-

Posts

5,195 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by michael mott

-

-

What an interesting thread, I have a few books but it is a small collection of Nautical and ship model ones, plus others on Art, the Railways, Aircraft, Architecture, Model engineering, Egyptian Archeology, Trees and Wood, Astronomy, Geography, Clocks and Watches Carriage Making and Wheelwrights, and the Environment, probably close to a thousand books or more. I had not thought about cataloging them, and my wife is a librarian My books are mostly reference my wife has mostly fiction.

Michael

-

Tom,

Actually, I hope the starboard light is green!

Made me laugh.

Tom The light s turned out well, you did a great job.

Michael

-

Oh, just take a piece of brass sheet, bent it this way then that way, file some here and there, drill a few holes and presto, done

But Piet after I read this that you said I then proceeded to follow the bend this way and that, and yes you do make it look easy, because this is exactly what you did.

Michael

-

Well Dimitris you certainly don't hang about do you, very nice work and fast. Your model looks very good.

Michael

-

Jud yes if I were using steel I would in fact use the upsetting method.

Michael

-

-

Very nice fabrication of the rim Elia.

Michael

-

A small update

Skipjack/Floss part 7

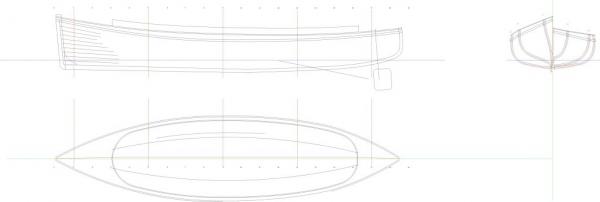

I have received some updated information from Roger this past month I got new dimensions of some critical areas and have been refining the plans which are getting much closer. Roger also sent some great pictures of details and information regarding the sizes of ribs and floor timbers and the way the stem and stern are built.

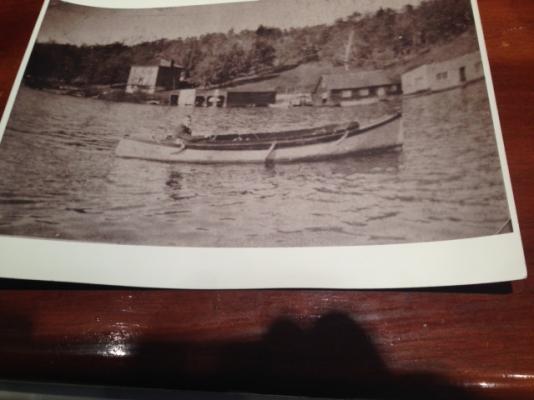

The stem was originally cast aluminum and was more upright than it is currently. The stem was modified after 1912 and a wooden one replaced the original and at a softer angle to the water. This pre 1912 photo shows the original stem

This next picture shows some restoration work that was done in 1987 showing some of the new floor timbers. and the ceiling boards.

this is the current itteration of the plans given the new data.

Michael

-

Dave they are different organizations, there are most likely some members in both.

Michael

-

OK, somewhere back there I totally failed to pick up on how small this model will be!

I have to admit i had exactly the same reaction when seeing the model between your fingers. Wow! very clean build.

Michael

-

Nenad that look like a very effective way to get a weathered look to the decking.

Michael

-

Mark the lines of your framing look superb by placing the hull upside-down one really gets to appreciate the graceful lines of your work.

Michael

-

Jud I understand the principles of forging techniques with iron and steel. I am not using steel for these very small shackles but Brass. The process you outline works very well on larger scale pieces of metal but is very difficult to achieve with 20 gauge brass wire, in fact the grip needed to hold the brass and either tap on the "cold" is enough to deform the brass in the first tap and also begins to work harden it at the same time, whereas by holding the brass wire in a vertical position which I did this morning the results are a consistent capillary type balling of the end using a simple soldering torch with propane or butane, all in one operation in seconds.

I also found it works best if the metal is cold so after each end is balled then I quench it in cold water before rotating it to ball the opposite end.

