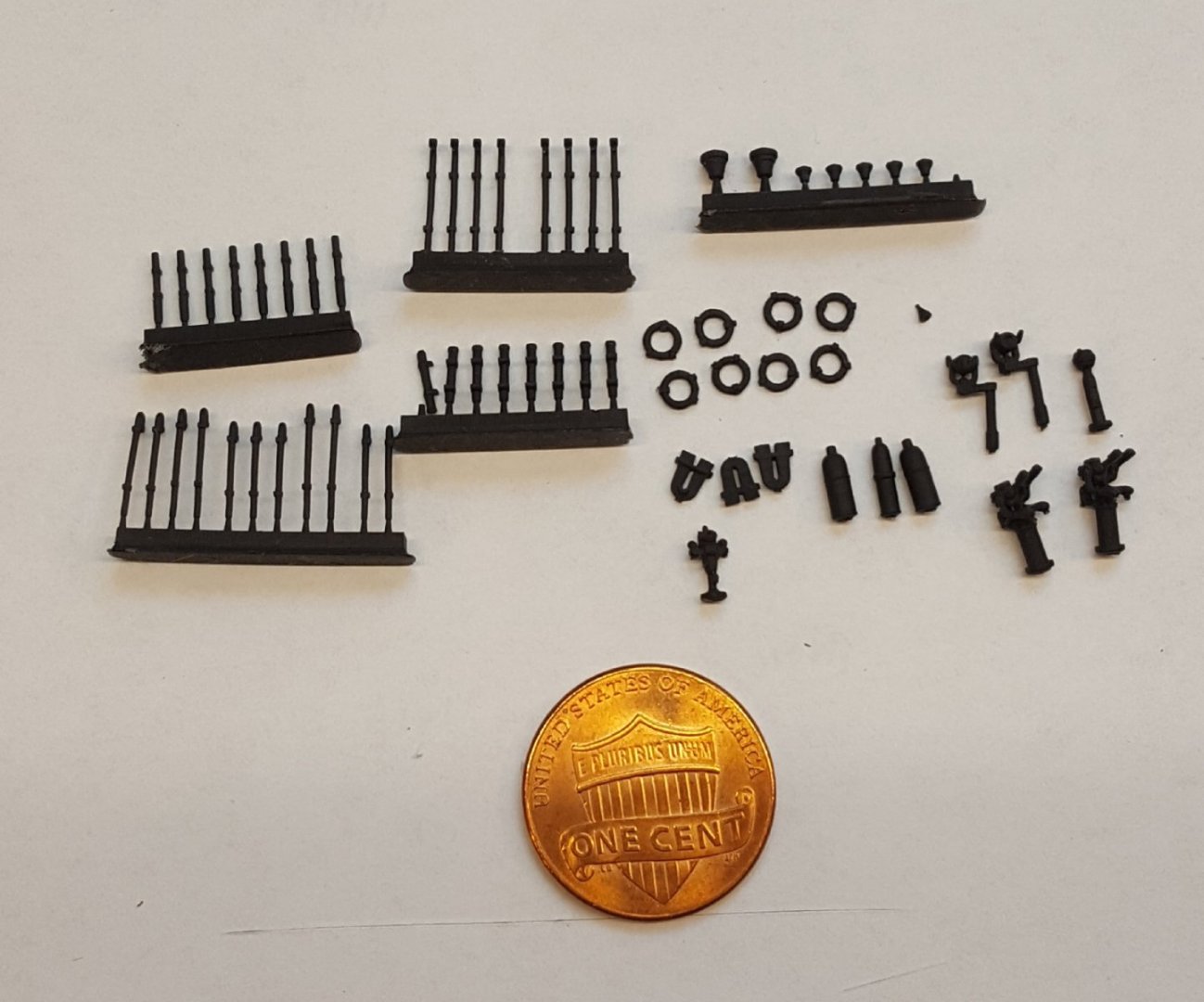

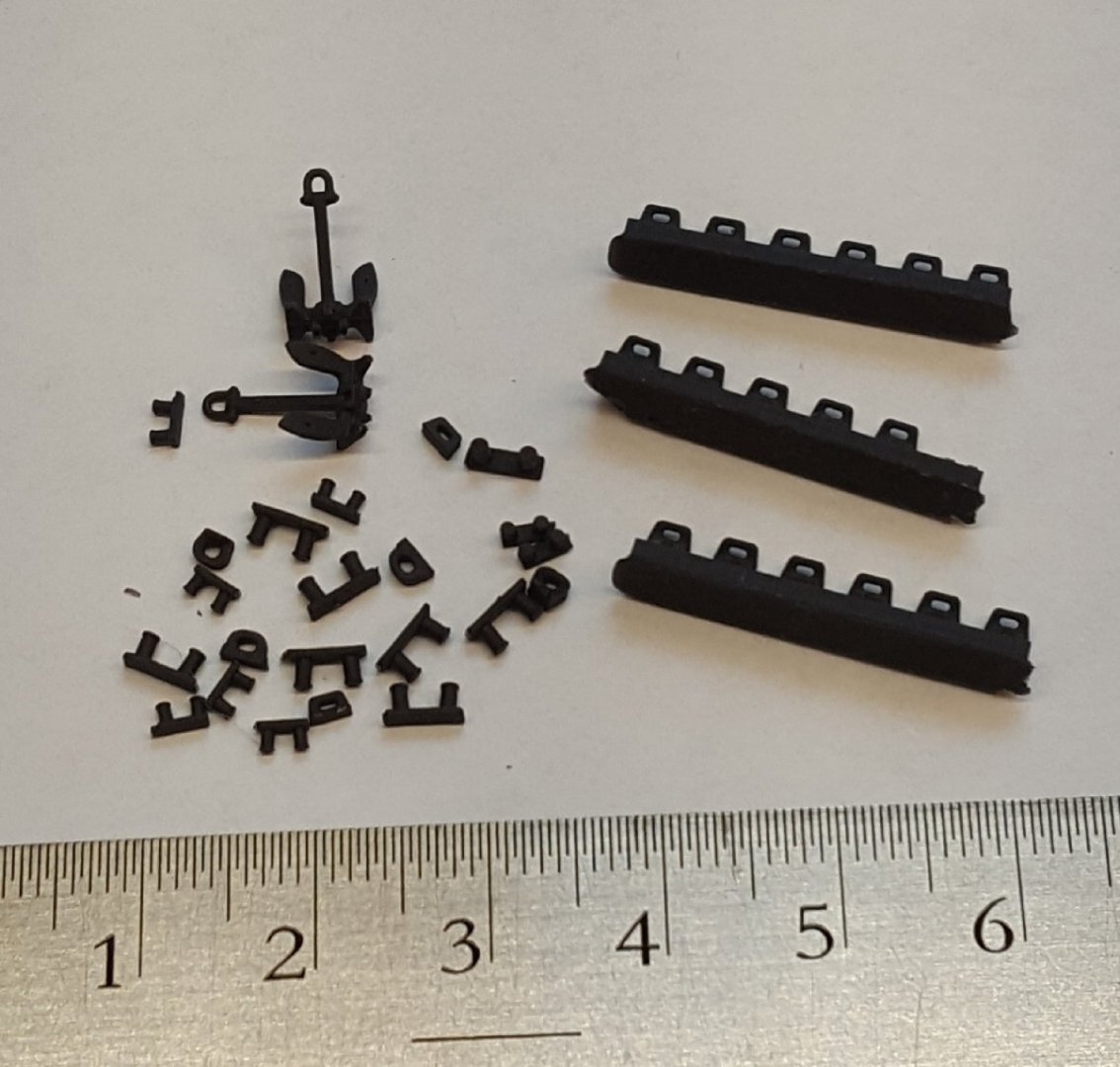

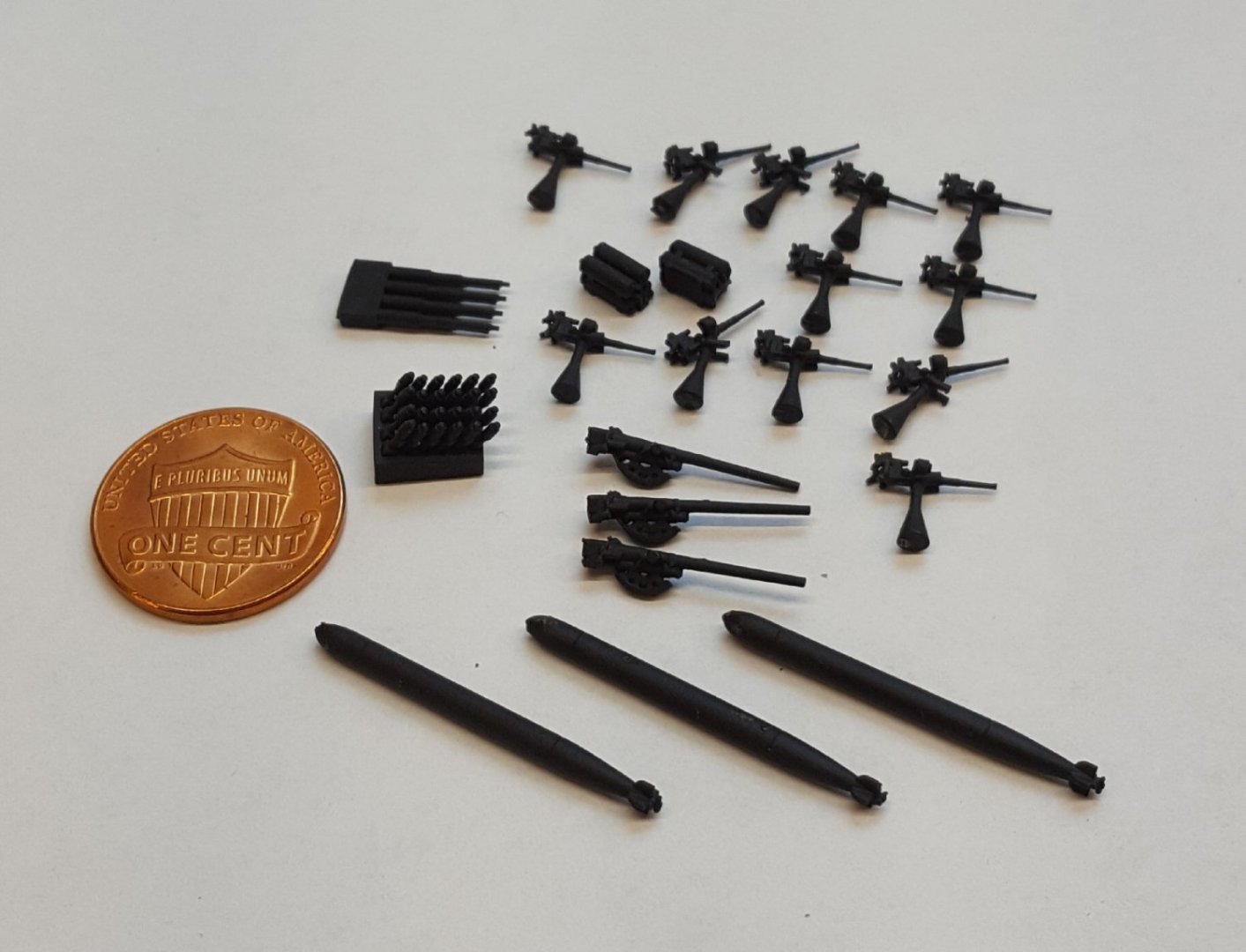

Some goodies arrived in the mail today. These are 3D-printed detail parts from Darius Lipinski, the kit's designer. I have already added the paper versions of some of these parts to the model, but the printed parts are so nice that I might just be tempted to see if I can safely remove some of those paper parts and replace them. So, what have we got? Vents, valves, life rings, hoses, binnacle, signaling lamps, directors. Anchors, bitts, fairleads. And finally, armament: 20 mm mounts, barrels for 3" and 1.1" guns, torpedoes, and hedgehog bombs. This build will probably go back on the bench after I complete the 109 build.

