timboni

Members-

Posts

58 -

Joined

-

Last visited

Recent Profile Visitors

-

Ryland Craze reacted to a post in a topic:

USS ST LOUIS by thorn21g - 1:24 - POF - Civil War Ironclad - Gateway Model Shipcrafter's Guild

Ryland Craze reacted to a post in a topic:

USS ST LOUIS by thorn21g - 1:24 - POF - Civil War Ironclad - Gateway Model Shipcrafter's Guild

-

yvesvidal reacted to a post in a topic:

USS ST LOUIS by thorn21g - 1:24 - POF - Civil War Ironclad - Gateway Model Shipcrafter's Guild

yvesvidal reacted to a post in a topic:

USS ST LOUIS by thorn21g - 1:24 - POF - Civil War Ironclad - Gateway Model Shipcrafter's Guild

-

Canute reacted to a post in a topic:

USS ST LOUIS by thorn21g - 1:24 - POF - Civil War Ironclad - Gateway Model Shipcrafter's Guild

Canute reacted to a post in a topic:

USS ST LOUIS by thorn21g - 1:24 - POF - Civil War Ironclad - Gateway Model Shipcrafter's Guild

-

Scott Crouse reacted to a post in a topic:

USS ST LOUIS by thorn21g - 1:24 - POF - Civil War Ironclad - Gateway Model Shipcrafter's Guild

Scott Crouse reacted to a post in a topic:

USS ST LOUIS by thorn21g - 1:24 - POF - Civil War Ironclad - Gateway Model Shipcrafter's Guild

-

Cathead reacted to a post in a topic:

USS ST LOUIS by thorn21g - 1:24 - POF - Civil War Ironclad - Gateway Model Shipcrafter's Guild

Cathead reacted to a post in a topic:

USS ST LOUIS by thorn21g - 1:24 - POF - Civil War Ironclad - Gateway Model Shipcrafter's Guild

-

JerryTodd reacted to a post in a topic:

USS ST LOUIS by thorn21g - 1:24 - POF - Civil War Ironclad - Gateway Model Shipcrafter's Guild

JerryTodd reacted to a post in a topic:

USS ST LOUIS by thorn21g - 1:24 - POF - Civil War Ironclad - Gateway Model Shipcrafter's Guild

-

ccoyle reacted to a post in a topic:

USS ST LOUIS by thorn21g - 1:24 - POF - Civil War Ironclad - Gateway Model Shipcrafter's Guild

ccoyle reacted to a post in a topic:

USS ST LOUIS by thorn21g - 1:24 - POF - Civil War Ironclad - Gateway Model Shipcrafter's Guild

