-

Posts

3,523 -

Joined

-

Last visited

Reputation Activity

-

Cathead got a reaction from Sea Hoss in Arabia 1856 by Cathead - FINISHED - Scale 1:64 - sidewheel riverboat from the Missouri River, USA

Cathead got a reaction from Sea Hoss in Arabia 1856 by Cathead - FINISHED - Scale 1:64 - sidewheel riverboat from the Missouri River, USA

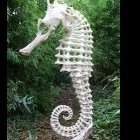

The Arabia as envisioned by artist Gary Lucy; used with permission of the Arabia Steamboat Museum

As a resident of rural Missouri, not far from its eponymous river, I've long been fascinated by the less-well-known steamboats that worked the “Big Muddy” from the river’s mouth at St. Louis all the way to the head of navigation at Fort Benton, Montana, an astounding 2,300 river miles. Most modern impressions of interior American steamboats are of the large, highly-decorated “floating wedding cake” craft of the lower Mississippi River, which represent a small fraction of the full diversity of steamboat design and use. Those craft are, to my eye, too gaudy by far, the equivalent of overbuilt Disney cruise liners; I don’t care for them, and I really don't care for the highly inaccurate and toylike models that most kits claim represent American riverboats. I prefer the smaller, leaner steamboats of the upper rivers, those designed to risk the rocky ledges of the Ohio River (such as the Chaperon) or fight their way up the narrow, shallow, ever-changing treacherous channels of the Missouri River. By the 1850s, their design had been nearly perfectly adapted to the unique conditions they faced, changing little for decades to come, until railroads finally cut them off at the knees. Two of the most well-known and well-documented steamboat wrecks from this period are the Bertrand (a sternwheeler that sank in 1865 and was rediscovered in 1968) and the Arabia (a sidewheeler that sank in 1856 and was rediscovered in 1988). Both boats now have excellent museums displaying their highly diverse and extraordinarily well-preserved cargo; the Bertrand at a wildlife refuge north of Omaha, Nebraska, and the Arabia at a museum in downtown Kansas City, Missouri.

I began researching the Arabia in earnest in spring 2017, writing about and documenting my research and sources for information in a separate thread, but am now ready to begin building the actual model. The text above is copied and rearranged from that thread, but I felt it provided an important introduction to this project and so should be repeated for those who may not go back and read the research thread. Although I am far from a master modeler, this will be my third scratchbuilt Missouri River steamboat. I built a rudimentary version of the Far West when I first became interested in wooden ship modeling, and later tackled a fully-framed and interior-detailed version of the Bertrand. Both of those were built in 1:87, a comfortable scale for me as a former HO model railroader.

However, for this project I wanted a new kind of challenge, so decided to build the Arabia in 1:64. The model will be around 32 inches (81 cm) long, allowing for more detail to be added overall. At the same time, though, I've decided not to recreate a fully-framed hull and interior as I did with Bertrand, for several reasons. First, that was a lot of work and material and would be even more expensive at 1:64, and I've already done that style now. Second, creating a framed model of Arabia would be both redundant and speculative; the museum preserves her stern intact for anyone to see, while the rest of the hull wasn't well-documented by the salvage team, so I'd be guessing more than I did with Bertrand (which was meticulously documented by an archeological team). Third, I just like the idea of a complete exterior model this time, trading a bit less interior detail for more focus on the overall appearance and higher detail allowed by the larger scale. Basically, this is just what I feel like doing this time, and doing a project the way you want to is part of what makes it engaging.

Although my initial plan was to develop a full set of blueprints for this project, that effort has stalled. It just isn't working for me to spend that much time on a computer, which I already do professionally as a freelance science editor. I'd rather spend my downtime working with wood than with pixels. So I stopped after developing a basic outline of the project and will just dive in, holding the design in my head and in various rough sketches and notes. This is, in fact, an authentic way to proceed, as riverboats in this era weren't built from printed blueprints either (one reason few construction records exist) but were simply laid out and built by artisans on the frontier shores of the Upper Ohio River. So any mistakes or quirks I may build into my Arabia as I proceed from the seat of my pants will be, at worst, a tribute to the real vessel's construction.

Above are my loose outlines of her design. The real Arabia was about 170' long and 30' wide (hull, not including the wheels) and drew about 5'.

And the sketches from which I'm getting started. There is no definitive information on the shape of her hull, other than the stern-most portion, which I've based on photos and measurements I took at the museum. So for the rest I've adapted a representative hull profile for the era from Alan Bates' The Western River Steamboat Cyclopoedium. The wheel and its supporting cylinder timbers are drawn directly from measurements I took at the museum. Centered within these drawings is the central internal bulkhead/keel I've laid out. These riverboats didn't have external keels the way normal ships did; their bottoms were generally perfectly flat with a stronger internal keelson instead. In this case, I'll be laying out horizontal bulkheads against this longitudinal one, just like a regular plank-on-bulkhead build. Hopefully now that I've laid the keel, so to speak, I can keep progress coming steadily. Thanks for reading, and for offering any ideas, suggestions, and criticisms that come to mind. I'd sure appreciate it if anyone points out concerns or problems that I can either explain or correct as I go along, as again I'm not a master modeler, just an ambitious one.

Table of Contents

Below I link to posts starting various portions of the build. This is intended to help folks looking for information on specific aspects of steamboats or their modelling, or just those wanting to catch up on a certain section. I'll try to keep this updated as I go along.

Framing the hull Guards and main deck framing Planking the hull Cylinder timbers & engines Planking the main deck Paddle wheels Boilers Main staircase & chimney breechings Framing the boiler deck & superstructure design Boiler pumps & other main deck details

-

Cathead reacted to semorebutts in Bismarck by Semorebutts - FINISHED - Trumpeter - 1/200 scale - PLASTIC - with MK1 detail set

Cathead reacted to semorebutts in Bismarck by Semorebutts - FINISHED - Trumpeter - 1/200 scale - PLASTIC - with MK1 detail set

I have delayed it long enough. Its time to paint.

-

Cathead reacted to semorebutts in Bismarck by Semorebutts - FINISHED - Trumpeter - 1/200 scale - PLASTIC - with MK1 detail set

Cathead reacted to semorebutts in Bismarck by Semorebutts - FINISHED - Trumpeter - 1/200 scale - PLASTIC - with MK1 detail set

RGL I thought about it but I would just make a mess 😬

Thats alot of deck fittings. ALOT of airbrushing and weathering/washing coming soon😕

-

Cathead reacted to Jim Lad in Arabia 1856 by Cathead - FINISHED - Scale 1:64 - sidewheel riverboat from the Missouri River, USA

Cathead reacted to Jim Lad in Arabia 1856 by Cathead - FINISHED - Scale 1:64 - sidewheel riverboat from the Missouri River, USA

That's a nice, workmanlike paddle wheeler - very different to our river boats down here. I'll be keen to see your progress.

