-

Posts

10,569 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by ccoyle

-

Congratulations on reaching the finish line!

- 110 replies

-

- san ildefonso

- occre

-

(and 1 more)

Tagged with:

-

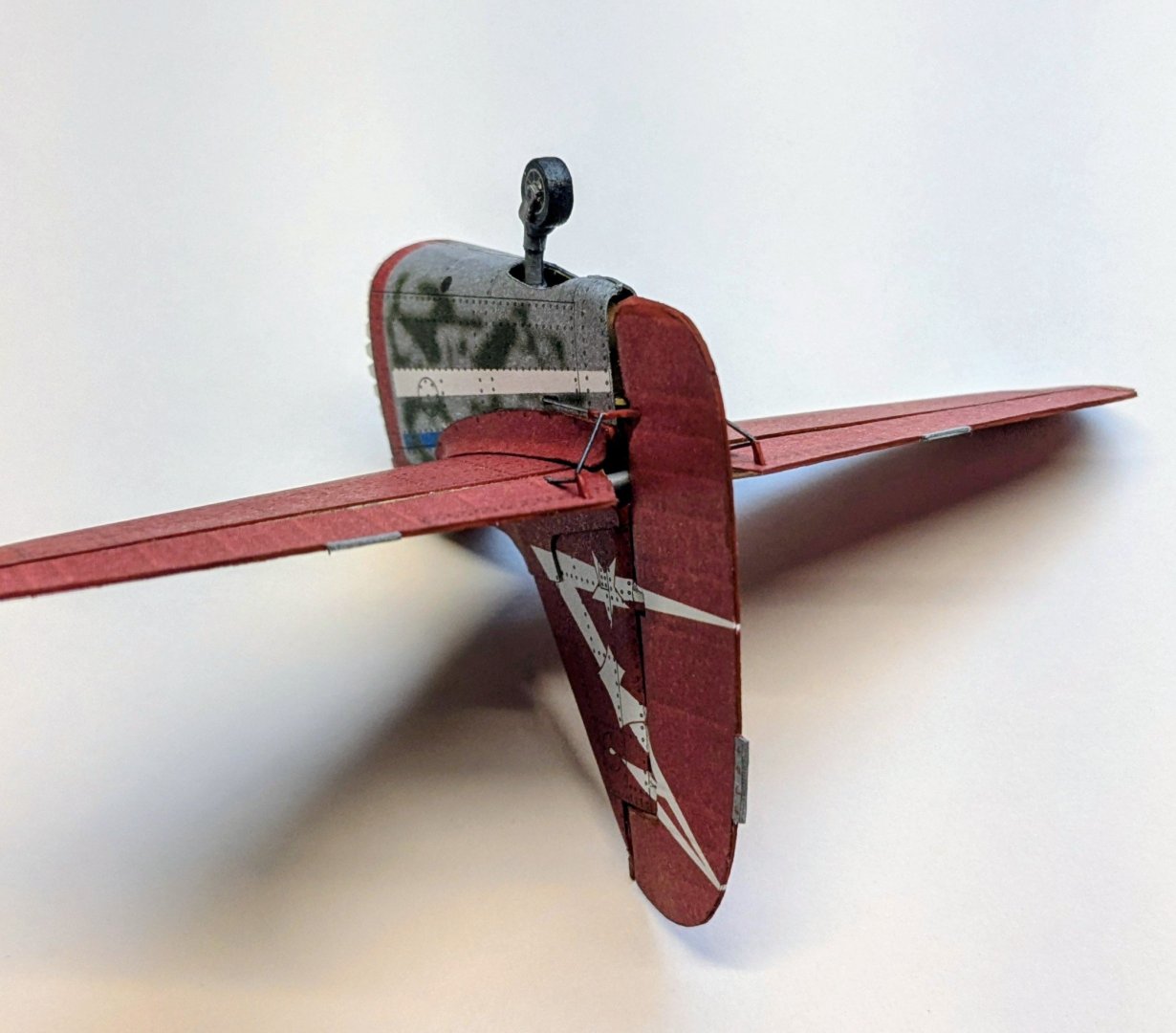

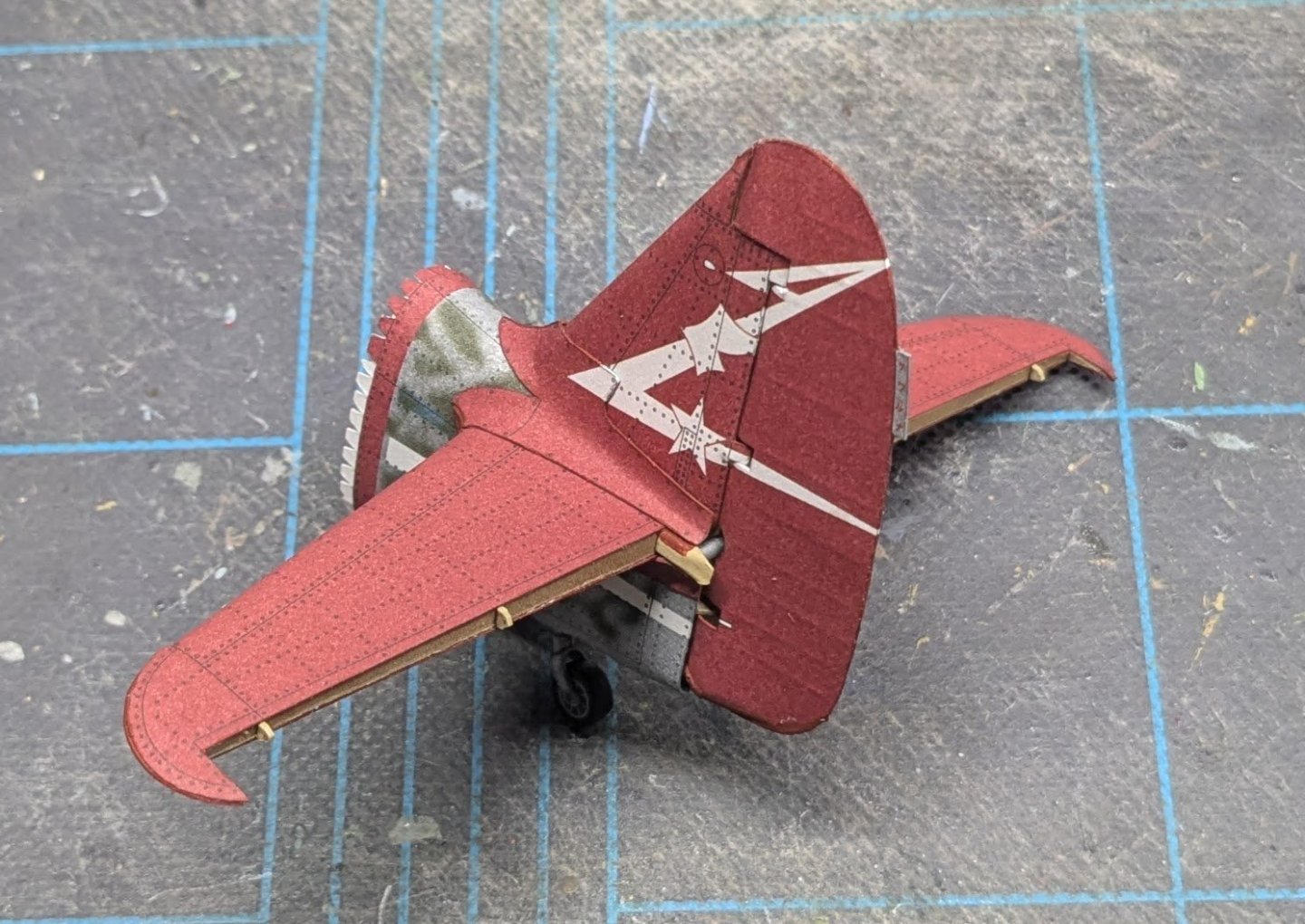

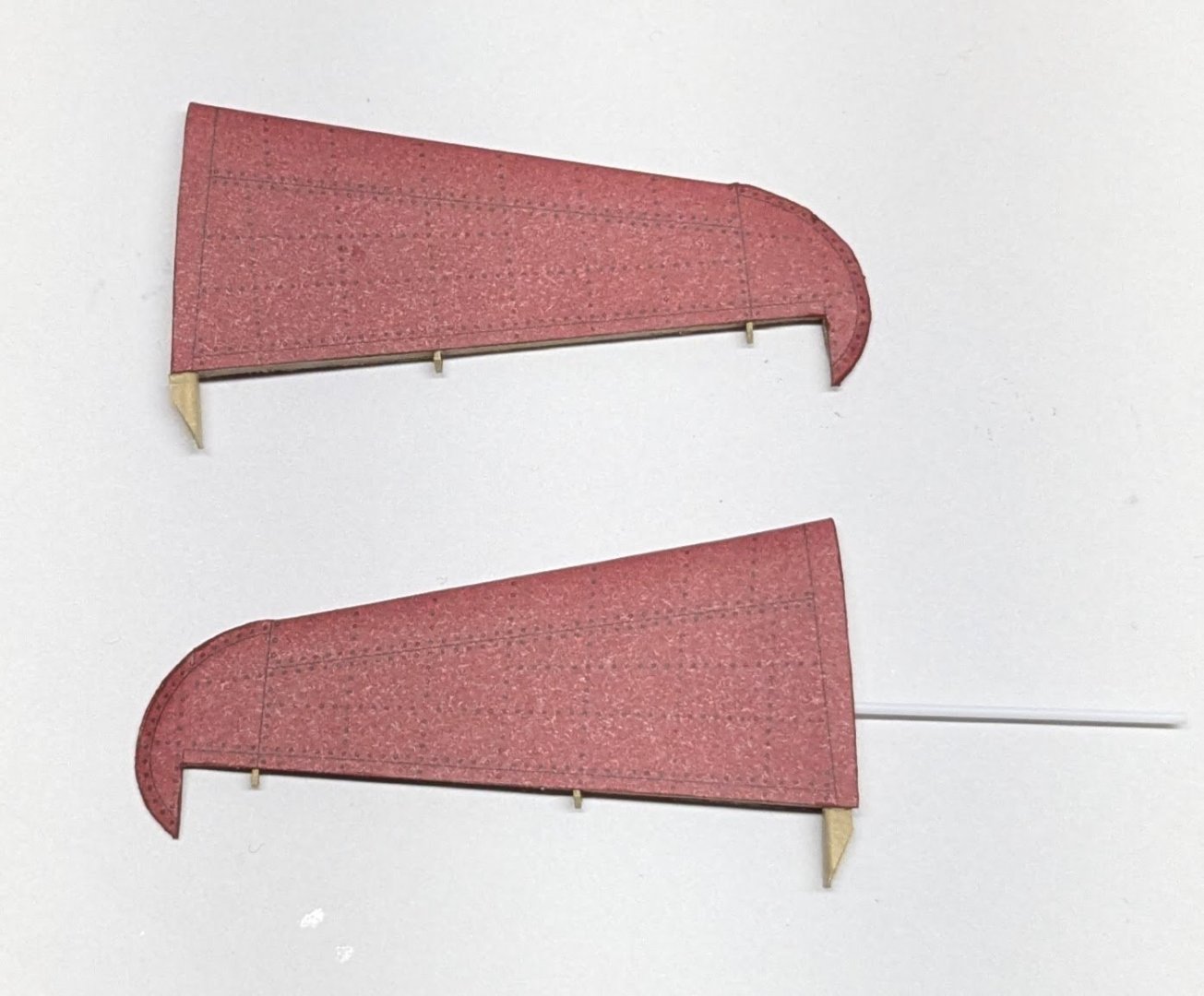

The empennage is complete. An odd thing on the Ki-61 is that the elevator and rudder actuators were linked; on the model this required six very small pieces of wire, along with the usual "special words" that such tiny parts invariably conjure. At least two attempts disappeared into the Carpet Monster.

-

Since it is manufactured under license, the name of the original manufacturer is appropriate. I have also tagged your log as a "first build" -- this just alerts members to modelers who can use that extra little bit of help and encouragement.

- 23 replies

-

- Lowell Grand Banks Dory

- Model Shipways

-

(and 1 more)

Tagged with:

-

Welcome aboard, Alexa! A couple of observations, based on your comments: Avoid kits on platforms like Amazon, eBay, AliExpress, etc., until you have become better acquainted with what's available out there. Especially