-

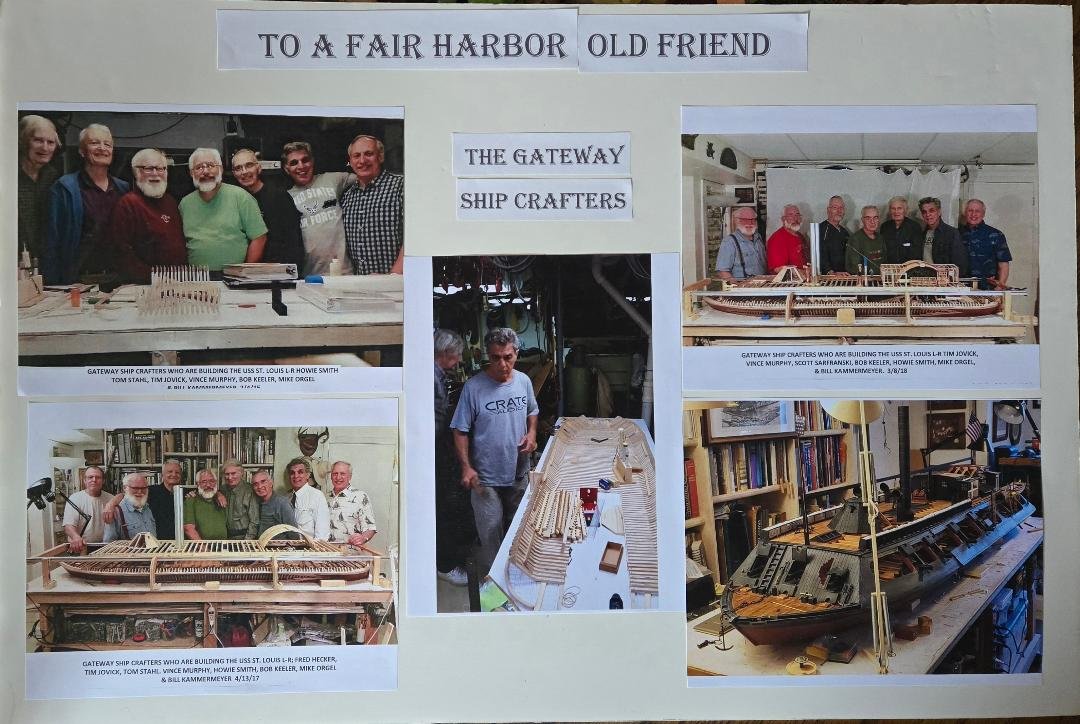

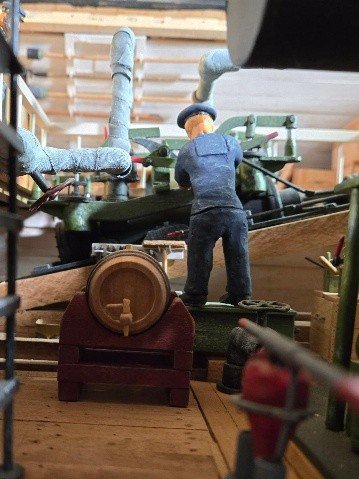

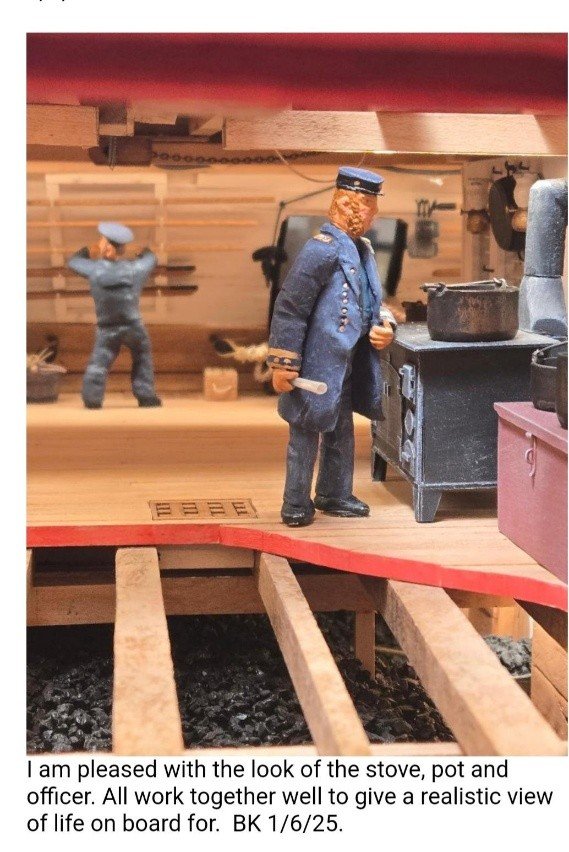

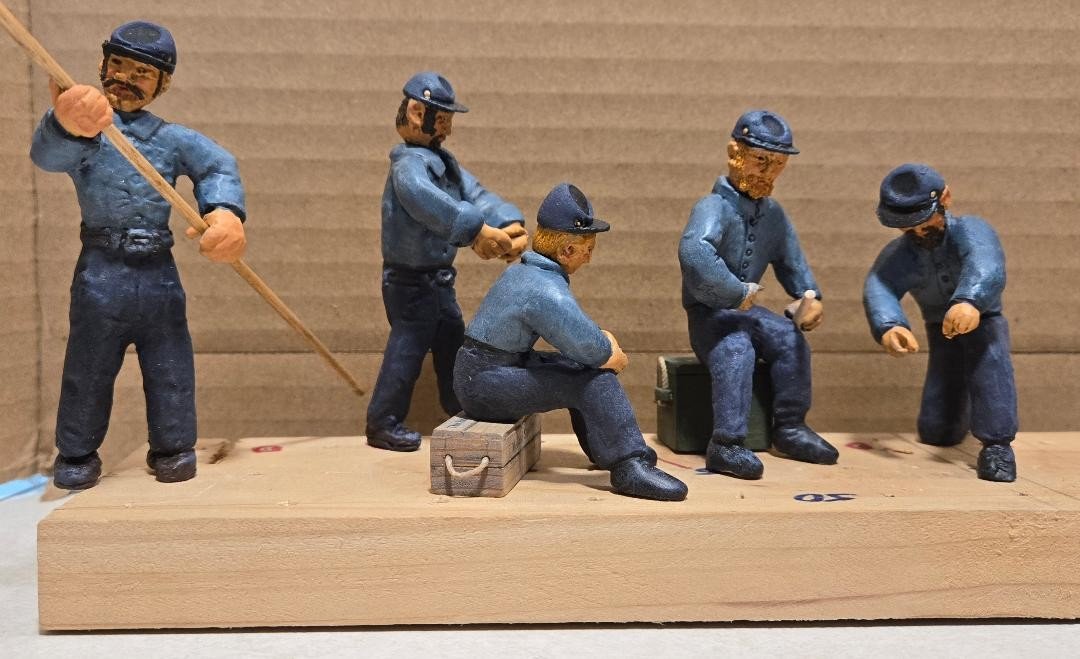

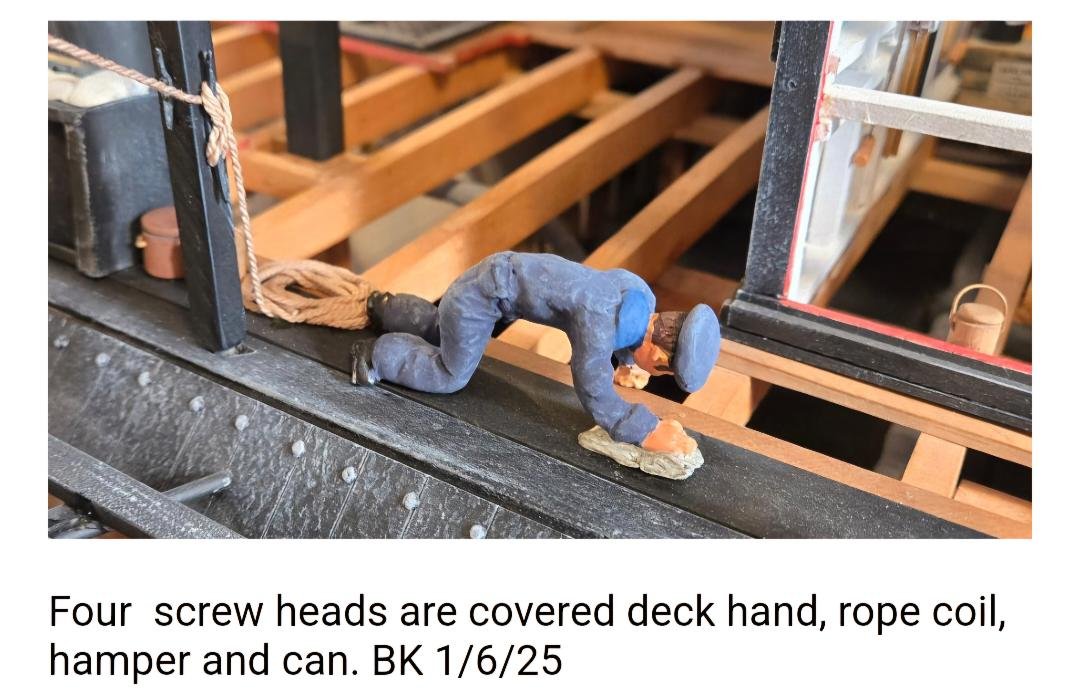

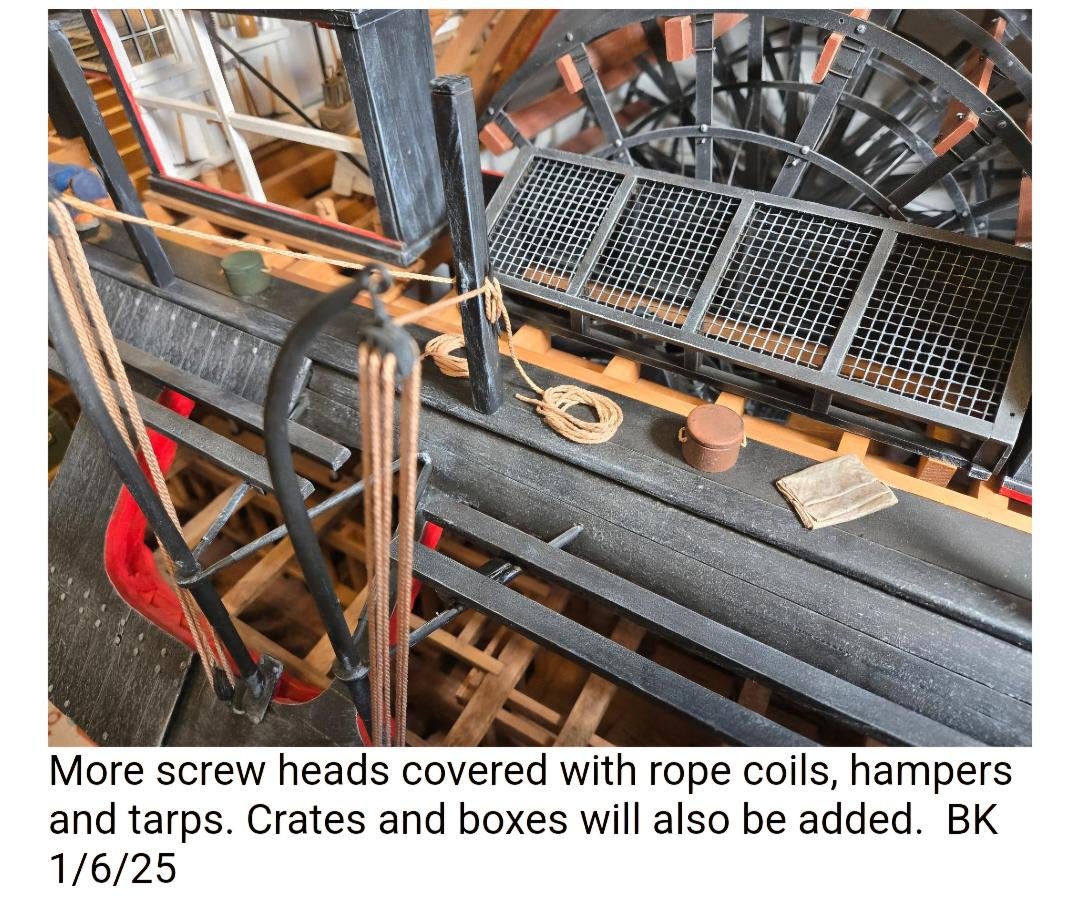

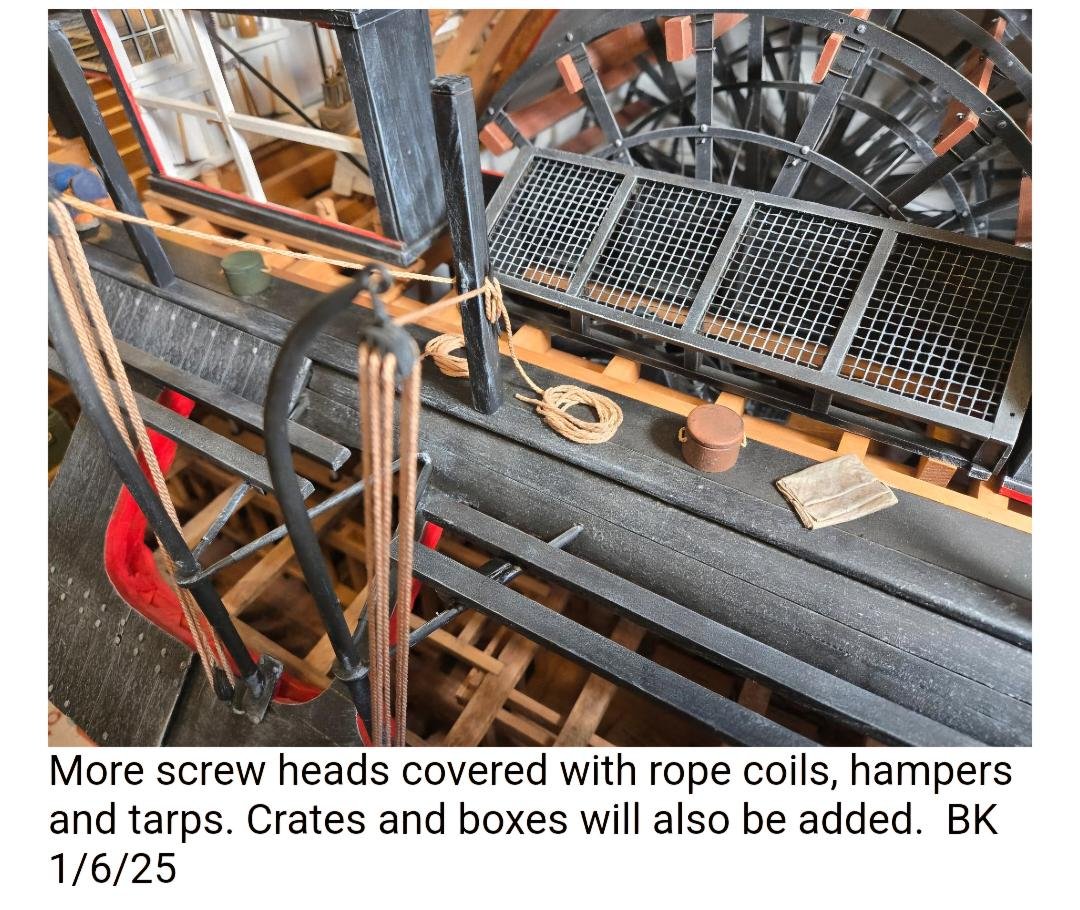

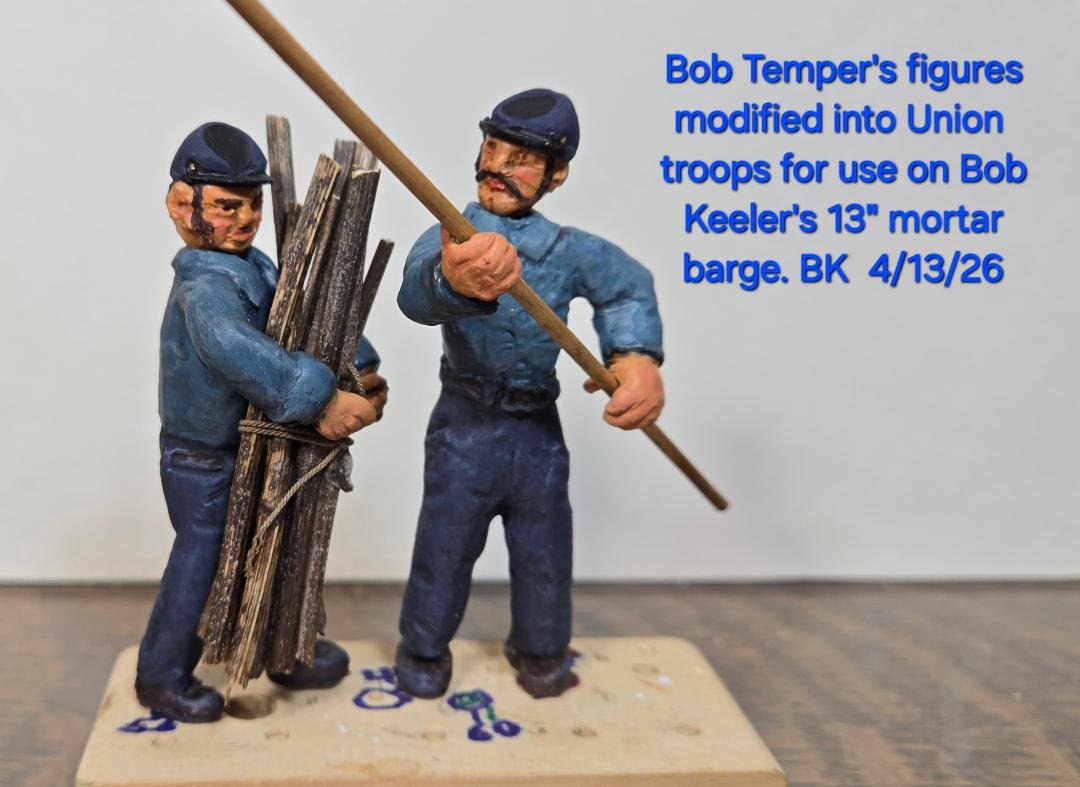

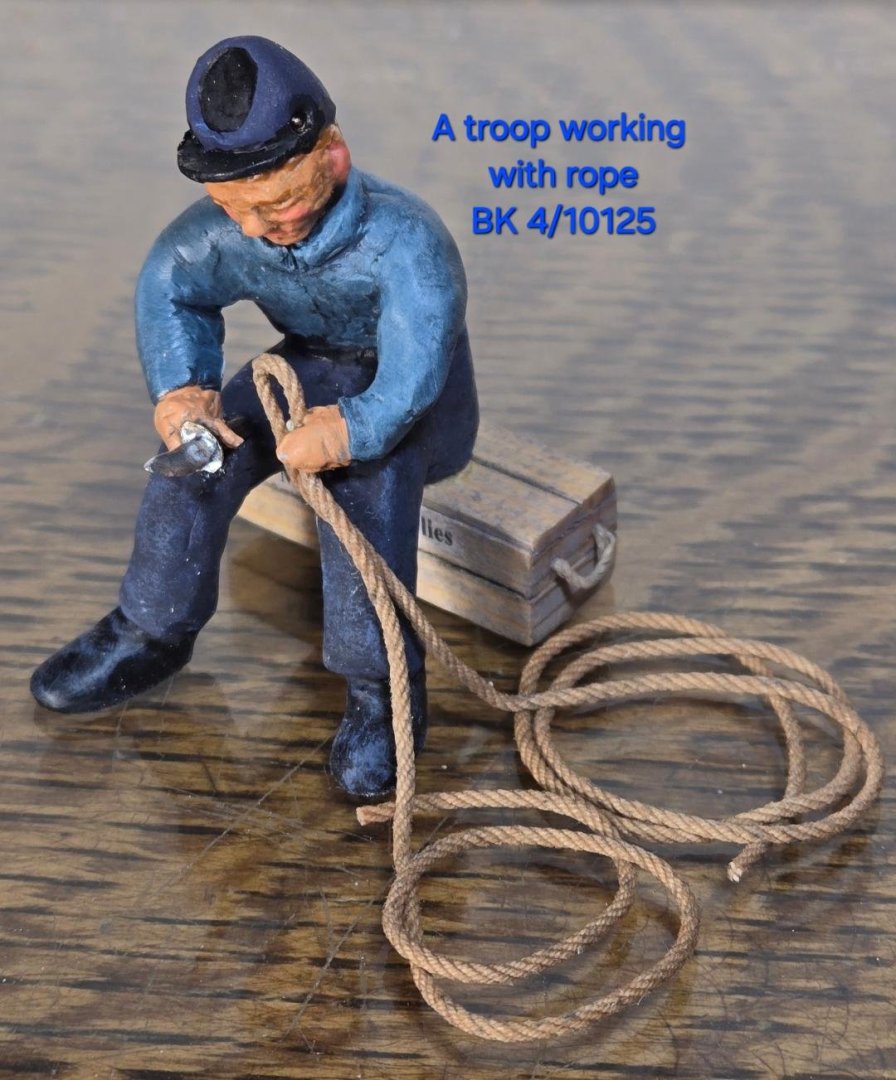

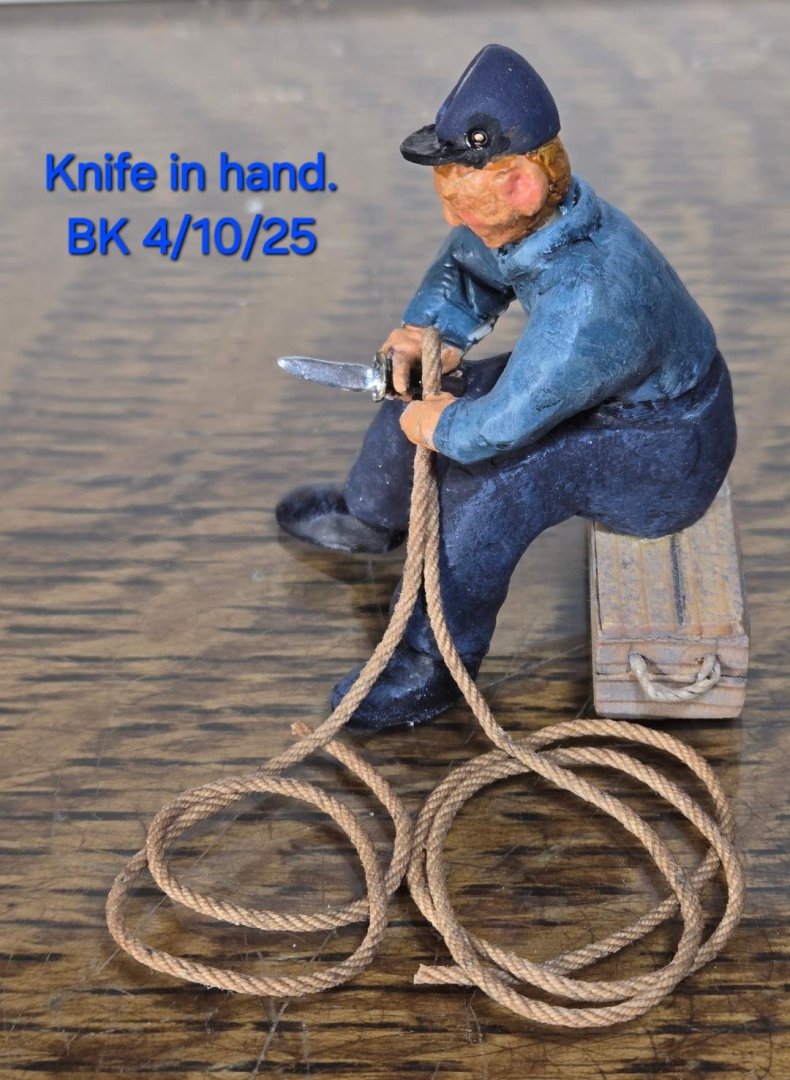

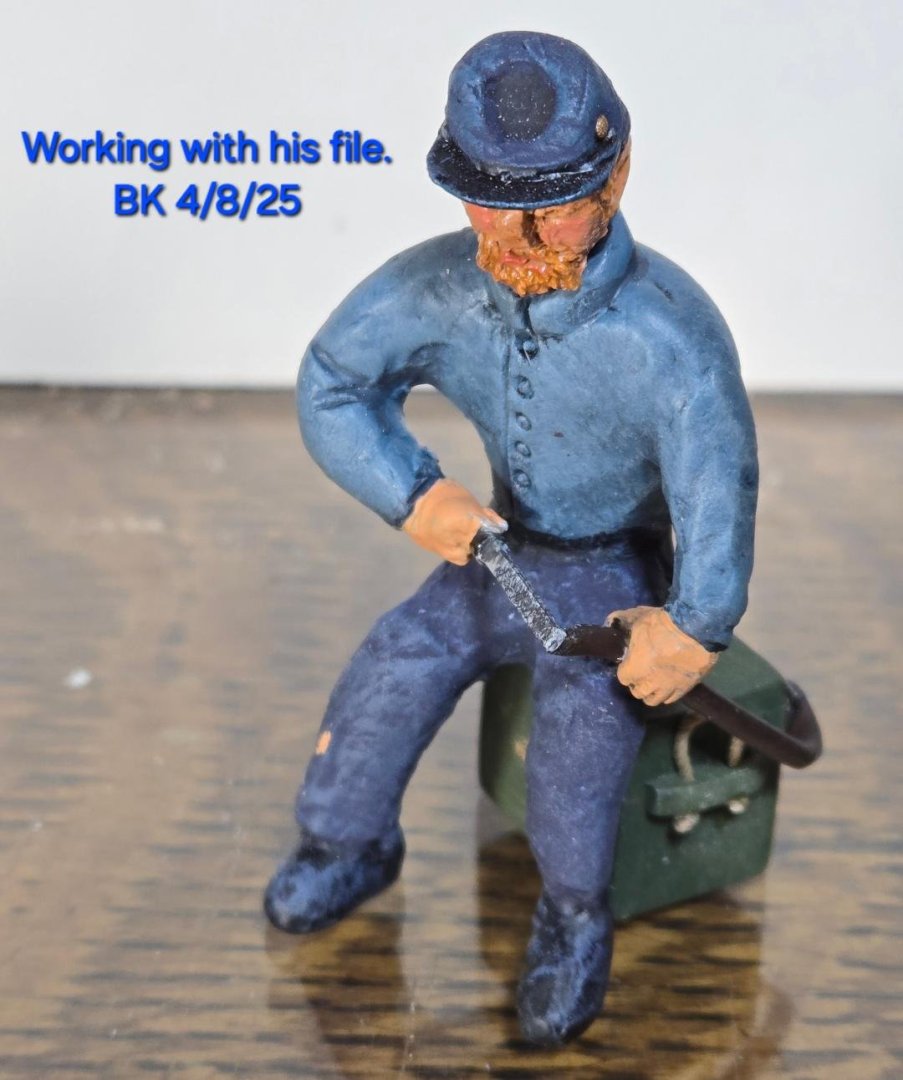

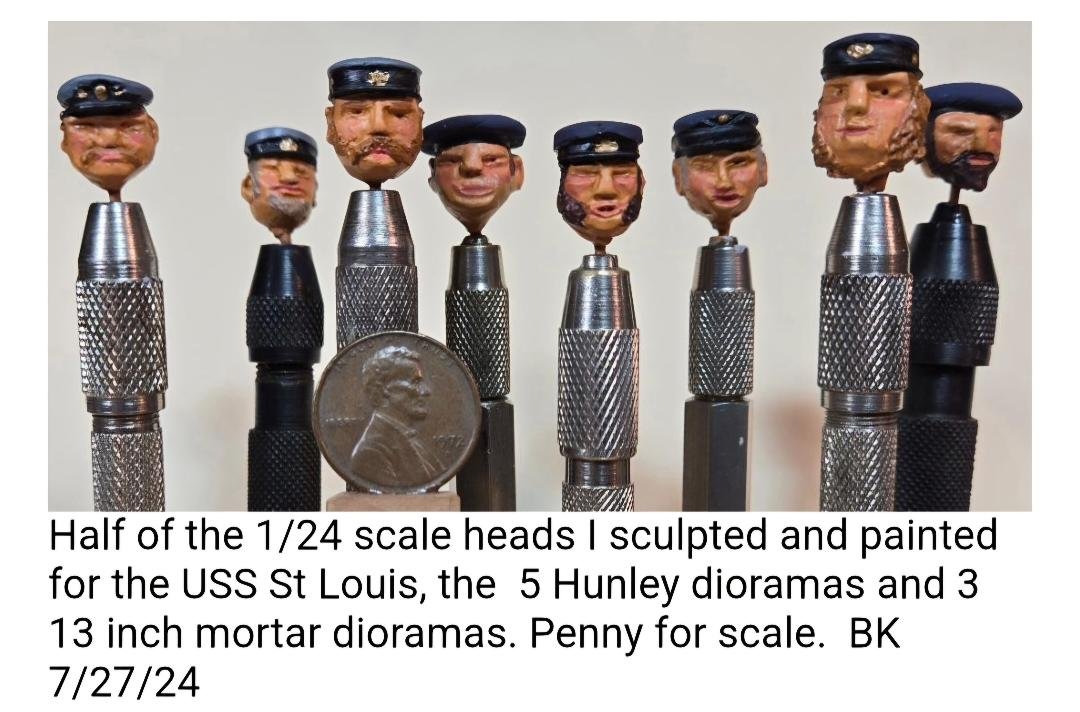

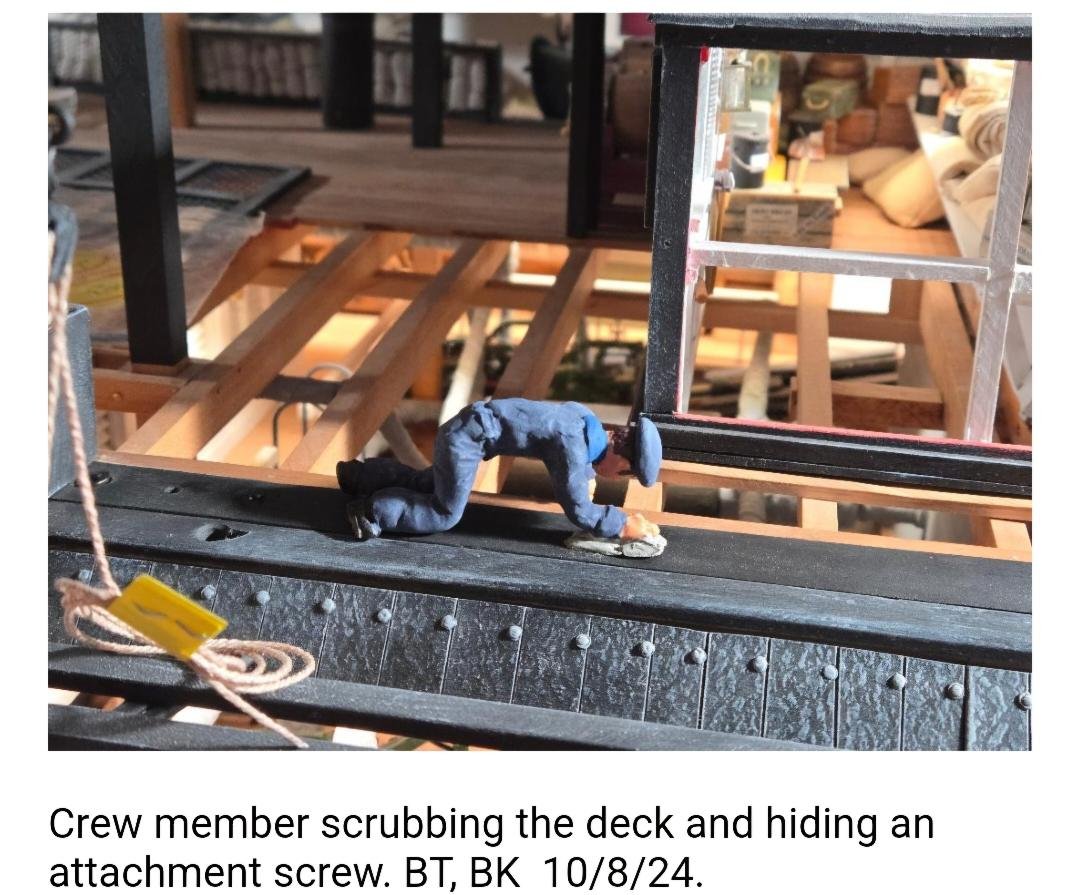

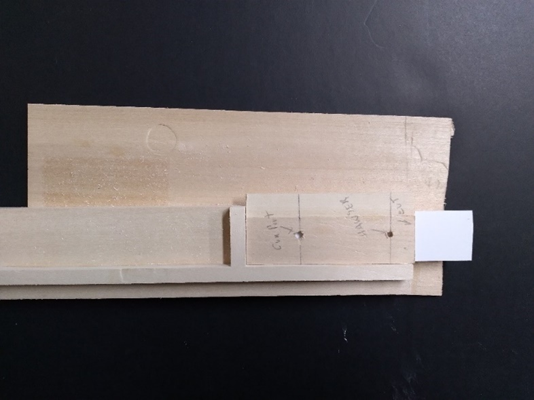

Been awhile since the last posting. These entries are from February of 2025: MICHAEL ORGEL, MD (AKA Dr. Mike) Some sad news to report: Our friend and long-term fellow shipmodeler Mike Orgel (Dr. Mike) died recently. He led a colorful life, being a physician, veteran (flight surgeon), and one who definitely knew his way around a machine shop, having worked in one on a residency in cardiology; he was inventor/co-inventor of several important medical devices, including a heart valve. Dr. Mike was involved in the USS St. Louis project from the beginning, and was a significant contributor, helping to fashion the paddlewheel and other complicated fixtures. He was also an avid cyclist and intimately involved in R/C planes Even at age 86, Dr. Mike still had a crushing handshake, a wide-ranging curiosity, and an associated ability and could talk excitedly and deeply about a variety of topics. And just an all-around good guy. You will be missed, Dr. Mike. Calm seas, fair winds. Officer Figurines, Continued (Bill Kammermeyer) Figures at work before attaching the Hurricane Deck Officers doing map conference BK/VM 12/10/24 Crewman working on 8-inch smooth bore. BK 12/11/24 Crewman with rope BK 12/13/24 Crewman standing on tool chest making adjustments BK 12/27/24 Officer giving tech instructions BK 12/14/24 Officer checking on food preparation BK 12/13/1SS USS St. Louis and CSA Hunley Figures USS St. Louis crewmember working with rope. BK 1/31/25 Hunley quay figures and resting USS St. Louis crewmen on Crates. BK 1/31/25 Hunley dock workers and officers. One on right carries a new signal flag. BK 1/31/25 Army crew for 13" mortars. More may be made for USS St. Louis at time of transition to the Navy. BK 1/13/25 More figurines for Bob Keeler's