John

-

Cathead got a reaction from hollowneck in Schooner Polotsk 1777 by Mike Y and his daughter - Master Korabel - 1:72

Cathead got a reaction from hollowneck in Schooner Polotsk 1777 by Mike Y and his daughter - Master Korabel - 1:72

Daria,

Mrs. Cathead (who is a scientist) thinks it's fantastic that you're interested and engaged in such things, as do I! I've been sharing all your updates and photos with her. There isn't much in the nautical way out here in the central US, so I quite envy you the chance to work on such a Viking ship (especially as someone of Norwegian descent).

-

Cathead reacted to kurtvd19 in Arabia 1856 by Cathead - FINISHED - Scale 1:64 - sidewheel riverboat from the Missouri River, USA

Cathead reacted to kurtvd19 in Arabia 1856 by Cathead - FINISHED - Scale 1:64 - sidewheel riverboat from the Missouri River, USA

Vossey:

Go to the link below where Eric has a bunch of photos from the Museum and general info on the Arabia. I will post photos here IF I get there - sometimes the best laid plans.....

Kurt

-

Cathead reacted to amateur in Arabia 1856 by Cathead - FINISHED - Scale 1:64 - sidewheel riverboat from the Missouri River, USA

Cathead reacted to amateur in Arabia 1856 by Cathead - FINISHED - Scale 1:64 - sidewheel riverboat from the Missouri River, USA

Interesting build. Will definitely follow thisone!

jan

-

Cathead got a reaction from popeye the sailor in Arabia 1856 by Cathead - FINISHED - Scale 1:64 - sidewheel riverboat from the Missouri River, USA

Cathead got a reaction from popeye the sailor in Arabia 1856 by Cathead - FINISHED - Scale 1:64 - sidewheel riverboat from the Missouri River, USA

That'll be a fun trip for sure. The museum hasn't changed that much overall but they have a lot more items from the cargo on display now. If you want company, I might be able to join you. We live a few hours away and it'd be fun to visit the museum together.

-

Cathead got a reaction from druxey in Arabia 1856 by Cathead - FINISHED - Scale 1:64 - sidewheel riverboat from the Missouri River, USA

Cathead got a reaction from druxey in Arabia 1856 by Cathead - FINISHED - Scale 1:64 - sidewheel riverboat from the Missouri River, USA

The Arabia as envisioned by artist Gary Lucy; used with permission of the Arabia Steamboat Museum

As a resident of rural Missouri, not far from its eponymous river, I've long been fascinated by the less-well-known steamboats that worked the “Big Muddy” from the river’s mouth at St. Louis all the way to the head of navigation at Fort Benton, Montana, an astounding 2,300 river miles. Most modern impressions of interior American steamboats are of the large, highly-decorated “floating wedding cake” craft of the lower Mississippi River, which represent a small fraction of the full diversity of steamboat design and use. Those craft are, to my eye, too gaudy by far, the equivalent of overbuilt Disney cruise liners; I don’t care for them, and I really don't care for the highly inaccurate and toylike models that most kits claim represent American riverboats. I prefer the smaller, leaner steamboats of the upper rivers, those designed to risk the rocky ledges of the Ohio River (such as the Chaperon) or fight their way up the narrow, shallow, ever-changing treacherous channels of the Missouri River. By the 1850s, their design had been nearly perfectly adapted to the unique conditions they faced, changing little for decades to come, until railroads finally cut them off at the knees. Two of the most well-known and well-documented steamboat wrecks from this period are the Bertrand (a sternwheeler that sank in 1865 and was rediscovered in 1968) and the Arabia (a sidewheeler that sank in 1856 and was rediscovered in 1988). Both boats now have excellent museums displaying their highly diverse and extraordinarily well-preserved cargo; the Bertrand at a wildlife refuge north of Omaha, Nebraska, and the Arabia at a museum in downtown Kansas City, Missouri.

I began researching the Arabia in earnest in spring 2017, writing about and documenting my research and sources for information in a separate thread, but am now ready to begin building the actual model. The text above is copied and rearranged from that thread, but I felt it provided an important introduction to this project and so should be repeated for those who may not go back and read the research thread. Although I am far from a master modeler, this will be my third scratchbuilt Missouri River steamboat. I built a rudimentary version of the Far West when I first became interested in wooden ship modeling, and later tackled a fully-framed and interior-detailed version of the Bertrand. Both of those were built in 1:87, a comfortable scale for me as a former HO model railroader.

However, for this project I wanted a new kind of challenge, so decided to build the Arabia in 1:64. The model will be around 32 inches (81 cm) long, allowing for more detail to be added overall. At the same time, though, I've decided not to recreate a fully-framed hull and interior as I did with Bertrand, for several reasons. First, that was a lot of work and material and would be even more expensive at 1:64, and I've already done that style now. Second, creating a framed model of Arabia would be both redundant and speculative; the museum preserves her stern intact for anyone to see, while the rest of the hull wasn't well-documented by the salvage team, so I'd be guessing more than I did with Bertrand (which was meticulously documented by an archeological team). Third, I just like the idea of a complete exterior model this time, trading a bit less interior detail for more focus on the overall appearance and higher detail allowed by the larger scale. Basically, this is just what I feel like doing this time, and doing a project the way you want to is part of what makes it engaging.

Although my initial plan was to develop a full set of blueprints for this project, that effort has stalled. It just isn't working for me to spend that much time on a computer, which I already do professionally as a freelance science editor. I'd rather spend my downtime working with wood than with pixels. So I stopped after developing a basic outline of the project and will just dive in, holding the design in my head and in various rough sketches and notes. This is, in fact, an authentic way to proceed, as riverboats in this era weren't built from printed blueprints either (one reason few construction records exist) but were simply laid out and built by artisans on the frontier shores of the Upper Ohio River. So any mistakes or quirks I may build into my Arabia as I proceed from the seat of my pants will be, at worst, a tribute to the real vessel's construction.

Above are my loose outlines of her design. The real Arabia was about 170' long and 30' wide (hull, not including the wheels) and drew about 5'.

And the sketches from which I'm getting started. There is no definitive information on the shape of her hull, other than the stern-most portion, which I've based on photos and measurements I took at the museum. So for the rest I've adapted a representative hull profile for the era from Alan Bates' The Western River Steamboat Cyclopoedium. The wheel and its supporting cylinder timbers are drawn directly from measurements I took at the museum. Centered within these drawings is the central internal bulkhead/keel I've laid out. These riverboats didn't have external keels the way normal ships did; their bottoms were generally perfectly flat with a stronger internal keelson instead. In this case, I'll be laying out horizontal bulkheads against this longitudinal one, just like a regular plank-on-bulkhead build. Hopefully now that I've laid the keel, so to speak, I can keep progress coming steadily. Thanks for reading, and for offering any ideas, suggestions, and criticisms that come to mind. I'd sure appreciate it if anyone points out concerns or problems that I can either explain or correct as I go along, as again I'm not a master modeler, just an ambitious one.

Table of Contents

Below I link to posts starting various portions of the build. This is intended to help folks looking for information on specific aspects of steamboats or their modelling, or just those wanting to catch up on a certain section. I'll try to keep this updated as I go along.

