-

Posts

1,307 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Gaetan Bordeleau

-

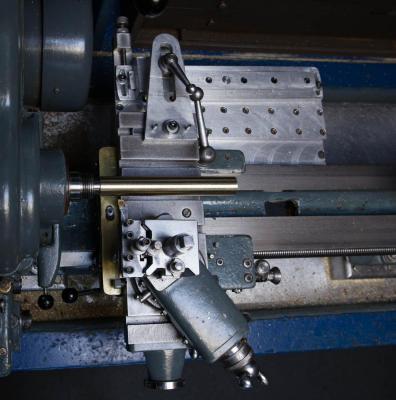

Hi Greg. No form tools are used, 4 knifes are used and about 3 or 4 files dor the whole process For the reinforcing ring, it is made in 3 stages, the ring, 1 groove on each side and for the round top, a file. Wooden templates are much faster to use than the digital read out when there are many repetitive measures, and also you can have a global view in 1 shot. I do not like to use digital read out on the lathe, I prefer to read the measure with a digital caliper directly on the part because like this I read what the diameter is really is not what it should be. On the milling machine, I use it sometime when by example I would need to drill 2 holes which needs to be exactly at .250 inches apart exactly.

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

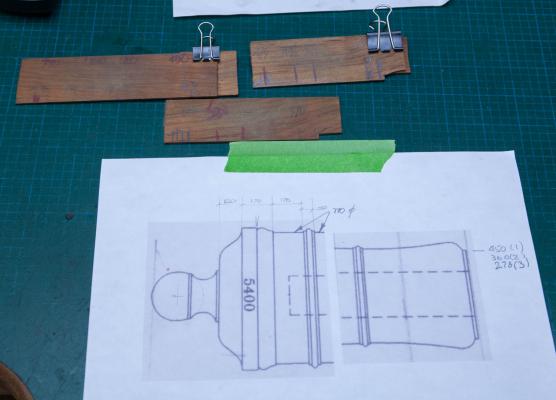

% of composition is probably the answer. If I would have to give it a name, I think this is probably free machining brass! The longest part to turn guns is done. 4 knives are use for the top and bottom turning. Lenght references are done by a reference wood plate, it is mucg faster this way. The head is done first and then the inside is drilled. This operation is done as late as possible so that the opening dos not enlarge because of the live center. The bottom part is kept for the last part.

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

http://www.theobrejaart.nl/frame.html Jaager, this guy in the Netherlands sells high quality linen" It is not 100/1 but rather 100/2, 120/2 and it is very easy to turn.

-

Now I see what you mean David. In fact I guess that the definition of a large scale is the longest lenght you are willing to realize a model in a an environment where you can move it.

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

Druxey, I do not know very much about brass grades. I do not know what grade I use. A quick search shows that there are 2 categories of brass: leaded or non leaded. Free Machining Brass (360 Brass). The most commonly used of the brass rod and bar items. The presence of lead (2.5 – 3.7%) in the alloy creates a highly machinable material that can easily be cut and shaped into whatever you need C464 (Naval Brass) offers high corrosion resistance to seawater. The substitution of tin equal to the same amount of zinc allows naval brass to be resistant to dezincification, but also gives greater strength and rigidity. As for the long curls parts, I have never seen that with the brass type I use, so may be I do not use 360 brass? Thank you Avsjerome2003. David, is 1/72 really a scale for a large model? I do not know, but as you say it is surely easier to handle; but also remember, the bigger it is the easier it is to build. I prefer easier build, so I think I will stay with a scale not smaller than 1/36.

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

Turning guns Le Fleuron had some guns with decorations on it. Also, we could have seen some 24 pounds but for some unknown reasons, this ship was poorly dress with low caliber guns. Considering that I prefer a more homogeneous look and also that I already a brass supply of round bars, I will only fabricate standard guns and for 1 side only: 12 x 18 pounds, 13 x 12 pounds and 5 x 8 pounds for 30 canons. This would have meant 60 guns plus 4 openings in the aft section from the first deck; 60 guns 64 openings. The key to turn the guns is to progress by set up and do identical operation for each gun. It would be unthinkable to turn 1 gun at the time and to repeat all the setup 30 times. Half inch collet will hold each blank. The use of collet is much more precise than a 3 jaw chuck. After cutting the blanks, a shoulder of half inch is done at 1 end and a pilot hole is drilled at the other end for each blanks. Next, a taper attachment is use to turn the required taper angle. The cross section leading screw is remove and the positionning is done by a guide following an angle. The easy way to set up the taper adjustment angle is to turn a taper blank and adjust the difference of diameter for a given distance, the adjustment can be done in 4 or 5 light passes . The tapered portion of the gun is in the middle section. Head and bottom are kept for later and do not require the taper attachment to be turned. For the middle section, 3 shoulders are turned. The rest of the turning will be done without the taper attachment. Brass is very different from steel to turn. Instead of long swirl, thousounds of small shine flies everywhere and also on the floor. The faster the turning speed, the farther the particles fly. Cleaning is longer to do than turning. It is important to keep the taper adjustment angle clean in all time to have a smooth operation. The only way to do so is to place a cloth over it to keep it free from particles.

