-

Posts

1,307 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Gaetan Bordeleau

-

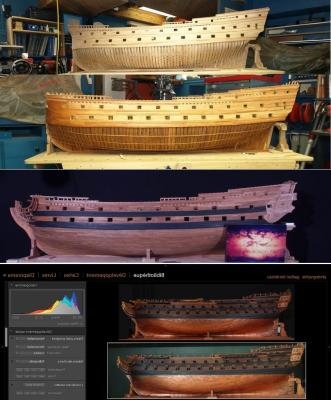

igloo making, no, but the same shape car wax used on the mold so the mold does not stick to the bread stove inside the wooden shell, modified shelf so that it can be self supported by the wall of the oven

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

Byrnes Table Saw Rip Capacity

Gaetan Bordeleau replied to Stefonroman's topic in Modeling tools and Workshop Equipment

Markus, True, theorically, the worst things can happen but there are differents ways to manage risks and you decide which measures of security you apply. -

Byrnes Table Saw Rip Capacity

Gaetan Bordeleau replied to Stefonroman's topic in Modeling tools and Workshop Equipment

Markus, everyone uses a tool with security he feels appropriate according to his experience. Does the same rules applies to a 10 and 4 inches table saw? No, even if it is the same tool, different reactions and power. -

Byrnes Table Saw Rip Capacity

Gaetan Bordeleau replied to Stefonroman's topic in Modeling tools and Workshop Equipment

''If this is not enough for your purposes you can ask Jim to make you one with a broader table to your specifications,'' or a simple modification to lift one side of the fence and you have no maximum lenght. -

Hi Nigel, carvings were made from boxwood. For the look, apple is better than pearwood in the way it has more grain. Interesting wood to work. I did some carving in pear, it was well acceptable. I think that apple is heavier than pear, pear being exceptionnally light for his density. I guess apple would produce very nice carving details and comparatively to the color of boxwood it would be in many cases more acceptable. The first year I used apple, many cuts were made about 1 cm thick and the wood was left to dry all winter long in a room inside. The smell was not very pleasing.

-

Captain Steve, What is pleasant with these mixes, everyone can create a mix which suits his needs. I do not follow any ratios. I add bitumen till I am satisfied with the result on a test piece of wood. In this case, 3 ingredients are involved; bitumen, tung oil and turpentine. Bitumen and tung oil can be mixed together but it is easier if turpentine is used first to help to dissolve the bitumen. Bitumen can be applied with or without the tung oil together or separately. Again, testing is the answer. When possible, I prefer 1 coat of tung oil. I have never tried by example 10 coats, but I suspect that there woul be a kind of brilliant finish with a certain thickness. Also I think that this finish could be reflective to the camera flash. I prefer the look of 1 coat, because it has a more natural look without this plastic finish. This reflective surface was particuliary true with linseed oil teck oil which, I guess, are not as refine. Chris, when you say that it sort of acts like a wash in oil painting this is true especially for the first coat but not so true for the second coat depending of the drying tie between the 2 coats.

-

W.. I did experiments with bitumen and i will try to explain what I observed. The main reason to use it is for properties to make the wood look like older, to give more aging to the wood. This cannot be compare to paint because it does not cover completely. It would be more on the side of dyes. One of the advantage of this powder, is depending of the amount you add, you will get different results. Asphalt can be mixed with many components depending of the look we want to produce. Beeswax Slows drying time, soften the color and more transparent. Mixing it with the bitumen allows beewax molecules to bind and make the asphalt more neutral paraffin: help beewax or could be white wax candle asphalt: Was used by the egyptiens for embalming Oil suluble pine resin: Gives plastic properties and can form a varnish if mixed with alcool natural soap: probably for the oils in the soap turpentine: Fluidity and solubility of the mix siccative: shorter drying time, max 10% of total mix. My preference is to mix it with tung oil, that I prefer to other oils. When dry, this oil does not produce a shiny finish which is particuliary visible when you use a flash on the camera. At first, I used only tung oil which gives a look of 50 years in aging the wood. Later I did experiment by adding asphalt. In small quantities, it will act as a dye but clearer, not as dark as a dye can go. In the mixing, when you exceed his property of absorption by dilution, asphalt powder will precipitate in the bottom of the container and if you use this mix, it will produce on the wood a general finish plus different spots which can look like dirt caused by time. I remember the first time I saw the utilisation of bitumen. It was on a 74 gun ship made by A French named Fichant. By using bitumen, he made his model look like 150 years older than it really was.