Framing the hull Guards and main deck framing Planking the hull Cylinder timbers & engines Planking the main deck Paddle wheels Boilers Main staircase & chimney breechings Framing the boiler deck & superstructure design Boiler pumps & other main deck details

-

Cathead got a reaction from Canute in Arabia 1856 by Cathead - FINISHED - Scale 1:64 - sidewheel riverboat from the Missouri River, USA

Cathead got a reaction from Canute in Arabia 1856 by Cathead - FINISHED - Scale 1:64 - sidewheel riverboat from the Missouri River, USA

That'll be a fun trip for sure. The museum hasn't changed that much overall but they have a lot more items from the cargo on display now. If you want company, I might be able to join you. We live a few hours away and it'd be fun to visit the museum together.

-

Cathead got a reaction from popeye the sailor in Arabia 1856 by Cathead - FINISHED - Scale 1:64 - sidewheel riverboat from the Missouri River, USA

Cathead got a reaction from popeye the sailor in Arabia 1856 by Cathead - FINISHED - Scale 1:64 - sidewheel riverboat from the Missouri River, USA

The Arabia as envisioned by artist Gary Lucy; used with permission of the Arabia Steamboat Museum

As a resident of rural Missouri, not far from its eponymous river, I've long been fascinated by the less-well-known steamboats that worked the “Big Muddy” from the river’s mouth at St. Louis all the way to the head of navigation at Fort Benton, Montana, an astounding 2,300 river miles. Most modern impressions of interior American steamboats are of the large, highly-decorated “floating wedding cake” craft of the lower Mississippi River, which represent a small fraction of the full diversity of steamboat design and use. Those craft are, to my eye, too gaudy by far, the equivalent of overbuilt Disney cruise liners; I don’t care for them, and I really don't care for the highly inaccurate and toylike models that most kits claim represent American riverboats. I prefer the smaller, leaner steamboats of the upper rivers, those designed to risk the rocky ledges of the Ohio River (such as the Chaperon) or fight their way up the narrow, shallow, ever-changing treacherous channels of the Missouri River. By the 1850s, their design had been nearly perfectly adapted to the unique conditions they faced, changing little for decades to come, until railroads finally cut them off at the knees. Two of the most well-known and well-documented steamboat wrecks from this period are the Bertrand (a sternwheeler that sank in 1865 and was rediscovered in 1968) and the Arabia (a sidewheeler that sank in 1856 and was rediscovered in 1988). Both boats now have excellent museums displaying their highly diverse and extraordinarily well-preserved cargo; the Bertrand at a wildlife refuge north of Omaha, Nebraska, and the Arabia at a museum in downtown Kansas City, Missouri.

I began researching the Arabia in earnest in spring 2017, writing about and documenting my research and sources for information in a separate thread, but am now ready to begin building the actual model. The text above is copied and rearranged from that thread, but I felt it provided an important introduction to this project and so should be repeated for those who may not go back and read the research thread. Although I am far from a master modeler, this will be my third scratchbuilt Missouri River steamboat. I built a rudimentary version of the Far West when I first became interested in wooden ship modeling, and later tackled a fully-framed and interior-detailed version of the Bertrand. Both of those were built in 1:87, a comfortable scale for me as a former HO model railroader.

However, for this project I wanted a new kind of challenge, so decided to build the Arabia in 1:64. The model will be around 32 inches (81 cm) long, allowing for more detail to be added overall. At the same time, though, I've decided not to recreate a fully-framed hull and interior as I did with Bertrand, for several reasons. First, that was a lot of work and material and would be even more expensive at 1:64, and I've already done that style now. Second, creating a framed model of Arabia would be both redundant and speculative; the museum preserves her stern intact for anyone to see, while the rest of the hull wasn't well-documented by the salvage team, so I'd be guessing more than I did with Bertrand (which was meticulously documented by an archeological team). Third, I just like the idea of a complete exterior model this time, trading a bit less interior detail for more focus on the overall appearance and higher detail allowed by the larger scale. Basically, this is just what I feel like doing this time, and doing a project the way you want to is part of what makes it engaging.

Although my initial plan was to develop a full set of blueprints for this project, that effort has stalled. It just isn't working for me to spend that much time on a computer, which I already do professionally as a freelance science editor. I'd rather spend my downtime working with wood than with pixels. So I stopped after developing a basic outline of the project and will just dive in, holding the design in my head and in various rough sketches and notes. This is, in fact, an authentic way to proceed, as riverboats in this era weren't built from printed blueprints either (one reason few construction records exist) but were simply laid out and built by artisans on the frontier shores of the Upper Ohio River. So any mistakes or quirks I may build into my Arabia as I proceed from the seat of my pants will be, at worst, a tribute to the real vessel's construction.

Above are my loose outlines of her design. The real Arabia was about 170' long and 30' wide (hull, not including the wheels) and drew about 5'.

And the sketches from which I'm getting started. There is no definitive information on the shape of her hull, other than the stern-most portion, which I've based on photos and measurements I took at the museum. So for the rest I've adapted a representative hull profile for the era from Alan Bates' The Western River Steamboat Cyclopoedium. The wheel and its supporting cylinder timbers are drawn directly from measurements I took at the museum. Centered within these drawings is the central internal bulkhead/keel I've laid out. These riverboats didn't have external keels the way normal ships did; their bottoms were generally perfectly flat with a stronger internal keelson instead. In this case, I'll be laying out horizontal bulkheads against this longitudinal one, just like a regular plank-on-bulkhead build. Hopefully now that I've laid the keel, so to speak, I can keep progress coming steadily. Thanks for reading, and for offering any ideas, suggestions, and criticisms that come to mind. I'd sure appreciate it if anyone points out concerns or problems that I can either explain or correct as I go along, as again I'm not a master modeler, just an ambitious one.

Table of Contents

Below I link to posts starting various portions of the build. This is intended to help folks looking for information on specific aspects of steamboats or their modelling, or just those wanting to catch up on a certain section. I'll try to keep this updated as I go along.

Framing the hull Guards and main deck framing Planking the hull Cylinder timbers & engines Planking the main deck Paddle wheels Boilers Main staircase & chimney breechings Framing the boiler deck & superstructure design Boiler pumps & other main deck details

-

Cathead reacted to kurtvd19 in Arabia 1856 by Cathead - FINISHED - Scale 1:64 - sidewheel riverboat from the Missouri River, USA

Cathead reacted to kurtvd19 in Arabia 1856 by Cathead - FINISHED - Scale 1:64 - sidewheel riverboat from the Missouri River, USA

Eric:

I'm on board. The Arabia is a fascinating story. I'm planning a spring trip to KC to see the museum again - last saw it the year they opened.