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

HMS Pandora

Gaetan Bordeleau replied to Magnus's topic in CAD and 3D Modelling/Drafting Plans with Software

I like the last video. It is very informative. It look like to be as on french ship. The height of the longboat probably means that they were not sitting as we normally do on smaller boat. I thing they were standing up and resting on like on the second picture. -

Hi Redshirt, 1/48 is the largest scale than you can easily handle for a 4 feet model. Why someone would like to go larger then? I like to try new challenges and I like to explore scales. For this I did a project of building a french 74 guns at 3 different scale. The first one was at 1/192. To like this scale you must be a good jeweler and almost always wear strong glasses. Then I did it at 1/48. After this experience, having tried 1 very small scale, 1 medium, only 1 was missing; a large scale. New challenges, new tools : for the big parts the small bandsaw is inadequate. The hardest tool to find for this project was the working table; I tried 3 different ones before to get 1 which adapts to height easily workable without getting titred because of bad positions. Wood is also a major aspect. This week end, a guy told me very seriously that this model surely worths $1000. I answered him : I bought 2 batchs of cherry wood for this project $700 and $1000. He did not ask other questions! I might look large quantities but I estimate that starting with a 2 by 12 inches over 65% is lost is shaving, saw dust and scrap wood especially when cutting the frames. The biggest problem building at 1/24 is to know where to put it when completed because it does not really belong in a house. In a way when the model is finish I could put it in the garbage and build another one. The pleasure is not to own it, but to build it. There are advantages to build a bigger scale. First it is easier; the easiet it is to hold a plank, the better the results will be. Larger scale allows to install more details and more importantly, it helps you very much to understand the way these superstructures were built and just for that last reason, it is worth it!

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

In Quebec province, the easy way to present a model ship is toparticipate to an exposotion. This year, it was : Montreal Model Train Exposition. There are rarely exposition for modelship only. Children are fascinated by trains, especially when they are moving. The only thing accessible to move on the 64 guns are the gun port openings and many peoples wanted to try it. I had to answer what do you need to make quality scluptures? In french we say ‘’sens des proportions’’, in english it would be something like the way of the proportions. By examples if I want to see if a piece is at scale, I install a figurine just beside it. For the sclupture of the human body it is essential to understand that every parts are made in proportions one to another. Before attempting to carve humans, you must understand it. Drawings books explain this very well. It is the same idea in the nature, often for something to be nice it is a matter of proportion. This exposition is to support Sun Youth and the nicest thing I saw was a stem locomotive. Such meetings are always instructive. While talking with other peoples, I realised that the small rudder size surely needed a very large radius to turn. Before the rudder wheel, it is possible to think that the rudder was narrower so that mens on 2 differents decks can be able to shift the rudder handle of the 64 guns. Later with the event of the rudder wheel, it was much easier to have the rudder to turn, especially because of the large diameter which geared down the effort. The same idea can be apply to the pulleys used for the cannons on the french ship like the 74 guns; the bigger the diameter of the pulley, the little effort it is needed.

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

Hi John, Here is the link the last time I wrote about tung oil : http://modelshipworld.com/index.php/topic/327-le-fleuron-by-gaetan-bordeleau-124/page-21 I do not plan to do the rigging, I would need a ceiling twice as high. Tung oil polymerize in presence of air but I do not think that it is faster drying than varnish. I have no problem to keep it liquid in the bottle. « Polymerizing generates significant heat » Possibly in larger and thicker quantity but there is no problem in small quantity as I use for the modelship or for the furniture. One nice quality of cherry is aging taking a darker and richer tone. This model is 100% cherry. There are many reasons for this choice and cost is one. At this scale, large quantity of wood is needeed , this is the second batch of wood I buy for this model. For the previous build, the 74 guns, I went with many exotic woods such as ebony and bocote. I can guaranty you one thing, the price was also very much exotic! The look from tung oil is more elaborate than what it can be with linen oil, danish teck oil or even shellac. There are 2 important qualities that I like about tung oil beside the look. In comparison with the others, this oil looks to be something like filtered and look like to be a pure oil. I took photo of all these oils on wood and often we see reflection like on a mirror. This is especially true with shellac. With tung oil, this problem is not there.