-

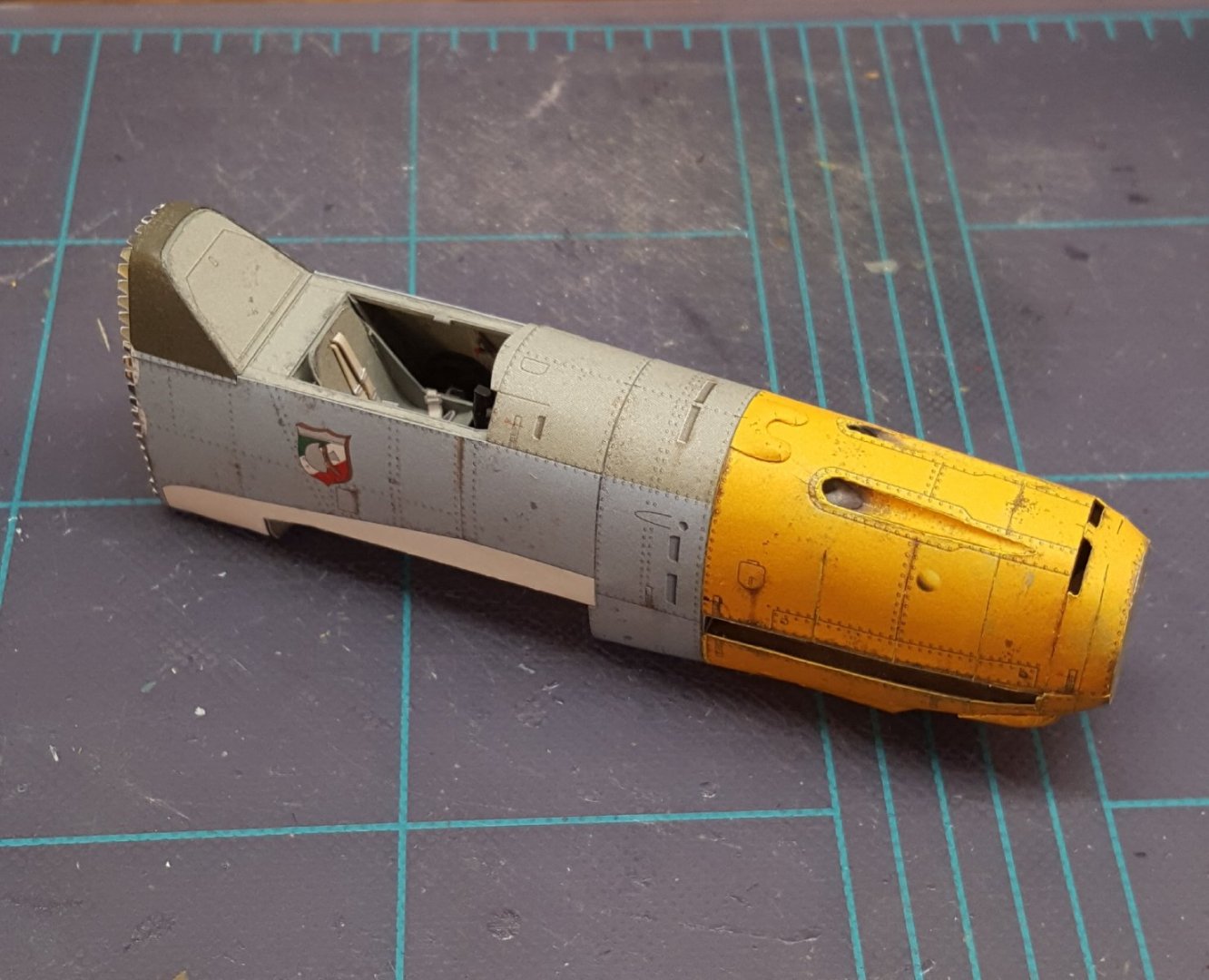

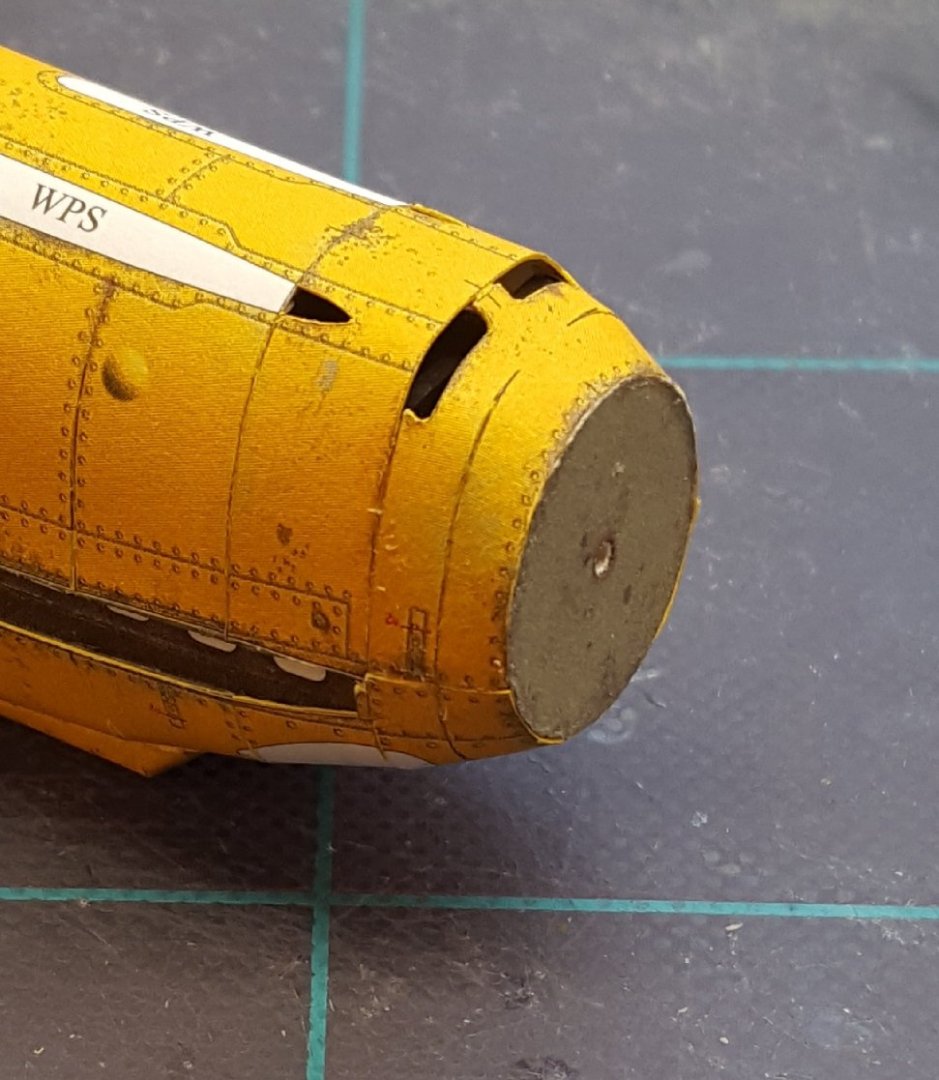

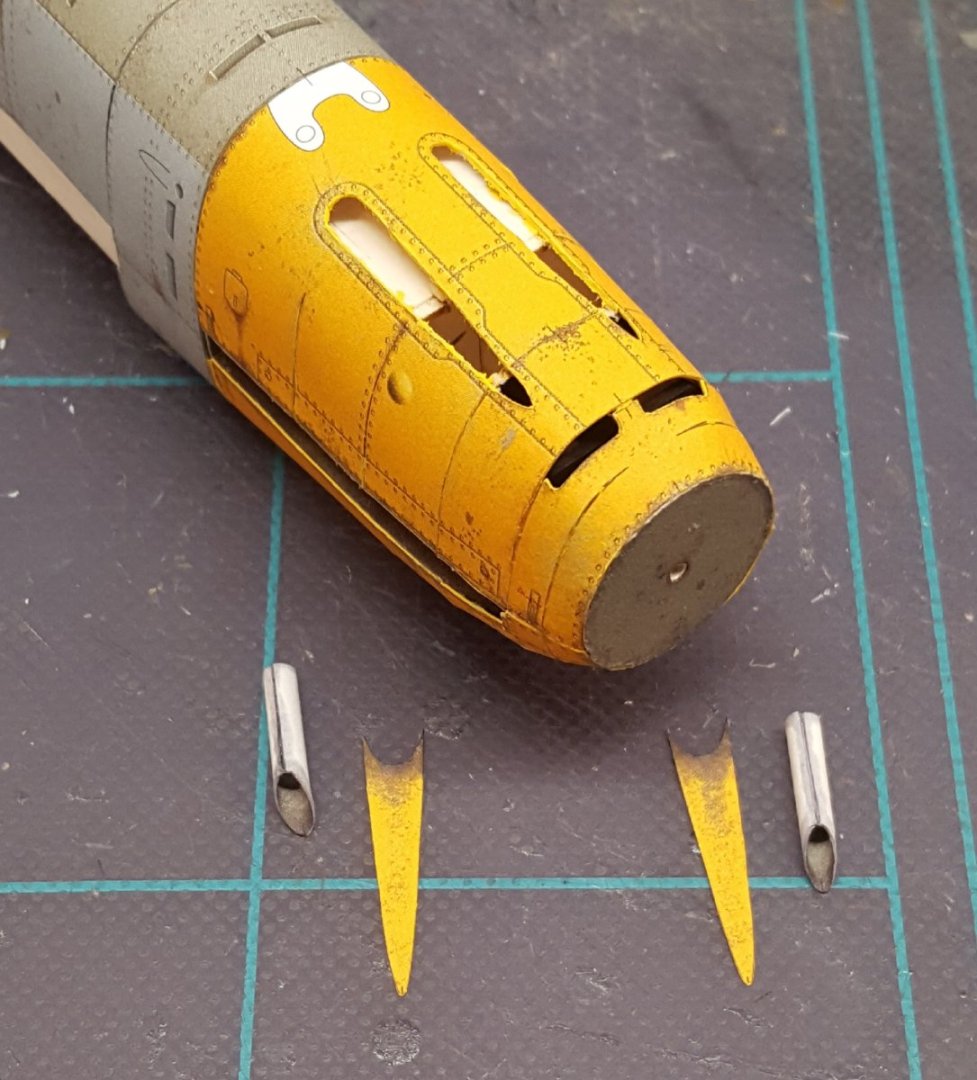

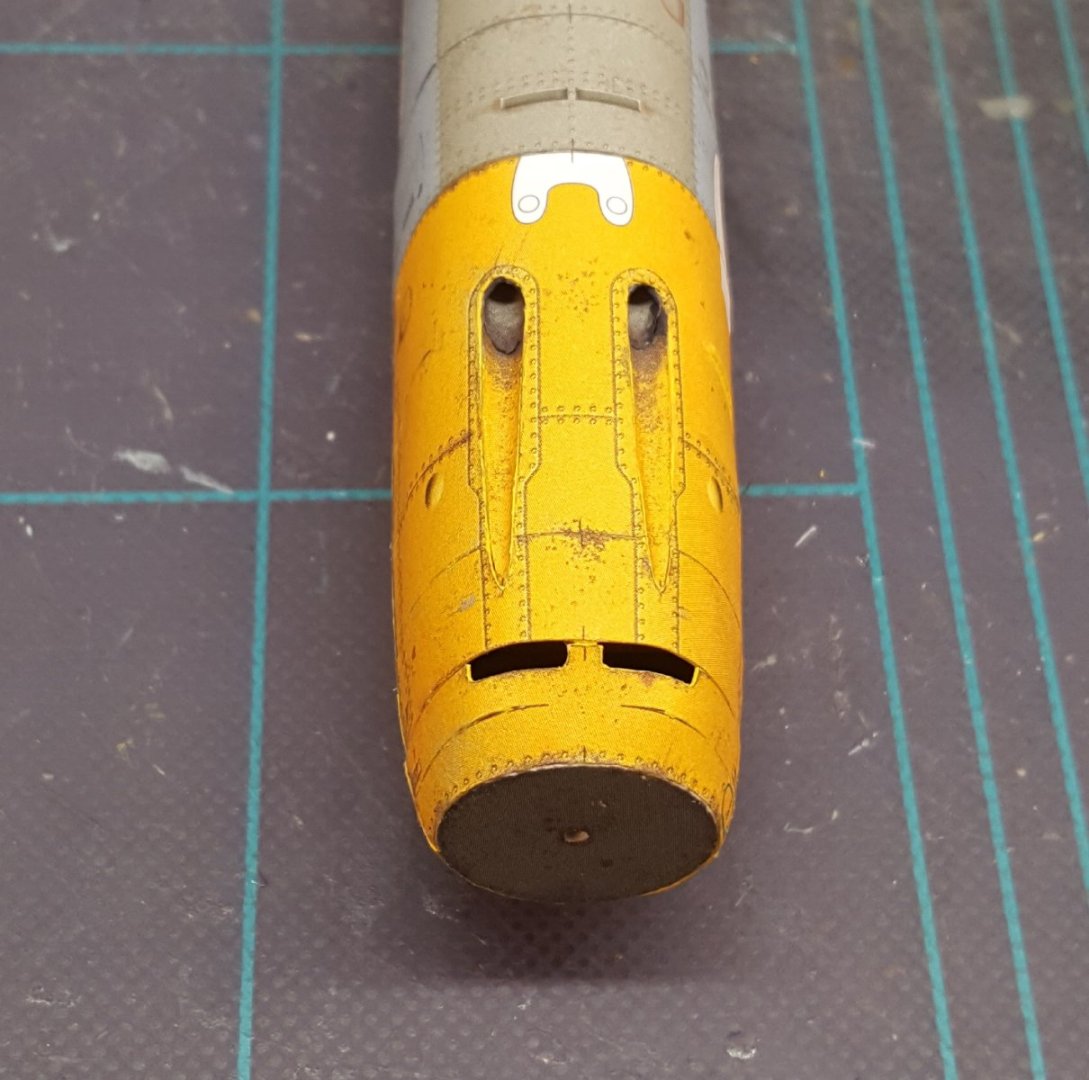

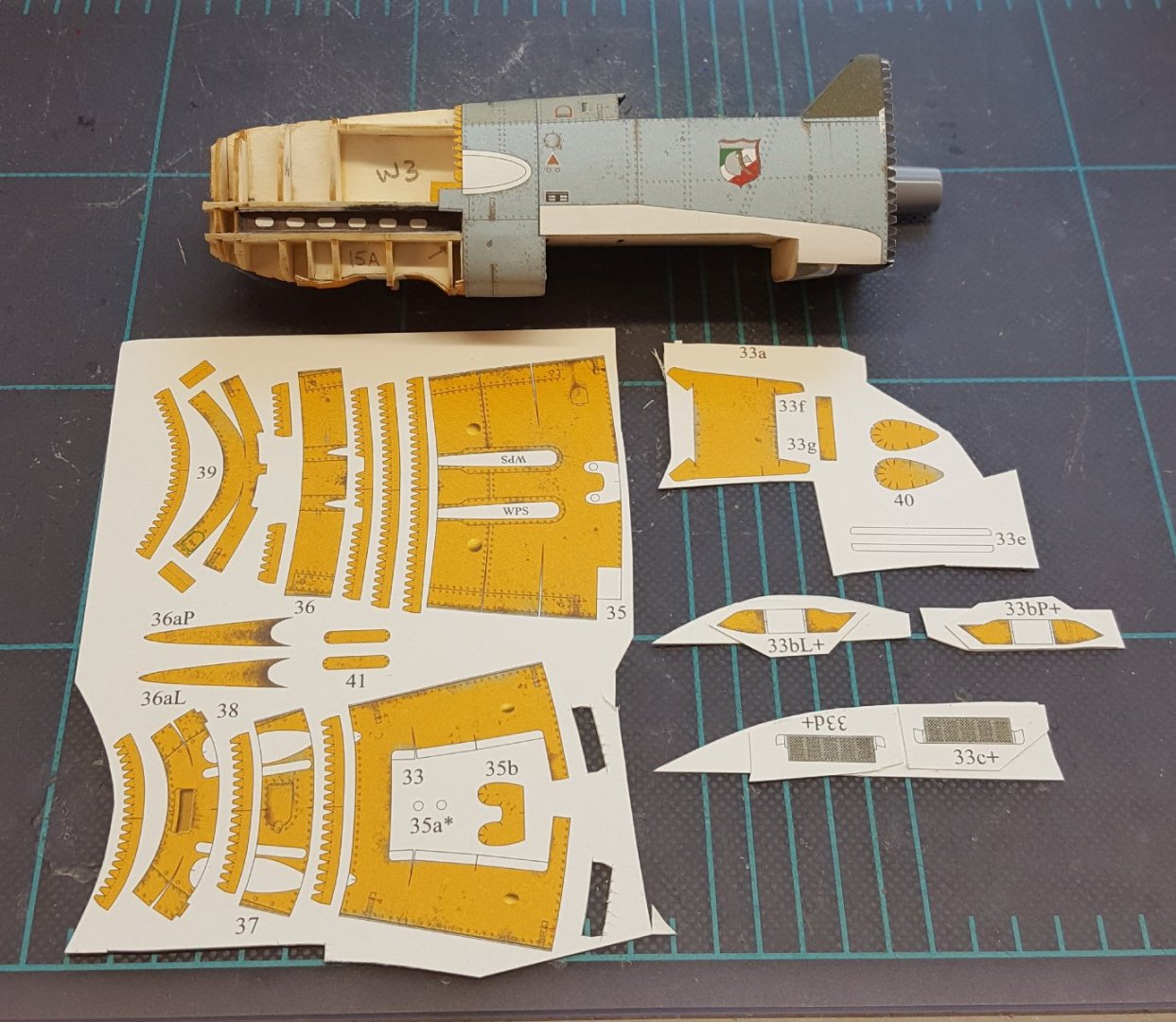

Further progress: First the penultimate nose skin was added to the fuselage. The last skin consisted of two pieces, which I chose to join together first before adding them to the fuselage. The last frame was also added to this piece. Then that structure was added to the fuselage. The fit so far has been no problem. The letters WPS indicate sections that are to be cut out after the part has been glued. These are of course the machine gun channels. Those portions were duly removed, and the parts for the channels were prepped. And here's the finished channels. That's all for now!

-

Witam, Wieslaw! I saw your ORP Piorun model in the gallery -- a very high level of craftsmanship. Thanks for sharing!