Mortar Barge, a companion project to the USS St. Louis: MAKING CRATES FOR DECK INTEREST Part of the 28 chests and boxes I built around pine cores with pear and cherry planks, cut to 0.05" on my new Byrnes 4" Micro Table Saw. What a joy! Great cuts with no need to sand. In fact, I wet the surface of each to raise the grain a bit so they did not appear to be furniture. A nice sawn look was achieved. BK 1/13/25 The 0.05" planks were glued to the ends and one side of the block and sanded to the block. The other side, and then the top, were added between sandings. Penny for scale BK 1/14/25 Boxes were stained with driftwood stain and dry brushed with flat gray. Holes were drilled in the ends for rope handles. Scale rope I made was stiffened with super glue, cut to length and bent around a rod, then glued in the holes, and bent down. BK 1/14/25 Onion skin printed labels were added for deck interest. Hail heads were suggested with 36 to 50 indents with a sharp awl. BK 1/14/25 COVERING SCREW HEADS Screws attaching the edge work are all covered save two. Those will each have a coil of rope on them. It should look like a working ship. BK 1/14/25 That's all for now. This project is about 99% completed and ready for transportation to the Missouri Civil War Museum. Unfortunatley, the Museum has sustained water damage from recent storms, which has delayed all of their functions. When the installation occurs, I'll be posting some pictures, also of any further progress on the project itself. Tim Jovick 314-761-5435

-

berhard reacted to a post in a topic:

USS ST LOUIS by thorn21g - 1:24 - POF - Civil War Ironclad - Gateway Model Shipcrafter's Guild

berhard reacted to a post in a topic:

USS ST LOUIS by thorn21g - 1:24 - POF - Civil War Ironclad - Gateway Model Shipcrafter's Guild

-

KeithAug reacted to a post in a topic:

USS ST LOUIS by thorn21g - 1:24 - POF - Civil War Ironclad - Gateway Model Shipcrafter's Guild

KeithAug reacted to a post in a topic:

USS ST LOUIS by thorn21g - 1:24 - POF - Civil War Ironclad - Gateway Model Shipcrafter's Guild

-

KeithAug reacted to a post in a topic:

USS ST LOUIS by thorn21g - 1:24 - POF - Civil War Ironclad - Gateway Model Shipcrafter's Guild

KeithAug reacted to a post in a topic:

USS ST LOUIS by thorn21g - 1:24 - POF - Civil War Ironclad - Gateway Model Shipcrafter's Guild