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

John In Canada it is sold as bitumen of judea, example sold in powder: https://artdec.ca/en/p/82/bitumen-of-judea

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

what is the ideal modelling table?

Gaetan Bordeleau replied to AON's topic in Modeling tools and Workshop Equipment

-

Before I bought stdio flash, I did a lamp with 2 adjustable LED spots. I took it out of the closet and installed it over the working table. You can see on the table top how it illuminates. The last picture is done with these 2 spots. I also did a table for the next exposition. I tried a new receipe for fast dying and waxiing wood : Drop Bee wax shavings in a pot cover with odorless turpentine This will make the wax liquid and it will be very easy to apply the wax, and the turpentine will then avporate in the air. To intensify the color and also to give a greater aged look, add bitumen and mix. Again turpentine will do the same action as it did to the beewax. For a final ingredient, double the quantity already mixed with tung oil which is also going to help the look of the wood grain m making iti look richer.

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

what is the ideal modelling table?

Gaetan Bordeleau replied to AON's topic in Modeling tools and Workshop Equipment

$400 US, max load 70 KG, for that price, it is surely good, the main difference is the max load is 150 KG for a standing desk. Another option, here in Quebec, on Kijiji, we can buy a used dental chair between $300 and $600 CA, with a max load of about 150 KG. 1 disadvantage; the weight, easy to compensate by adding wheels. -

Here are the pictures I would have enter in a 2015 Contest ; but I forgot to enter. I took what they considered weak points in the 2013 Contest and turned it in strong points: CONSTRUCTION D’UN MODÈLE D’UN VAISSEAU DE 74 CANONS FRANÇAIS À BREST EN 1780 POUR L’INSTRUCTION DES GARDES DE LA MARINE SELON LES ORDONNANCES NAVALES You will enter in an Innotive approach for the construction of this 1/24 scale model, 8 feet long. This bigger scale made possible the discovery of new opportunities and provided another layer in Hull construction techniques. Here are some words of wisdom from the Great Master Builder SJSoane : « All details should be considered in light of the overall artistic effect of the model as a whole. Building the details helped me understand how these ships were made, and how the parts functioned » Underline part is similar in essence to what Jean Boudriot said about when determining the shape of the rail that in a sense the shape had no specific shape but it must perfectly blend with the whole model when making the main, middle and lower rail. New scale means new problems : How to bend ½’’ of ebony? You must cut it from blocks. The model weighs 125 pounds. How do you adjust the working height of the model? Quite easily in fact, with an electric modified dental chair. Bigger scale means larger wood grain. Cherry wood is a good example at 1/24 scale. When carefully selected, nice wood grain patterns appears. Woods for this build are also chosen for their color. The rarest wood used is Bocote. Other than his distinctive nutty odor when cutting it, this wood quickly darkens in presence of air. On the model, outside planking above the wales shows this wood as if it has been aged for 100 years. No paint is use, only Tung oil, a finer oil than linen seed, clearer with no deposit. Whenever greater aged look is required, natural Bitumen in powder is added. This work was inspired by ‘’Naval Ordonnances’’ for Marine Guards in Brest, France. It is intended to be built as an instructionnal model, which could be use by Naval officers to teach the aspiring officers. Instructions were grouped in 2 categories : Masting and Rigging, the standard methods according the ship size and category. For this build, the other category was deeply explored : Hull construction is unique for each ship according to his own decorations and sculptures. Big cares are taken to build the inside and it would be a shame not to show it. Decks are left open as much as possible to facilitate inside looks. Port side is left open to show the double framing structure. Cannons are installed on 1 side only, so that construction methods can be emphasies the other side. Oversized recoil pulleys, standard french navy procedure, increasing the diameter to reduce the number of men required.