Kurt

-

Cathead got a reaction from ScottRC in Arabia 1856 by Cathead - FINISHED - Scale 1:64 - sidewheel riverboat from the Missouri River, USA

Cathead got a reaction from ScottRC in Arabia 1856 by Cathead - FINISHED - Scale 1:64 - sidewheel riverboat from the Missouri River, USA

The Arabia as envisioned by artist Gary Lucy; used with permission of the Arabia Steamboat Museum

As a resident of rural Missouri, not far from its eponymous river, I've long been fascinated by the less-well-known steamboats that worked the “Big Muddy” from the river’s mouth at St. Louis all the way to the head of navigation at Fort Benton, Montana, an astounding 2,300 river miles. Most modern impressions of interior American steamboats are of the large, highly-decorated “floating wedding cake” craft of the lower Mississippi River, which represent a small fraction of the full diversity of steamboat design and use. Those craft are, to my eye, too gaudy by far, the equivalent of overbuilt Disney cruise liners; I don’t care for them, and I really don't care for the highly inaccurate and toylike models that most kits claim represent American riverboats. I prefer the smaller, leaner steamboats of the upper rivers, those designed to risk the rocky ledges of the Ohio River (such as the Chaperon) or fight their way up the narrow, shallow, ever-changing treacherous channels of the Missouri River. By the 1850s, their design had been nearly perfectly adapted to the unique conditions they faced, changing little for decades to come, until railroads finally cut them off at the knees. Two of the most well-known and well-documented steamboat wrecks from this period are the Bertrand (a sternwheeler that sank in 1865 and was rediscovered in 1968) and the Arabia (a sidewheeler that sank in 1856 and was rediscovered in 1988). Both boats now have excellent museums displaying their highly diverse and extraordinarily well-preserved cargo; the Bertrand at a wildlife refuge north of Omaha, Nebraska, and the Arabia at a museum in downtown Kansas City, Missouri.

I began researching the Arabia in earnest in spring 2017, writing about and documenting my research and sources for information in a separate thread, but am now ready to begin building the actual model. The text above is copied and rearranged from that thread, but I felt it provided an important introduction to this project and so should be repeated for those who may not go back and read the research thread. Although I am far from a master modeler, this will be my third scratchbuilt Missouri River steamboat. I built a rudimentary version of the Far West when I first became interested in wooden ship modeling, and later tackled a fully-framed and interior-detailed version of the Bertrand. Both of those were built in 1:87, a comfortable scale for me as a former HO model railroader.

However, for this project I wanted a new kind of challenge, so decided to build the Arabia in 1:64. The model will be around 32 inches (81 cm) long, allowing for more detail to be added overall. At the same time, though, I've decided not to recreate a fully-framed hull and interior as I did with Bertrand, for several reasons. First, that was a lot of work and material and would be even more expensive at 1:64, and I've already done that style now. Second, creating a framed model of Arabia would be both redundant and speculative; the museum preserves her stern intact for anyone to see, while the rest of the hull wasn't well-documented by the salvage team, so I'd be guessing more than I did with Bertrand (which was meticulously documented by an archeological team). Third, I just like the idea of a complete exterior model this time, trading a bit less interior detail for more focus on the overall appearance and higher detail allowed by the larger scale. Basically, this is just what I feel like doing this time, and doing a project the way you want to is part of what makes it engaging.

Although my initial plan was to develop a full set of blueprints for this project, that effort has stalled. It just isn't working for me to spend that much time on a computer, which I already do professionally as a freelance science editor. I'd rather spend my downtime working with wood than with pixels. So I stopped after developing a basic outline of the project and will just dive in, holding the design in my head and in various rough sketches and notes. This is, in fact, an authentic way to proceed, as riverboats in this era weren't built from printed blueprints either (one reason few construction records exist) but were simply laid out and built by artisans on the frontier shores of the Upper Ohio River. So any mistakes or quirks I may build into my Arabia as I proceed from the seat of my pants will be, at worst, a tribute to the real vessel's construction.

Above are my loose outlines of her design. The real Arabia was about 170' long and 30' wide (hull, not including the wheels) and drew about 5'.

And the sketches from which I'm getting started. There is no definitive information on the shape of her hull, other than the stern-most portion, which I've based on photos and measurements I took at the museum. So for the rest I've adapted a representative hull profile for the era from Alan Bates' The Western River Steamboat Cyclopoedium. The wheel and its supporting cylinder timbers are drawn directly from measurements I took at the museum. Centered within these drawings is the central internal bulkhead/keel I've laid out. These riverboats didn't have external keels the way normal ships did; their bottoms were generally perfectly flat with a stronger internal keelson instead. In this case, I'll be laying out horizontal bulkheads against this longitudinal one, just like a regular plank-on-bulkhead build. Hopefully now that I've laid the keel, so to speak, I can keep progress coming steadily. Thanks for reading, and for offering any ideas, suggestions, and criticisms that come to mind. I'd sure appreciate it if anyone points out concerns or problems that I can either explain or correct as I go along, as again I'm not a master modeler, just an ambitious one.

Table of Contents

Below I link to posts starting various portions of the build. This is intended to help folks looking for information on specific aspects of steamboats or their modelling, or just those wanting to catch up on a certain section. I'll try to keep this updated as I go along.

Framing the hull Guards and main deck framing Planking the hull Cylinder timbers & engines Planking the main deck Paddle wheels Boilers Main staircase & chimney breechings Framing the boiler deck & superstructure design Boiler pumps & other main deck details

-

Cathead reacted to Canute in Arabia 1856 by Cathead - FINISHED - Scale 1:64 - sidewheel riverboat from the Missouri River, USA

Cathead reacted to Canute in Arabia 1856 by Cathead - FINISHED - Scale 1:64 - sidewheel riverboat from the Missouri River, USA

Eric, being an ACW Brown Water Navy fan, I'm in, too. Will follow with interest.

-

Cathead reacted to mtaylor in Arabia 1856 by Cathead - FINISHED - Scale 1:64 - sidewheel riverboat from the Missouri River, USA

Cathead reacted to mtaylor in Arabia 1856 by Cathead - FINISHED - Scale 1:64 - sidewheel riverboat from the Missouri River, USA

Count me in. I find these boats and their history fascinating.

-

Cathead got a reaction from hexnut in Arabia 1856 by Cathead - FINISHED - Scale 1:64 - sidewheel riverboat from the Missouri River, USA

Cathead got a reaction from hexnut in Arabia 1856 by Cathead - FINISHED - Scale 1:64 - sidewheel riverboat from the Missouri River, USA

The Arabia as envisioned by artist Gary Lucy; used with permission of the Arabia Steamboat Museum

As a resident of rural Missouri, not far from its eponymous river, I've long been fascinated by the less-well-known steamboats that worked the “Big Muddy” from the river’s mouth at St. Louis all the way to the head of navigation at Fort Benton, Montana, an astounding 2,300 river miles. Most modern impressions of interior American steamboats are of the large, highly-decorated “floating wedding cake” craft of the lower Mississippi River, which represent a small fraction of the full diversity of steamboat design and use. Those craft are, to my eye, too gaudy by far, the equivalent of overbuilt Disney cruise liners; I don’t care for them, and I really don't care for the highly inaccurate and toylike models that most kits claim represent American riverboats. I prefer the smaller, leaner steamboats of the upper rivers, those designed to risk the rocky ledges of the Ohio River (such as the Chaperon) or fight their way up the narrow, shallow, ever-changing treacherous channels of the Missouri River. By the 1850s, their design had been nearly perfectly adapted to the unique conditions they faced, changing little for decades to come, until railroads finally cut them off at the knees. Two of the most well-known and well-documented steamboat wrecks from this period are the Bertrand (a sternwheeler that sank in 1865 and was rediscovered in 1968) and the Arabia (a sidewheeler that sank in 1856 and was rediscovered in 1988). Both boats now have excellent museums displaying their highly diverse and extraordinarily well-preserved cargo; the Bertrand at a wildlife refuge north of Omaha, Nebraska, and the Arabia at a museum in downtown Kansas City, Missouri.