-

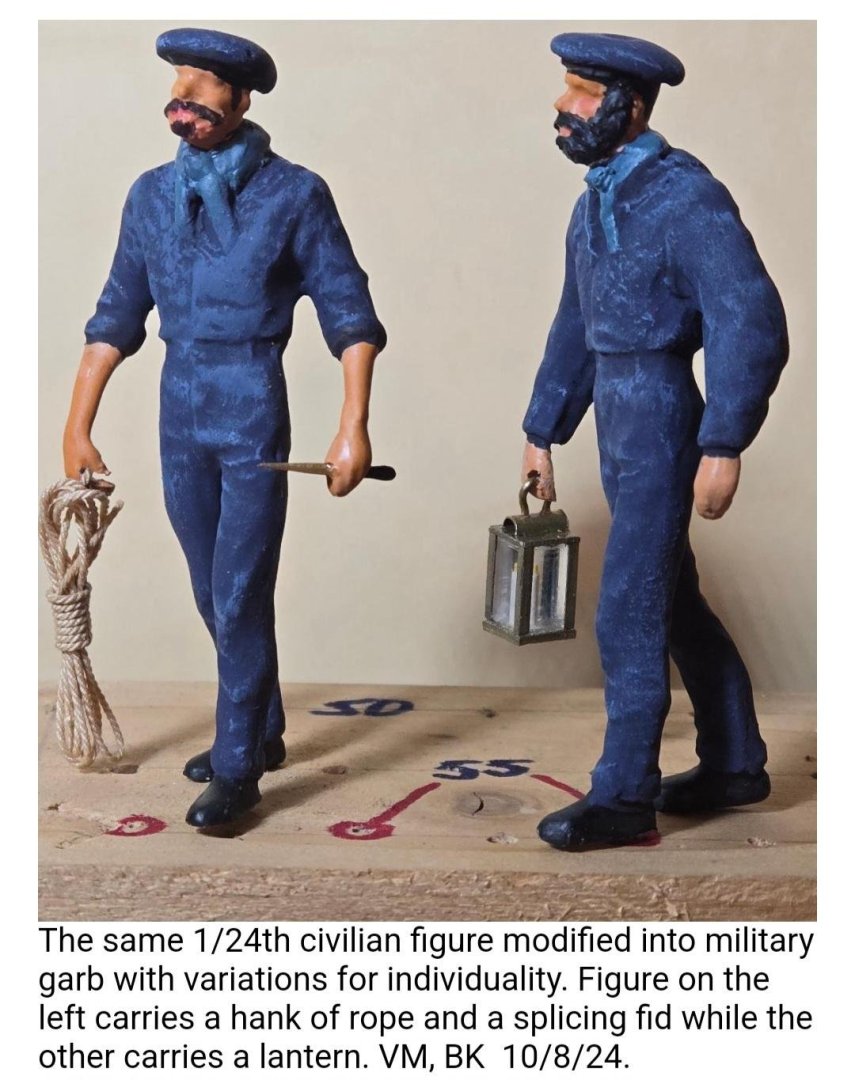

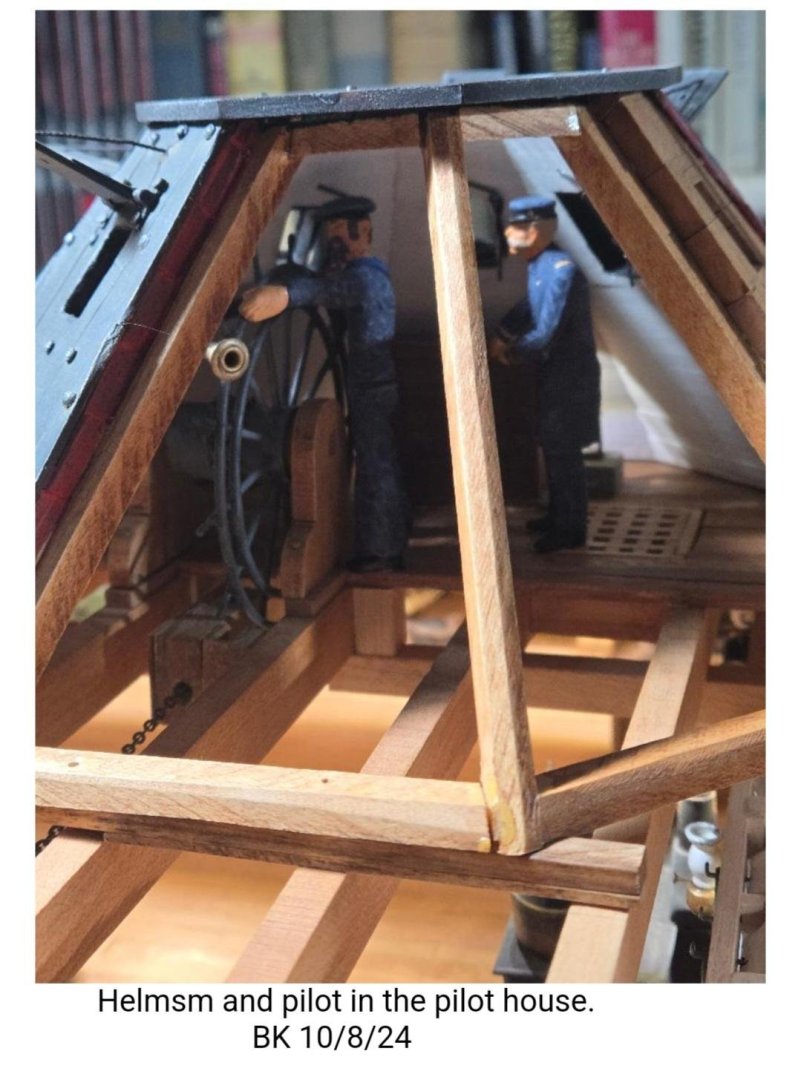

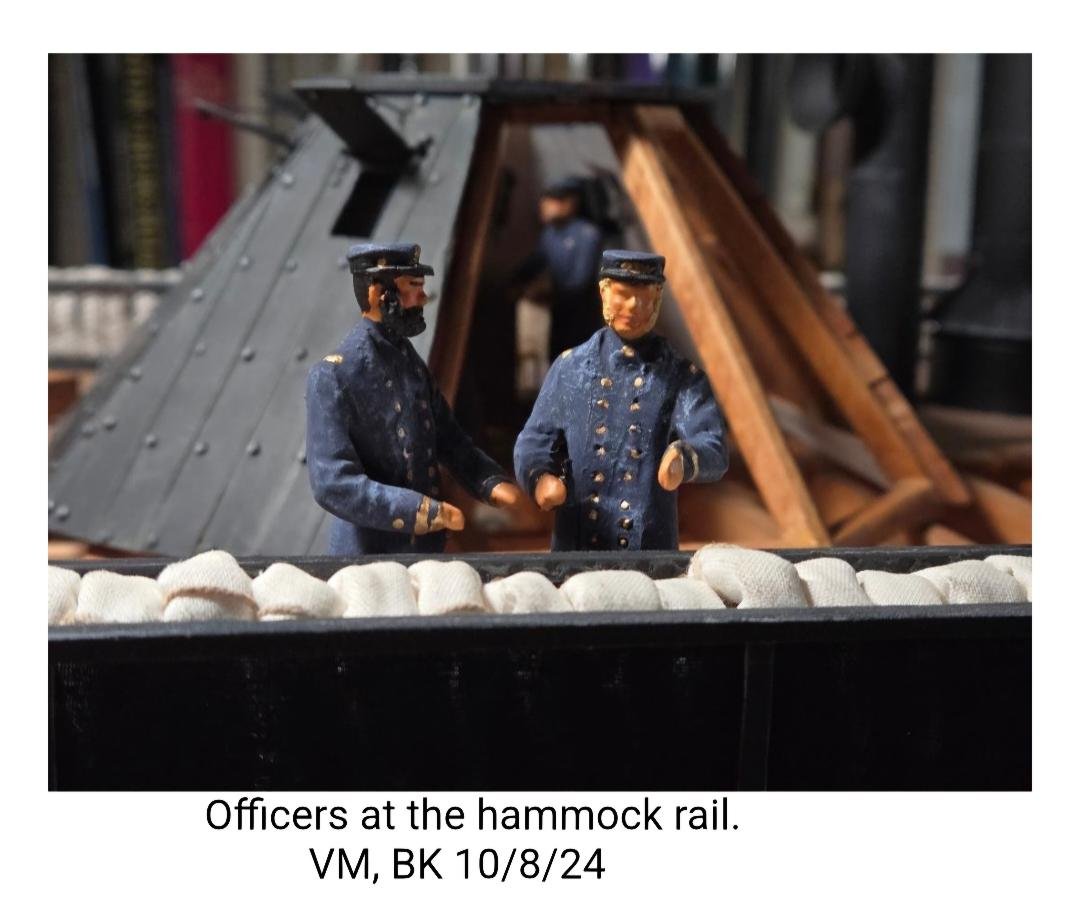

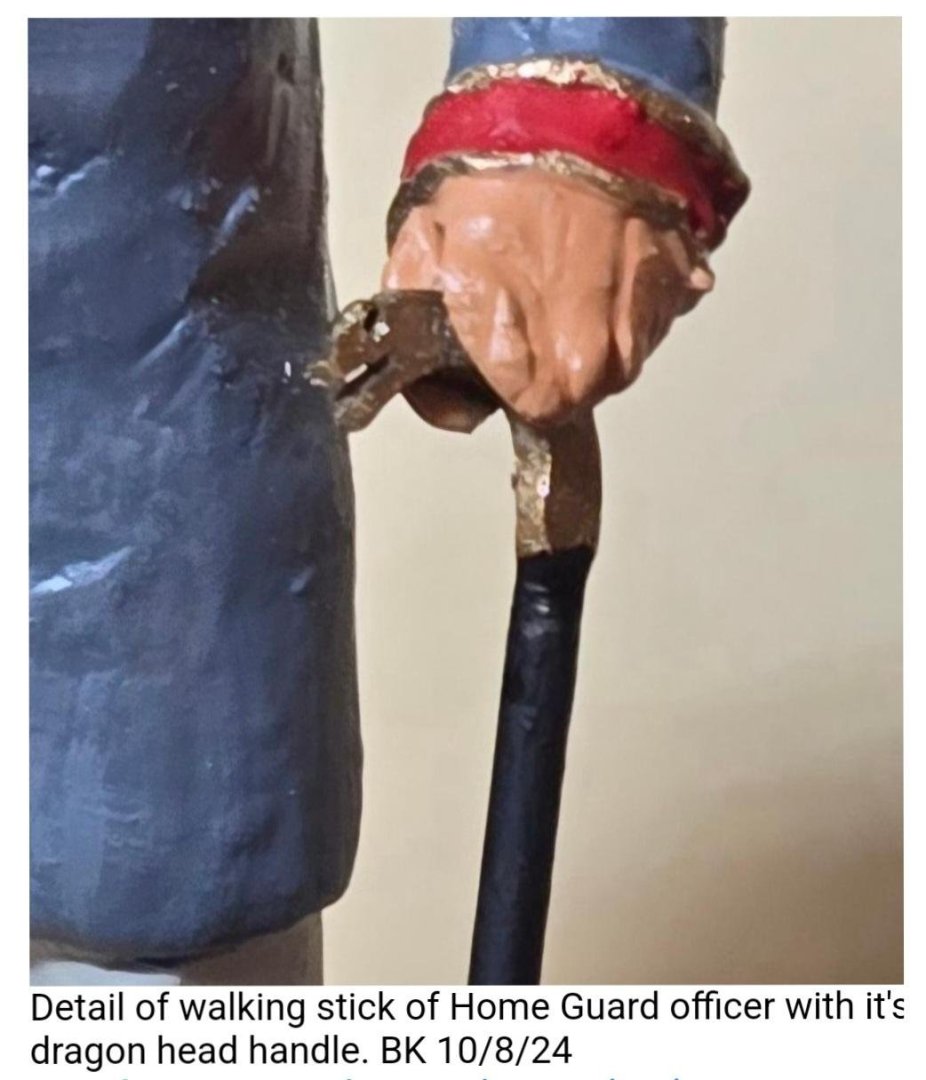

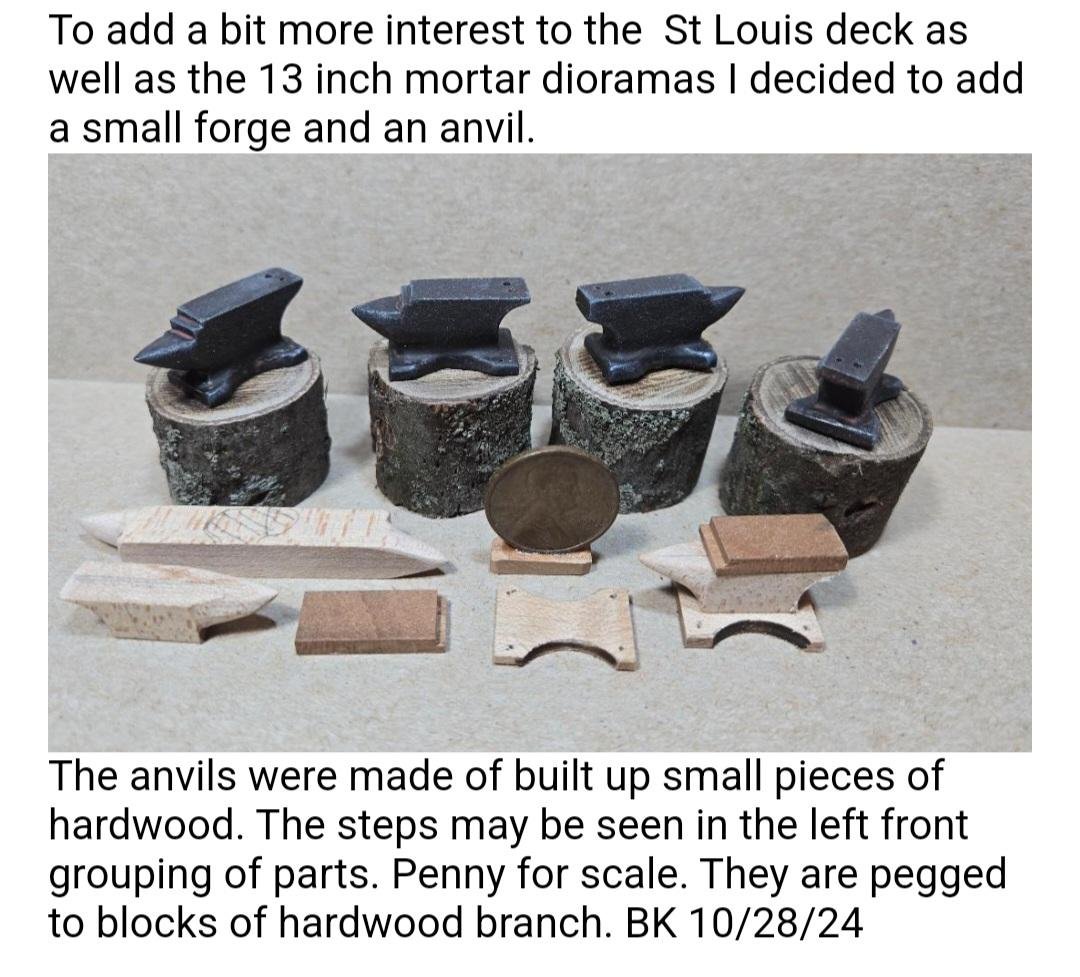

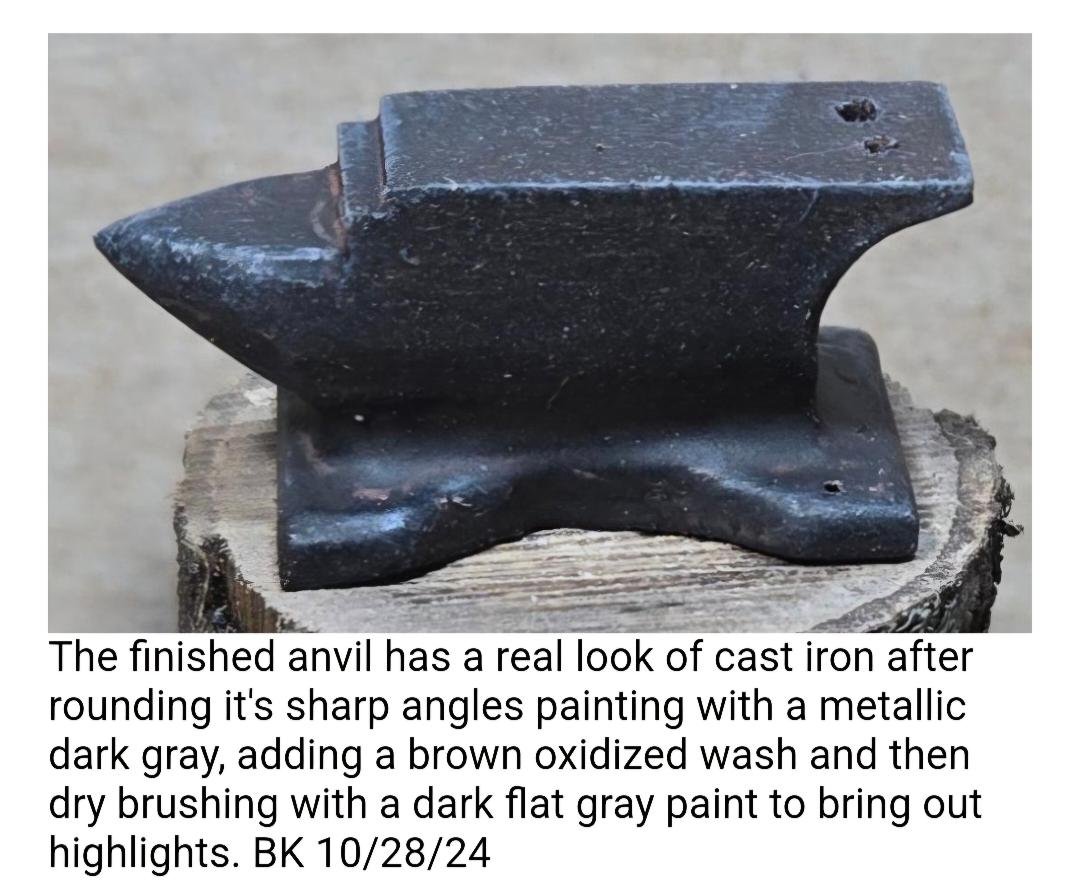

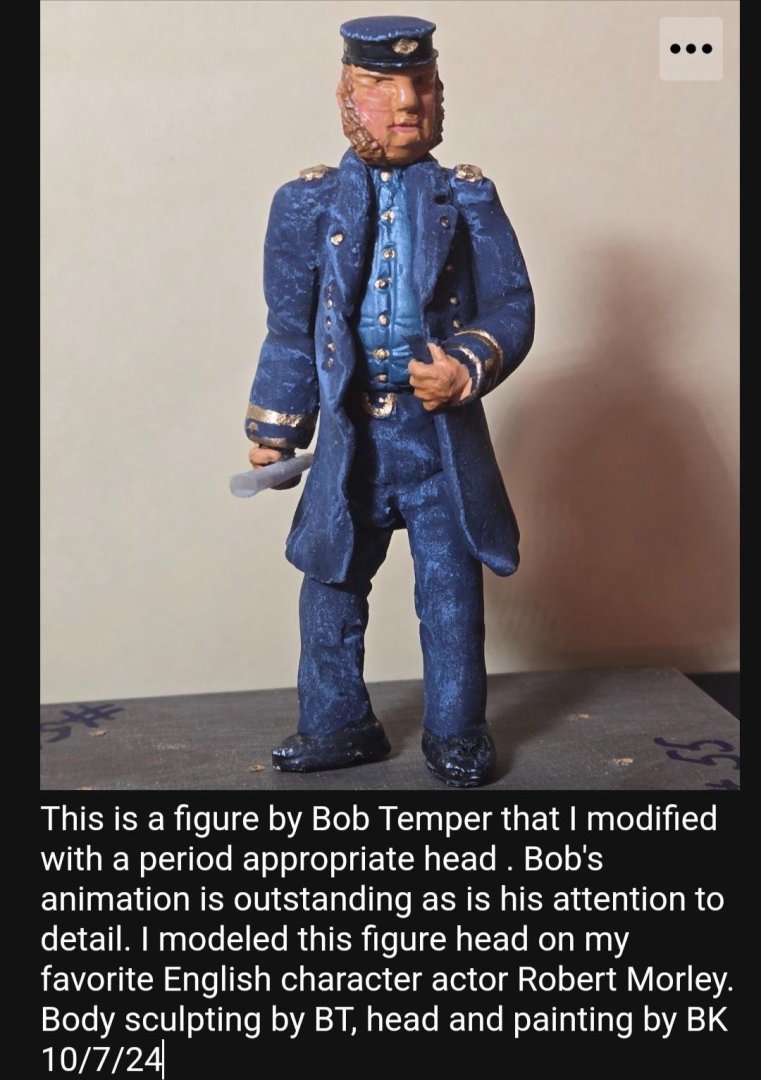

Happy New Year! Here's the latest, from October of 2024, mostly regarding modifying and placing the figurines, but also some anvils, just for fun. All photos and captions are by Bill Kammermeyer. Officer Figurines, Continued (Bill Kammermeyer) The figurines (officers and ordinary seamen) shown in the July Newsletter have been modified by Bill Kammermeyer to better reflect more realism and historical accuracy. Figures before modifications Figures before modifications Figures with more realistic/softer, better-fitting hats, also with facial hair. Sculpey added to figure, to add mass and softer lines. Officer figure initially designed by Bob Temper, plus a modified head, unpainted. Bill has been working on these figurines for both the USS St. Louiss and the Hunley dioramas. Not only painting and animating them, but also staging them to look as natural as possible. ANVILS That's all for now. More on the Figurines and other fun stuff coming soon. Please to enjoy. Tim Jovick 314-761-5435

-

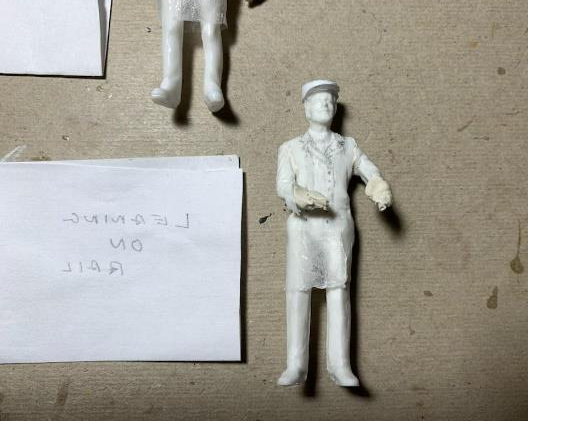

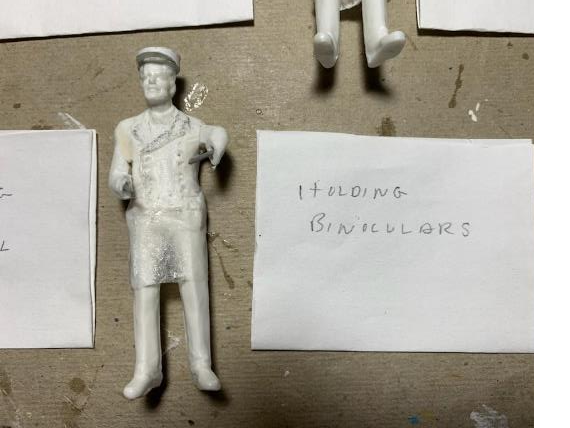

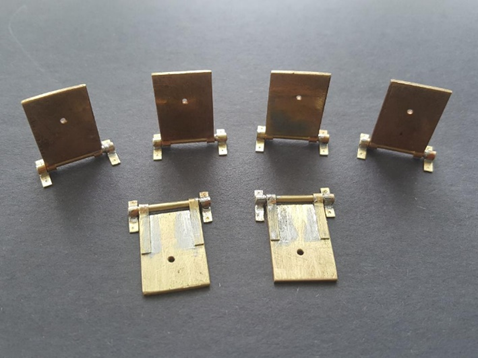

OFFICER FIGURES, Continued: Photo of offices aboard the USS St. Louis. Officer figures, some with beards, jackets painted a dark blue with gold buttons. The Notice that the jackets are about knee-length and Kleenex lengthens the jackets quite nicely. are either open at the neck or buttoned up, with a double row of gold buttons. The hats are flat on top, with a stiff bill in the front. Officer with binoculars. Officer with pointer. Will likely be placed in Captain’s cabin, pointing at a map on the wall. Officer with hands on rails. PEDESTALS (To rest the gunboat on the stand) This is one of two proposed sets of pedestals for the USS St. Louis to rest on. There are four, two at the bow and two at the stern. These are 2-1/4” by 4” and painted gold. There is a hole in the stern starboard pedestal to allow the wiring from the boat to go down into the stand unnoticed. Another set is painted brown and is somewhat taller. That's all for now, which briings us up to July of 2024. The next entry will be from October 2024 and will have more on modifications of the figurines.

-

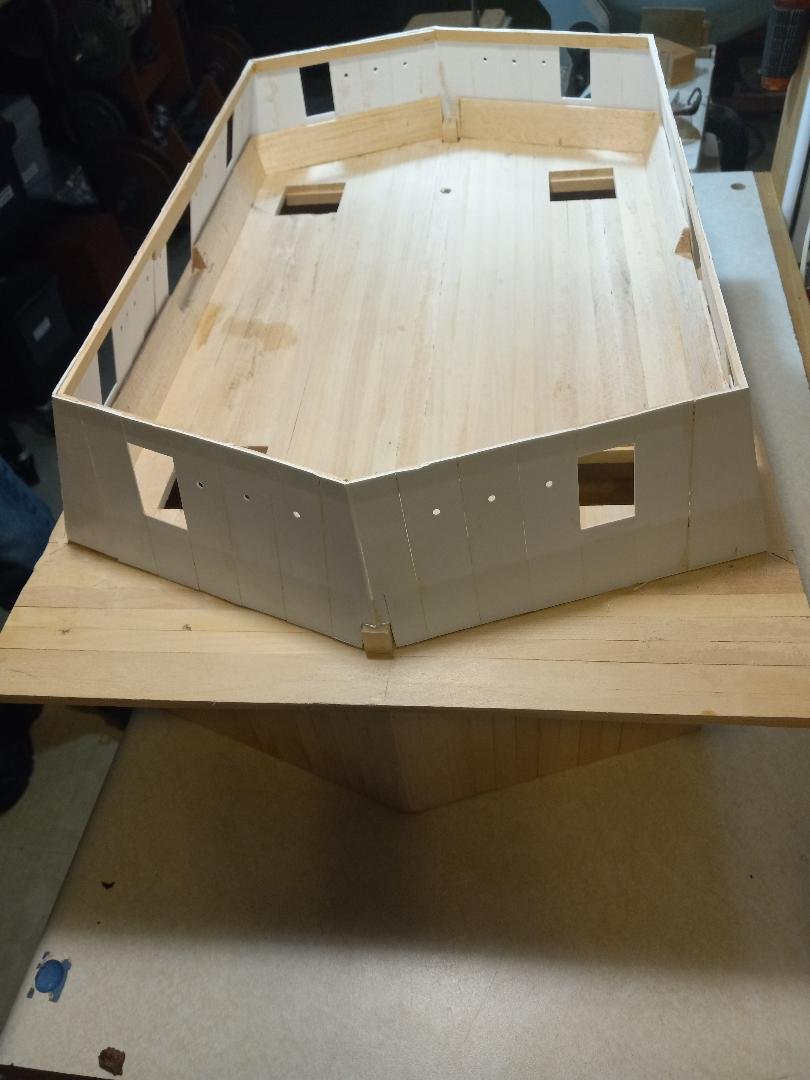

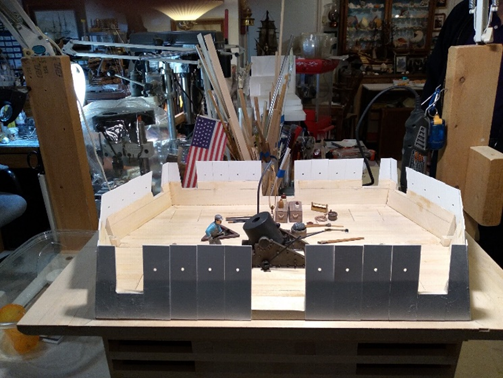

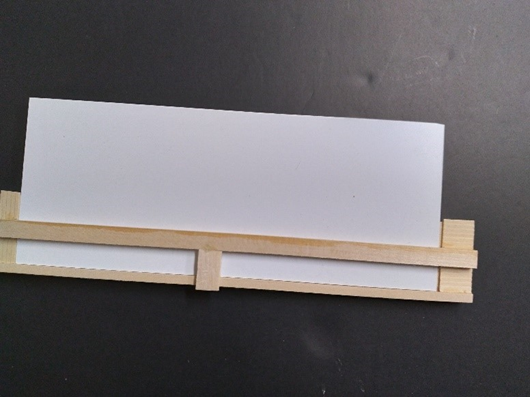

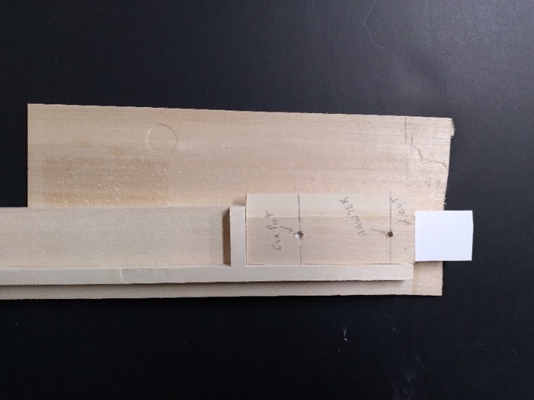

MORTAR BARGE UPDATE (Bob Keeler) I redid the upper walls to more accurately reflect the scale seven-foot-tall scale (1/24). They are made from .040” plastic sheeting and are 1¼” tall (as opposed to a previous try, which was 1” high and found to be too short). The walls lean in at a ten-degree angle. The supports are made of balsa “trailing-edge” planks, which are used in R/C airplane models, glued together. Holes for doors and windows had to be recut to reflect placement on the 7’ scale. Doors and windows will be fashioned to scale. Interior of walls, floor supports and upper supports. Interior view, with previously constructed (by Bill Kammermeyer) mortar, cannonballs, equipment/tools, and figures. View through door Another view through door That's all for March/April of 2024. The next entry will be from July of 2024 and will look at further work on the Offier figures and pedestals for the gunboat. Coming soon! Tim Jovick

