-

Posts

5,200 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by michael mott

-

Bob Patrick and Mark, thanks for the kind remarks, and thank you too All who visited and pushed the like button. build part 8 Well things have a habit of creating little issues that need to be sorted. first I began shaping the stem and forward section of the keel Then after placing it on the molds something just did not seem quite right. A lot of measuring and revisiting the drawings there was some errors in the alignment of the keel parts. to solve this I needed to rework the way I am putting things together and so I cut a sheet of 1/4 inch MDF to act as a central support for the keel this way it will be exactly as the lines profile. It meant cutting the stations in half and removing the 1/4 inch from the middles but I was also then able to check that both halves matched properly as well. A bit more fettling before I get to the planks. I need to cut some notches for the frames and the glued plates to slip back in. Michael

-

To quote a line from an old Movie "That's not a knife this is a knife" Merchen thanks for the picture i can see how the way you are holding it that it works more like an engraving knife. Michael

-

She is looking great Vaddoc, nice work on all the rigging fittings, i like the chocks, what type of wood did you use? Michael

- 253 replies

-

- ketkch

- gaff-rigged

-

(and 1 more)

Tagged with:

-

Patrick She looks like you have got the superstructure pretty much solved. coming together nicely. Michael

- 1,083 replies

-

build part 6 A little more work shaping the stern post, I have a whole new appreciation for those members who cut and shape the hawse timbers and the rebates in the stern and deadwood of the larger ships of the line. This is a lot more difficult than it looks on all the other build logs I have looked at. These first fittings are an eye opener to the complexities of the shape of the keel and stern on these little boats. Michael

-

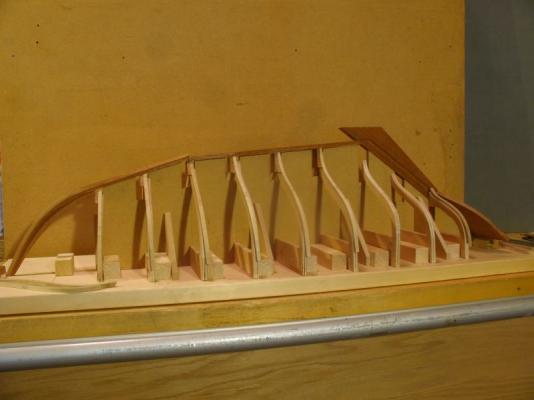

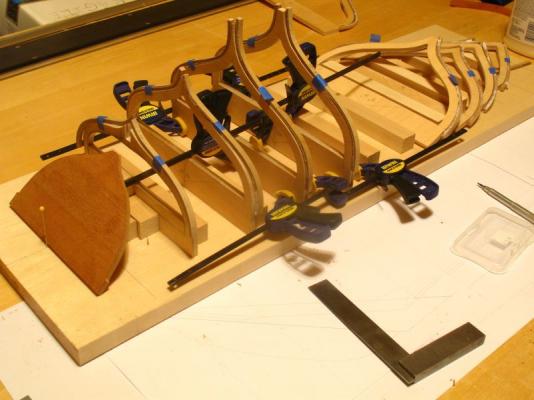

Thanks for the nice comments Pete and Patrick, Build part 5 The building bard is a piece of 1x10 clear pine, I wanted to keep this simple The support pieces are 3/4 x 3/4 and just glued with a couple of small spots of glue to hold them in place without a lot of fuss. I did position them so that the stations aft of midships are set to the aft side of the line and the forward ones forward of the line. this will help when fairing the frames. The transom is glued from three pieces of 3/16 x 1 5/16 mahogany I glued them the same way that I would a board for a cabinet. I planed the edge with a hand plane then rubbed the joints together with the glue and propped it up to dry. this method does not impart any stresses into the glued material. The plywood molds were not perfectly flat and are glued to the support blocks with a couple of spots and clamped. I will attach the transom to the stern-post once it is cut and shaped. Michael

-

Matti, first Merry Christmas and welcome. Very nice work on the Clara May. Birch is a wonderful and very versatile wood for building with, it is obvious from the speed and skill with the materials that you will enjoy many hours with the ships and boats. Michael