-

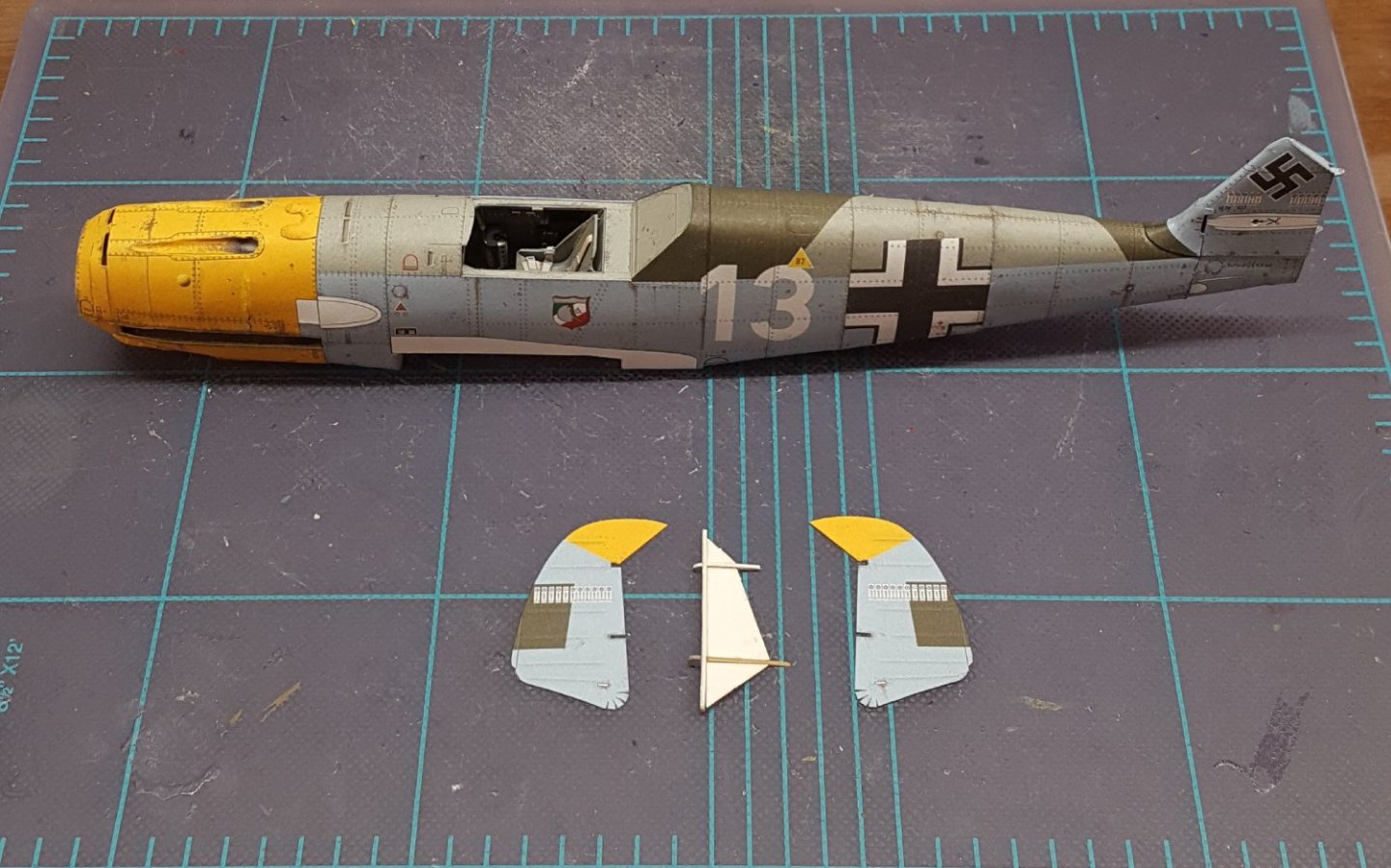

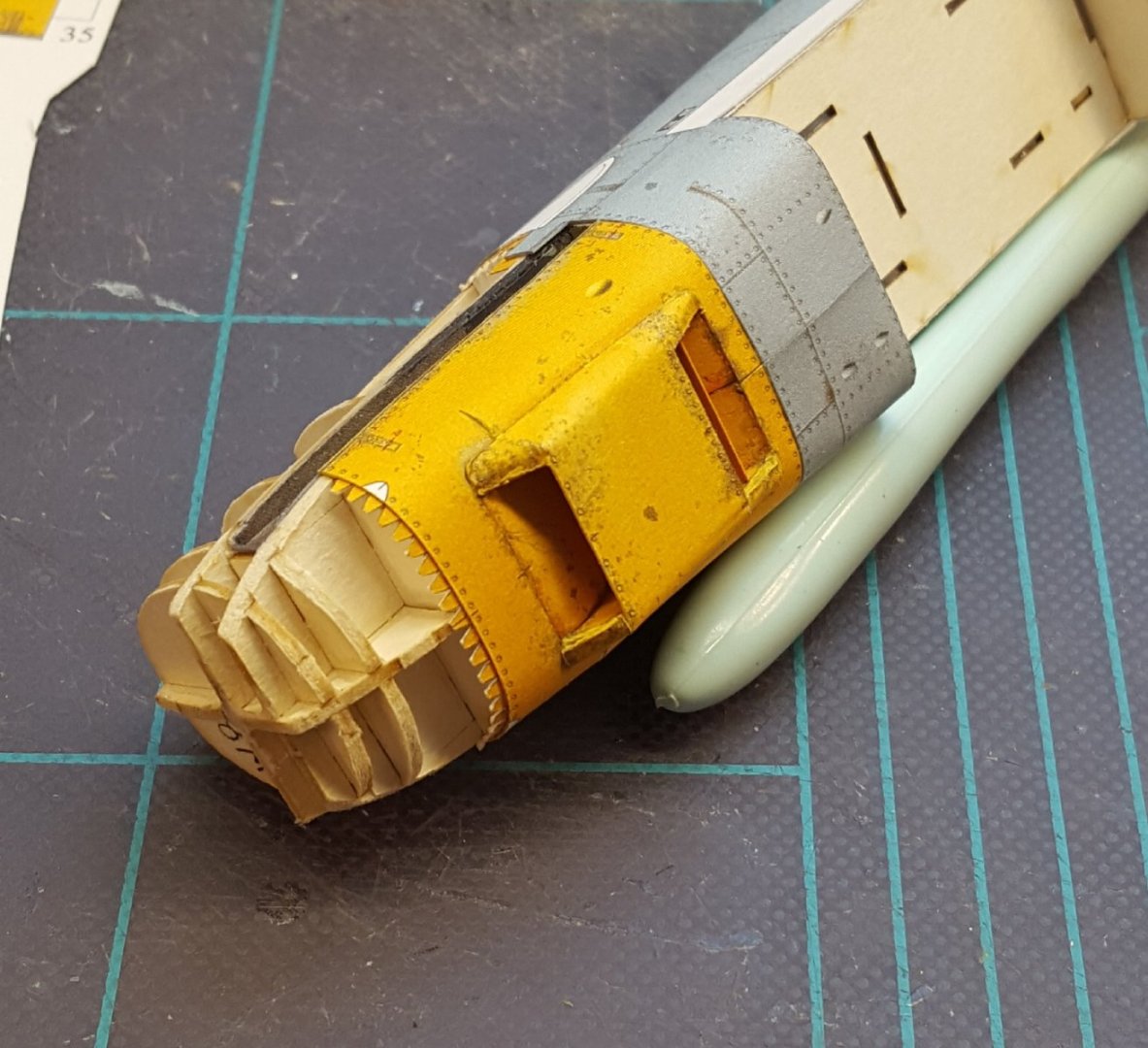

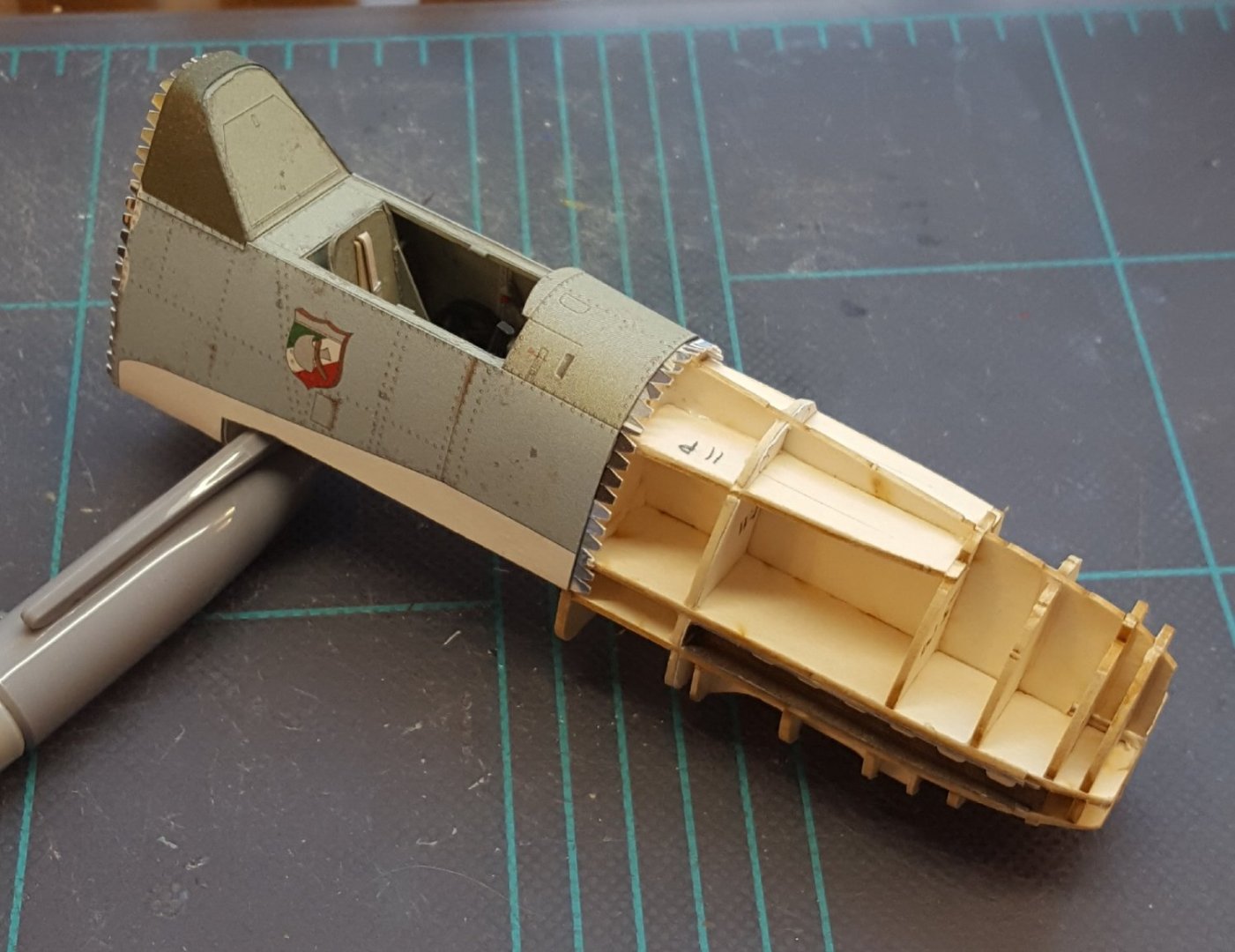

A nice milestone moment in the construction of a plane is getting the first outer skin on. On some Halinski builds, I have had a lot of issues with the inner cockpit skins not fitting correctly -- they must align precisely and have no gaps at the seams, otherwise the outer skins won't fit either. Fortunately, this time around only some light sanding was needing to achieve the desired inner skin fit, and the outer skin thus went on without a hitch. The nose frames were then assembled and mated to the cockpit section. You can see that there is a substantial amount of substructure. After adding one more fuselage skin (it fit perfectly and won't even require any seam touch-ups), it's time to work on the nose. The Emil had a rather lumpy, bumpy nose (a characteristic that was addressed in the 109F), and that is reflected in the jigsaw puzzle-like nose assembly sequence for the model. Patience will be the order of the day!

-

Anyone out there working on a card model?

ccoyle replied to gagliano1770's topic in Card and Paper Models

Me, too -- but if I recall correctly, I have to go off-site to see the build log for this one (hint, hint). 🤨😉 -

