-

Posts

1,222 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by jbshan

-

Every book mentioned is a good one. What seems best is to gather from several sources, then distill that to your particular vessel. You will learn more and will have the principles rather than merely information for one vessel. Those that cover multiple types of vessel and time periods will tell you that so you can determine the suitability of a particular feature. Give a man a fish and feed him for one day. Give a man a fish hook and feed him for life.

-

That's all based on size of main mast, right? Breadth for the cables? If the tables are right, the largest would go with the largest hull or masting.

-

Jay, there are conventions about the shift of butts for planking. I don't have any to hand right now, but I believe not only would there be a certain number of planks between butts on the same beam, but also beams between butts on adjacent planks. Sort of: | | | | | | | | | | | | I believe Goodwin, "Construction and Fitting" would have this, among other authors.

-

My late friend Neb, a rigging expert, was of the opinion that the course yard halliards were belayed and much of the fall cut off. When needed, and these weren't lowered very often, the fall could be spliced back together in only a couple of minutes. If it is 100 feet to the jeer blocks, trebles, you could have a quarter of a mile of line to deal with.

-

Not to detract from anybody else's work, the boat at the Smithsonian has the fireplace on the deck just forward of the port gun. ????

- 308 replies

-

- finished

- model shipways

-

(and 1 more)

Tagged with:

-

gunport posts

jbshan replied to harlequin's topic in Building, Framing, Planking and plating a ships hull and deck

The outer layer of the lid will be the same thickness as the hull planking, so the lining should be held back by that amount. -

Certainly they needed long straight pieces for masts and keels, etc., oak, elm or beech for keels, pines for masts. Both France and England would have needed imported pines of those sizes, mostly Baltic, though England had sources in America until the late unpleasantness beginning in 1775, thereafter Canada, and France had sources in Europe and the Med. I don't think the French took advantage of their North American possessions for timber nearly as much; they were more interested in furs. Possibly an offcut from one of those keel or mast pieces might be used for planking somewhere. A short distance *to water* would be desirable. Once they could get a big timber onto a boat or barge it got a lot easier. They could have, but would they have? Perhaps strakes next to the hatches, under the guns, or other 'binding strakes' would have been advantaged by long lengths. If Boudriot gives a generally shorter length, I would go with him. He did the research and wrote the books.

-

Soft pencil on one edge and one end of each plank for me. It has variety from place to place and is subtle generally. As far as fasteners, check the scale very carefully. A nail head would be maybe 1/8". On the quarterdeck and officers' country the nail holes would be plugged with a small chip of wood, diamond shaped, and with the grain matching the plank. Practically invisible even if you were standing on the actual deck.

-

Before you try it again, open up the slot just a smidge so you don't have to force it, just snug. White or yellow glue will wet and swell the wood enough to make it tight again when you do the final assembly.

- 52 replies

-

- muscongus bay lobster smack

- Midwest Products

-

(and 2 more)

Tagged with:

-

Looks pretty good. Thanks for sending that tip along.

-

'Cutter' as a rig type implies the bowsprit could be extended for larger sails. 'Cutter' as vessel type is more of a dispatch vessel, fast, nimble, large sail area for the size of the hull. The Sherbourne drawing looks as if it is a shifting bowsprit. Some of the other examples do as well, there are two with an additional 'fid' hole forward of the bitts, and several look as if there would be clearance above the bitts for the bowsprit to shift aft, as does Alert. (Aside) If nothing else, those pics show there is more than one way to skin that cat. No two alike, are there?

- 1 reply

-

- Sherbourne

- 18th century cutters

-

(and 3 more)

Tagged with:

-

Generally, I would suggest cleaning, restoring the rigging as far as you can determine it was originally installed, and to the same level of sophistication, and basically returning a refurbished piece of folk art to its owner. Otherwise you might as well buy a current Mayflower kit and go that route. I think to go further would be a big heart breaker.

-

Thanks, Daniel. I have a dime the size of a manhole cover that can be confusing to some people. I see what you're saying. Interesting that Longridge shows top hinges and Goodwin working a little later shows forward hinges. Presumably both had the same source, although perhaps Trincomalee or Unicorn entered in there somewhere, if not a source for authors, as a source for restorers.

-

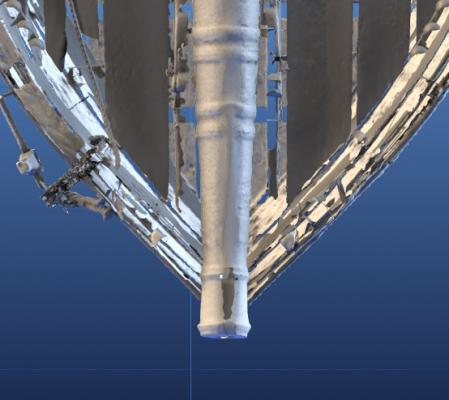

I took a blowup of the Smithsonian 3D scan. The rail seems to end at about the cathead, but there is more stuff down inside, apparently. Blocking?

- 259 replies

-

- Gunboat

- Philadelphia

-

(and 1 more)

Tagged with:

-

The best I've seen is 'Construction and Fitting', Peter Goodwin. He shows a solid scuttle lid that is the same thickness as the port lid. It is secured inboard with the sliding deadbolt in dafi's post #4, bottom picture. This should not be surprising since Goodwin was Curator of Victory and the pic is of Victory. Goodwin says this is the original style, that later scuttles had glass. Perhaps the kit scuttle lids are intended to represent this later style.

-

Copper on Hermione

jbshan replied to JagMkV's topic in Building, Framing, Planking and plating a ships hull and deck

Thank you, Gaetan. I defer to your more rigorous scholarship. So, Jag, there are the relevant dates. -

Don't worry about me going off topic again. I already removed about six posts of mine from a thread where the original question was not what the questioner wanted an answer to.

- 396 replies

-

- Idea

- Bright Idea

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.