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

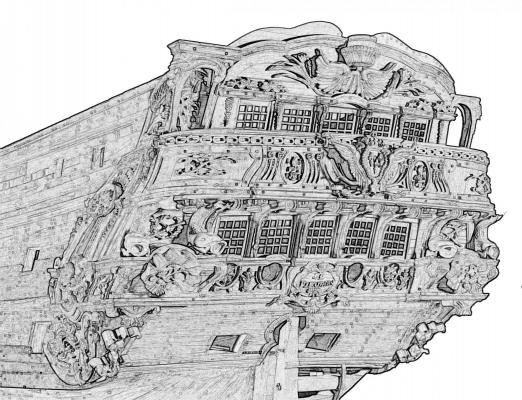

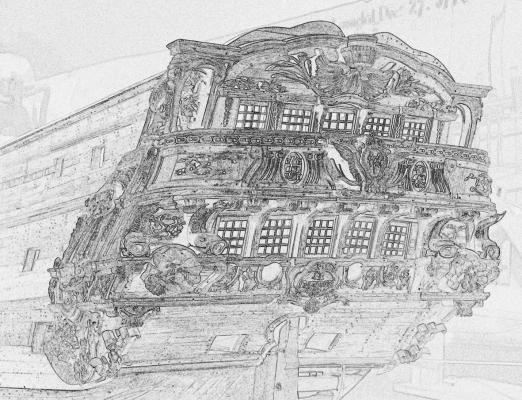

While I am on holiday, I explore some aspects from photoshop. Taking the same last picture, I went 1 step farther with the pencil drawing effect.

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

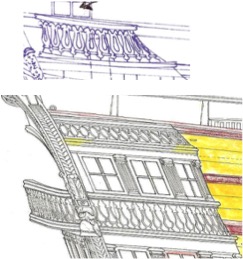

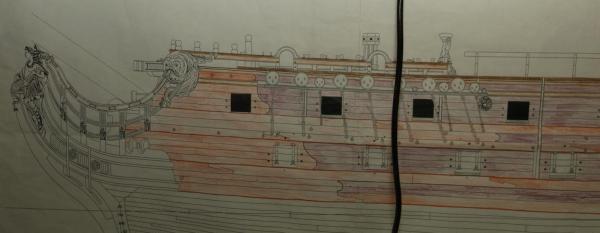

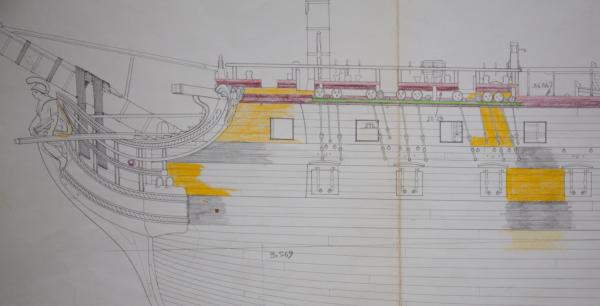

Hi Mark, 2 comparisons with 64 and 74 guns. -Observe the similutude between the pilaster, on yours and on the 74. -Roughly, planking has 2 thickness. For the 64 guns, 1729, in orange is the thickess and in purple is thinner. I would guess that 40 years later, although planking still has 2 thickness, they simplyfied the process. For the 74 , in black, for the wales only, planking is thicker and in yellow, thinner.

-

THE 74-GUN SHIP by Jeronimo

Gaetan Bordeleau replied to Jeronimo's topic in - Build logs for subjects built 1751 - 1800

Hi Karl, Why are you doing 2 models: 1/36 and 1/48? Gaetan- 194 replies

-

Hi Richard, I have never seen peach wood. Would it be possible to post a picture? A fruitwood with close grain and a nice brown color could be a very good choice. Also you should try to work a piece and sand it a bit to see how the wood reacts. How the wood reacts to the knife? How easy the wood can be sanded? Who knows, may be you have a winner!

-

Hi Mauricio, I agree also with you, but if the solution was good in 1729, why this method is dangerous in 1780? What is less dangerous? The shape of the stair or the rope passing on the stair? Gaetan

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

Further comment to Druxey's stairs observation and Ed's. I was measuring the lenght of the rope which will be use to pull the anchor cable out of the water. On the 74 guns, this rope was passing above the stair and it was surely a potentially situation. On Le Fleuron that rope passes below the stair and has a lot of place. Walking stair usually have constant height between each one. In this situation it is like a stair made in 2 parts, one first descent, one stair plate and one final descent; the same principle when a stair gets down turn and get down for the final steps.

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

5 seconds in photoshop: Filtre / Esthétiques / Tracé des contours. That would be a good way to add a drawing in a monograph.

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.