I began researching the Arabia in earnest in spring 2017, writing about and documenting my research and sources for information in a separate thread, but am now ready to begin building the actual model. The text above is copied and rearranged from that thread, but I felt it provided an important introduction to this project and so should be repeated for those who may not go back and read the research thread. Although I am far from a master modeler, this will be my third scratchbuilt Missouri River steamboat. I built a rudimentary version of the Far West when I first became interested in wooden ship modeling, and later tackled a fully-framed and interior-detailed version of the Bertrand. Both of those were built in 1:87, a comfortable scale for me as a former HO model railroader.

However, for this project I wanted a new kind of challenge, so decided to build the Arabia in 1:64. The model will be around 32 inches (81 cm) long, allowing for more detail to be added overall. At the same time, though, I've decided not to recreate a fully-framed hull and interior as I did with Bertrand, for several reasons. First, that was a lot of work and material and would be even more expensive at 1:64, and I've already done that style now. Second, creating a framed model of Arabia would be both redundant and speculative; the museum preserves her stern intact for anyone to see, while the rest of the hull wasn't well-documented by the salvage team, so I'd be guessing more than I did with Bertrand (which was meticulously documented by an archeological team). Third, I just like the idea of a complete exterior model this time, trading a bit less interior detail for more focus on the overall appearance and higher detail allowed by the larger scale. Basically, this is just what I feel like doing this time, and doing a project the way you want to is part of what makes it engaging.

Although my initial plan was to develop a full set of blueprints for this project, that effort has stalled. It just isn't working for me to spend that much time on a computer, which I already do professionally as a freelance science editor. I'd rather spend my downtime working with wood than with pixels. So I stopped after developing a basic outline of the project and will just dive in, holding the design in my head and in various rough sketches and notes. This is, in fact, an authentic way to proceed, as riverboats in this era weren't built from printed blueprints either (one reason few construction records exist) but were simply laid out and built by artisans on the frontier shores of the Upper Ohio River. So any mistakes or quirks I may build into my Arabia as I proceed from the seat of my pants will be, at worst, a tribute to the real vessel's construction.

Above are my loose outlines of her design. The real Arabia was about 170' long and 30' wide (hull, not including the wheels) and drew about 5'.

And the sketches from which I'm getting started. There is no definitive information on the shape of her hull, other than the stern-most portion, which I've based on photos and measurements I took at the museum. So for the rest I've adapted a representative hull profile for the era from Alan Bates' The Western River Steamboat Cyclopoedium. The wheel and its supporting cylinder timbers are drawn directly from measurements I took at the museum. Centered within these drawings is the central internal bulkhead/keel I've laid out. These riverboats didn't have external keels the way normal ships did; their bottoms were generally perfectly flat with a stronger internal keelson instead. In this case, I'll be laying out horizontal bulkheads against this longitudinal one, just like a regular plank-on-bulkhead build. Hopefully now that I've laid the keel, so to speak, I can keep progress coming steadily. Thanks for reading, and for offering any ideas, suggestions, and criticisms that come to mind. I'd sure appreciate it if anyone points out concerns or problems that I can either explain or correct as I go along, as again I'm not a master modeler, just an ambitious one.

Table of Contents

Below I link to posts starting various portions of the build. This is intended to help folks looking for information on specific aspects of steamboats or their modelling, or just those wanting to catch up on a certain section. I'll try to keep this updated as I go along.

Framing the hull Guards and main deck framing Planking the hull Cylinder timbers & engines Planking the main deck Paddle wheels Boilers Main staircase & chimney breechings Framing the boiler deck & superstructure design Boiler pumps & other main deck details

-

Cathead got a reaction from kees de mol in Arabia 1856 by Cathead - FINISHED - Scale 1:64 - sidewheel riverboat from the Missouri River, USA

Cathead got a reaction from kees de mol in Arabia 1856 by Cathead - FINISHED - Scale 1:64 - sidewheel riverboat from the Missouri River, USA

The Arabia as envisioned by artist Gary Lucy; used with permission of the Arabia Steamboat Museum

As a resident of rural Missouri, not far from its eponymous river, I've long been fascinated by the less-well-known steamboats that worked the “Big Muddy” from the river’s mouth at St. Louis all the way to the head of navigation at Fort Benton, Montana, an astounding 2,300 river miles. Most modern impressions of interior American steamboats are of the large, highly-decorated “floating wedding cake” craft of the lower Mississippi River, which represent a small fraction of the full diversity of steamboat design and use. Those craft are, to my eye, too gaudy by far, the equivalent of overbuilt Disney cruise liners; I don’t care for them, and I really don't care for the highly inaccurate and toylike models that most kits claim represent American riverboats. I prefer the smaller, leaner steamboats of the upper rivers, those designed to risk the rocky ledges of the Ohio River (such as the Chaperon) or fight their way up the narrow, shallow, ever-changing treacherous channels of the Missouri River. By the 1850s, their design had been nearly perfectly adapted to the unique conditions they faced, changing little for decades to come, until railroads finally cut them off at the knees. Two of the most well-known and well-documented steamboat wrecks from this period are the Bertrand (a sternwheeler that sank in 1865 and was rediscovered in 1968) and the Arabia (a sidewheeler that sank in 1856 and was rediscovered in 1988). Both boats now have excellent museums displaying their highly diverse and extraordinarily well-preserved cargo; the Bertrand at a wildlife refuge north of Omaha, Nebraska, and the Arabia at a museum in downtown Kansas City, Missouri.

I began researching the Arabia in earnest in spring 2017, writing about and documenting my research and sources for information in a separate thread, but am now ready to begin building the actual model. The text above is copied and rearranged from that thread, but I felt it provided an important introduction to this project and so should be repeated for those who may not go back and read the research thread. Although I am far from a master modeler, this will be my third scratchbuilt Missouri River steamboat. I built a rudimentary version of the Far West when I first became interested in wooden ship modeling, and later tackled a fully-framed and interior-detailed version of the Bertrand. Both of those were built in 1:87, a comfortable scale for me as a former HO model railroader.

