-

Posts

1,307 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Gaetan Bordeleau

-

"Few coats were applied same evening" If 1 coat takes a few days to dry, how much time take 5 thick layers? 1 month or 2 50-50 mix dry about half the the time of a 100% tung oil because there is about 50% less of oil 50-50 mix is applied so that the oil penetrates deeper but how much deeper? Also tung oil is not the champion to penetrate rapidly in the wood. To mix with odorless turpentine is helpfull The usual way to apply a coat; wipe 1 coat wait 15 minutes and wipe the excess, because there is always excess because of the poor penetration factor of tung oil Finally do not use Danish oil, your wife will not like the smell, and if you absolutely want to mix with turpentine use odorless turpentine because again your wife will not like it

-

Rope Making Basics

Gaetan Bordeleau replied to mikiek's topic in Rope Making/Ropewalks's Discussions about Rope Making

Mike you are asking a lot. 3 linen ropes no 120 made from 3 ropes of .006": .016" -

How about something like this : http://www.whitediabolo.co.uk/bisley-10-multidrawer-filing-cabinet-2910---oxford-blue-155-p.asp for small drawers?

- 968 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

Hi Dee Dee I have no 7D and no android tablet, I use a full frame sensor and if I want to see it in live view I pass by an Eos utility program. If I a want to see the picture taken, it is done without wire. Eyefi mobi pro which is a SD HC card to store pictures also transfers pictures to Lightroom which are then viewed in full screen a Mac Book Pro. which is easier to appreciate the picture on a 15 inches screen than on a 3 inches LCD monitor.

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

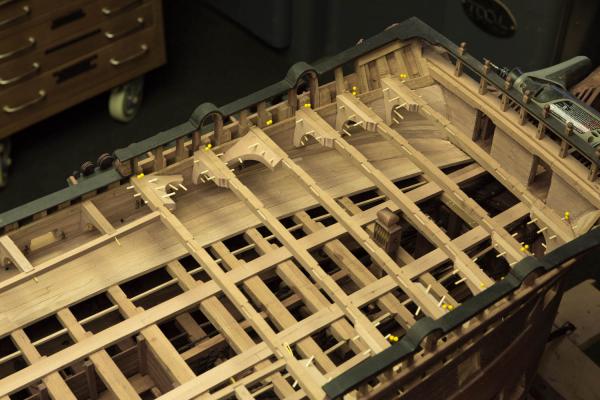

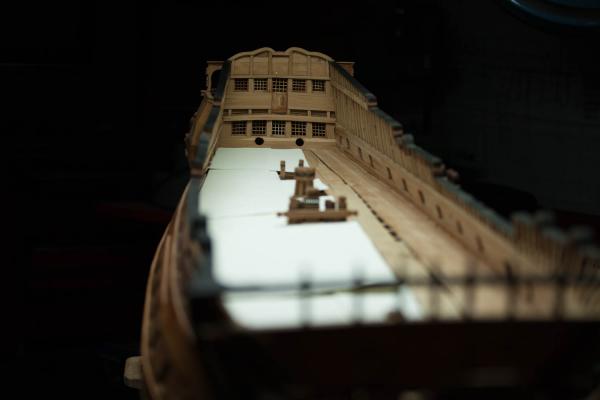

Continuation We have seen in few post an height adjustable table. It is particularly interesting when work while standing. An height adjustable chair is also helping. Taking pictures also helps to see errors we would not note otherwise as in the last picture which shows that there are still some adjustments to be made in the lenght of some parts.

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

I just learned the 400 pages of the booklet to drive the drone as on the first picture. The other pictures are the result of the camera on board.

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

Thank you for your comments. Model-ship building is a multi-disciplinary-art. You need to understand how to work with wood and metal, but ideally you should also try to understand how to present your work, and photography is there to help us. Photography also has an important part in model ship building. If this forum had any pictures to show, the number of members would not be as much significative. For reasons out of my comprehension, this subject looks like to be taboo here. This forum is not about photography but it does not mean that we should not talk about it or try to take better pictures.

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

Planking floor and walls I wanted to show what I use when I want a white background for a medium object. The idea is not to have a demarcation between the wall and the floor. A sheet of coroplast 4 by 8 feet is used.

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

-

By comparison, here in Quebec it is easy to get cherry and the last lot I bought I paid $2 pmp. The last time I bought pear more than 5 years ago, I paid over $10 pmp. The most difficult with cherry is to choose the dark planks because we do not always see the color of the wood especially when it did not pass to the planer I bought 3 lots of cherry; the first group had dark planks up to 12 inches wide 1 inch thick. second time pale wood milled 1X 5 inches and the last lot nice dark planks up to 2 X 15 inches to make a lot of projects.

-

Proxxon TG125 Bench Disk Sander

Gaetan Bordeleau replied to pompey2's topic in Modeling tools and Workshop Equipment

If you give me the choice between a sanding belt or disk, I would never choose a disk. Sanding belt can sand in the same direction of the grain, and the finish will always be nicer than what can do a disk. -

Cherry and pear wood are similar in some aspects to work with. Pear has a very straight wood grain and in this field cherry has a much wider range. Pear wood can be work from every side, cherry is easier to work with wood grain. Jerry, I like your change from maple to cherry. Cherry is a much more stable wood than maple. Cherry is very easy to sand in comparison with maple. The wood grain of maple is not interesting as a ''scale'' wood grain. I have never seen a complete model made of maple but I have seen a complete model made from cherry.