-

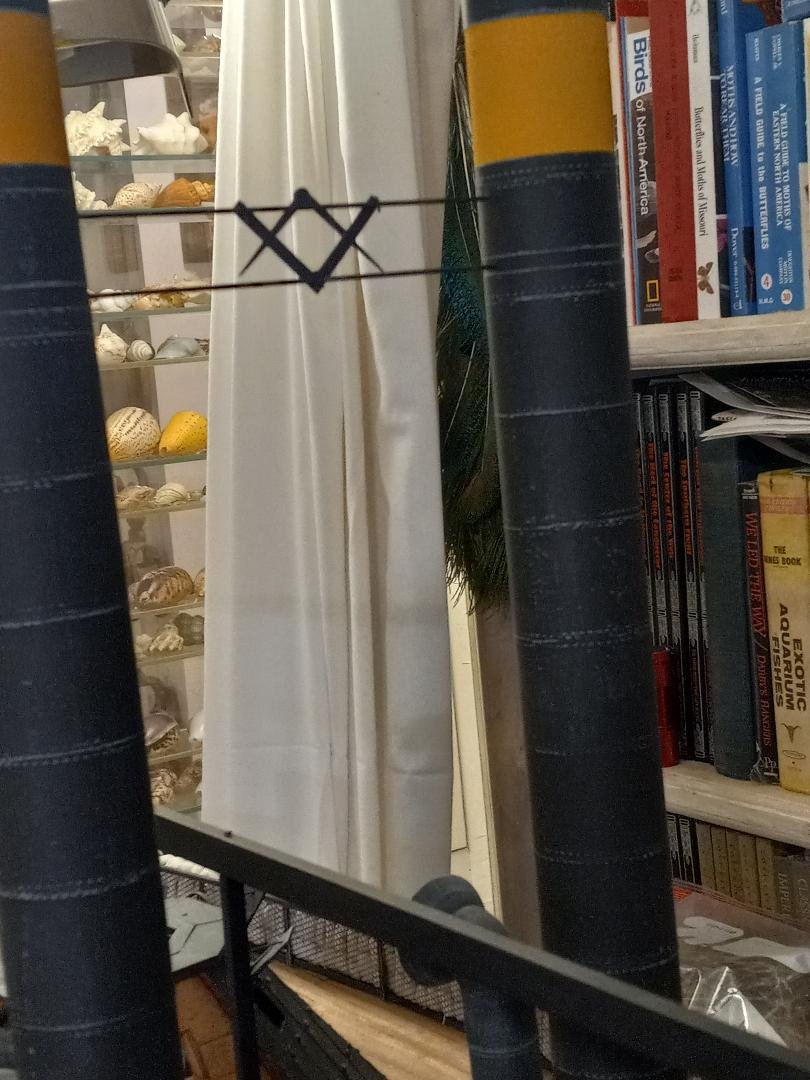

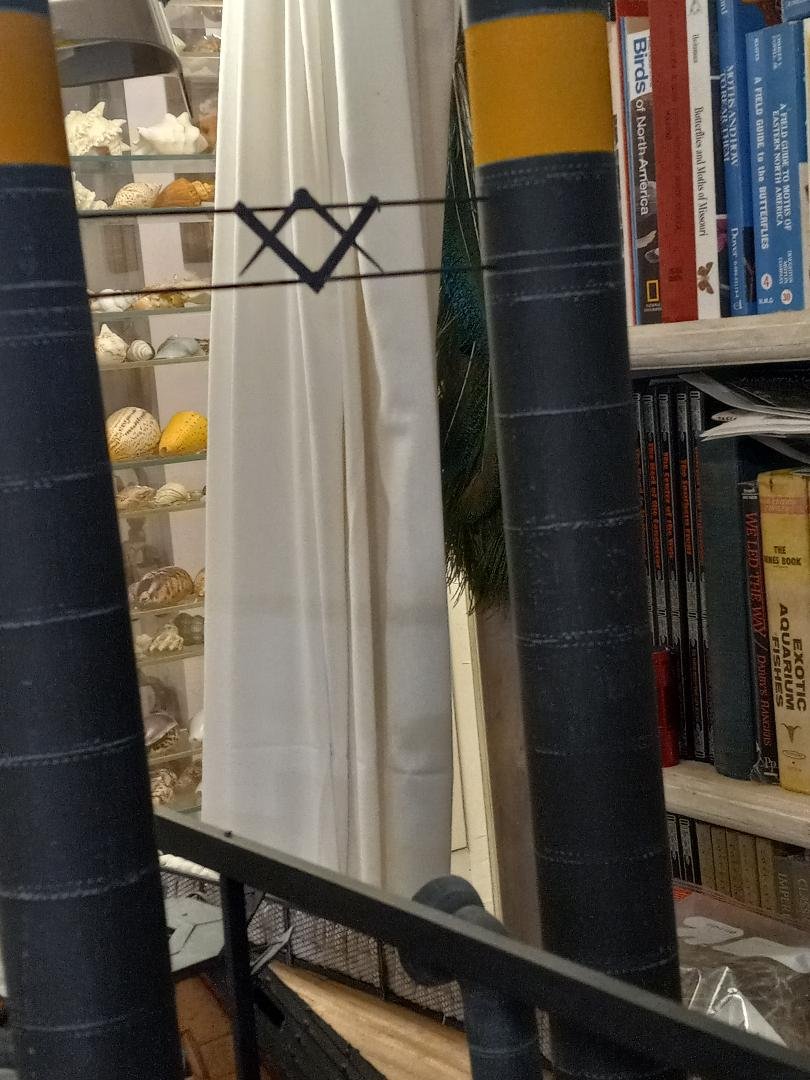

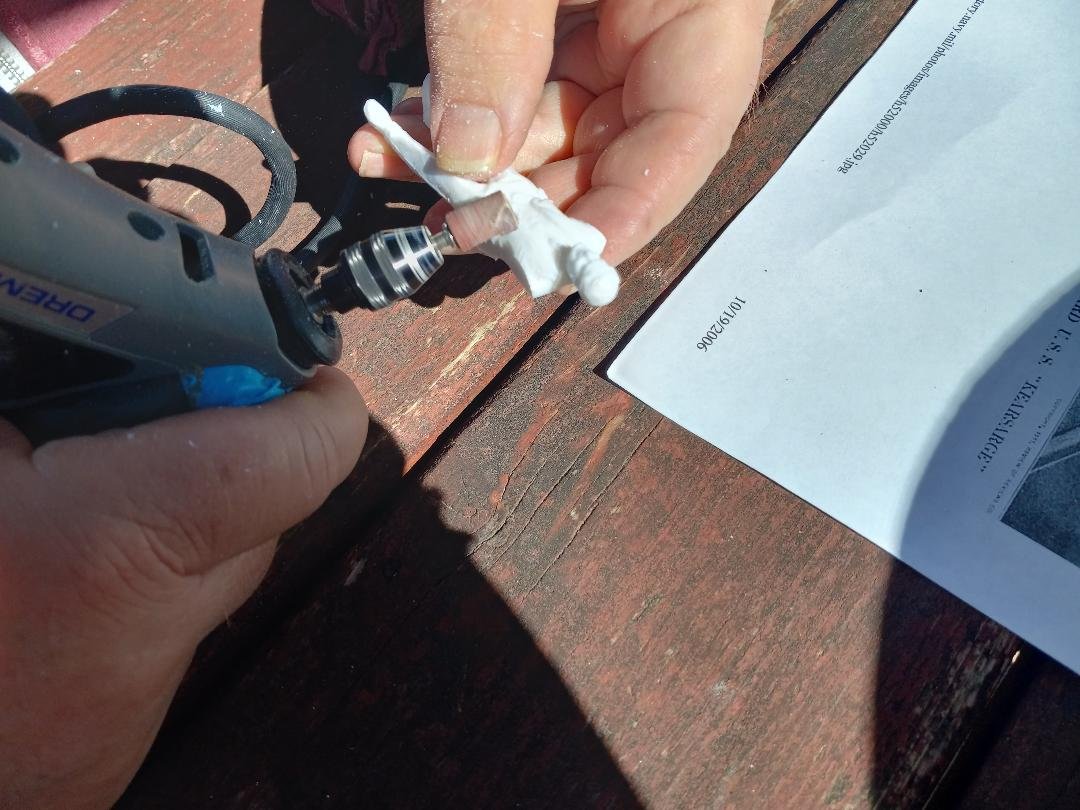

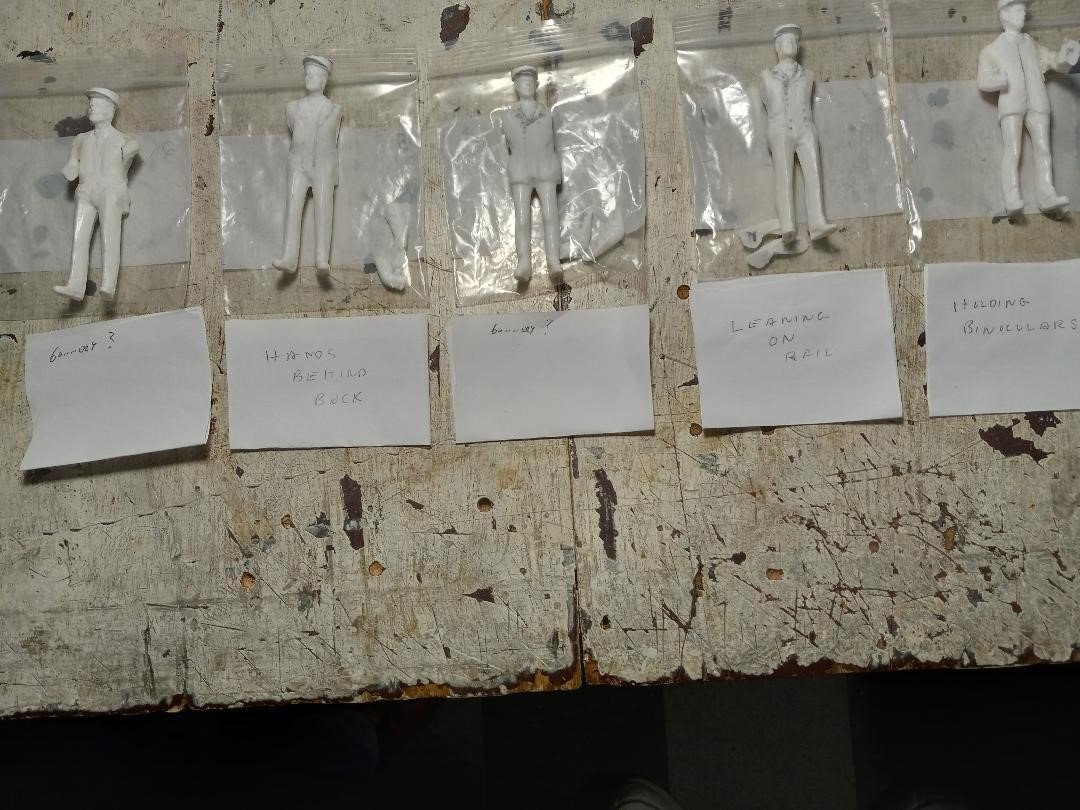

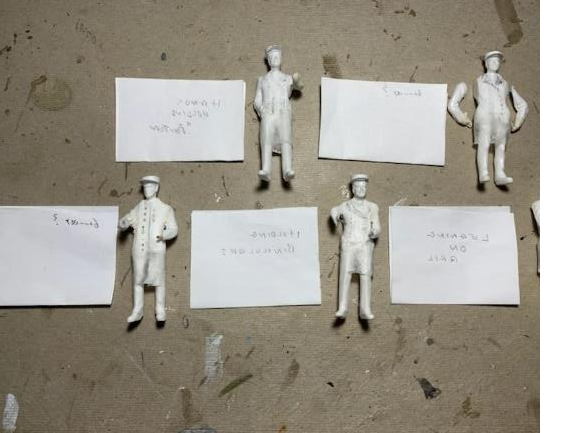

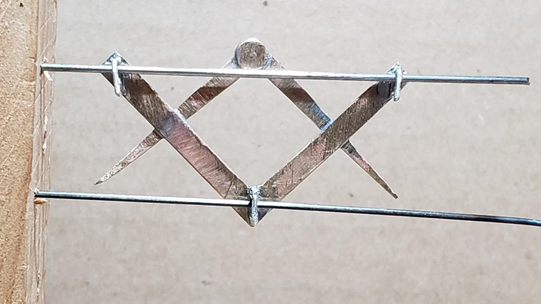

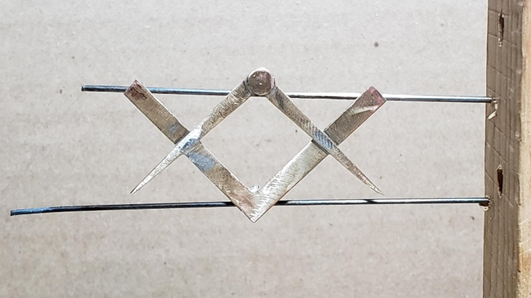

Hi all, back with some more pictures of our USS St. Louis project. Again apologies for the delay in posting. As of this writing, we're still closing in on completing the gunboat, mostly figurines, but also other mini-projects. Unless otherwise noted, alll photos and captions are by Bill Kammermeyer. Completed smokestacks, painted, with Masonic symbol attached, painted black (Note Bill's seashell collection in the background). FIGURINES: OFFICERS AND ORDINARY SEAMEN (made by Vince Murphy and Tim Jovick) Making figurines from 1/24 scale plastic figurines, male, with suits or regular shirts and ties. Procedure is to cut off the arms, at least for the officers (the figures for the Ordinary Seamen already had rolled-up sleeves), and grind off areas such as ties and pockets, as well as molding seams. This required delicate work, using not only grinding attachments but also small /dental burrs. (ta follow-up note: These figurines were in the Model Railroad section of the hobby shop we go to (Schaefer's in St. Louis), but when we recently went to purchase more, we were informed that they are no longer available, as there were veery few customers that had wanted them). Ordinary Seamen figures. The hats were made from plastic tubing, with the tops of the hats made of plastic sheet cut into circles. The front neckerchief and back flap were outlined with a scribing tool. These appear to reflect the period pictures and drawings. Officer Figures, after grinding off irrelevant details. Hats made of plastic tubing, with bill made from plastic sheeting . Hats “filled in” with plastic wood filler. The labels indicate what function each figure will be doing, at least at this point. Thus, there are two gunnery officers, one holding binoculars, one leaning against the railing, and one with his hands behind his back. A good deal of work still needs to be done on these figures, including modification of the arms and hands, lengthening the jackets to about knee-length, and placement of many buttons on each side. Officer figurines with coats lengthened using Kleenex (toilet paper was too flimsy and paper towels were quilted). After wrapping around the figure from waist to knee, they were stiffened using thin CA glue. Additionally, the coats were modified to make them appear to be closed. Rows of buttons (eight on each side) were marked and then shallowly drilled with a small drill in a Dremel, to be filled with a Pentel gold-paint pen. That's all for today. Next entry will be progress on Bob Keeler's 124 Mortar Barge