However, for this project I wanted a new kind of challenge, so decided to build the Arabia in 1:64. The model will be around 32 inches (81 cm) long, allowing for more detail to be added overall. At the same time, though, I've decided not to recreate a fully-framed hull and interior as I did with Bertrand, for several reasons. First, that was a lot of work and material and would be even more expensive at 1:64, and I've already done that style now. Second, creating a framed model of Arabia would be both redundant and speculative; the museum preserves her stern intact for anyone to see, while the rest of the hull wasn't well-documented by the salvage team, so I'd be guessing more than I did with Bertrand (which was meticulously documented by an archeological team). Third, I just like the idea of a complete exterior model this time, trading a bit less interior detail for more focus on the overall appearance and higher detail allowed by the larger scale. Basically, this is just what I feel like doing this time, and doing a project the way you want to is part of what makes it engaging.

Although my initial plan was to develop a full set of blueprints for this project, that effort has stalled. It just isn't working for me to spend that much time on a computer, which I already do professionally as a freelance science editor. I'd rather spend my downtime working with wood than with pixels. So I stopped after developing a basic outline of the project and will just dive in, holding the design in my head and in various rough sketches and notes. This is, in fact, an authentic way to proceed, as riverboats in this era weren't built from printed blueprints either (one reason few construction records exist) but were simply laid out and built by artisans on the frontier shores of the Upper Ohio River. So any mistakes or quirks I may build into my Arabia as I proceed from the seat of my pants will be, at worst, a tribute to the real vessel's construction.

Above are my loose outlines of her design. The real Arabia was about 170' long and 30' wide (hull, not including the wheels) and drew about 5'.

And the sketches from which I'm getting started. There is no definitive information on the shape of her hull, other than the stern-most portion, which I've based on photos and measurements I took at the museum. So for the rest I've adapted a representative hull profile for the era from Alan Bates' The Western River Steamboat Cyclopoedium. The wheel and its supporting cylinder timbers are drawn directly from measurements I took at the museum. Centered within these drawings is the central internal bulkhead/keel I've laid out. These riverboats didn't have external keels the way normal ships did; their bottoms were generally perfectly flat with a stronger internal keelson instead. In this case, I'll be laying out horizontal bulkheads against this longitudinal one, just like a regular plank-on-bulkhead build. Hopefully now that I've laid the keel, so to speak, I can keep progress coming steadily. Thanks for reading, and for offering any ideas, suggestions, and criticisms that come to mind. I'd sure appreciate it if anyone points out concerns or problems that I can either explain or correct as I go along, as again I'm not a master modeler, just an ambitious one.

Table of Contents

Below I link to posts starting various portions of the build. This is intended to help folks looking for information on specific aspects of steamboats or their modelling, or just those wanting to catch up on a certain section. I'll try to keep this updated as I go along.

Framing the hull Guards and main deck framing Planking the hull Cylinder timbers & engines Planking the main deck Paddle wheels Boilers Main staircase & chimney breechings Framing the boiler deck & superstructure design Boiler pumps & other main deck details

-

Cathead got a reaction from gjdale in Arabia 1856 by Cathead - FINISHED - Scale 1:64 - sidewheel riverboat from the Missouri River, USA

Cathead got a reaction from gjdale in Arabia 1856 by Cathead - FINISHED - Scale 1:64 - sidewheel riverboat from the Missouri River, USA

The Arabia as envisioned by artist Gary Lucy; used with permission of the Arabia Steamboat Museum

As a resident of rural Missouri, not far from its eponymous river, I've long been fascinated by the less-well-known steamboats that worked the “Big Muddy” from the river’s mouth at St. Louis all the way to the head of navigation at Fort Benton, Montana, an astounding 2,300 river miles. Most modern impressions of interior American steamboats are of the large, highly-decorated “floating wedding cake” craft of the lower Mississippi River, which represent a small fraction of the full diversity of steamboat design and use. Those craft are, to my eye, too gaudy by far, the equivalent of overbuilt Disney cruise liners; I don’t care for them, and I really don't care for the highly inaccurate and toylike models that most kits claim represent American riverboats. I prefer the smaller, leaner steamboats of the upper rivers, those designed to risk the rocky ledges of the Ohio River (such as the Chaperon) or fight their way up the narrow, shallow, ever-changing treacherous channels of the Missouri River. By the 1850s, their design had been nearly perfectly adapted to the unique conditions they faced, changing little for decades to come, until railroads finally cut them off at the knees. Two of the most well-known and well-documented steamboat wrecks from this period are the Bertrand (a sternwheeler that sank in 1865 and was rediscovered in 1968) and the Arabia (a sidewheeler that sank in 1856 and was rediscovered in 1988). Both boats now have excellent museums displaying their highly diverse and extraordinarily well-preserved cargo; the Bertrand at a wildlife refuge north of Omaha, Nebraska, and the Arabia at a museum in downtown Kansas City, Missouri.

I began researching the Arabia in earnest in spring 2017, writing about and documenting my research and sources for information in a separate thread, but am now ready to begin building the actual model. The text above is copied and rearranged from that thread, but I felt it provided an important introduction to this project and so should be repeated for those who may not go back and read the research thread. Although I am far from a master modeler, this will be my third scratchbuilt Missouri River steamboat. I built a rudimentary version of the Far West when I first became interested in wooden ship modeling, and later tackled a fully-framed and interior-detailed version of the Bertrand. Both of those were built in 1:87, a comfortable scale for me as a former HO model railroader.

However, for this project I wanted a new kind of challenge, so decided to build the Arabia in 1:64. The model will be around 32 inches (81 cm) long, allowing for more detail to be added overall. At the same time, though, I've decided not to recreate a fully-framed hull and interior as I did with Bertrand, for several reasons. First, that was a lot of work and material and would be even more expensive at 1:64, and I've already done that style now. Second, creating a framed model of Arabia would be both redundant and speculative; the museum preserves her stern intact for anyone to see, while the rest of the hull wasn't well-documented by the salvage team, so I'd be guessing more than I did with Bertrand (which was meticulously documented by an archeological team). Third, I just like the idea of a complete exterior model this time, trading a bit less interior detail for more focus on the overall appearance and higher detail allowed by the larger scale. Basically, this is just what I feel like doing this time, and doing a project the way you want to is part of what makes it engaging.

Although my initial plan was to develop a full set of blueprints for this project, that effort has stalled. It just isn't working for me to spend that much time on a computer, which I already do professionally as a freelance science editor. I'd rather spend my downtime working with wood than with pixels. So I stopped after developing a basic outline of the project and will just dive in, holding the design in my head and in various rough sketches and notes. This is, in fact, an authentic way to proceed, as riverboats in this era weren't built from printed blueprints either (one reason few construction records exist) but were simply laid out and built by artisans on the frontier shores of the Upper Ohio River. So any mistakes or quirks I may build into my Arabia as I proceed from the seat of my pants will be, at worst, a tribute to the real vessel's construction.

Above are my loose outlines of her design. The real Arabia was about 170' long and 30' wide (hull, not including the wheels) and drew about 5'.