-

Thank you Druxey, the exhibit is there for few weeks. Thank you Mark, a visitor who has never seen a model before cannot imagine what he is going to see. He thinks he will see some sort of kit at the best. When he sees the first models, he is very much surprise and for what he sees after, well he was not prepare, to see two 8 foot models. I would have liked to bring more things, but too much is like not enough. There was a possibility for 2 cases: 1 for ropes and 1 for tools which are used to build model ship. A rope machine always has success when she does a little demonstration because most of the peoples have never seen how ropes are turned. The other case has some tools. Some are made, some are bought. On the stand, one of my favorite is the hammer handle, I bought some and I did some. Since I tried these balanced handles (wood counterweight at the opposite of the handle), I love it and I would never return to an ordinary handle. I also brought some machinist tools used with the lathe or the milling. I did fabricate tools about 10 years as a hobby, using these to climb in a spiral to build more and more complex tool. Last Sunday I did a 3 hours lecture about this hobby. In the first part, accordingly to what I recently discovered, model ship began in England around 1650 and few years later in france in 1689 , following an Ordinance about Instructions for Navy Guards in Brest. The main part being a complement after you saw the models outside only, peoples were able to look inside a model at every level and I guess they liked to see in pictures this side of the model ship.

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

The Byrnes Saw "inside and around"

Gaetan Bordeleau replied to nobotch's topic in Modeling tools and Workshop Equipment

-

Hi Craig, Every one who is facing his first scratchbuild is wondering if it is too much ambitious project, but as you progress in your build, you gain confidence. I would suggest you 3 things: Create a log in this forum for your gros ventre, the simple fact to share your work on this forum, will allow you to learn very much faster and also many excellent builders are present on the forum to help everyone who needs it. You should have a look at another French forum and you can go by google chrome to help to translate if you need it. There are some peaples building le Gros ventre: http://5500.forumactif.org/f36-le-gros-ventre-1766-plans-gerard-delacroix As such, I do not know if there is a practicum for le gros ventre. There are few practicums which are on the market. Although these practicums are not for the gros ventre, you could buy one and it could be very useful. When you are confronted to your first build you do not really know in which order you should begin the construction. With a practicum, you will see examples in which sequence to do it. Examples of practicum are available there: http://www.seawatchbooks.com/ I do not know if books from Harold Hahn are still available but he wrote few practicums http://www.dlumberyard.com/hahn-PART1.html http://www.amazon.com/Harold-M.-Hahn/e/B001KIL38Y If you think you can do it, I strongly encourage you to continue and I wish you good luck.

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

The Byrnes Saw "inside and around"

Gaetan Bordeleau replied to nobotch's topic in Modeling tools and Workshop Equipment

May be instead to install a splitter to prevent kickback, I would read the manual how to use the saw, especially the part on how to hold the plank to prevent kickback. For modifications, i like this one, a simplified version which appeared in NRG journal. -

Hi Michael, you can have an idea at this address. http://antoinelacombe.com/evenements/gaetan-bordeleau/ + a lecture in 3 parts: 1- Provenance of modelship building (when and why) 2- Few realisations from other contries (examples of recent and old models) 3- Construction of a model for the Naval Instruction (explaining what is a model for the instruction of the Naval officers through the construction of the 74 guns at 1/24 scale)

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

In over 30 years, this is the first time there are no model ships at home. The 5 left I have are regrouped in an unlikely duo; model ships and spiritual paintings. I think, even if there are only 5 models, scale scope is covered and I guess that nobody was prepared to see models at 1/24.

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

That should be very good. In Europe they were and they are still using this wood. One of the best advantage it can be work in every direction. Could you show us a picture please? If you want I can show a picture of european pearwood but because it is dried with steam, the wood turns some kind of pink.

