-

Posts

314 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Moxis

-

I have both. A small Delta bandsaw and a Delta 40-560 scroll saw. I use only the bandsaw, because it is very difficult to have accurate cuttings with the scroll saw. Or perhaps I just cannot use it correctly. I like the band saw a lot, and have had different blades made in a special shop, both for wood and metal. The narrowest blade is about 6 mm, and can be used for quite tight curves too. But recently there have been tasks where a good scroll saw could have been more useful, so I have been thinking to invest to a good one in a near future. But which one is the best? ChrisLBren is very happy with his DeWalt, but is that the best one?

-

Any model steam engine builders here?

Moxis replied to Moxis's topic in Metal Work, Soldering and Metal Fittings

You have built a nice machine Keith. And thanks for the link, I must study it carefully. -

Any model steam engine builders here?

Moxis replied to Moxis's topic in Metal Work, Soldering and Metal Fittings

Thanks Keith. This paddle duck might be a very interesting model to start with. Yes I have a metal lathe and milling machine, together with the tooling for them. And also a little bit experience to use them, but so far I have never made anything which needs tight tolerances and accuracy within 1/100 millimeter. -

When starting my new project, a steamship from the beginning of 20th century, I have thought hard to build a steam engine to power the model. My preferred engine would be a two cylinder compound engine, which would be the same type as used in the original ship. There are a few possible engines offered at Internet, both ready machined and sets of castings. It seems that prices for ready made engines are beyond my possibilities, but sets of castings are more reasonably priced. But how difficult it is for a beginner to machine a steam engine? How accurately you must work to get pistons and cylinders work together, to fabricate crankshaft, bearings, steam valves etc. or should I just forget these wild dreams and use electric power instead?

-

Every time I start a new project I have wondered how easy it would be to scan the bulkheads from drawing, have them converted into vector format and then scale them in CAD & finally cut the bulkheads with a CNC mill. But all the programs I have studied need enormous work to clean all the unwanted pixels from the drawing. I wonder if there exist any programs that make this cleaning automatically?

-

I have always wondered which one is more suitable to prepare wood for our hobby, a thickness sander or a Proxxon thicknesser https://www.proxxon.com/en/micromot/27040.php What are the pros and cons for these machines?

-

Desktop CNC Router, Engraver, Mill

Moxis replied to pompey2's topic in Modeling tools and Workshop Equipment

Thanks Moflea, that is a great news. I have thought a lot about Fusion, but understood that you have to pay every month a certain fee for them. But if a retired hobbyist can get free access to the program, seems very attracting. -

Desktop CNC Router, Engraver, Mill

Moxis replied to pompey2's topic in Modeling tools and Workshop Equipment

Thanks hjx. I will check those programs you suggested. I don't have any connections to companies using cnc. I am just a humble retired individual building models as a hobby. -

Desktop CNC Router, Engraver, Mill

Moxis replied to pompey2's topic in Modeling tools and Workshop Equipment

Very interesting hjx. I have also a 3 axle cnc machine made by German Eas gmbh http://www.easgmbh.de/CNC-Maschinen/Fraesmaschinen/EASY I have used it a lot when building my models, mainly with cars and tanks. The problem is that I only have a 2D CAD, which gives me the possibility to produce 2D and 2.5D parts. I would like to upgrade my programs into 3D to be able to make also the carvings. So the question is: Which CAD program are you using to make those carvings shown in your pictures? -

