-

Posts

5,195 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by michael mott

-

-

Thank you all for the likes today.

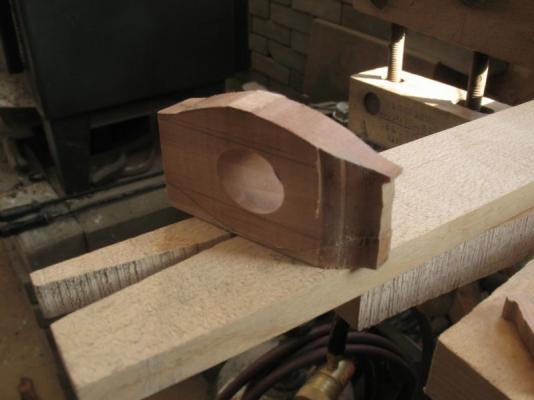

This afternoon I finished the shoe. I don't know what else to call it.

A small slab of apple was set up in the mill and the broken reground 5/8 endmill was used like a fly-cutter to bore the 5/8 hole.

Next the basic shape was fretted out with the jewelers saw

The pieces from one side were then stuck back on with some double sided tape so that the other profile could be cut.

After a lot of filing and sanding then steel wool the shape is almost finished

Tomorrow a few hold down screws. then back to the cockpit cap rail.

Michael

-

First time I have used super glue

on a model ship.

on a model ship.There is always a first time for just about everything,.... nicely done.

michael

-

Very interesting stuff that I am learning about submarines in your build log Piet, thanks for the historic pictures.

Michael

-

-

John, thanks.

Joe thanks for checking in I will do my best.

Drazen, thanks for your comment, i am wondering about how to deal with the sailing. Sometimes I wish we had a local pond and not a big lake.

Denis I definitely plan to get her in the water. I hope to pull it off this summer.

Bob thanks again,

It also occurs to me as I've read your log, that you must have an inexhaustible inventory of brass and wood

Tom I wish, the thing is that I am a bit of a pack rat and over the last 45 years I have been collecting material, wood metal plastic leather wire and so on, A funny story is this one: for one of the projects built for a client when I was building models and exhibits before retiring, needed some fine spring wire for a model rocket that was to launch and rise 35 feet the rocket was in a science centre and the cabinet looked like a payload for the shuttle, the wire I needed was two lengths about 40 feet of some wire about the same thickness as the smallest string in a guitar. I went to a local manufacturer of springs in Edmonton and told them what I wanted the chap at the desk went out to the back and took longer that I thought it would take to come back with 40 feet of fine wire. after about 20 minutes he came back out with a coil of wire that was about 15 inches in diameter that looked like it had a couple of miles of this stuff, he was clearly frustrated and told me that he couldn't spend any more time trying to find the end, and I could purchase the lot for 20 dollars. I agreed and walked out with a couple of miles of very fine wire. and I have enough wire to last the next three lifetimes for what I need it for.

I guess as I purchased materials for projects over the years the left overs would be saved instead of being tossed because I knew that down the road I would be able to use them.

The same goes for tools over a long time doing a great variety of different models and exhibit projects if a specific tool was needed I would build it into the price. I would rather make something than buy it.

Sometimes there are also minimums that one has to purchase when doing this stuff commercially, this is the case with most of the brass that I have that is odd sized and not the usual hobby type sizes.

And if a tool breaks then I save the parts and regrind them into another.

The curse is I never want to move again...ever.

The reason is, I've recently been playing with microprocessors and stepper motors, and I am now utterly certain that the best way to handle sheets on an R/C sailing vessel is to turn it into "an exercise for the programmer".

Andy thanks for stopping by your thoughts about the control are interesting, that said my knowledge about electronics and microprocessors would fit on the head of a pin. I'm of the old flashlight battery and bulb school of electronics.

And if I thought I could get away with it I would train a couple of mice to handle the sheets, Joking aside I am hoping to keep this as simple as the old pond yachts (I know that this is really not possible given what I have already done) the sailing is important but only so far as I will know that it will sail, for me the design and building of the next boat will take over as soon as this one is finished. For me the process is what drives my energy not the finished product so much. As I finish each piece the next task or item becomes the next challenge to solve, keeping track of all the parts would be overwhelming otherwise. I'm not sure that this is making sense but it is what it is.

Daniel I look forward to seeing your jig. because I do want to add one.

Michael

-

-

-

Aussie, thanks

used to Sail, the Lilac was a small tree like White Lilac that I pruned in 1973 I only have a little left so I keep it for special occasions.

Bob thanks and I think it looks even better now.

Nils Yes I would like a full size one of these too.

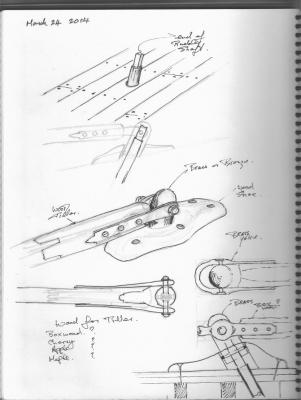

Today I finished up shaping the brass yoke and have almost finished shaping the tiller, it is such a lovely wood to work with.I really like the way the wood curls off when using the chisels. All that is left is the very end. after the shaping with the chisels i just gave it a rub down with a little steel wool I could not bring myself to putting any sandpaper on it.

As I was shaping the brass I kept thinking of famous line "less is more" usually associated with Ludwig Mies Van Der Rohe (1886-1969) (the origin of the phrase surprised me) and so I continued to shape until it felt better. one of the things that occurred to me as I was shaping was the potential chafing of ropes on the yoke and so a more simple shape lessens that possibility.

Tomorrow I will add the transition shoe for the deck.

