-

Posts

10,459 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by ccoyle

-

Finnarctis was sailing under the name Alouette Arrow as of 2019.

-

Bristol Bulldog by Danstream - Airfix - 1/48 - PLASTIC

ccoyle replied to Danstream's topic in Non-ship/categorised builds

I have a similar issue with some of my card airplanes. After they've sat on a shelf for several months, I sometimes notice that the landing gear have sagged. I don't usually have much motivation to repair them. My modeling mojo tends to regard finished models with a bit of indifference. -

The answer to that question depends in large measure on what kinds of ships tickle your fancy. Men-of-war or merchantmen? Lots of rigging or little? Ancient or modern? Knowing what you like will help narrow the field of candidates.

-

Welcome aboard, and nice work!

-

I have a short list of kits that I would probably snap up if they were to be published by one of my favorite publishers or designers: Devastator, Corsair, Avenger, Swordfish, Dr.I, S.E. 5a, SPAD XIII, Albatros D.III/V. Most of these do exist in kit form, but they are either old kits with poor graphics, the work of designers I don't trust much, or electronic downloads (I prefer the offset-printed kits). Kartonowa Kolekcja just released a new kit, but it's a repaint, a Fokker D.VII in Polish markings that is almost entirely covered in lozenge camouflage. In the first place, I just built the original kit a few months ago, and secondly, instead of one of the many colorful D.VIIs that could have been published, we got lozenge. 😑 No, thanks. But -- we can only pick from what the publishers offer!

-

Welcome aboard, Gus!