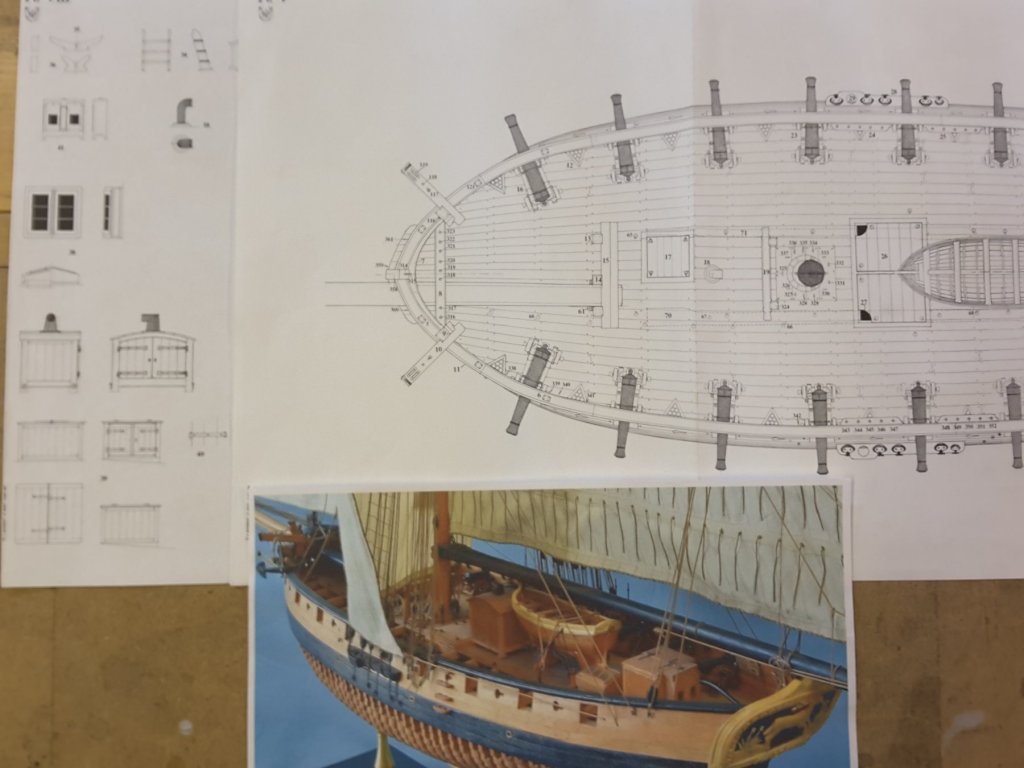

Earlier here was a folder for finished scratch built projects. This does not exist any more, so this is why I have to introduce my completed project at this folder. I am sorry that I didn`t issue any building blog about my project, but in the beginning I was not sure at all, if I ever will finish this project. So, during about two years I have been building a model of French cutter Le Cerf, and finally a few days ago it could be regarded as finished. When searching a new project to build, from the beginning I somehow liked the one mast cutter Le Cerf, issued by French Ancre. So I purchased the documentation package, which included much information about French Navy in general, and especially about the vessel itself. Included were also 12 sheets of plans, which were drawn in the scale of 1/48, which suited me very well, because my previous build was also made at this scale. After having studied the documents and plans for a couple of days, I started the project by making the bulkheads out of plywood. Hull & deck planking were made using strips sawn of abachi wood, which was a positive surprise for me, because it was very easy to work with and to bend the strips and attach them in place. The hulls of French cutters were made in clinker method, and after first difficulties it seemed to me easier to make than "normal" smooth hulls. Gun carriages and othe small details were made of cherry wood, and decorations at the stern were carved of boxwood. Gun barrels are made of brass, together with the blocks and rigging threads they were the only purchased parts. Sails were made of thin Egyptian cotton. It was colored with acrylic paints together with a small amount of white glue diluted in water. I am quite happy with the result. Now again I am in the situation of trying to decide what to build next.

-

Hello Kurt. The biggest is the galley between mast and dinghy. Some drawings include the galley, some don't. I made my model without it. See the attached photo. Then there are some numbering of blocks, eyebolts etc. at the rigging plan, which do not match with the description. But nothing very severe.

-

I am being building Le Cerf from scratch according to Ancre's plans: https://ancre.fr/en/monographies-en/34-monographie-du-cerf-cotre-1778.html in 1/48 scale. The monogram includes also quite comprehensive history about the ship's life, and French navy in general at that era. In my opinion the clinker hull is much easier to build than the carvel one. There are some minor discrebancies in plans, but nothing very serious. I have been building the model about two years now, and finally it gets closer to finalization, being in the rigging and sails production phase.

