-

Posts

1,222 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by jbshan

-

A couple of items: Fish Glue and Hide Glue are made from, you guessed it, fish and hides, as well as hooves and antlers. Hence a dead horse is 'sent to the glue factory'. The collagen in them, when processed properly, acts as an adhesive. They were used in cabinetry, and when I was in College we used hide glue sometimes on theatrical scenery, to hold the canvas to the wooden framework. CA doesn't fail to hold, it more dissolves things like cloth and thread, so go ahead and use it on your rigging, but I'll refrain, if you don't mind.

-

I use computer paper wrapped a couple of times, a small amount of glue under the paper, and between the layers. I also make my own crossbar from wood as it is two pieces that do not meet in the middle, only at the ends, squeezing the shank of the anchor between, in a little notch.

-

Unsticking White Glue

jbshan replied to shortgrass's topic in Building, Framing, Planking and plating a ships hull and deck

Isopropyl alcohol 90%. I got a bottle at the drug store. Smear on, let soak in, scrape away as it softens. For a deep joint, soak until it softens up. I used either a toothpick or small brush to apply. -

Caulking deadwood

jbshan replied to DocBlake's topic in Building, Framing, Planking and plating a ships hull and deck

Allan, I believe that is correct. There is a book about the rebuilding of Susan Constant at the Jamestown Park, which used a smearing of paint in the keel, stem, deadwood joints. I also have a book about wooden boat building where the author suggests smearing the joints with 'your favorite poison', including all the leftover paint in the shop. -

Caulking deadwood

jbshan replied to DocBlake's topic in Building, Framing, Planking and plating a ships hull and deck

If not caulked, a layer of canvas soaked in oil paint or some such put in the joints before assembly. Don't forget the stop waters along the rabbet. -

I think inside they want you to take the ends of two adjacent lines and tie them together. You could simply put a knot on the inside end of each one individually.

-

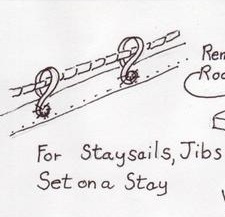

Here is a small clipping from a sketch I made for my club newsletter. It is based on an old magazine article. I think it shows the final shape and lashing to the sail.

-

Filler block question.

jbshan replied to Ronjja76's topic in Building, Framing, Planking and plating a ships hull and deck

You can dry fit them, mark with a pencil against the bulkhead, etc., then cut out on the bench or with a power saw, but leave some 'meat' for final fitting. -

Here is a link to a page with further links to three pages concerning building the boat to go on deck, a 22 ft. yawl. Most of the information for this boat comes from W E May, The Boats of Men of War, which I highly recommend. These pages originally appeared in my club's newsletter. http://uvsmgshipmodelguild.wikispaces.com/Scratchbuilding+a+Ship's+Boat This link will no longer work. The wiki people want $150 for the privilege of using their site and that ain't happenin'. I'll maybe find another place to put the material.

-

A sail could be held to the mast with wooden hoops or with rope, both would use grommets as described above. The rope could be fastened (perhaps with an eye splice) through a grommet, passed around the mast and fastened to the next grommet. The setup would be repeated for the next pair of grommets and so on up the sail. I don't like the round and round lashing you see sometimes, if the sail is intended to travel up and down on the mast. You need a way to keep the rope from tightening up and jamming. On a stay, hanks at each grommet could be used if the sail is to travel on the stay. This is a handle on a cauldron, but the basic shape is correct. It would be twisted so the large ring was at right angles and the two rings at the ends lined up to be lashed to the grommet. This is a sail with hanks ready to be furled. Pull on the uphaul (right) to set the sail.

-

That big gap up front is supposed to have balsa blocks put in, then you trim the blocks down to mate with the plank material. This is one reason I don't ever recommend this kit to new builders. It's easy neither to understand nor to do, and it isn't in any way real life practice.

- 52 replies

-

- muscongus bay lobster smack

- Midwest Products

-

(and 2 more)

Tagged with:

-

You might also consider what I think are called cuticle scissors. A large drug store would probably have some, or the ladies in your life may be able to help.

-

How would you improve your Byrnes tools?

jbshan replied to Keith_W's topic in Modeling tools and Workshop Equipment

(Tongue firmly in cheek) A friend of mine wanted to be able to cut 2 inch stock so installed a five horse motor in his saw. Shortly thereafter most of the northeast and parts of Canada went dark. This may be only anecdotal. -

endeavour shrouds & ratlines (moved by admin)

jbshan replied to geoff's topic in Masting, rigging and sails

If the AOTS is correct, the replica setup may be for modern safety reasons, as are many other features on these modern vessels. -

Question about stoves and how the rotisserie worked

jbshan replied to Modeler12's topic in Nautical/Naval History

wq3296 wrote: Properly designed fireplaces and stoves incorporate exhaust gas velocity enhancement features. And if your stovepipe or chimney flue is the wrong size for the fire box you'll have a quick lesson in venturi effects. -

Here are many WWI ships, built toward the end of hostilities and towed here for breaking up. Potomac River, across and downstream from Quantico, in Mallows Bay. Part of the 'Ghost Fleet'.

-

Look for fly tying supplies. Sharp, small tips but with man-sized finger holes.

-

Exactly, Jud. A gun tube is delineated by the number of calibres of length. A ten inch 50 caliber gun is 500 inches long. In olden times they would measure the barrel on the outside as in the drawing in an above post. You could have guns from the same batch differing by a few inches since they were cast muzzle up and the excess cut off. The weight and length then became identifying characteristics of that barrel and could be chiseled onto it. In the Royal Navy guns were provided by the Ordnance Board as available and as close as they could to the request of the Navy. It was then up to the Navy to distribute them about each ship for best effect. This is mostly all covered in the Lavery volume cited above. You may, once you see it from the Library, decide to bite the bullet and buy your own copy on one of the used book services.

-

Just in a general way, on board ship the larger calibres tended to be 'short' compared to the smaller ones because of the need to keep barrel length from limiting reloading on account of limited recoil space. I didn't say that well. If a barrel was so long that it couldn't recoil far enough before hitting hatch coamings, etc. to reload easily it wasn't much use on a ship. Even among a group of barrels cast as a batch, there would be differences in length and weight, to the point that length of barrel was a VIN number of sorts, to identify guns provided to particular ships.

-

Deadeye Diameter and Thickness based on Shroud Size?

jbshan replied to molasses's topic in Masting, rigging and sails

Bingo. Thanks, John. -

Deadeye Diameter and Thickness based on Shroud Size?

jbshan replied to molasses's topic in Masting, rigging and sails

Yes, there is. Patience. -

Petersson is based on observation of one model in (?) the Science Museum. Darcy Lever is more of an omnibus, but sticking to his own time frame. Read Lever for procedures also. If you make your masting and rigging so it can work properly, it will also look right.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.