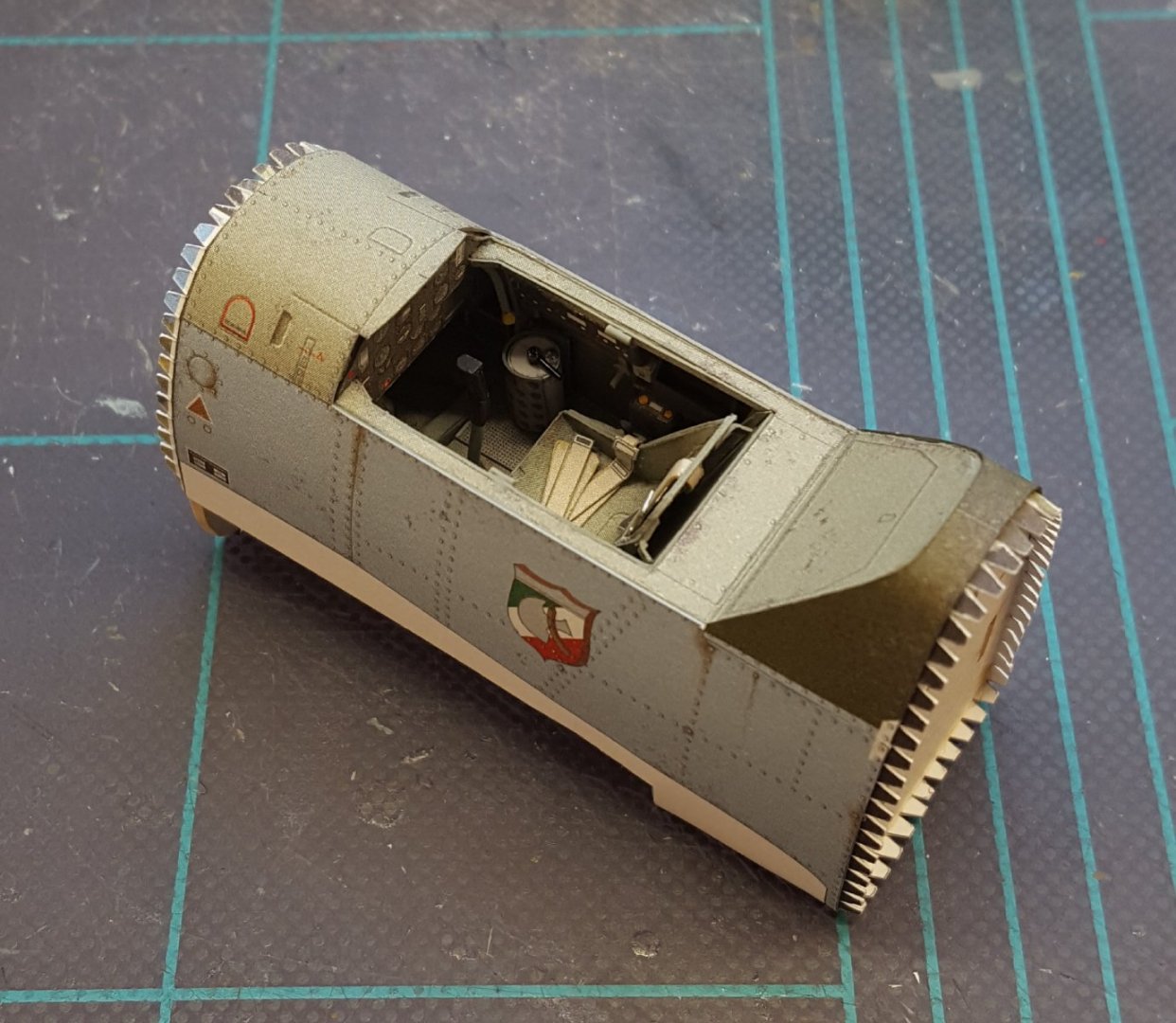

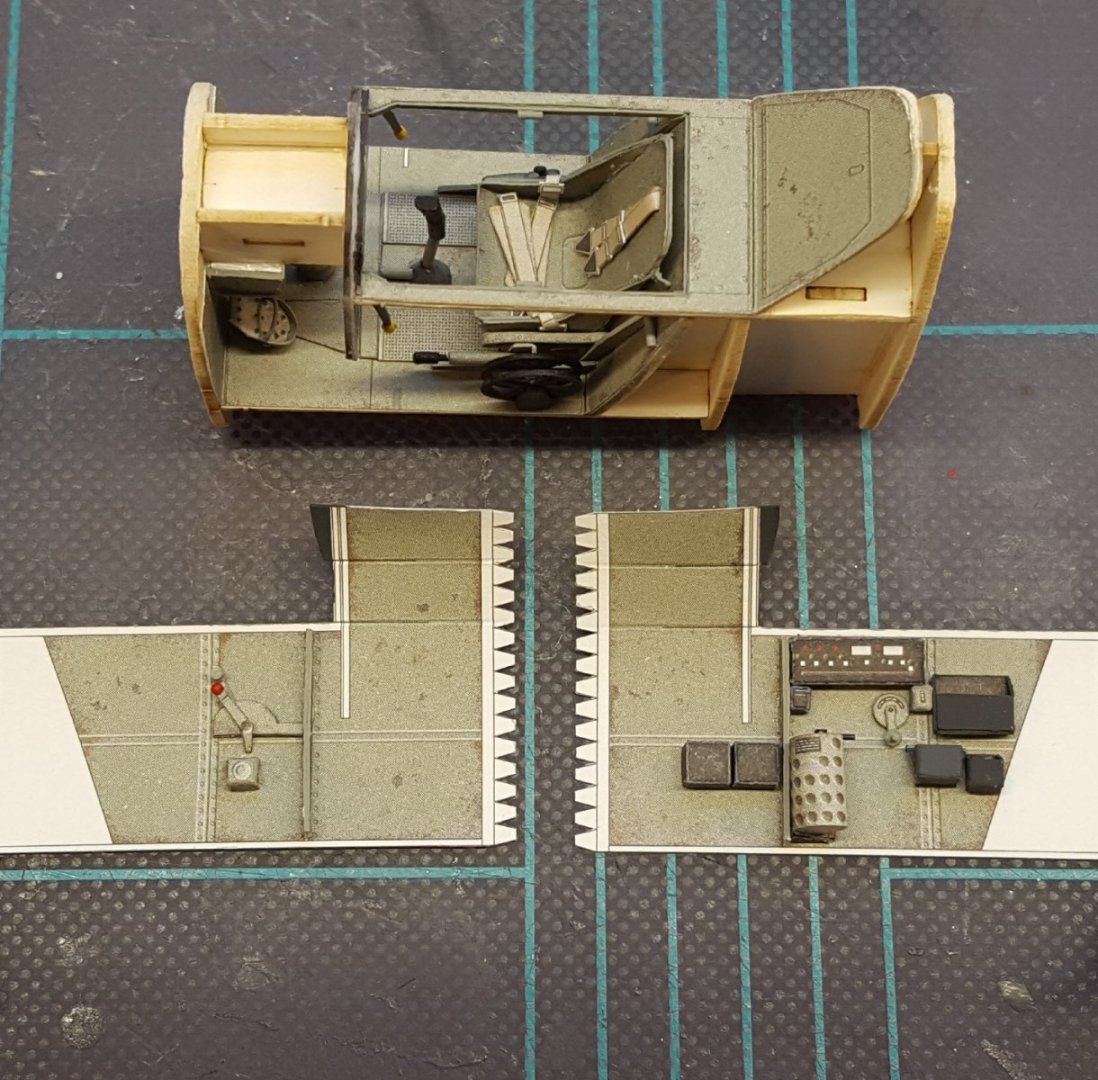

Take a good look -- this is the last time you'll be able to clearly see all of the cockpit elements before everything gets closed up. Port side on the left, starboard on the right. The disparity in the number of controls on the two sides makes me wonder whether the Luftwaffe chose only right-handed pilots for fighter pilot duty. 🤔

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.