-

Living near orchards of cherry and apple, I have obtained some samples when I asked the owners for pruned branches. The apple samples serve as some deck furniture, but never had the opportunity to use cherry, even though I like the rich color. Montani semper liberi Happy modeling The ''perfect'' wood grain at scale and color I used for a build

-

Mark! dulls blades quickly; if I remember correctly, there was occasionally 1 kind of mineral in ebony. I did cut a lot of ebony and it did not dull blades more than other exotic woods. It was probably true before carbide blades but not today. Oily.. glue doesn't like to stick to; Ebony is not oily, teck is oily. I never had any issues to glue ebony. For healt issues we talked about it a few times, the last time probably in wood toxicity subject few months ago.

-

scroll saw choice

Gaetan Bordeleau replied to hamilton's topic in Modeling tools and Workshop Equipment

Hi Craig, Excalibur and Hegner are 2 good scroll saw. Which one is the best I do not know. There are some video on U-Tube showing how to change a blade. They are not all using the last version of the saw. Depending how you do it, the blade can be change in less than 30 seconds. I use mainly 2 blades 1 for thin and 1 for thick material. Each blade has a top and bottom holder to fix in the saw. -

finish

Gaetan Bordeleau replied to Barbara's topic in Painting, finishing and weathering products and techniques

Tung oil, easy to apply, very forgiving, mat finish + wood grain enhancer at the same time. -

scroll saw choice

Gaetan Bordeleau replied to hamilton's topic in Modeling tools and Workshop Equipment

Hegner is selling in US. Vibration free, it can cut as thin a paper layer and it very easy to cut in straight line. It can cut as thick as 1''... and at 90 degrees. Scroll saw blades are very effective also and are offered by many companies. -

I have stopped using dyes. I tried many kinds and inks but I never was 100% satisfied. I use the water-based wood stain that my wife use for his hobby. http://www.saman.ca/products/22-saman-water-based-stain and there is the American standard http://www.michaels.com/search?q=americana Both apply the same way. Look like paint but is transparent as a dye. The application is more homogeneous than dyes are.

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

Mike, You will never get too much lighting. To get 200 lumen with a 400 lumen light, you just need to put your lamp on some kind of arm, you can easily fabricate and back up a couple of feet.

- 968 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

Hi Mike, Depending of the wood species,wood fibers can rise when you apply a liquid on the surface. We try to eliminate fibers rising before painting so that after we have a softer surface without wood fiber peaks.

- 968 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

I hope I do not get too much intrusive, but after a little research, here is what I found. Tung oil has been known about for hundreds of years in China, where it was used as a preservative for wood ships. The oil penetrates the wood, then hardens to form an impermeable hydrophobic layer (repels water) up to 5 mm into the wood. In a pure form, the oil is an amber color, and has the approximate consistency of glycerine. The first reason to oil the wood is to enhance the color of the grain. Wood stability is another good reason. It reduces the rate and amount of water vapor entering the wood so that it does not swell either to quickly or too much. Pure tung will give you a matte finish. Tung oil seeps into the grain of the wood, giving it a perpetual wet look that highly accentualizes the grain of the wood, commonly referred to as "making the grain pop". Because of this, the color of the wood is slightly darkened, giving the wood a rich, warm color that is very pleasing. Application: Raise the grain, sand, and then begin. Almost all experts agree that using a cloth moistened with warm water is the easiest way to raise the grain on your project before oiling. When using pure tung oil, you need several coats. It’s very important that you thin each coat with the first coat being the thinnest (I recommend 70 percent solvent). Each successive coat should be thicker (less thinned), and the last coat must be the thickest. Your thinner needs to be an organic solvent, one that is carbon based like turpentine. Every layer except the last must be sanded, so the next layer of tung oil will bond to the previous layer. 320 grit sandpaper creates the “tooth” that grips the next layer. Sanding sealers are usually used to fix problems with uneaven absorption of stains, however it is not required under penetrating oil finishes such as tung oil. If you do choose to use sanding sealers, it is recommended that you are sanding to 180/220 grit, and only move on to finer sanding once the sealer is applied. In my case,sanding is below 100, the sanding roller is 80 grit, so I do not believe a sanding sealer would be any help as long as the kind of wood I use , in this case cherry evenly absorbs the oil which in this case is not a problem. They recommend 3 or 4 coats in the real life to obtain hydro properties. In my situation 1 coat is enough to enhance the color of the grain which is the main reason to use it. 100% pure Tung Oil is slower drying, but this will be improved with thinners. Tung Oil loves to be rubbed, and the more heat generated the faster it dries. This makes it a great "friction polish" for lathe finishing or hand rubbing. The next seed oil that I will try will be grape seed oil which has been apparently used by generations of instrument makers. It has excellent drying nature being high in Linolenic to be a main reason why this particular oil has been used.

- 968 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

Remco, May be it could be interesting to try to go 1 step further. I use 1 coat ofTung oil straight because I like the look of it and it is very easy to apply. 2 questions: what is the advantage to go 50-50 with turpentine? does the wood could benefit from a treatment before applying Tung oil which could help to enhance the final look when completed? I do not know the properties of a sanding sealer but I could try a test 2 cherry planks 1 with Tung oil only and 1 with as a preparation. May be I could read instructions before applying too to see if they have some good ideas.

- 968 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.