-

timboni reacted to a post in a topic:

USS ST LOUIS by thorn21g - 1:24 - POF - Civil War Ironclad - Gateway Model Shipcrafter's Guild

timboni reacted to a post in a topic:

USS ST LOUIS by thorn21g - 1:24 - POF - Civil War Ironclad - Gateway Model Shipcrafter's Guild

-

Hi all, It's been quite awhile since I posted, so, with apologies, and with massive gratitde to Kurt Van Damm, who guided me through a myriad of glitches and false starts, herein we do some catching up: TRIP TO MISSOURI CIVIL WAR MUSEUM Several members of the Gateway Ship Crafters visited the Missouri Civil War Museum, which had commissioned the USS St. Louis project. We spoke with Mark Trout, Director of the Museum, who gave us a tour and showed us a couple possible places where the USS St. Louis will be displayed. Very impressive place, would recommend visiting it. The address is 222 Worth Road, St. Louis MO 63125. Their phone number is 314-845-1861. Below are a few pictures relevant to our project: This is the display of the “Brown Water Navy,” referring to the seven sister ships of which the USS St. Louis is one. It has, among other things, a statue of James Eads, designer of the Eads Bridge, who designed these gunboats. Closer view of an Officer’s uniform, which we are using as a guide in making the “Officers” figurines. Stand for the USS St. Louis, made of oak, with a groove around the top to insert the sides of the acrylic case, which has yet to be made. This is a beautiful piece of woodwork, which is actually lighter in color than the photo appears. That's all for today, I'm exhausted! More coming in the next few days. Thanks again, Kurt! Tim

-

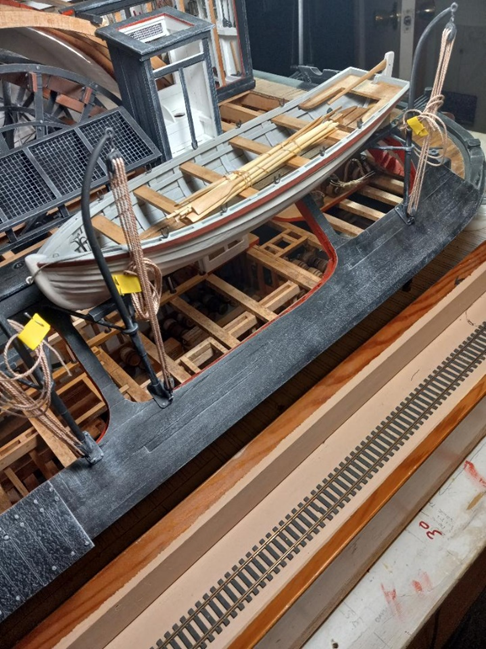

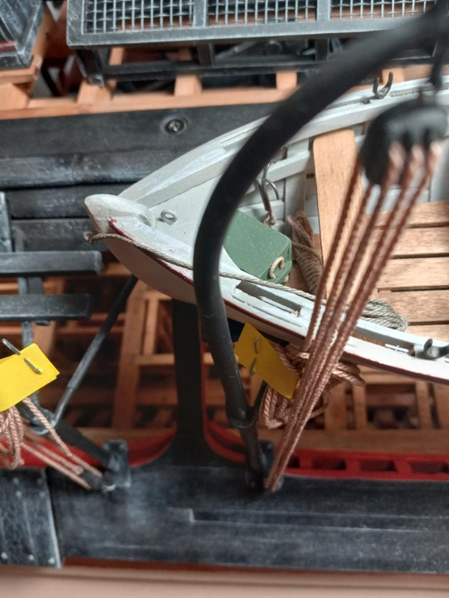

Hi all, and Happy New Year! Bill is still working on the figurines, but in the meantime, here are some pictures of one of the ship's boats on davits, with tackle, and also some items such as oars, a boat hook, a box for smaller items, a grappling hook, an axe, and several lengths of rope. (The "railroad track" is in fact part of a ropewalk device made by Bill) Tim

-

Don, this project was commissioned by the Missouri Civil War Museum, located on Jefferson Barracks (now a veterans' cemetery) in St. Louis. To be honest, there have been some communication problems between us and the Museum's director, so we're uncertain if and when the installation will be done. Hopefully it will come to pass, and if so, I'll be posting some pictures of the dedication/installation ceremony. Thanks for asking. Tim

-

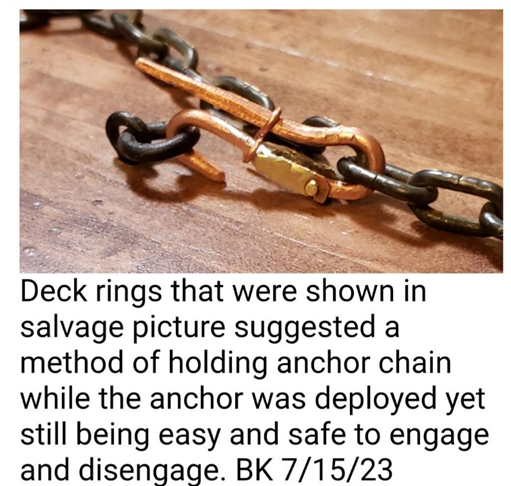

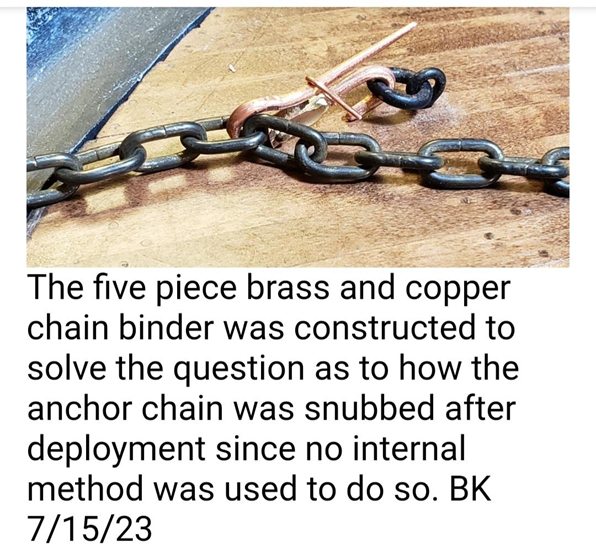

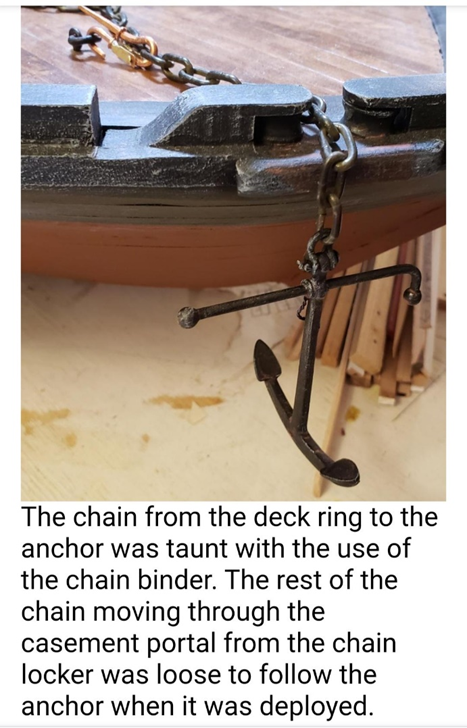

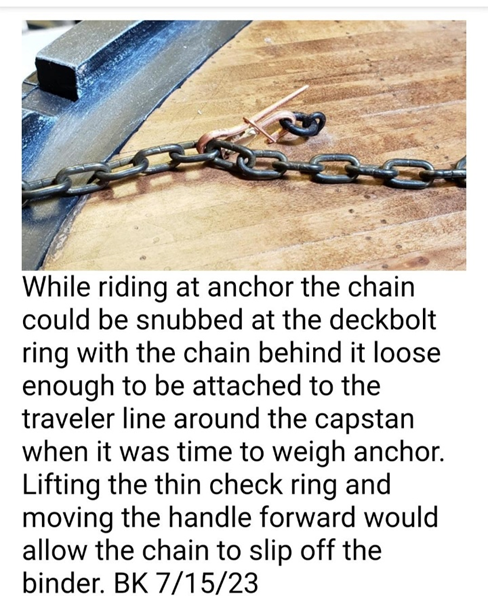

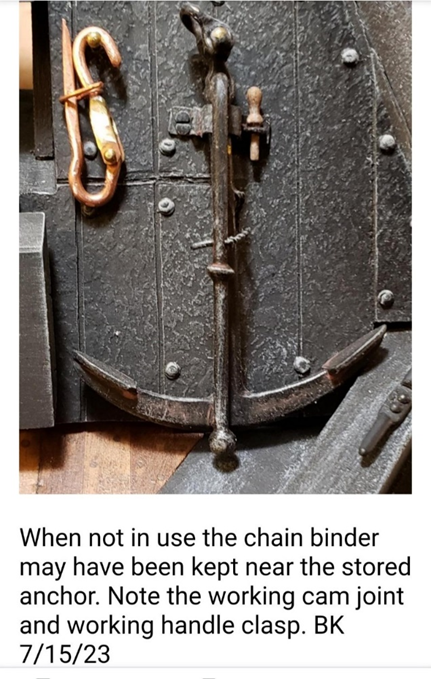

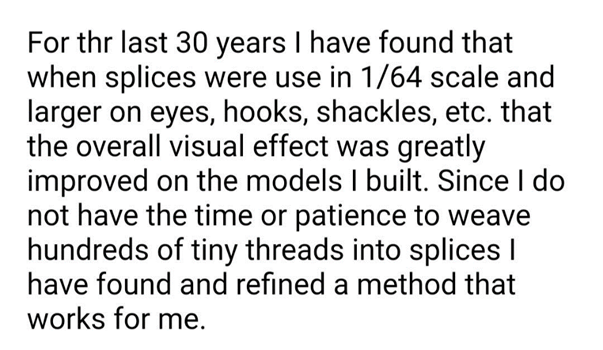

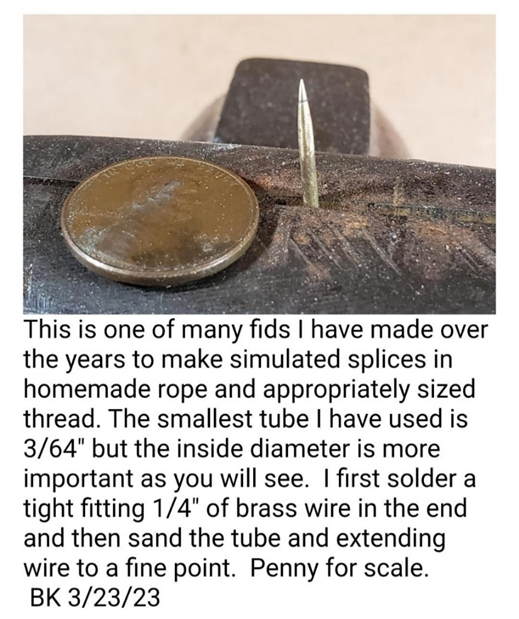

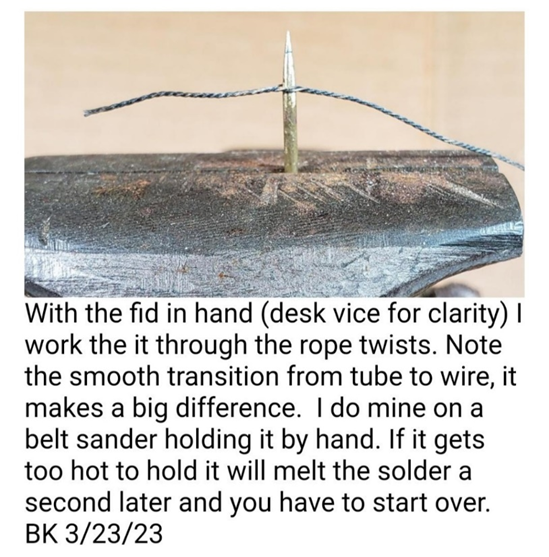

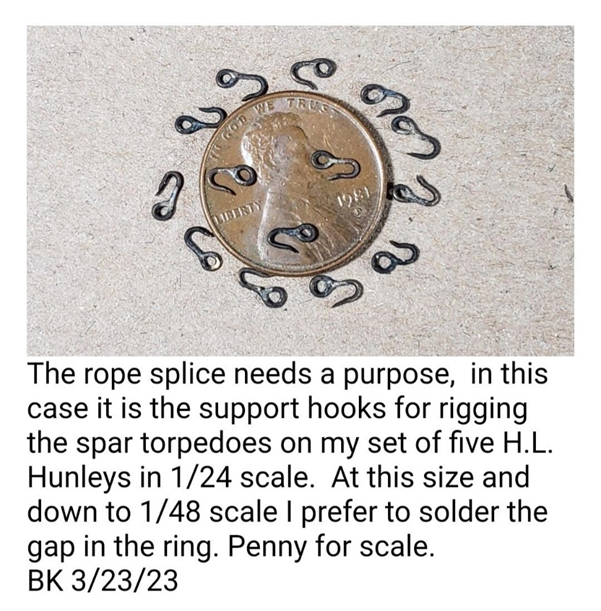

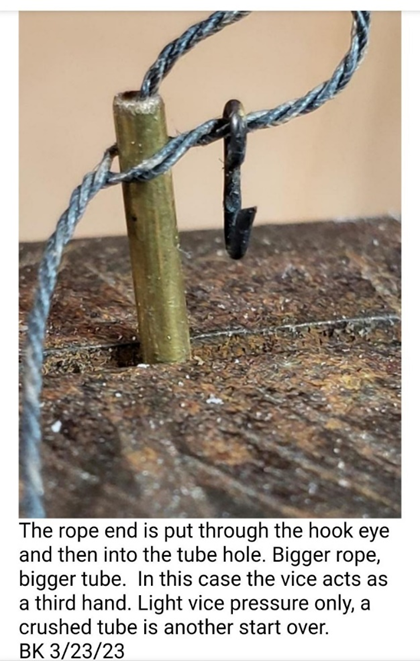

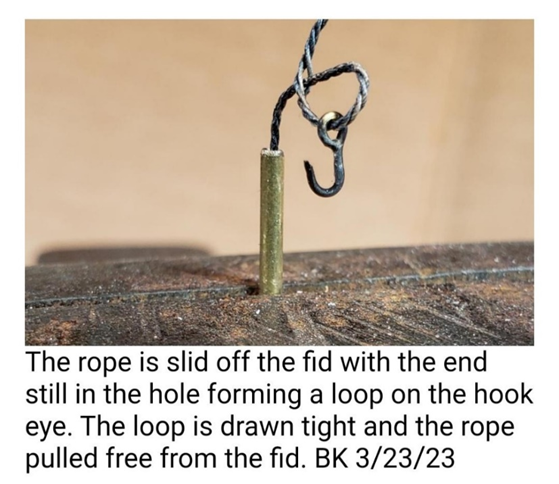

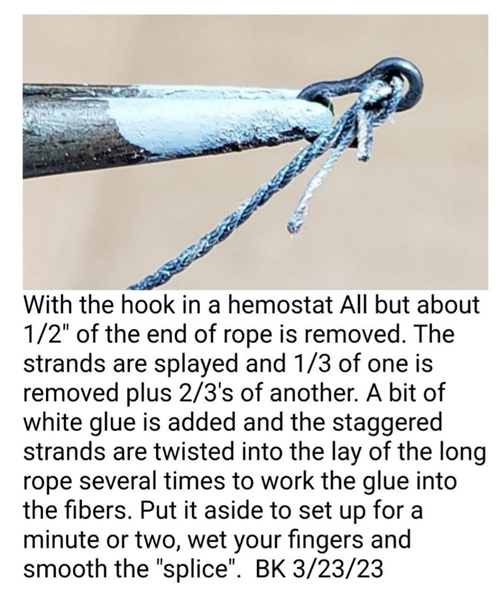

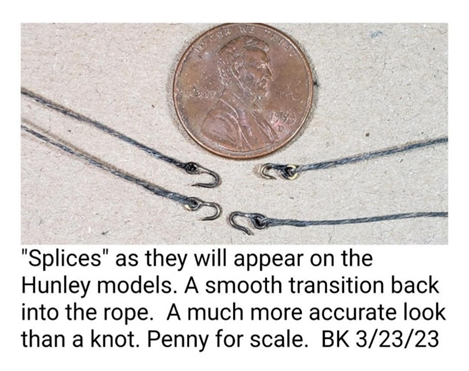

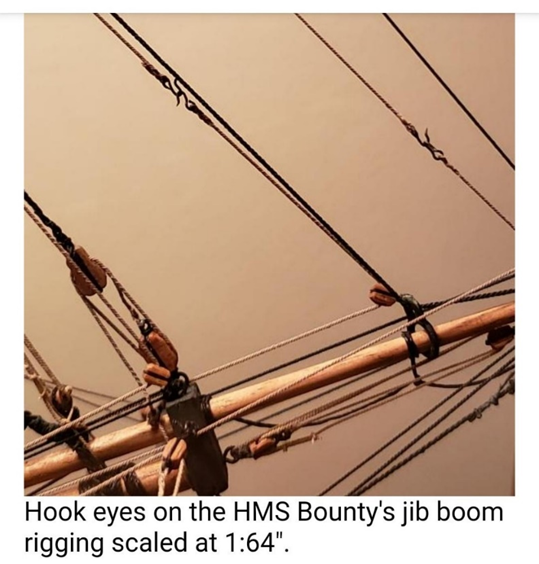

Hi all, This entry is from July, 2023 and looks at making a chain binder w/ slip handle, and how to do splices using a homemade fid: LEVER CHAIN BINDER WITH SLIP HANDLE This device answers two questions on the fore deck of the St Louis. Number one, what was the purpose of the large ring bolt in one of the salvage pictures? Number two how did they control the anchor chain when deploying, it snubbing it, and weighing the anchor? This type of lever chain binder may have been used in this period of time. MAKING SPLICES IN ROPES, with illustrations of their uses on Bill’s C. L. Hunley and HMS Bounty (Pictures and captions by Bill Kammermeyer). While not technically OK, folks, we're caught up! The project is almost finished, with most of the effort going to making figurines 1/24 scale. Previous entries have looked at making armatures, heads and some clothing, which will be supplemented by adding specific figures in various poses around the gunboat. Tim 314-761-5435