-

- 64 replies

-

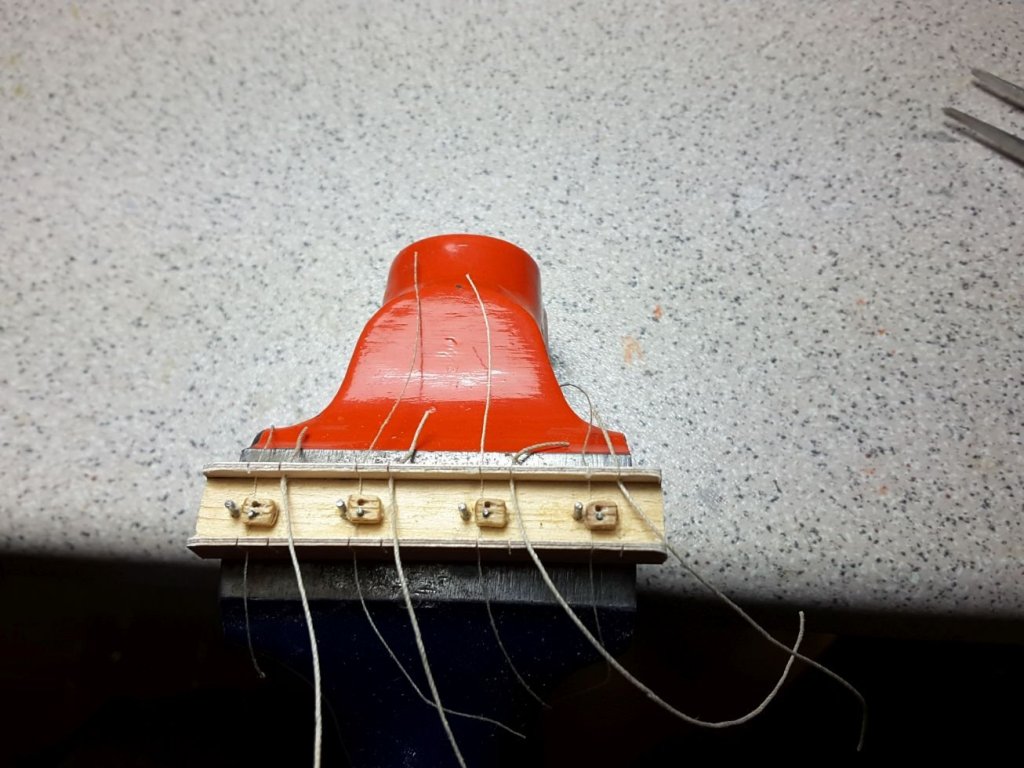

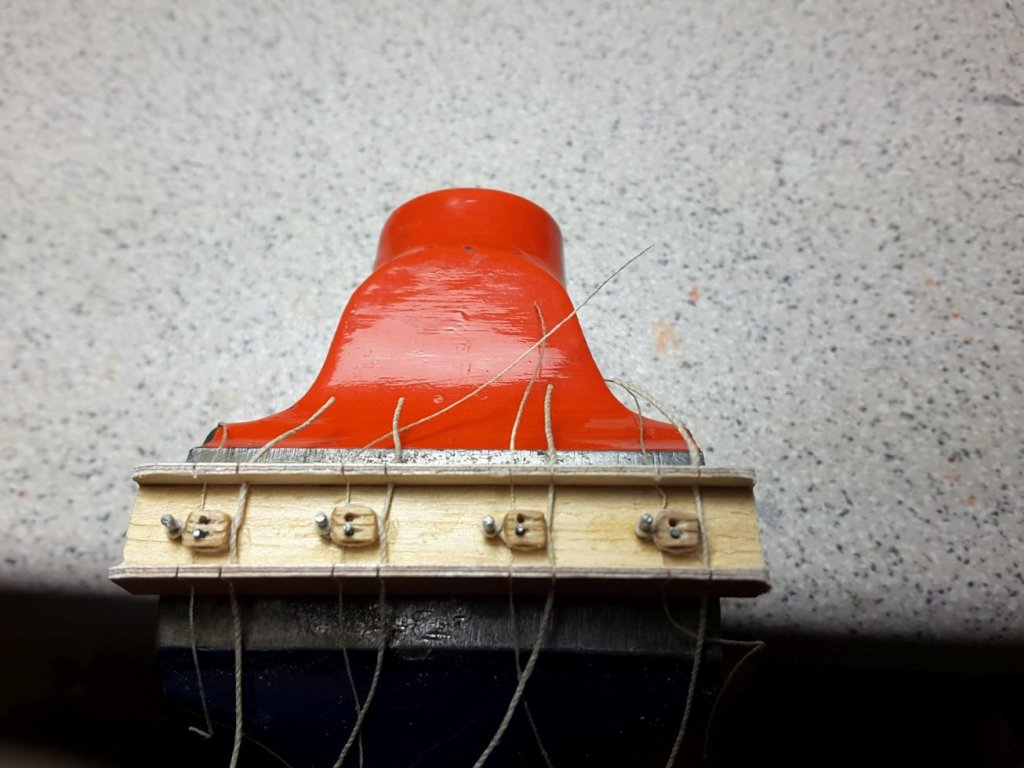

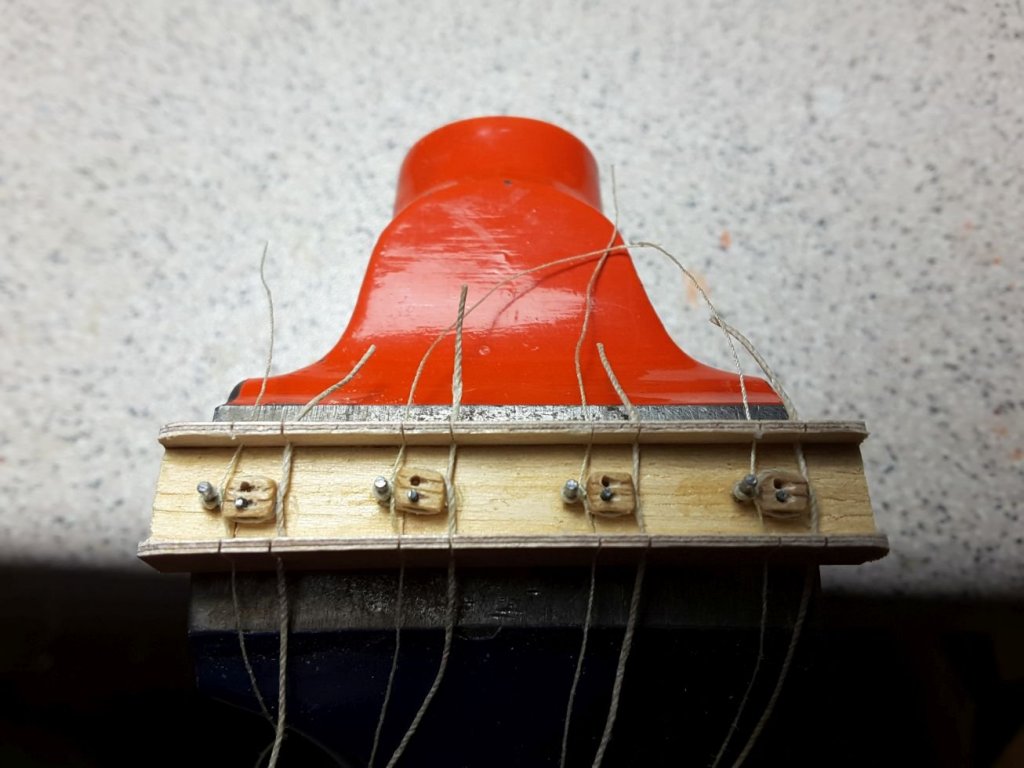

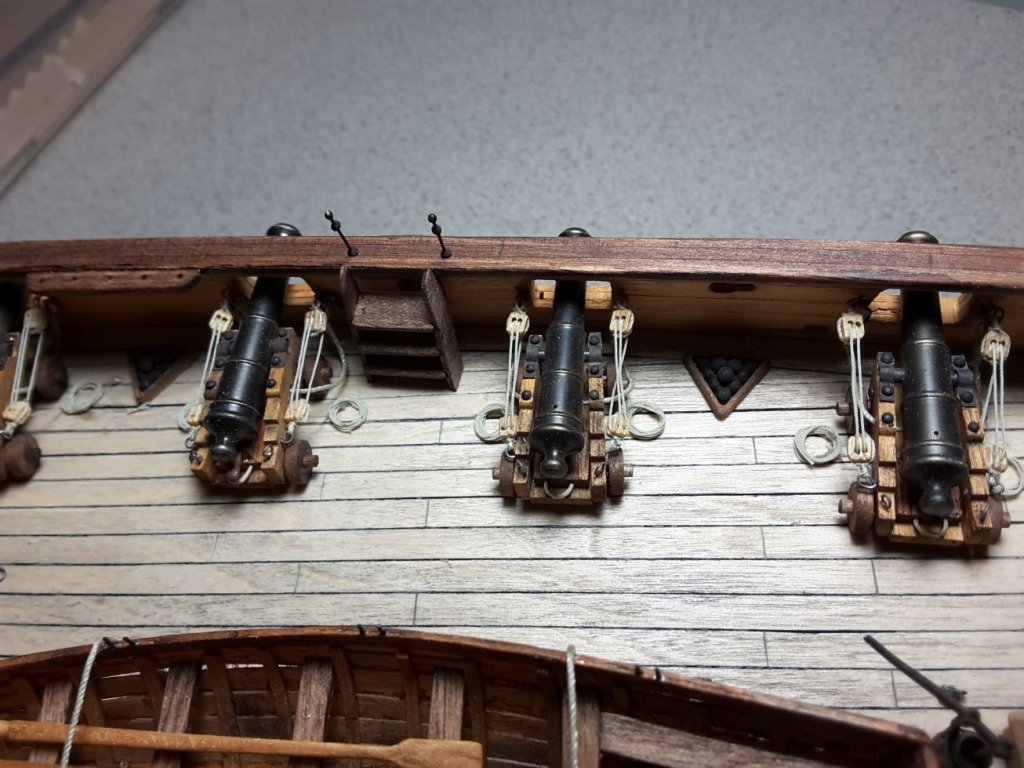

There has been recently many methods shown to make strops around small blocks. When rigging the guns for my Le Cerf I needed a big number of small 3 mm double blocks. For making strops around these I made this simple fixture, which fullfilled it`s task quite reasonably. First a simple construction was made of a piece of scrap wood and 2 mm plywood. Small pieces of 1 mm and 0,6 mm iron wire were glued into the bottom of the jig, and grooves were sawn with jeweler`s saw into the plywood walls: Pieces of 0,15 mm thread were put into the first grooves, and blocks were positioned to the jig so that the 0,6 mm wire was put through one hole of the block: Then small pieces of 0,6 mm rigging thread were placed into the second grooves: And then it was rotated around the block and then around the 1 mm iron wire: And now