-

Posts

5,195 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by michael mott

-

Mike and Druxey thanks, for your comments. Denis I am not sure, but I'm thinking about it. I placed the soldered up side in to see how well it lines up, it slipped in with a little bit of fiddling at the forward end. Once I have the white paint matched fully I will strip off the paint from the brass on the side piece before setting it in permanently. Michael

- 749 replies

-

- albertic

- ocean liner

-

(and 2 more)

Tagged with:

-

Nice move on coloring the pins for port and starboard, funny it looks like a centipede having a perm. Michael

-

Druxey this is the direction I was leaning in. I do have an airbrush, the funnel is entirely metal pretty much all brass. I will after stripping give it a fine coat of Zinc Chromate primer before applying the colors. All of the stay eyes are through holes then bent on the inside so all of these will also be removed. Roger, I do not have an air eraser and do have acetone which on brass will work well enough and if it has difficulty with any of the paint I will use Lacquer thinner which I also have. Thank you all for your suggestions and input, it really is helpful to hear your opinions and Ideas on this area. Yesterday before we went into the city I glued up the boat deck. After setting overnight I just removed the clamps to see the next milestone achieved. An additional thank you to all who are visiting quietly it is encouraging to see the interest in this project. Michael

- 749 replies

-

- albertic

- ocean liner

-

(and 2 more)

Tagged with:

-

What a great shot of the clothing that the men wore. It doesn't look that warm for a polar type expedition though. Michael

- 15 replies

-

- gjoa

- polar exploration

-

(and 1 more)

Tagged with:

-

I had a look at the paint on the funnels today in the natural daylight, following Druxey's suggestion of cutting through the top layer(s) of paint this is what I found. So some history is revealed, this is a guess. Working up from the lowest layer which seems closer to the top color. a-bottom original b-middle possible smoke discolored or an off coloured repair, I am open for other opinions on this. c-top a last repair working to match the original. The top color is pretty close to the original but the person doing the repair looks like they used the same brush that they painted the fence in the back yard with. And yes to be fair, initially I used a rather heavy sanding stick. Michael

- 749 replies

-

- albertic

- ocean liner

-

(and 2 more)

Tagged with:

-

Good to hear there wasno damage from the flooding the model progress looks good. Michael

- 15 replies

-

- gjoa

- polar exploration

-

(and 1 more)

Tagged with:

-

Wefalck, thank you for this. I have not seen this type of tool before, I will definitely look into getting one. Michael

- 749 replies

-

- albertic

- ocean liner

-

(and 2 more)

Tagged with:

-

Cutty Sark by NenadM

michael mott replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

I like this it has a great charm to it. The overall shot shows just how far you have come on this enjoyable journey. Michael- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

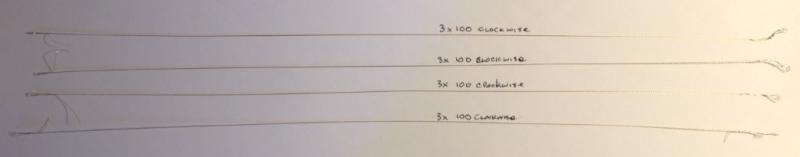

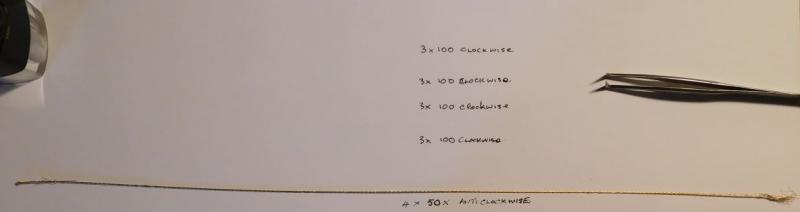

Thanks for all the positive comments and feedback. I am now satisfied with the color and the lay of the wire to match the Bassett Lowke cables This is the final lay up And how I achieved it first wind up the 4 sets of 3 in clockwise direction next set the wound sets onto the hook then wind up the set of 4 anti clockwise These beginning lengths of 15 inches shrink down to 12 inches of usable cable for the funnels, after the ends are snipped off. There are only 2 aft mast shrouds that need replacing, so I will need to make a couple of longer lengths for those. Michael

- 749 replies

-

- albertic

- ocean liner

-

(and 2 more)

Tagged with:

-

Wefalck can you provide details of your tool, manufacturer etc? Michael

- 749 replies

-

- albertic

- ocean liner

-

(and 2 more)

Tagged with:

-

Druxey that was a brilliant Idea. I got up this morning and while waiting for the kettle to boil, I laid a length of assembled cable on the ceramic top of our kitchen stove set the burner to low and watched the heat cycle on and off as it does after about 5 cycles the wire did in fact turn a tint of a more aged look. top-untreated middle-heated bottom-off the ship The photograph shows the effect clearly, now it just becomes a matter of adjusting the timing. Carl as noted above the heat works well and is a lot less messy than any form of dipping or coating. Thank you very much gentlemen for your suggestions. Michael

- 749 replies

-

- albertic

- ocean liner

-

(and 2 more)

Tagged with:

-

This image from Vallejogallery shows an obvious change or repair. if you look at the shrouds you can see the new brighter wire. I have been doing some further tests with the new brass wire. the top and bottom cables are from the aft funnel the second cable from the bottom is as close as I have come yet to replicating the Bassett Lowke cables it is made from a) 4 sets of 34 gauge non tarnishing brass colored wire each set is 15 inches long twisted with 80 turns clockwise c) the 4 sets are then combined and twisted with 50 turn anticlockwise The second cable from the top is made from 3 lengths of 28 gauge brass non tarnishing brass wire wound clockwise 80 turns and given a smear of brown Pebeo Vitrail stain for colored glass, I dipped the wire then immediately wiped it off once with a tissue it leaves an tinted aged look to the brass. Michael

- 749 replies

-

- albertic

- ocean liner

-

(and 2 more)

Tagged with:

-

Carl, I know that of course. I said it with a smile on my face. your comment though helped me see a better way. Michael

- 749 replies

-

- albertic

- ocean liner

-

(and 2 more)

Tagged with:

-

This is my hope. I have learned so much from all of the work that has been posted here by others. This site is more than a gold mine in my view. Carl I think that this will meet with your approval, thanks for the thought. I picked up my brass wire today and am doing some tests with it. Michael

- 749 replies

-

- albertic

- ocean liner

-

(and 2 more)

Tagged with:

-

Mike one of the things that I liked about watching the video of the operation of the tool was the fine control that comes with the ease with which the carriage moved and the simplicity of gripping the part being cut. What is the finest blades that work well with this tool relative to the fine jeweler's saw blades? I like to use a # 3/0 for thin wood and # 7/0 for thin brass. Michael

-

Thanks Joe, sometimes I wonder if I am being a little too detailed. My hope is that there are nuggets of info that will be useful. Michael

- 749 replies

-

- albertic

- ocean liner

-

(and 2 more)

Tagged with:

-

Hi Nils, they are made of brass, I cannot see yet if they are lost wax (which I doubt) or are a composite of rods tubes and forged elements the tall open type are a combination of tube and turned parts. The shorter large scoop type appear to be assembled as well. All of the chipped paint on them have exposed a brass color. Michael

- 749 replies

-

- albertic

- ocean liner

-

(and 2 more)

Tagged with:

-

Jan, me too, and I have to deal with them. The fall would have been a smooth arc it was the chair in the way and the glass case being shattered then the sudden stop at the end that did all the damage. Good point Carl. I shall rework it. Michael

- 749 replies

-

- albertic

- ocean liner

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.