-

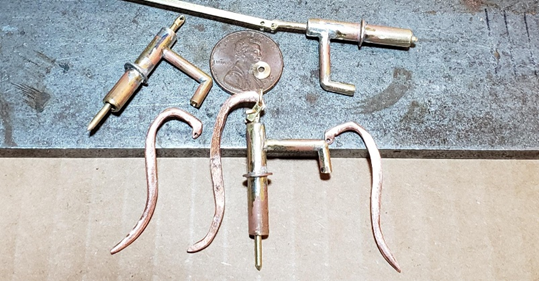

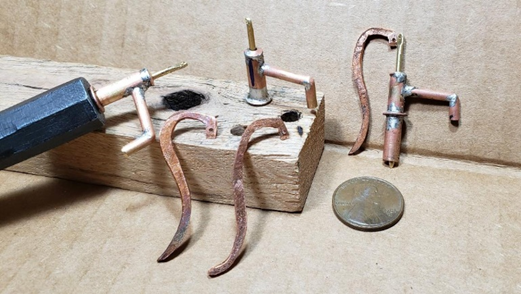

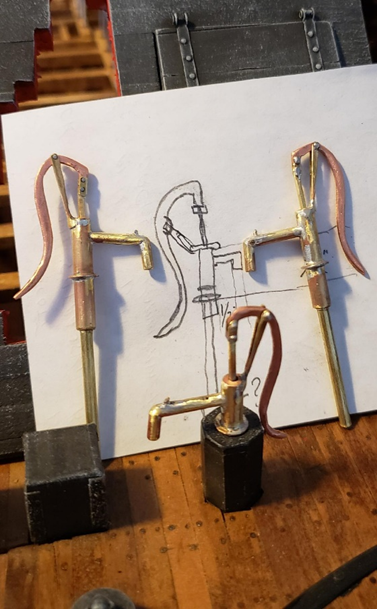

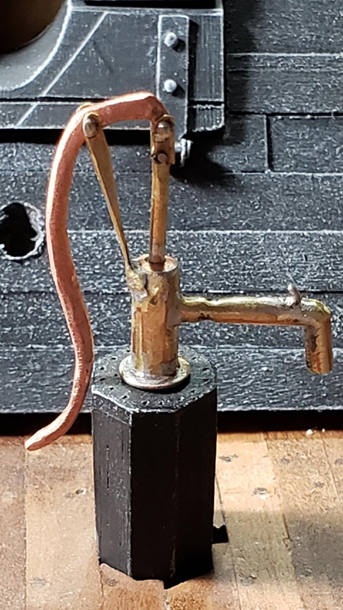

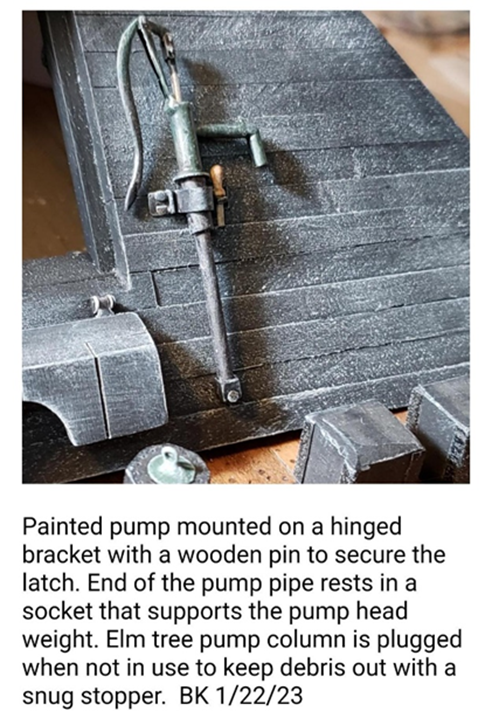

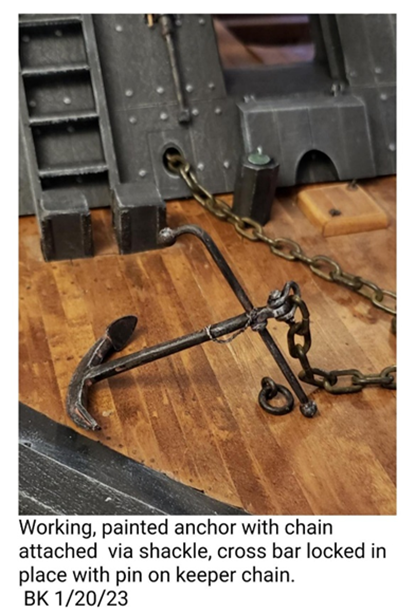

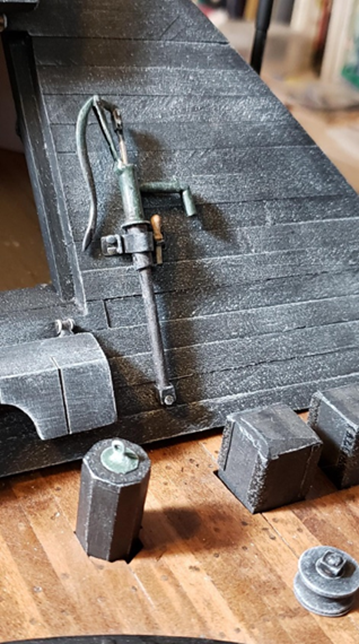

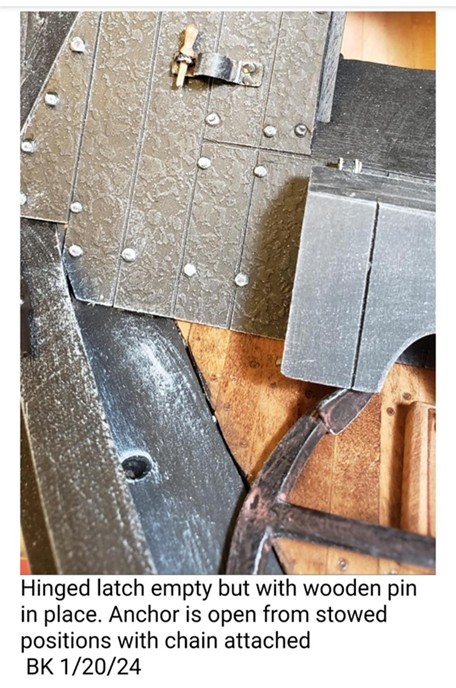

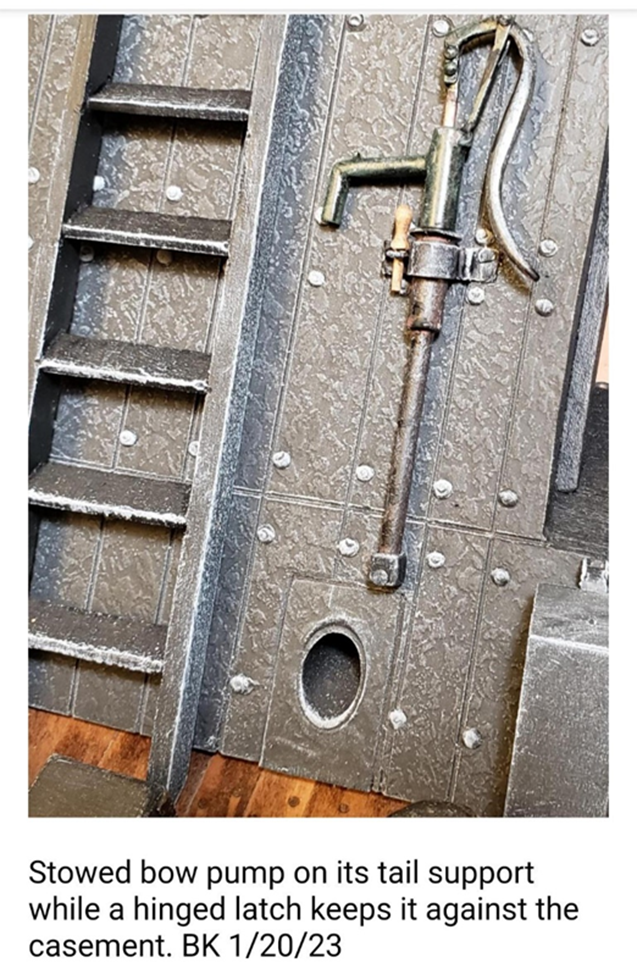

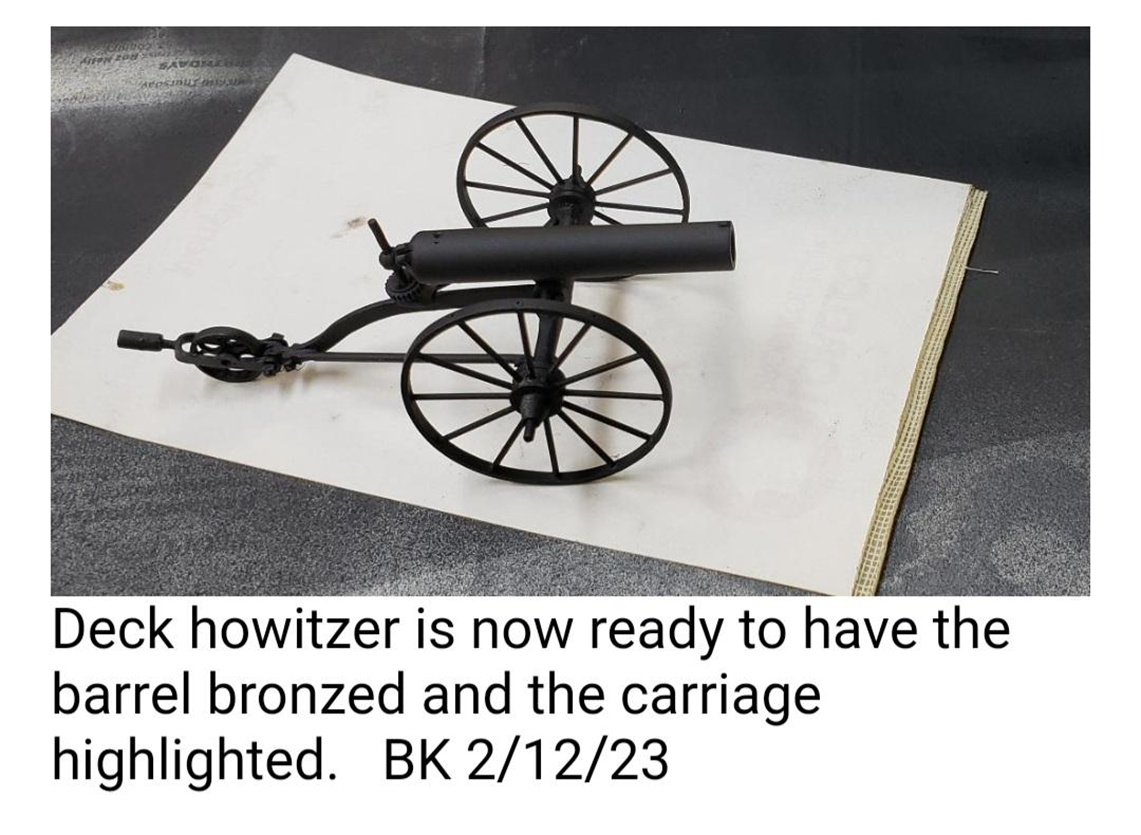

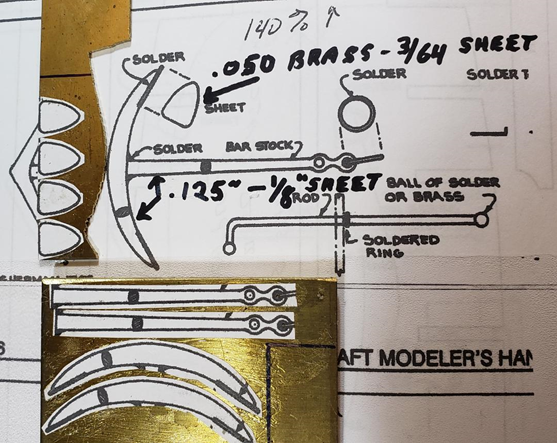

Hi all, This next installment is from January/February of 2023. 12 Pound Deck Howitzer BK 11/23/22 Deck Pump Heads Three octagonal "oak tree pump" shafts were made 4 years ago by Vince and Tim and installed in the bow and stern decks as per the Cairo plans. No pump heads were shown on the plans. Research shows that hand pumps were removable and stored on deck casements. I found a number of period pumps and drew plans for plausible type. These were used to empty the bilges, not as emergency water removal. In an emergency, the ship was run aground and the emergency addressed. Brass tube, rod, sheet stock and 14 guage copper wire were cut and soldered. The hardest part was attachment points so the pump handles would work the internal pump rod. BK 1/4/23 Plan that I drew as guide for pump construction behind the finished pumps. The 2 in back will be mounted on the casements. The tail pipes will fit into a water-tight fitting to create a vacuum after the pump is primed. BK 1/11/23 The mechanism that drives the pump rod works well, and all pivot points pins are soldered in place in a fashion that allows movement. When they are painted this feature may disappear. BK 1/11/23 The pump heads rotate 360° with a nib on top of the spout to hold an attachment for a leather or heavy waterproof cloth hose to take the foul water over the side. No internal discharge was shown on the plans. BK 1/11/23 Our scale figure shows relative size of the pumps. When in action, the pumps needed to be stowed to avoid damage by cannon discharge. BK 1/11/23. Painted pump mounted on a hinged bracket with a wooden pin to secure the latch. End of the pump pipe rests in a socket that supports the pump head weight. Elm tree pump column is plugged when not in use to keep debris out with a snug stopper. BK 1/20/23 Painted, working pump head in the elm tree well that goes into the port bilge. The plug is stored in the pump tail support on the casement. BK 1/20/23 Port anchor painted and stowed against the bow casement in its hinged latch with a wooden pin to secure it. BK 1/20/24 That's all for this time. Next will be the fashioning of anchor chain binders. See you then! Tim 314-761-5435

