-

Posts

5,195 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by michael mott

-

-

-

-

Johann, it is such a joy to see such craftsmanship.

michael

-

Steve this is looking great and the thing is that you have already had her in the water, I am envious! I am looking forward to that day as well.

Michael

-

Grant, Tom, Row, Pete and Edwin, Thanks for the kind words and for all the likes. I have not had a lot of time in the shop the last couple of days and tomorrow I will be taking a few days up at Jasper Park Lodge for the Alberta Libraries Conference. Will bring back pics of the mountains. I hope to catch up on some reading about sail making because that aspect is beginning to loom large (sorry Bob) and I need to learn quite a few things. I am sitting hear drooling over the cover photo of the August 2009 issue of Wooden Boat magazine The image of a Gill Smith look-a-like by Lance Lee some absolutely seductive lines on a boat if ever there was some.

I have almost finished the second pair of hinges and have been taking a lot of pictures. I will be posting a step by step set in the metalwork area. This method of making hinges can apply to a lot of different hinge shapes. I will also detail the small countersink that I needed to make for them.

Michael

-

-

Very nice straps Remco, did you heat treat (anneal) the brass or bend them hard?

Michael

-

-

the perseverance pays in the end, nice work Bob.

Michael

-

Rich since you are only cutting short lengths, you can also use a jewelers saw to cut the brass.

The particular strip of .25mm brass was originally cut from a standard KS sheet of brass that you can purchase at the hobby shops. I needed some strips that were 3/8th by .010" which is basically the same as .25mm. I cut the bit strips on the table saw some time ago, by sandwiching the sheet between some plywood and using a sled. but that is another kettle of fish.

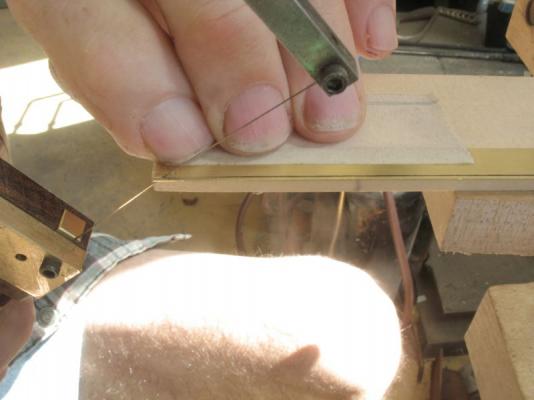

Here is a step by step I just did to show what I mean using the jewelers saw.

1 tape the .25mm ( .010") to the edge of a piece of thin wood, leaving the 1mm+ overhanging the edge, this gives the metal a lot of support

2 using the finest blade you can find and then using a jewelers saw cut along the line holding the saw at an proximately 45 degree angle this makes the teeth seem closer together, (it's the geometry)

cut with a smooth and gentle motion

The set up of the camera took much longer than the cut which took about 30 - 40 seconds

Anything much thinner than this you can cut with a good pair of scissors, in fact I did cut a small strip off the end of this brass strip with a pair of scissors.

Michael

-

Looks good Denis, a neat tip with the shim to give the right amount to the fan.

Michael

-

The launch is looking very good Steve.

Michael

-

Ed it is great to read your methodology nice tip with the steel straight edge.

Michael

-

-

An interesting bit of Kit, for sure.

Michael

-

That looks like a good clean design Steve.

Michael

-

A good looking start on a very nice looking hull shape, I will be following along as well.

Michael

-

Congratulations Albert, a very clean piece of shipbuilding.

Michael

-

-

-

Steve the white stripe really helps to define the shape of the hull, nice job.

Michael

-

-

-

Hmmmmm tough situation there! can tou use a different bottle so that you do not have to rebuild the whole thing?

Michael

J Boat Endeavour by fnkershner - Amati - 1:35

in - Kit build logs for subjects built from 1901 - Present Day

Posted

Floyd Walmart, I paid $6 per tin for it, I don't normally shop there but they were the only supplier within 50 miles.

michael