And the sketches from which I'm getting started. There is no definitive information on the shape of her hull, other than the stern-most portion, which I've based on photos and measurements I took at the museum. So for the rest I've adapted a representative hull profile for the era from Alan Bates' The Western River Steamboat Cyclopoedium. The wheel and its supporting cylinder timbers are drawn directly from measurements I took at the museum. Centered within these drawings is the central internal bulkhead/keel I've laid out. These riverboats didn't have external keels the way normal ships did; their bottoms were generally perfectly flat with a stronger internal keelson instead. In this case, I'll be laying out horizontal bulkheads against this longitudinal one, just like a regular plank-on-bulkhead build. Hopefully now that I've laid the keel, so to speak, I can keep progress coming steadily. Thanks for reading, and for offering any ideas, suggestions, and criticisms that come to mind. I'd sure appreciate it if anyone points out concerns or problems that I can either explain or correct as I go along, as again I'm not a master modeler, just an ambitious one.

Table of Contents

Below I link to posts starting various portions of the build. This is intended to help folks looking for information on specific aspects of steamboats or their modelling, or just those wanting to catch up on a certain section. I'll try to keep this updated as I go along.

Framing the hull Guards and main deck framing Planking the hull Cylinder timbers & engines Planking the main deck Paddle wheels Boilers Main staircase & chimney breechings Framing the boiler deck & superstructure design Boiler pumps & other main deck details

-

Cathead got a reaction from popeye the sailor in L’Etoile by glennreader - FINISHED - Billing Boats - Scale 1:50 - Updated to represent her current fitting out

Cathead got a reaction from popeye the sailor in L’Etoile by glennreader - FINISHED - Billing Boats - Scale 1:50 - Updated to represent her current fitting out

Regarding the inflatable, I wonder if adding some seams would help with the realism, especially internally? It would break up the long run of smooth plastic and give some more visual interest. Looks nice, nonetheless

-

Cathead got a reaction from Dan Vadas in Arabia 1856 by Cathead - FINISHED - Scale 1:64 - sidewheel riverboat from the Missouri River, USA

Cathead got a reaction from Dan Vadas in Arabia 1856 by Cathead - FINISHED - Scale 1:64 - sidewheel riverboat from the Missouri River, USA

The Arabia as envisioned by artist Gary Lucy; used with permission of the Arabia Steamboat Museum

As a resident of rural Missouri, not far from its eponymous river, I've long been fascinated by the less-well-known steamboats that worked the “Big Muddy” from the river’s mouth at St. Louis all the way to the head of navigation at Fort Benton, Montana, an astounding 2,300 river miles. Most modern impressions of interior American steamboats are of the large, highly-decorated “floating wedding cake” craft of the lower Mississippi River, which represent a small fraction of the full diversity of steamboat design and use. Those craft are, to my eye, too gaudy by far, the equivalent of overbuilt Disney cruise liners; I don’t care for them, and I really don't care for the highly inaccurate and toylike models that most kits claim represent American riverboats. I prefer the smaller, leaner steamboats of the upper rivers, those designed to risk the rocky ledges of the Ohio River (such as the Chaperon) or fight their way up the narrow, shallow, ever-changing treacherous channels of the Missouri River. By the 1850s, their design had been nearly perfectly adapted to the unique conditions they faced, changing little for decades to come, until railroads finally cut them off at the knees. Two of the most well-known and well-documented steamboat wrecks from this period are the Bertrand (a sternwheeler that sank in 1865 and was rediscovered in 1968) and the Arabia (a sidewheeler that sank in 1856 and was rediscovered in 1988). Both boats now have excellent museums displaying their highly diverse and extraordinarily well-preserved cargo; the Bertrand at a wildlife refuge north of Omaha, Nebraska, and the Arabia at a museum in downtown Kansas City, Missouri.

I began researching the Arabia in earnest in spring 2017, writing about and documenting my research and sources for information in a separate thread, but am now ready to begin building the actual model. The text above is copied and rearranged from that thread, but I felt it provided an important introduction to this project and so should be repeated for those who may not go back and read the research thread. Although I am far from a master modeler, this will be my third scratchbuilt Missouri River steamboat. I built a rudimentary version of the Far West when I first became interested in wooden ship modeling, and later tackled a fully-framed and interior-detailed version of the Bertrand. Both of those were built in 1:87, a comfortable scale for me as a former HO model railroader.

However, for this project I wanted a new kind of challenge, so decided to build the Arabia in 1:64. The model will be around 32 inches (81 cm) long, allowing for more detail to be added overall. At the same time, though, I've decided not to recreate a fully-framed hull and interior as I did with Bertrand, for several reasons. First, that was a lot of work and material and would be even more expensive at 1:64, and I've already done that style now. Second, creating a framed model of Arabia would be both redundant and speculative; the museum preserves her stern intact for anyone to see, while the rest of the hull wasn't well-documented by the salvage team, so I'd be guessing more than I did with Bertrand (which was meticulously documented by an archeological team). Third, I just like the idea of a complete exterior model this time, trading a bit less interior detail for more focus on the overall appearance and higher detail allowed by the larger scale. Basically, this is just what I feel like doing this time, and doing a project the way you want to is part of what makes it engaging.

Although my initial plan was to develop a full set of blueprints for this project, that effort has stalled. It just isn't working for me to spend that much time on a computer, which I already do professionally as a freelance science editor. I'd rather spend my downtime working with wood than with pixels. So I stopped after developing a basic outline of the project and will just dive in, holding the design in my head and in various rough sketches and notes. This is, in fact, an authentic way to proceed, as riverboats in this era weren't built from printed blueprints either (one reason few construction records exist) but were simply laid out and built by artisans on the frontier shores of the Upper Ohio River. So any mistakes or quirks I may build into my Arabia as I proceed from the seat of my pants will be, at worst, a tribute to the real vessel's construction.

Above are my loose outlines of her design. The real Arabia was about 170' long and 30' wide (hull, not including the wheels) and drew about 5'.

And the sketches from which I'm getting started. There is no definitive information on the shape of her hull, other than the stern-most portion, which I've based on photos and measurements I took at the museum. So for the rest I've adapted a representative hull profile for the era from Alan Bates' The Western River Steamboat Cyclopoedium. The wheel and its supporting cylinder timbers are drawn directly from measurements I took at the museum. Centered within these drawings is the central internal bulkhead/keel I've laid out. These riverboats didn't have external keels the way normal ships did; their bottoms were generally perfectly flat with a stronger internal keelson instead. In this case, I'll be laying out horizontal bulkheads against this longitudinal one, just like a regular plank-on-bulkhead build. Hopefully now that I've laid the keel, so to speak, I can keep progress coming steadily. Thanks for reading, and for offering any ideas, suggestions, and criticisms that come to mind. I'd sure appreciate it if anyone points out concerns or problems that I can either explain or correct as I go along, as again I'm not a master modeler, just an ambitious one.

Table of Contents

Below I link to posts starting various portions of the build. This is intended to help folks looking for information on specific aspects of steamboats or their modelling, or just those wanting to catch up on a certain section. I'll try to keep this updated as I go along.