-

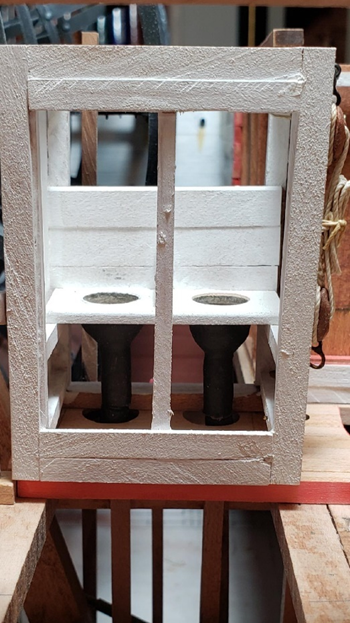

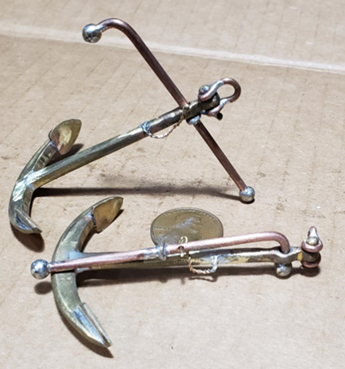

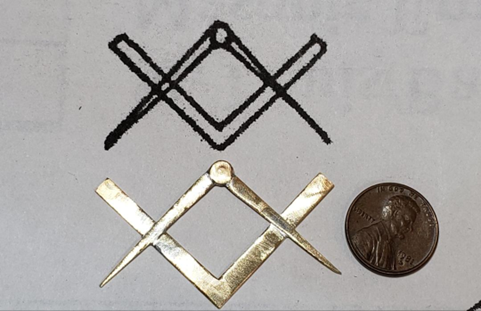

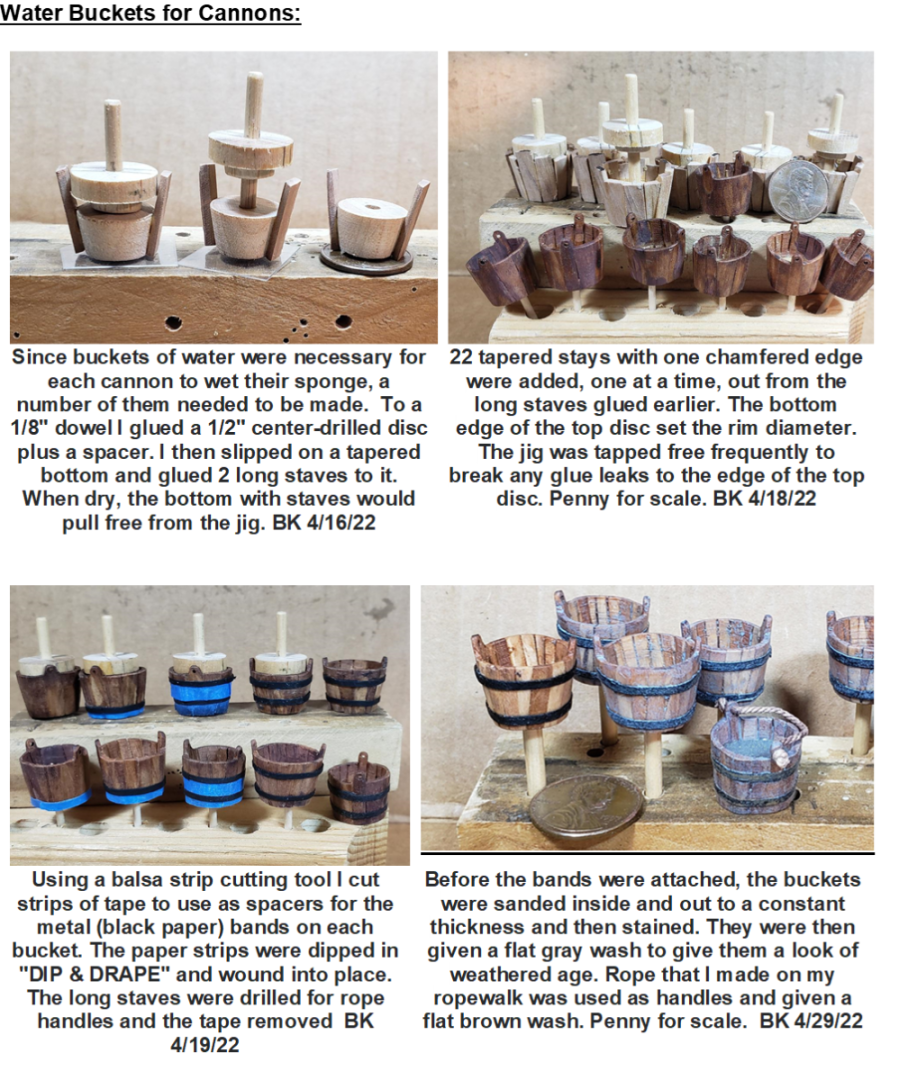

OK, this next session cover much of 2022, and covers not only further progress on the USS St. Louis , but also progress on the accompanying Mortar Barge built by Bob Keeler. USS ST LOUIS (Photos and text by Bill Kammermeyer unless otherwise noted) In the pilot house, the lanyards for holding the armor plate window lids open are put in place around their pins. LED lighting has been put in place as a trial. Fred and I are looking into fiber optics for the candle flame. BK 3/21/22 CREW HEADS: The difficult mechanism for building the plumbing apparatus for the crew heads was as overcome by turning Styrofoam molds to be covered with liquid epoxy in the shape of a bowl and pipe using a pattern and duplicator. BK 4/24/22 The Styrofoam mold was trimmed and then removed from the dry epoxy bowl shapes using a moto tool with a round bit. After most of it was removed, a drop of acetone melted the rest. The rims were sanded flat. BK 4/26/22 The bowls were painted copper on the inside and black outside. The flat edges of the bowl were glued to the underside of the seats of ease with the pipes making a right-angle turn into the waterway. A drain from the starboard upper head may be seen with a stain in the background. BK 4/28/22 MASKING AND PAINTING OF THE CASEMENTS: Blocks of Styrofoam were cut, with Vince and Tim’s help, for a tight fit in the gun ports and open viewing cuts. BK 6/9/22 With Styrofoam plugs in place and masking complete the casements and the upper portion of the hull are ready to be painted. BK 7/27/22. Bow and stern casements were painted off the ship and the side casements are ready to be painted. Aluminum foil works very well with irregular surfaces. BK 7/27/22 Painting went off without a hitch. The Styrofoam plugs worked very well. The use of a flat red paint to designate removed sections of casement were applied. BK 8/4/22. All the edges of the gunports as well as well as the removed area had to be painted flat black and flat red respectively. BK 8/4/22. SPITOONS, CHICKEN COOP AND LADDERS: Using beads as the base and paper as the rims, Vince and Tim made a number of spittoons for placement around the ship. Pegs were attached to the bottoms of the spittoons so they could be placed solidly in holes drilled in the decking. They were painted brass. (see below regarding “straw” for the flooring of the coop) Chicken coop (unpainted), and ladders for bow and stern casements, made by Vince 1/25 scale chickens (hard to find, gotten from a Canadian company) white (see on right), painted brown, in preparation for their becoming residents of the coop. They came with pegs on the feet, for anchoring on the coop floor, and these pegs were placed in the end of a piece of corrugated cardboard while the paint was drying. VM/TJ 9/9/22 Coop painted black. Floor had standing chickens (including one rooster). Upper shelves had “nests” made from buttons. The legs were cut off these and the hens placed in the “nests” as if they are laying eggs. The “straw” for the floor and shelves was made from scale “rough grass’ and “dirt.” ANCHORS: Research plans for an Admiralty anchor were printed to the proper scale, cut to rough shape and rubber cemented to brass sheet. 1/8" for the arms and shanks. .0218" for the palms. BK 10/28/22 The brass parts were cut to pattern size, filed, and sanded to final shape with a notch in the top of the arm and a shoulder filed on the end of the shank for a stronger soldered joint. These parts were pinned to scrap wood with a hole under the joint so the wood would not act as a heat sink. BK 10/30/2 The joints were fluxed and then overwhelmed with torch heat. Silver bearing solder was touched to the joint and I was done. A solid joint that just needed to be cleaned and filed. BK 10/30/22 The finished joints after filing and sanding were smooth and true. 12-gauge copper wire was cut and bent as per plans with balls added to the ends. Balls were from an old brass bead chain with the links cut and one end drilled for the cross arm. BK 10/30/22 The palms and notches in the arm tips were fluxed and tinned, then spring clamped together and torch soldered while in a vise. The clamp was removed and palms were finish set using pliers and torch. Balls were soldered in place. Penny for scale. BK 10/31/22 Shackles were made from 14-gauge copper wire. Stop rings and retaining pins were made of 22-gauge brass wire. Pins were drilled and 28-gauge brass wire was twisted and soldered to simulate the keeper chain. Anchors shown in working and stowed positions as they will be displayed on the bow deck. Penny for scale. 11/5/22 Anchors displayed on bow deck, top view View from the bow. The anchors store more easily with the cross bar stowed. MASONIC SYMBOL: The existence of a Masonic symbol located hanging from the support rods between the smokestacks is seen in some period pictures, although it has been difficult to verify. It is known that the USS St. Louis was renamed the USS Baron DeKalb (named after Johann DeKalb, a French military officer who served as a Major General in the Continental Army) in September of 1862 when it was transferred from Union Army service to Union Navy service. Her last Captain, Lt. Commander John Grimes Walker, was known to be a Mason. It is also known that during combat, Masonic members would not fire upon other Masons, even if they were the enemy. (thanks to Casey Jovick and Keith Dockins for their research assistance). Thus, despite the speculative nature of this symbol, it was decided to construct one, which could be removable but still part of the display if need be. Sheet brass .021" from an old award plaque was cut to make the square, compass, and hinge buttons. Buttons were made with a Whitney #5 jr. punch. Penny for scale. BK 10/26/22 Assembled parts were tinned, clamped and then flash soldered with a propane torch. Excess solder was sanded and filed away. The result was pretty close to the plans I used. Penny for scale. BK 10/26/22 20 gauge brass wire hooks was soldered to the back for optional mounting between the stacks. It will be firm but not glued, giving us the option of removing it if proof is presented that in fact it was not historically accurate. BK 10/26/22 Finished Masonic symbol as it will appear on the stack support rods viewed from the bow. BK 10/26/22 Buckets to be used on Bob Keeler's 1:24 scale 13" mortar barge (see below). Long rope attached to retrieve bucket when thrown over the side to refill the sponge tub. Stained water in buckets is liquid steel. It dries level and has a water sheen. Penny for scale. BK 4/21/22 MORTAR BARGE, Continued (photos and text by Bob Keeler, 06/03/22) Shows .04 in x 1.25 in x 3.25 in styrene shielding representing 1 in x 30 in x 7 ft iron shielding on wooden supports. Side view View showing Bill’s mortar and supporting hardware with our scale man for perspective. No, I didn’t paint the shields black; just the lightingeffect. It does show the rifle ports to advantage. Another view showing the interior details Tool for cutting styrene into 1.25 in wide strips Tool for cutting strips to 3.25 in length. Right hole is for drilling 1/8 in rifle holes; left hole is for locating hawser holes in 4 pieces. After doing all this, it didn’t look right. When I went back to the plans, I found out that I had made wrong calculations. The supports should have been 1 in. high instead of 1.75 in. high, and the shields should have been 1 in. wide (24 in wide) instead of 1.25 in. wide (30 in wide). So I will remove these supports and shield and build new correct ones. WHEW! Lotta stuff there! Next installment will be from January/February and will look at the deck howitzer and the pump heads. Tim 314-761-5435

-

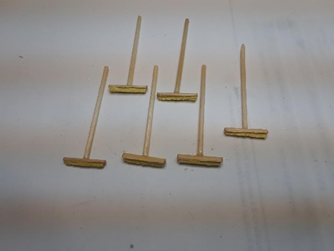

Hi again all, More from February 2022, this time focusing on making and displaying tools as well as ceramic jugs. The former involved several people, including Bill Kammermeyer, Fred Heckr, Bob Keeler, Vince Murphy and myself. Making Shovels I formed blades and soldered tubes to them to make collars. Penny for scale. BK 5/18/21 Using the same size tube with teeth filed into the end (as seen on the penny) a peg is formed that fits perfectly into the socket. BK 5/18/21 Old brass weatherstripping was repurposed into shovel blades with tube shafts soldered to them. BK 5/18/21 Tools, Lanterns, Brooms, etc. Axes built and painted by Bob Keeler 8/9/21 Push brooms by Tim (VM 9/15/21) Oil cans by Vince (VM 10/6/21) Tools for the deck storage sheds and the engine room. Lanterns by Fred. Saws, shovels, sledgehammers, clinker rakes and hook and most painting by Bill. Brooms, mattocks, hammers, wrenches and tool boxes by Vince and Tim. Axes by Bob. Penny for scale. 10/14/21. FH / BK / VM & TJ / Bob K. View into forward work shed with tools in place. BK 10/21/21 Forward work shed corner detail. Front boxes had bottoms reduced to cover "L" of cardboard that was glued to the bottom of the walls to allow the crates to be removed intact when the shed was removed from the hurricane deck. BK 10/15/21 Rear shed tool and equipment placement. BK 10/20/21 Tools and lanterns by everyone, selection and placement by Bill. BK 10/20/21 Detail in rear shed. Rope, sledges and shovels by Bill. Tool box and tools by Vince and Tim, lantern by Fred. 10/21/21 BK /VM-TJ / FH Shelving attached to the curve of the wheel house made sense for added storage in the deck sheds. Canvas sun shade would have been stored here along with miscellaneous everyday ship needs. BK 10/10/21 Unlit and empty lanterns along with beans and general supplies. FH/BK 10/10/21 All sacks, boxes, canvas tarps and barrels are attached to shelves and surface of the wheel house so they will stay in place when the wheel house and sheds are made into one unit that can be removed. BK 10/21/21 CERAMIC JUGS FOR PLACEMENT AROUND THE USS ST LOUIS First I turned them by hand. Penny for scale. BK 1/31/22 Then I attached handles, painted as with a ceramic glaze, and corked them. BK 2/3/22 I made 1/2 gal.,1 gal. and 2 gal. size. Lookin' pretty good! Penny for scale. BK 2/3/22 OFFICERS’ STARBOARD QUARTERS Covered mockup by Vince with thin planks and added doors and corrected after gap. VM/BK 10/28/21 Framed the doors and painted as the casement. Using the fit/sand/fit/sand method I was able to get a tight fit. BK 10/27/21 Using a punch, I was able to make door hardware. BK 10/29/21 Detail of door handles made of bent and worked copper wire with plates made wIth punch. BK 10/20/21 View aft with officers’ cabins installed, painted, doors framed and handles attached. BK 10/19/21 I spent more time than I should for a snug fit for this curved wall. I forgot that boxes would be blocking my handiwork. BK 10/29/21 That's all for now. Next entry will be from October, 2022. Please to enjoy. Tim

-

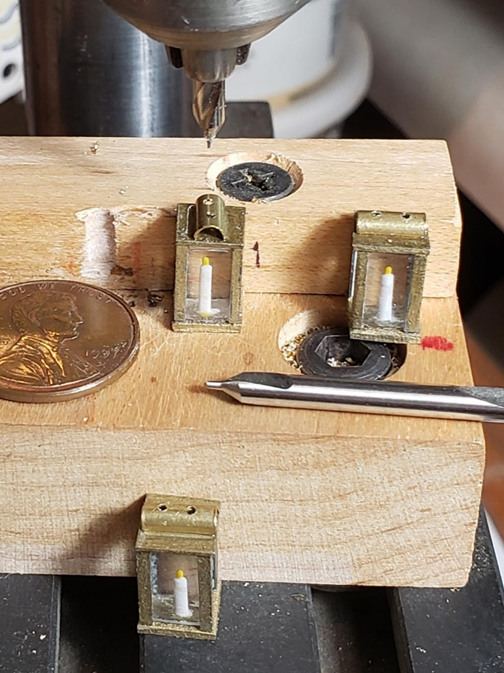

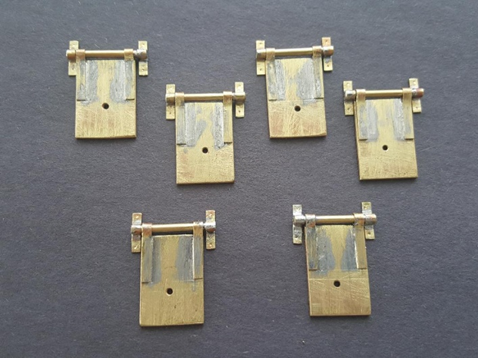

Hi all, Here's the next installment, which is from February of 2022: MAKING SMALL BRASS LANTERNS (built by Fred Hecker and Bill Kammermeyer; photos and captions by Bill unless otherwise noted) An alternative method of making the lanterns was developed by Fred using square, clear, acrylic rod as the glass. The edges were the same plastic angle with a brass tube cut in half for the vent. The bottom of the rod was drilled with a tiny bit, frosting the side of the hole-- PRESTO!, a candle! Some were “lit” by using an even smaller bit for the wick and a bit of paint on a thin wire for the flame. Great job, Fred ! FH 5/28/2021 Drilling holes in the brass lantern vent for wire bail handles was Bill's job. The use of a special bit allowed the holes to be drilled without the use of a center punched mark. This is a good view of the candles with their lit flames. these will be used in the lower working part of the engine room and storage holds. Penny for scale. BK 8/10/2021 Use of a machinist’s centering bit allowed for pilot holes to be drilled quickly without damaging the glue joints and then they could be slightly enlarged later to fit the 20-gauge brass wire used for the bails. the relatively heavy shank of this type of bit relative to its tip keeps the tip from wandering on the surface as would a standard bit. Penny for scale.. BK 8/10/2021 The 20-gauge wire handles add a touch of realism to the look and will be added to a few of the crew below deck as with the 1/24 figure that I use as a gauge for my figure sculpting. Penny for scale. Fred made a total of 21 lanterns that will be used around the "dark places" of the ship as well as in the deck storage sheds ready for night maneuvers. BK 8/11/2021 OPERATING PILOT HOUSE WINDOW ARMORED COVERS (MADE BY FRED HECKER) Operating pilot house window armored covers. 2 will be in closed position, 4 will be open and 2 will be left off of open viewing sections. Another outstanding job done by Fred. Hinge plates have been punched for Bill to drill to appropriate size for attachment pins. FH 10/13/21 MAP CASE FOR PILOT HOUE (made by Fred Hecker) When Fred Hecker sent these photos of a map chest to me, I thought it was for my approval. I thought they were pictures of an antique chest. I wondered if they would fit in the pilot house. FH 10/4/21 Fred said this was what he built. It looks so good I thought it was a photo of an antique. It looks great in place and there is still room for officer and crew as well as floor hatch use. FH/BK 10/7/21 That's all for today. Next time, also from February 2022, many many tools. Tim

-

Hi Bruce, Beautiful picture of your Whaleboat! You can be sure Vince and I will be visiting your build log for it when we start our build. Tim

- 245 replies

-

- model shipways

- Finished

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.