-

Posts

5,195 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by michael mott

-

-

-

Great job Tom, looking at those final pictures gave me pause, what a sad end for this good looking vessel. certainly something that you will never have to worry about, when she is docked in her final berth of honour.

Michael

-

Remco the wales look really sharp and I would agree with druxey that over time the character of the work on the treenails and joints will be readable.

Michael

-

Pete thanks for the answer, the pictures of the full size ones are making me drool all over the keyboard' regarding the louvres if you look at some of the shots of the lockers on Toni's build perhaps that will help sort them out they are 1:48 and yours are 3 times larger scale but smaller louvres so the same system might work.

Michael

-

Dave, Brilliant! the jig is a keeper. the dead eyes look so crisp.

Michael

-

I have to echo the previous comments regarding the sweet lines of this beauty. I do have a question regarding the transom it looks a bit odd sticking up above the planking is that the way it will look when finished? I ask this because of the picture that Rick posted of his boat.

Michael

-

-

Wow they are coming together very nicely. Raising and lowering sails with RC is more that I would want to tackle.

Michael

-

-

-

A very nice tool there Remco, I have to agree with Druxey regarding all those who share their knowledge it has certainly helped me a great deal. lovely work on the whales.

Michael

-

A nice bit of complicated woodwork there Bob.

Michael

-

-

Ed your continued excellence is inspirational.

Michael

-

Richard they look like they are in reasonable shape, they certainly are cheap enough. I don't use ebay so am not familiar with the rest of it.

michael

-

And please don't overlook making your own plane. You can make it any size you wish, any shape you wish, and out of any materials you wish.

Alex

Alex have you made any yourself and do you have pictures?

I use Veritas low angle block planes, available also at Lee Valley, and also Druxey's comment about using the chisel is a good one.

Michael

-

Danny you are absolutely correct about buying only the best you can afford and get them as you need them, I came across this article on files that is well worth the read. I inherited a number of 6 inch number 6 cut Grobet files from a watchmaker and they are wonderful even though they are old and a little worn.

Michael

-

John I will get around to some brass ones probably some form of jam cleat.

I was tired of the beard so shaved it off on Tuesday, it was beginning to get too warm, now that spring is finally here. I have also started to experiment with some miniature seascape watercolours.

When I get the sea looking decent I will start adding some boats.

Michael

-

-

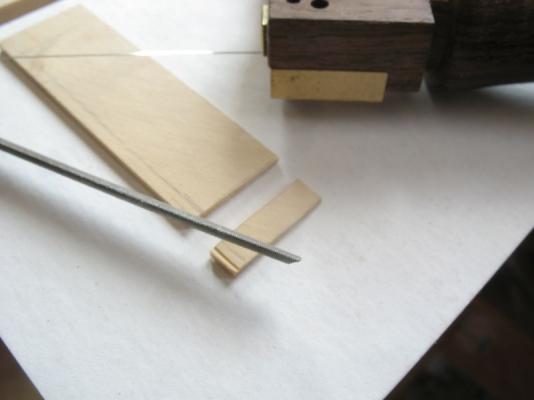

A set of tiny cleats on Kieth's build log intrigued me regarding how difficult would it be to make a couple for the pilot cutter.

The first task is choosing the right approach, I prefer to have a large enough piece of material that I can hold it in my hand while using files because I can feel the work being done.

I started by cutting a 5mm strip off the end of a strip of boxwood that was extra from the block making

The first cleat vanished as the saw completed the cut through the wood and I knew that it would be faster to make another than the futile endeavor to look for the one that took off. This first one was made by working the bottom sides first, then partially shaping the topside before cutting it off the bulk

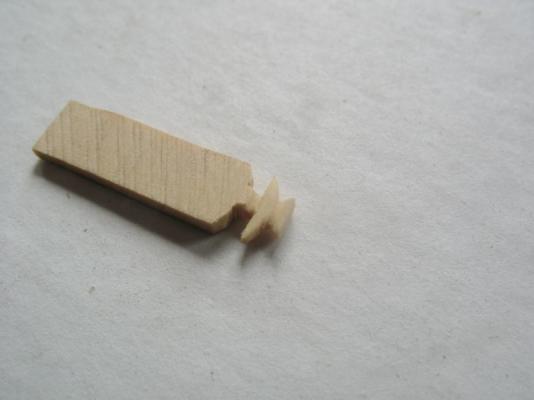

On to version 2, this one I began in the more conventional way of shaping the top first using a rectangular needle file with a squared safe edge, the safe edge is very useful and I put it on the one side with a sharpening stone.

I clamped a small wooden clamp on the end so that when the saw cut off the cleat from the main block it was captive for the next operation.

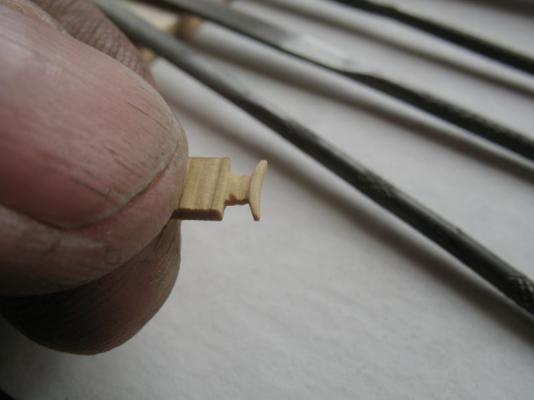

Here the small cleat is next to the hinge on the companionway door for size comparison in scale this cleat would be 1.5 inches long by 3/8ths wide

and next to the 10 inch brass cleat on the deck.

Michael

- druxey, Mirabell61, themadchemist and 16 others

-

19

19

-

Ollie My thought are regarding the access to the belaying pins on the starboard side where the boat is stored, it feel just a little cramped.

Michael

-

(try, fail, ponder, adjust, try agin, fail, ponder,.....)

Seems to be the story of my life.

The model is looking superb.

michael

-

Very nice Dan.

Michael

-

The stove looks pretty rugged, and the distiller is a neat idea, I suppose they thought about Rum too?

Michael

Herreshoff Buzzards Bay 14' by pete48 - FINISHED - 3/4" = 1' - SMALL

in - Build logs for subjects built 1901 - Present Day

Posted

Beautiful lines and such a sweet job on the planking.

Michael