Framing the hull Guards and main deck framing Planking the hull Cylinder timbers & engines Planking the main deck Paddle wheels Boilers Main staircase & chimney breechings Framing the boiler deck & superstructure design Boiler pumps & other main deck details

-

Cathead reacted to semorebutts in Bismarck by Semorebutts - FINISHED - Trumpeter - 1/200 scale - PLASTIC - with MK1 detail set

Cathead reacted to semorebutts in Bismarck by Semorebutts - FINISHED - Trumpeter - 1/200 scale - PLASTIC - with MK1 detail set

Before and after weathering.

-

Cathead reacted to semorebutts in Bismarck by Semorebutts - FINISHED - Trumpeter - 1/200 scale - PLASTIC - with MK1 detail set

Cathead reacted to semorebutts in Bismarck by Semorebutts - FINISHED - Trumpeter - 1/200 scale - PLASTIC - with MK1 detail set

2 guns. I still have to weather the guns and searchlights.

-

Cathead got a reaction from shipmodel in Arabia 1856 by Cathead - FINISHED - Scale 1:64 - sidewheel riverboat from the Missouri River, USA

Cathead got a reaction from shipmodel in Arabia 1856 by Cathead - FINISHED - Scale 1:64 - sidewheel riverboat from the Missouri River, USA

The Arabia as envisioned by artist Gary Lucy; used with permission of the Arabia Steamboat Museum

As a resident of rural Missouri, not far from its eponymous river, I've long been fascinated by the less-well-known steamboats that worked the “Big Muddy” from the river’s mouth at St. Louis all the way to the head of navigation at Fort Benton, Montana, an astounding 2,300 river miles. Most modern impressions of interior American steamboats are of the large, highly-decorated “floating wedding cake” craft of the lower Mississippi River, which represent a small fraction of the full diversity of steamboat design and use. Those craft are, to my eye, too gaudy by far, the equivalent of overbuilt Disney cruise liners; I don’t care for them, and I really don't care for the highly inaccurate and toylike models that most kits claim represent American riverboats. I prefer the smaller, leaner steamboats of the upper rivers, those designed to risk the rocky ledges of the Ohio River (such as the Chaperon) or fight their way up the narrow, shallow, ever-changing treacherous channels of the Missouri River. By the 1850s, their design had been nearly perfectly adapted to the unique conditions they faced, changing little for decades to come, until railroads finally cut them off at the knees. Two of the most well-known and well-documented steamboat wrecks from this period are the Bertrand (a sternwheeler that sank in 1865 and was rediscovered in 1968) and the Arabia (a sidewheeler that sank in 1856 and was rediscovered in 1988). Both boats now have excellent museums displaying their highly diverse and extraordinarily well-preserved cargo; the Bertrand at a wildlife refuge north of Omaha, Nebraska, and the Arabia at a museum in downtown Kansas City, Missouri.

I began researching the Arabia in earnest in spring 2017, writing about and documenting my research and sources for information in a separate thread, but am now ready to begin building the actual model. The text above is copied and rearranged from that thread, but I felt it provided an important introduction to this project and so should be repeated for those who may not go back and read the research thread. Although I am far from a master modeler, this will be my third scratchbuilt Missouri River steamboat. I built a rudimentary version of the Far West when I first became interested in wooden ship modeling, and later tackled a fully-framed and interior-detailed version of the Bertrand. Both of those were built in 1:87, a comfortable scale for me as a former HO model railroader.

However, for this project I wanted a new kind of challenge, so decided to build the Arabia in 1:64. The model will be around 32 inches (81 cm) long, allowing for more detail to be added overall. At the same time, though, I've decided not to recreate a fully-framed hull and interior as I did with Bertrand, for several reasons. First, that was a lot of work and material and would be even more expensive at 1:64, and I've already done that style now. Second, creating a framed model of Arabia would be both redundant and speculative; the museum preserves her stern intact for anyone to see, while the rest of the hull wasn't well-documented by the salvage team, so I'd be guessing more than I did with Bertrand (which was meticulously documented by an archeological team). Third, I just like the idea of a complete exterior model this time, trading a bit less interior detail for more focus on the overall appearance and higher detail allowed by the larger scale. Basically, this is just what I feel like doing this time, and doing a project the way you want to is part of what makes it engaging.

Although my initial plan was to develop a full set of blueprints for this project, that effort has stalled. It just isn't working for me to spend that much time on a computer, which I already do professionally as a freelance science editor. I'd rather spend my downtime working with wood than with pixels. So I stopped after developing a basic outline of the project and will just dive in, holding the design in my head and in various rough sketches and notes. This is, in fact, an authentic way to proceed, as riverboats in this era weren't built from printed blueprints either (one reason few construction records exist) but were simply laid out and built by artisans on the frontier shores of the Upper Ohio River. So any mistakes or quirks I may build into my Arabia as I proceed from the seat of my pants will be, at worst, a tribute to the real vessel's construction.

Above are my loose outlines of her design. The real Arabia was about 170' long and 30' wide (hull, not including the wheels) and drew about 5'.

And the sketches from which I'm getting started. There is no definitive information on the shape of her hull, other than the stern-most portion, which I've based on photos and measurements I took at the museum. So for the rest I've adapted a representative hull profile for the era from Alan Bates' The Western River Steamboat Cyclopoedium. The wheel and its supporting cylinder timbers are drawn directly from measurements I took at the museum. Centered within these drawings is the central internal bulkhead/keel I've laid out. These riverboats didn't have external keels the way normal ships did; their bottoms were generally perfectly flat with a stronger internal keelson instead. In this case, I'll be laying out horizontal bulkheads against this longitudinal one, just like a regular plank-on-bulkhead build. Hopefully now that I've laid the keel, so to speak, I can keep progress coming steadily. Thanks for reading, and for offering any ideas, suggestions, and criticisms that come to mind. I'd sure appreciate it if anyone points out concerns or problems that I can either explain or correct as I go along, as again I'm not a master modeler, just an ambitious one.

Table of Contents

Below I link to posts starting various portions of the build. This is intended to help folks looking for information on specific aspects of steamboats or their modelling, or just those wanting to catch up on a certain section. I'll try to keep this updated as I go along.

Framing the hull Guards and main deck framing Planking the hull Cylinder timbers & engines Planking the main deck Paddle wheels Boilers Main staircase & chimney breechings Framing the boiler deck & superstructure design Boiler pumps & other main deck details

-

Cathead reacted to cog in Arabia 1856 by Cathead - FINISHED - Scale 1:64 - sidewheel riverboat from the Missouri River, USA

Cathead reacted to cog in Arabia 1856 by Cathead - FINISHED - Scale 1:64 - sidewheel riverboat from the Missouri River, USA

Front row ... after your research, I am now prepped to follow the actual work ...

-

Cathead reacted to vossy in Arabia 1856 by Cathead - FINISHED - Scale 1:64 - sidewheel riverboat from the Missouri River, USA

Cathead reacted to vossy in Arabia 1856 by Cathead - FINISHED - Scale 1:64 - sidewheel riverboat from the Missouri River, USA

Really looking forward to following this new project of yours Eric. Just love the picture of her at the beginning of the thread.

Chris