-

Posts

1,307 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Gaetan Bordeleau

-

Is there a better #11 blade handle

Gaetan Bordeleau replied to roach101761's topic in Modeling tools and Workshop Equipment

Swan Morton has or had a handle covered with some kind of blue plastic. A lot easier to handle and much more comfortable. -

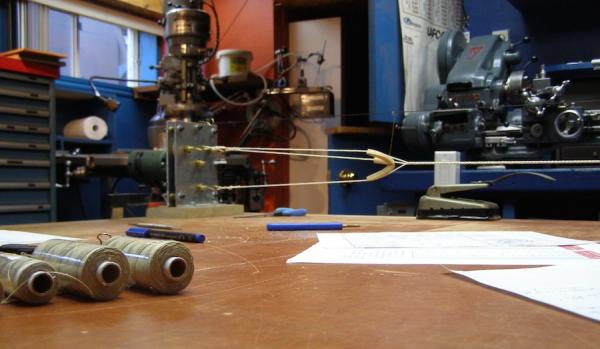

Stretching is the result of the material used and the way the rope is turned. Quality linen resolves most of the stretching problems. The machine used fixes the rest, the more adjustment the better, and no adjustments the worst. Other qualities of the ropes can be adjust such as the flexibility or the rigidity by turning too much turns.

-

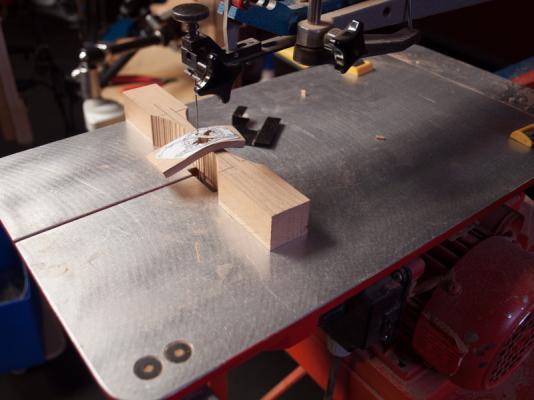

Jig on the second picture to cut a piece in round. The idea is to have the part which is being cut always standing at 90 degres with the table.

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

Optivisor is surely a good avenue and the quality of the lenses is good. There are other similar much less expensive but the quality of lenses are uncertain and this is not a good idea to work a long period with it. Also the light provide is also of bad quality especially in the way that is unsufficient power. When buying magnifier, a corresponding light source is also needed. 3 neons lights, the kind used by jewelers is a general light which can be use in most situations. In the same price range as optivisor, there is also this little support with a good lens, and a clamp to go on a standard pair of glasses.

-

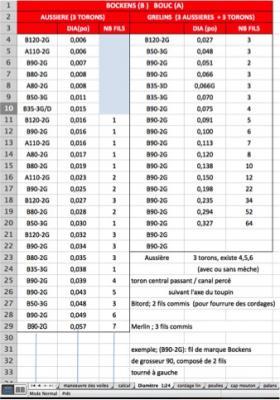

Hi Peter, http://www.theobrejaart.nl/frame.html This is high quality linen and with this type of material stability to temperature and humidity will not be an issue. Once the thread is turned, the lenght will be final. Theo is a nice gentleman and he can provide whatever you like. I bought 1 Kg roll, and with it I can produce every diameter I need. I think that 120 size is the smaller diameter available. Using it at a lager scale I chose 90 size, composed of 2 threads left turned. Knowing that most of the threads you need to turn will be with 3 ropes right turn, it is a good thing that you choose a roll which is left turned, because if you buy right turn ropes, you will have to unroll before you can turn it right. On the picture, you refer, sizes are mainly between 50 and 120.

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

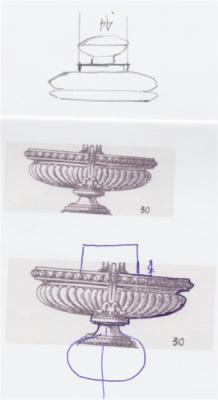

It is very easy to make a sculpture; Print a copy, glue it on wood, pass it under the scrollsaw and voilà!