avoid kits coming from China; this is not a blanket condemnation of all Chinese kits (some are quite good), but unfortunately for right now China is a hotbed of kits that are either of very poor quality (as you have experienced), are stolen intellectual property (quite commonplace -- see the list of banned manufacturers here) or both. Of course, you already have your next project in hand, so you can just file this recommendation away for future reference. You seem to have a very good command of English, so if you can get your hands on a copy, I highly recommend the book Ship Modeling Simplified by Frank Mastini (this item you can safely purchase from Amazon, and it is available in both print and digital formats). The book is a bit dated, but it is still a very good introduction to the world of wooden model ship kits. It will suggest solutions to many of the issues you listed. ALL of us have made mistakes on our models, even the masters of the craft! It's just part of the learning curve, so don't let any fear of mistakes paralyze you into inaction. It's a hobby, so enjoy it! Cheers!

-

Tell me you haven't tried a card model without telling me you haven't tried a card model. 😂 We take a dim view of such experts at this site. I have said this of myself many times. I feel no great urge to scratch-build something, although I greatly admire the artisanship of members who do. I just like to put things together. So, welcome aboard!

-

Welcome aboard!

-

Congratulations! There's nothing dishonorable about presenting your subject as a hull model -- this is a not uncommon stylistic choice. Cheers!

-

6 mm works out to a little over 11" in 1/48 scale -- I suspect this is too large for your model, but to be certain you'd need to get hold of the actual block sizes for Alma. That would take some digging.

- 48 replies

-

- San Francisco Bay Scow Schooner

- Scow Scooner

-

(and 1 more)

Tagged with:

-

Check BlueJacket, though theirs will be metal.

- 48 replies

-

- San Francisco Bay Scow Schooner

- Scow Scooner

-

(and 1 more)

Tagged with:

-

Understandable, but just know that the Syren blocks will not be period-correct -- if Alma is representative of the type, scow schooners were rigged with internally-stropped blocks.

- 48 replies

-

- San Francisco Bay Scow Schooner

- Scow Scooner

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.