-

Druxey, the reason i raised it a little was because in reviewing the photo once more that Dan had posted on his blog I noticed that the gaff was pretty much the same angle as the forestay, I could split the difference and see how that looks because I tend to agree with you. This is a better configuration I think Michael

-

Thanks Druxey, and thank you as well Mike for the tip about the CD cases, I shall have a look at that. Michael

- 2,215 replies

-

Mark, I think that the hull looks great. I am not sure that boxwood would look as warm and mellow as what you have achieved. Michael

-

Hi Patrick, The other thing that I particularly like about the gaff rig is the lower Centre of effort of the rig. I have tweaked it just a little, by lowering the gaff jaws and raising the peak this moves the CE just a little forward as well without changing the sail area by any significant amount. sail plan 2.pdf Michael

-

Laurence thank you for your kind words and the link. Michael

- 2,215 replies

-

Beautiful workmanship John. enjoy the holidays and merry Christmas. Michael

- 745 replies

-

- francis pritt

- mission ship

-

(and 1 more)

Tagged with:

-

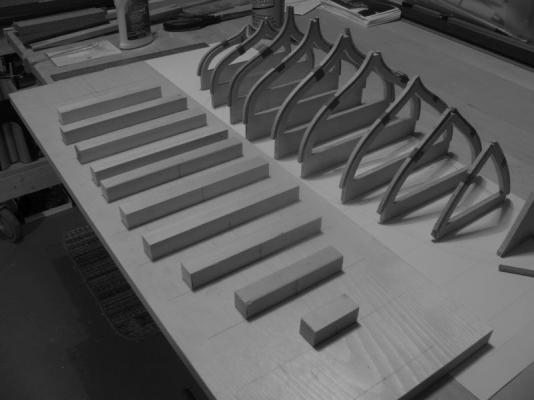

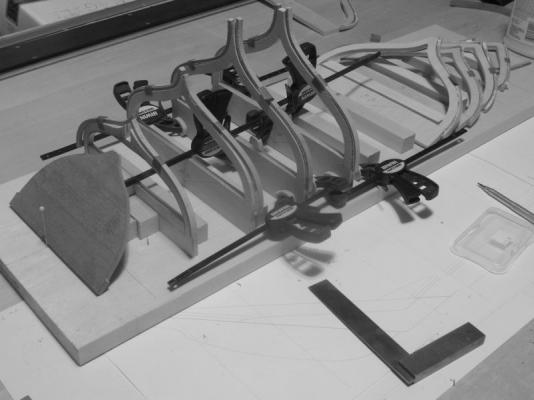

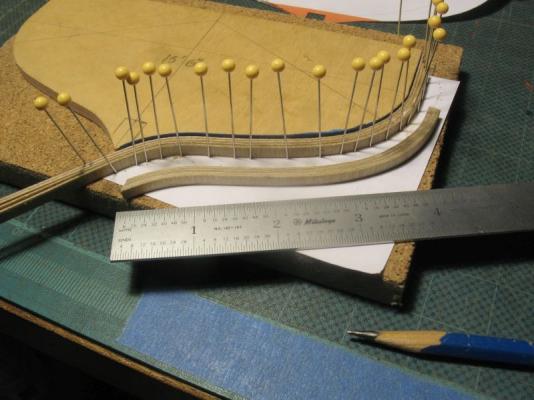

Thanks for all the views and comments and likes. Build Part 2 The laminating of the frames continues, if you ever get the chance to pick up one of these for cheap or even free which is how I got mine grab it, they are amazing paper cutters. And as you can see they do a great job on thin aircraft ply as well. The laminating of the frames continues alongside other seasonal tasks I am waiting about 3 -4 hours before pulling the frames off the form then leaving a full 24 hours before doing any sanding. I have two more stations to go the one at 9' and the one at 6'. Once all the frames are laminated I will set up and fret out the centre sections, I will need to do this out in the shop where it will be a little easier than at the desk. The stations will then be set up on a board to receive the stern post keel, and stem elements.I will also carve a block once all the planking is done and fair it so as to make a mold for the lead keel. If I don't get a chance to wish everyone a great Christmas holiday and any other forms that are celebrated at this time of the year. Judy and Me wish you all Merry Christmas Michael

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.