-

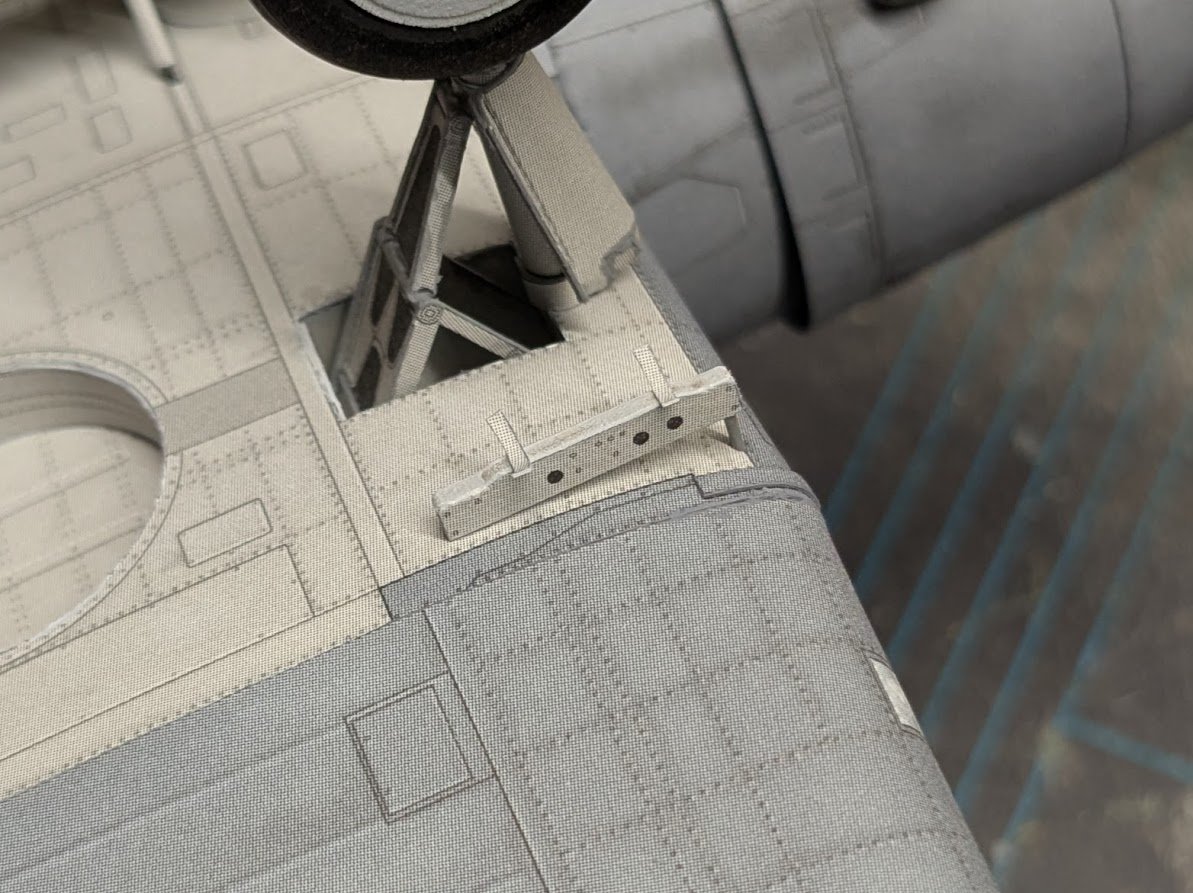

The Big Reveal! So, this one is officially done! Not much to say in conclusion except that this is another simply wonderful kit from Pawel Mistewicz and Kartonowa Kolekcja. The diagrams required some pondering here and there, but on the whole this was a relatively pain-free building experience -- a kit that can be heartily recommended without reservation. Enjoy the pictures!

-

I just found out this morning that NRG member David Okamura has passed away. You may not know of him, but if you have ever enjoyed any of the card model builds I have shared here at MSW, then you owe a small debt of gratitude to David -- he's the man who got me started in card modeling. I first met David at a meeting of the Ship Modelers Association (they met in Placentia, California) about twenty-five years ago. He was already a very skilled card modeler at the time, and when I saw his models at the club's show-and-tells, I said, "Wow, I can't believe that's made out of paper!" Sound familiar? David almost always had a new model or two to show at the meetings. He often did beta builds for designers, and if you had ever had the chance to admire his work, you would understand why those designers sought David's assistance. I decided I had to try a card model, too, and that was all it took to get me hooked. So, if any of my models have tempted you, or perhaps even persuaded you, to try a card model, it's partly thanks to David's having persuaded me to try one. Rest well, friend. David showing one of his models at a 2009 SMA meeting

-

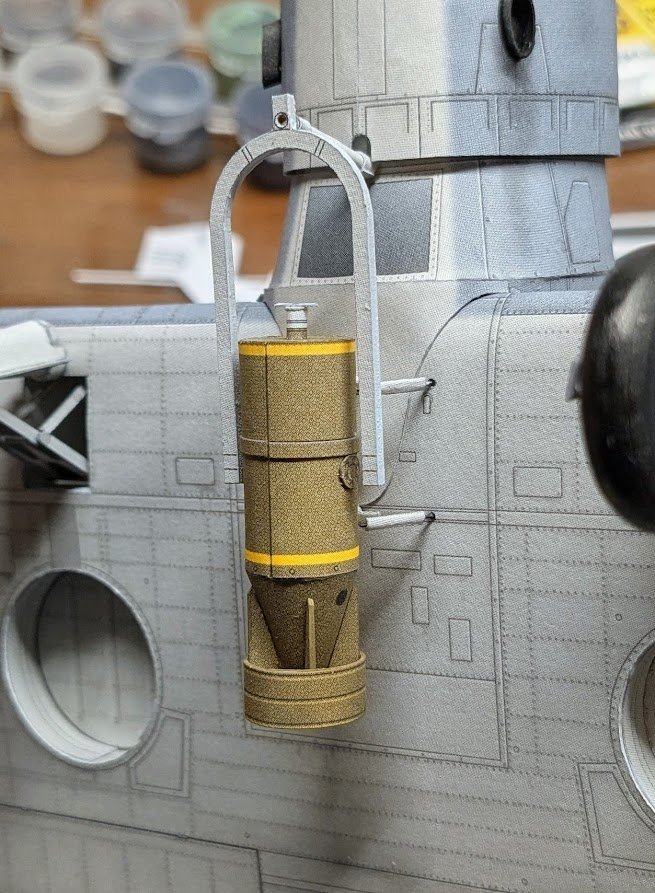

The shackles are simple card rectangles wrapped around lengths of wire. Only the center portion of the shackle is "load bearing" (if that is true in any real sense), i.e. the center piers are glued to the depth charge on one end and to the fuselage at the other end. The outer bits of the shackle are just cut to length and fitted afterward, held by spots of glue.

-

That is a pair of unique and well-executed models!

- 457 replies

-

- sternwheeler

- Hard Coal Navy

-

(and 1 more)

Tagged with:

-

Back in my CCC days, we were taught this same rule with regards to the off-highway logging trucks we encountered while driving around in our little Chevy S-10 pickups. It was all a simple matter of momentum. If one chanced upon an off-highway hauler while traversing a one-lane wooden trestle bridge with no guard rails, one backed off the bridge just as fast as humanly possible!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.