it remained only to make a small knot between the block and the 1 mm loop using the thinner thread, and attach small blops of diluted PVA glue into both ends of the block. After the glue had dried, ends of threads were cut as near as possible of the block..... ..... and blocks were ready...... ......and used for rigging the guns:

-

Hello Egon. Here you can find some https://www.google.fi/search?q=steam+capstan&client=firefox-b&source=lnms&tbm=isch&sa=X&ved=0ahUKEwj-_9y3jKHUAhVF6CwKHfgQAHUQ_AUICSgB&biw=1024&bih=636

-

Thanks Chuck! Again a very nice solution to copy. I will certainly follow your method when the time comes to fabricate these.

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thank you very much for a marvellous project with all the tutorials and how to's. As the others have already said, we have learned a lot and I hope we are able to improve our humble skills when building our models. However one question still comes to my mind when studying your work: Could you explain a little how did you make those wooden rings around the main mast? And of which material they are made?

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I found also the company Automated Artists, and have placed my order for certain thicknesses of Polybak for testing. Even when Chuck told us that this material is too weak for routing, I would like to try that. When producing very tiny parts, they must not be very strong to fullfill their purpose, which is only to emulate small metal parts. And when machined with 0,3 mm router bit very carefully I am almost sure that I can manage that work. However being material which is very hard to find and transport from US to Europe especially in small quantities, it would be nice to find some equivalents nearer. So this "Hartpapier" or Bakelite, as we also know it here, would also be very interesting material to know better and worth testing how it would suit for the purposes of model ship building.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.