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

Thank you Karl, David + another picture also at 1/24; in both examples: cherry works fine at 1/24 and 1/48. Works as fine if not better than pseudo-boxwood: castello. The idea is to have close grain often in the fruit wood group. I have never seen orange wood in my life, but I have always wonder how it would work Apple is in the same class, may be it could be a bit better.

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

I wanted some kinds of flowers on the ceiling. I looked in the past, to find a solution in the present. This vase from b J.C. Delafosse has the same style, few years too late but the curve of the profile is what I was looking for.

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

Ed, you nailed it. 5 minutes, 2 parts epoxy worked very good to apply plates, enough time to position and then masking tape to hold till it dries.

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

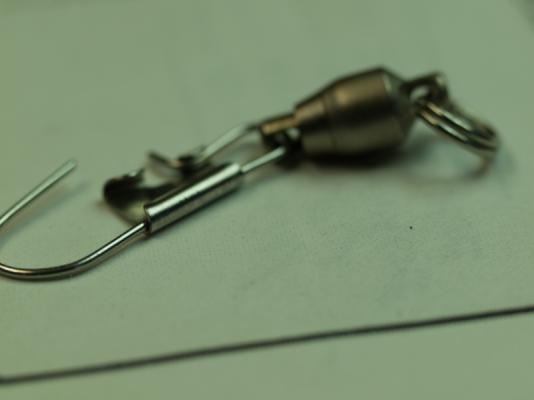

Hi Mark, Yes the thread is size 110 made of 2 threads left turned. This means that if I want to turn 3 strands, I will turn right. For the bullet shape, that sometimes we see made of 1 piece, but in this case it is made in 3 parts with a groove in each one. The utility of this part is obvious if not installed; lines forms too fast and the lines want to tangle. When you see the swivel in action you would be surprise how much turns it can do. I added other pictures to try to be clear. Mainly ropes are made from 3 strands and when I go for anchor cables, I take 3 of these to make a bigger cable. The largest number I used was round 576 lines for one anchor cable. Without excel tables it would have taken too much try to get the right diameter.

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

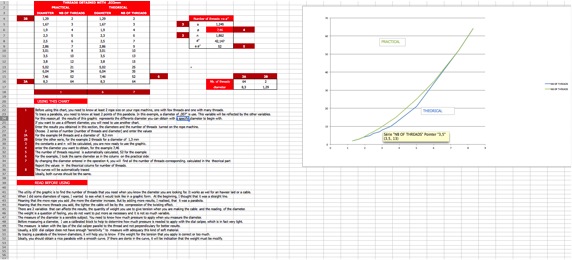

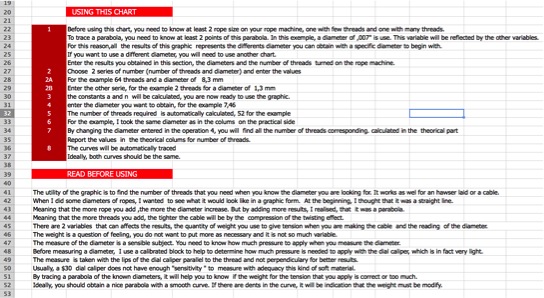

Here is a picture of a ball bearing swivel. Also to control up to a certain extent the diameter the degree of stiffness or the flexibility of the rope the quantity of lest which is added at the other end; more weight the stiffer the rope; the stiffer the rope the smaller the diameter. The diameter can be know before turning the ropes and the lest can be adjusted as needed. On the drawing, there are 2 curves, calculated and practical

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

Hi Karl, I just added in the Fleuron a comparison of the rope machine I use and the rope color also. Gaetan

- 662 replies

-

- bonhomme richard

- frigate

-

(and 1 more)

Tagged with:

-

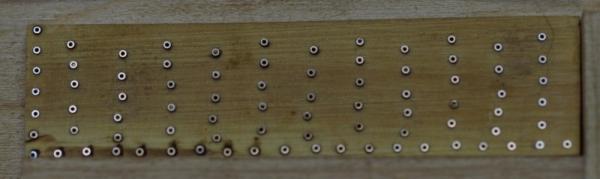

Recently, I saw many variations in machine to turn ropes. Also I saw many complaints about the in stability of the cotton. By using a good linen quality, none of these problems will occur. Here is the version of the turning machine I use which has a major advantage on the other models. This machine uses a swivel at one end. This is a mechanical insurance that the torsion in the ropes will be adequate. Other methods I saw, the rotation ratio is adjusted by eyes and for this reason is approximate. Picture 1; gears, motor and variable speed control, reverse switch to turn left or right Picture 7; at the other end of the rope, there is a swivel used for fishing. This is a very important part because the swivel mechanically adjust how much rotation is needed to equilibrate the torsion in the ropes. This swivel is held on a trolley which compensate for the diminution of the lenght of the ropes when turning. Picture 15 and 15a; 2 wooden nails showing the color of the french ropes around 1750 reddish brown Picture 33 : samething shown by Boudiot Picture 55 : high quality linen, expensive but very stable to temperature and humidity

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

Thank you for your comments, Michael, when I began taking pictures of model ships, many years ago, nobody knew how to photograph among the group of model makers. The consensus seemed at that time, and that was based purely on inexperience, that a flash should not be used. The truth is just the opposite. Very often, additional lighting is required, you just have to make sure not to overexpose, and the idea is to soften light and shadows, with a white semi transparent object (cloth, white plastic cover or even some kind of transparent paper just in front of the flash. Avsjerome2003, to go happy modeling, just do like me, you do not need to be good, a lot of model maker are better than I am, but just take some photography lessons, ounce you understand the idea, you will not become a pro instantly, but it will be easier to make it looks better than it really is...

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

The next parts will be under the balcony. General height to work on a table is 30 inches. To work, especially on small parts, 30 inches is far from being ideal height, it is often too low; easy solution; adjustable height table, electric or by hand or even at lower price in the used. If I would have known before this is the kind of tool I would have bought a lot sooner.

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

Hi Ed, I guess that after 100 years or so, some lines of cotton would break because too much thin after deterioration. Cotton is not a very resistant material, this is why in the industry reinfore it with polyester in different %. Twisting strenght must be balanced mechanically, not by eye, when turning the ropes. About pre-stretching, I think it is more true with cotton than it is with linen; and often unnecessary with linen, because of his nature which is more rigid than cotton. We had previous discussion about the tint color. For English ship, dark brown is more appropriate than black. I would say that linen is preferable to cotton, and by seeing some experimentation on this forum; linen has not the elasticity problem that cotton has. Gaetan

-

It is not normal for a line to sag so fast. It is not only humidity but also the temperature which are exterior factor. As one example for the temperature even if it is not metal here, on large electric line, the cable is sag in function of the temperature only, not the humidity. The first to look is the kind of material, the worst to use would be 100% cotton, very extensible and I think that after many years it would have disintegrate quite a bit. The best to use would be linen for stability and longevity. The second factor to check is how much the lines were twisted, insufficient twisting will cause the lines to easily to easily change length, a bit like a bungee cable. There is an optimum rate in twisting lines for stability and I saw some peoples having tendencies to simplify the turning method.

-

Thank you mark, here is my latest model at 1/48 scale... and the set-up is ready to begin the next stage.

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

Thinking Things Through - French Frigates

Gaetan Bordeleau replied to mtaylor's topic in Nautical/Naval History

Here is the example. 3 inches 6 lines 195/100e I really do not know the answer, are these 2 values the same thing, is the unit of 195 represented in 1/100? -

Thinking Things Through - French Frigates

Gaetan Bordeleau replied to mtaylor's topic in Nautical/Naval History

Mark, which page, I will look in the french version. -

Thinking Things Through - French Frigates

Gaetan Bordeleau replied to mtaylor's topic in Nautical/Naval History

Who wrote that book? Is he comparing old english and french foot? 3 po 6 lignes 195/100 1,95 x 2,707 5,27cm 3.5 pouces x 2.707 cm/pouces : 9.47 cm link : centieme partie de la chaine: 7,92 pouces 1,95x 5,27 9,87 195/100 : 9,87 cm Link: chain subdivision in arpentage in England -

Except for 2 dolphins and 1 set of flowers, we have a good idea of what the side view will look like. As for the white background , for a piece of 8 feet large, I still need some practice

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.