Michael

- SailorGreg, archjofo, usedtosail and 15 others

-

18

18

-

Keith said

Well the seizures have subsided and thought I'd comment.

Made me laugh out loud!

Denis the colours are vibrant, you are doing a great job on this. It is interesting how different eras had their different colour schemes, I wonder what the 20th century one will be when looking back in a couple of hundred years.

Michael

-

Well according to the Random House Dictionary definition 2 is that a jack shaft is the shaft upon which an idle wheel or fair-lead turns. I thought that there were fair-leads on ships and boats

Michael

-

On the other hand the jack of all trades learns less and less about more and more until he knows nothing about everything.

So let us all hope that we are not named Jack.... no offense meant to the Jacks of the world.

So where is the Jack-staff located to bring this back to the build?

Michael

-

Beautiful work Sherry, and I see no reason why the function of a particular part as Dan points out should not be as beautiful as any other part.

Michael

-

Steve, yes it is rather bigger than a lot of the models on the forum.

John, sometimes I think I should stay out of the RC conversations as well.

Mark, sometimes I think that I should forget about sailing her.... but then I would always wonder.

Sherry, thanks, I like the term full fledged, conjures up thoughts of flight and wind.

This evening I did a little more work on the tiller, after doing a few sketches this morning to get a better sense of the shape.

the next step in shaping the yoke on the mill

and the new Lilac tiller, I am looking forward to the fine work on the lilac it is such a wonderful wood to work with and has the aroma of aromatic cedar. and is very fine grained with purplish streaking.

Michael

-

Oh dear its a shame it doesnt work as you hoped - I loved the video !!

Spyglass I am not sure I understand your comment the way it is working is the way I thought it would work. I'm happy you liked the video.

Michael

-

Robert your work with the bone looks very good, it must be a very challenging material to work with.

Michael

-

Denis wrote

in this way, one line would be coiling up, while the other is being let out.

Hi Denis, after my test I discovered that this does not work for the following reason.

1 There is no fixed position of the sheet to the boom.

2 It is only when one end of the sheet is fixed , ie cleated or a winch stopped that the boom can be let out or pulled in. and this is where the triple purchase gives the crew member the extra advantage of the triple purchase for fine adjustment.

3 If I were to do that then the number of turns for either side of the centre would be doubled. to let the sheet out fully. on either drum.

4 if one is coiling up and the other being let out the the position of the boom does not change, it would only change with a differential speed of the two drums which in my limited view would greatly increase the complexity of the controlling a transmitter even if it was computer programmed.

For all the reasons stated I think that having both drums moving simultaneously and in the same direction will be adequate. of course the test was under very false and controlled conditions I am looking forward to trying the test with a sail bent to the spars and a light breeze to see how the sail snaps past centre as the boat crosses the line of wind.

I will do this test on dry land using a turntable of some sort.

Bob we must have been posting at the same time.

Thanks for your thoughts about the stops, I agree that there will need to be some form of mechanical stop at both ends. A definite stop with a clutch rather than a micro switch which can have overriding effects due to the incoming speed of the switch riser on the drum

Michael

-

Steve, thanks for your thoughts about my machining.

Doris it is always an honour to receive your praise.

Bob, sometimes I wish you lived just around the corner so I could talk to you about design issues, your experience would be very informative.

Tom, thanks and yes I think it is on the right track.

Mark thanks, each day I realize how much more work and testing there is so it is really nice when they work out.

today I also managed to get a start on the reworking of the rudder shaft top. I machined a 1 1/2 inch length of 1/2 inch diameter brass rod to a dome end and bored out the inside to fit the copper shaft and also to fit a piece of square brass tube then slipped a piece of 1/4 inch brass tube in after these were soft soldered into the hole then the cross hole was drilled and tapped 4x40 for the yoke fixing screws.

The body of the yoke is just rough machined at this point and the apple wood tiller will need to be replaced with a new one because it is about a 3/64 too narrow. so some masking tape thickener to see how the length looks.

I like the way it is articulated now so will finalize the shaping of the yoke tomorrow. I will make a wood shoe to clean up the transition from the deck to blend in the angles.

Michael

-

-

-

Beautiful woodwork, the wood you cut looks like European Boxwood nice re sawing.

Michael

-

Mauro that you are doing the sewing by hand shows your skill with the materials, very nicely done.

Michael

-

I guess they dont last forever, did the Echo and started Pegasus all on one blade at the cost of $0.39, I think I'll put a reminder up to change them more often!

Ben I think we all tend to use them until they just don't cut well or most often break because they are dull and then overheat. perhaps a small label like the oil change one on the car. Blade good for x number of board feet of cutting.

Michael

-

Nice to see the re purposing of some packaging material.

Michael

-

I rigged up a couple of drums to test my thoughts about this, I used the camera to make a video clip here

The drum is only about 4 inches in diameter I used a couple of discs of oak left over from a project they rotate 6 times from centre to full swing. I think I will be able to make this work, In all my sailing I have never used a main sheet rig like this so I was unfamiliar with the actual mechanics of the way it would work.

I full scale I would think that the double set of cleats gives the person working the sheet more control by letting out one or other sides for when the added leverage is needed and then using both at the same time lets out the main faster. That is the way it appears to me anyway.

The deck cleats did double duty as guides, but I think a couple of fair-leads would be useful I am thinking that for display the sheets can be coiled up and when sailing they could be led into the cabin in some simple way.

Michael

Cutty Sark by NenadM

in - Build logs for subjects built 1851 - 1900

Posted

nice work on the deck Nenad. I think that modelwork is a great antidote for politics, take one hour of modelwork each day to overcome the effects on ones mind.

michael