-

Norman, I am surely not an expert about bitumen, but here is how I use it. About UV stability, I do not think that it does matter simply because models are intended to see the sun. The key is the quantity, effectively, too small quantity, it will not be enough apparent and too thick it will not dry. Usually bitumen is applied mainly on the hull, on large surface. Bee wax is added in the mixture, so oxidation, I guess, is not acting that much. Bee wax has been used for centuries for wood cabinetry. In this case bitumen is added to this mixture to simulate time aging and I like the effect.

-

Chris, I would not do carving with an exacto, in fact I do not use anymore this kind of blade. I use almost exclusively sclalpel 5A with a handle, blue plastic covered and blade 11. When you use scalpel, you find that an exacto does not cut. Peaple say that scalpel blades breaks too easily. In fact, it is true, but when you learn that this kind of blade is not made to be use in torsion, then you rarely breaks it. Also, carving is a strange world, hand are made to do carving and feel shapes. Of course you need to practice, but when you try an you see what you can achieve, then a little miracle happens, you beleive that you can do it, and then you carve it.

-

The Russians introduced ourselves to the ‘’bitume de judée’’. The first time I saw it was on the French forum. Alex talked about his receipe containing the following ingredients. Beeswax: Slows drying time, soften the color and more transparent. Mixing it with the bitumen allows beewax molecules to bind and make the asphalt more neutral paraffin: help beewax or could be white wax candle asphalt: Was used by the egyptians for embalming Oil soluble pine resin: Gives plastic properties and can form a varnish if mixed with alchool natural soap: probably for the oils in the soap turpentine: Fluidity and solubility of the mix siccative: shorter drying time, max 10% of total mix. An easier version can effectively be done by mixing tung oil and bitumen. Depending of the bitumen solubility, an agent can be added to help to incorporate with tung oil. As long as bitumen is not applied in a too thick coat, there will be no problem to dry. On the picture, concentrating on the first 3 tops ones, bare wood, tung oil, bitumen. Another way to apply it is with beewax + turpentine odorless to give it some flexibility and ease in application and add bitumen and then some polishing is needed (but this method is better suited for wood cabinet). Wax is easy to apply on large surface. but when too many corners, it is a less interesting option.

-

French Ships - Operational Question

Gaetan Bordeleau replied to mtaylor's topic in Nautical/Naval History

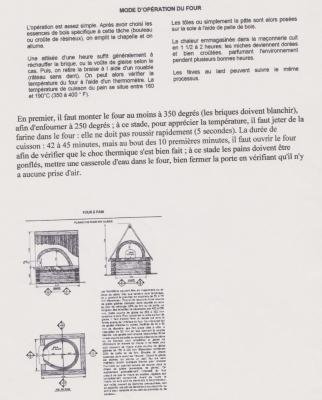

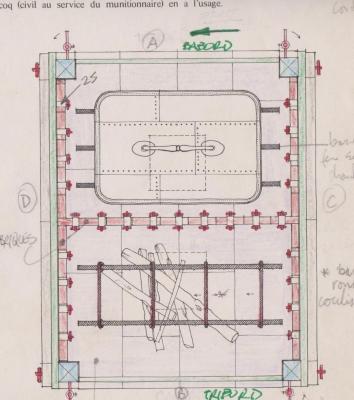

Mark, you want to make things more complicated than what they really are, and you must be careful about O. Bello; in the french forum, he would never be use as a reference. On a 74 guns ship, there was 3 stoves; bakery, bread and the general one for the kitchen. For these 3, the fuel is wood. Here is a method, unfortunately in french, explaining how to use the bakery oven. -

Thank you Messieurs! The pelican was just a nice gift. Unfortunately, there are no such birds in Canada, unless may be at the zoo.

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

''my dremel is much to aggressive for this type of drilling and the smaller drills do not fit in my other micro motor'' Remco, could you explain more? Dremel adjusts at the lowest speed turns very slow Drill 080 fits in the 3 jaws chuck from Dremel

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.