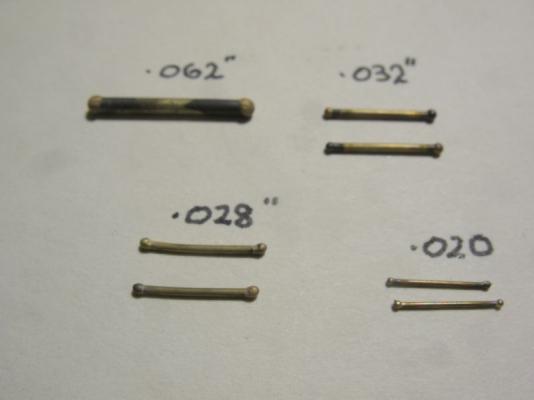

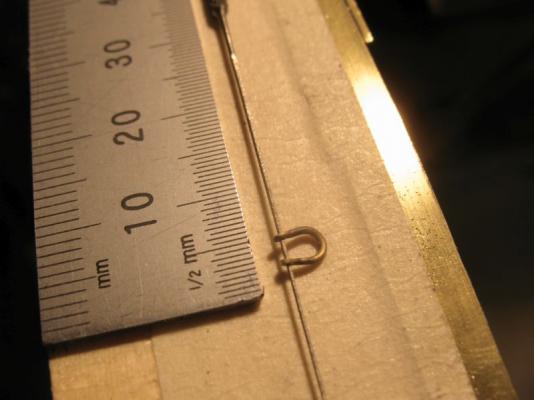

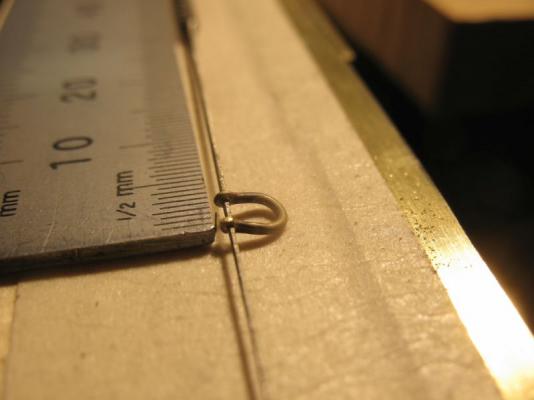

the first pic shows .028 diameter brass balled at both ends in the spring tweezers

This is the torch I used for this mornings test it is a pencil flame I used the only bottle I had around the shop.

the results for the balling were quite consistent and with a little practice this would become quite a fast way to accomplist this task

The fine copper was more difficult to do than the brass, in all likelyhood because the alloy of copper zinc and tin melts at a lower temp than the pure copper but it is only a guess on my part based on empirical results.

Michael

-

Excellent work on the brackets and catheads Sherry.

Michael

-

Thanks for the likes

Bob Thanks it has taken a while to learn to be gentle with the torch

This is the torch set up that I have, it just uses acetylene and air is entrained through the handle, the only adjustment needed is the gas.

John thanks and yes do give it a try I am interested in how well it works with different torches I did an experiment this evening to see what the best tip is for different diameter wire.

I set them all up on the 1/4 inch steel bar to act as a heat sink, I had to be very careful not to blow them off with the torch. Originally I had set a second bar on top but it worked far to well as a heat sink, and I did not want it to work in reverse by getting too hot. I used the #1 tip in the torch for the .020" the .028" and the .032" I used the #3 tip for the .062" rod

the .020" showing the flattening on one of the set I used the same blue pliers as before to squeeze the end flat.

As you can see it will take a little practice to get the flattening sorted to be consistent, I will likely use the small vise and use a mark on the rod.

I was not up to drilling the holes tonight so will tackle them in the morning.

Michael

-

Captain Al ,perhaps a small razor saw would be a better tool for cutting across the wood it would give a square cut and actually remove the material in the same way that a chisel cuts . if you think about how a saw blade is designed it is a row of micro chisels. An eXaco blade works more like an axe it is a wedge albeit a sharp wedge.

Michael

-

I agree with Nigel use some double sided tape and make yourself some long sanding sticks if you use the edge of a wider board it will remain rigid and be easier to hold.

Michael

-

Jud thanks for the extra information regarding the forging of the metal for different shackle arrangements.

Michael

-

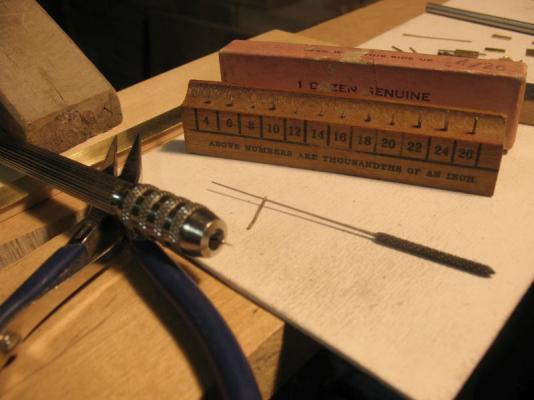

An Idea came to me reading on Keith's build log here regarding the flattening of the ends of fine gauge wire.

By melting the end of the wire

we also create an annealed ball which can be flattened with a pair of smooth pliers

A watchmakers pivot drill was then used to drill the hole by hand the hole is .022"

Drilling the holes was the hardes part of this project.

I am pleased with the final outcome but this will need a little practice to finesse the shape of them for further use.

This method will most likely work with some heavier gauge wire which will eliminate having to use the lathe to create the ball ends.

Michael

-

-

-

Bob thanks for the update, things are looking very shipshape.

Michael

-

Hi Elia, a belated greeting for your B'day I look forward to seeing the next update. Russ thank you for your link your paintings are wonderful.

Michael

-

Beautifully clean work on the channels Ed.

Michael

HM Colonial Cutter Mermaid by olliechristo - FINISHED - Modellers ShipYard -

in - Kit build logs for subjects built from 1801 - 1850

Posted

Hi Ollie, I just finished going through you entire log, what a wonderful job you are doing. Your planking certainly deserves to be shown. really clean joinery on the deck furniture as well.

Michael