-

Posts

7,760 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by CDW

-

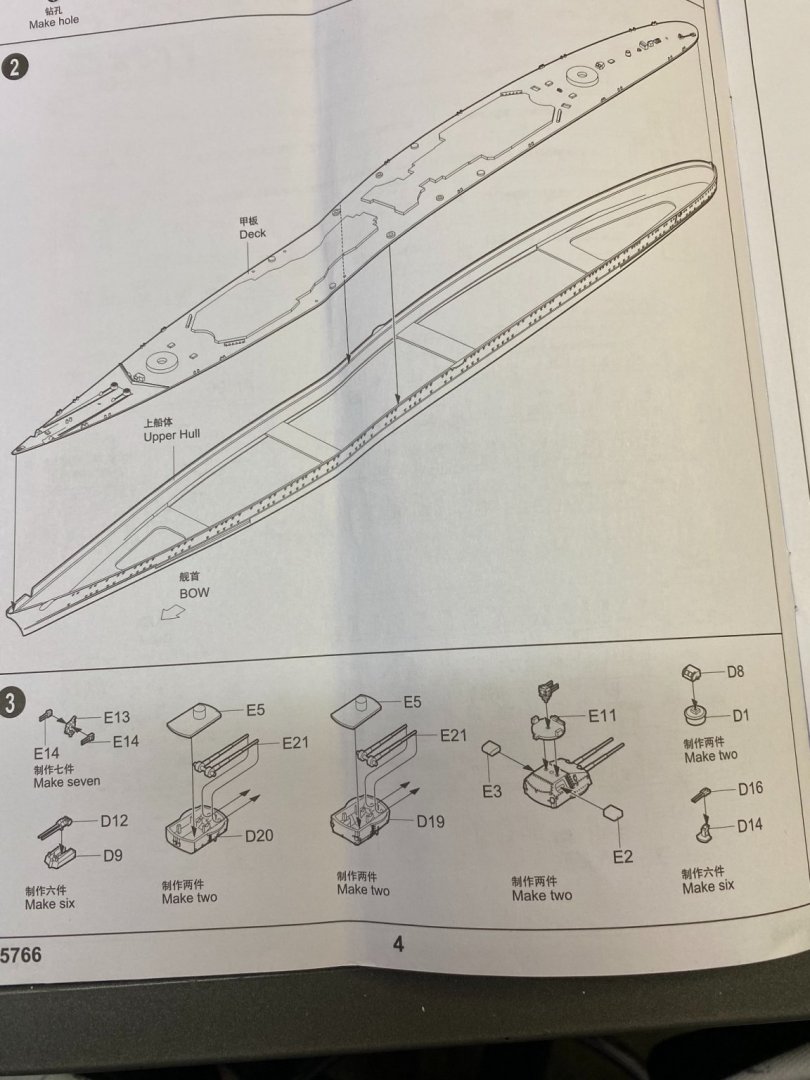

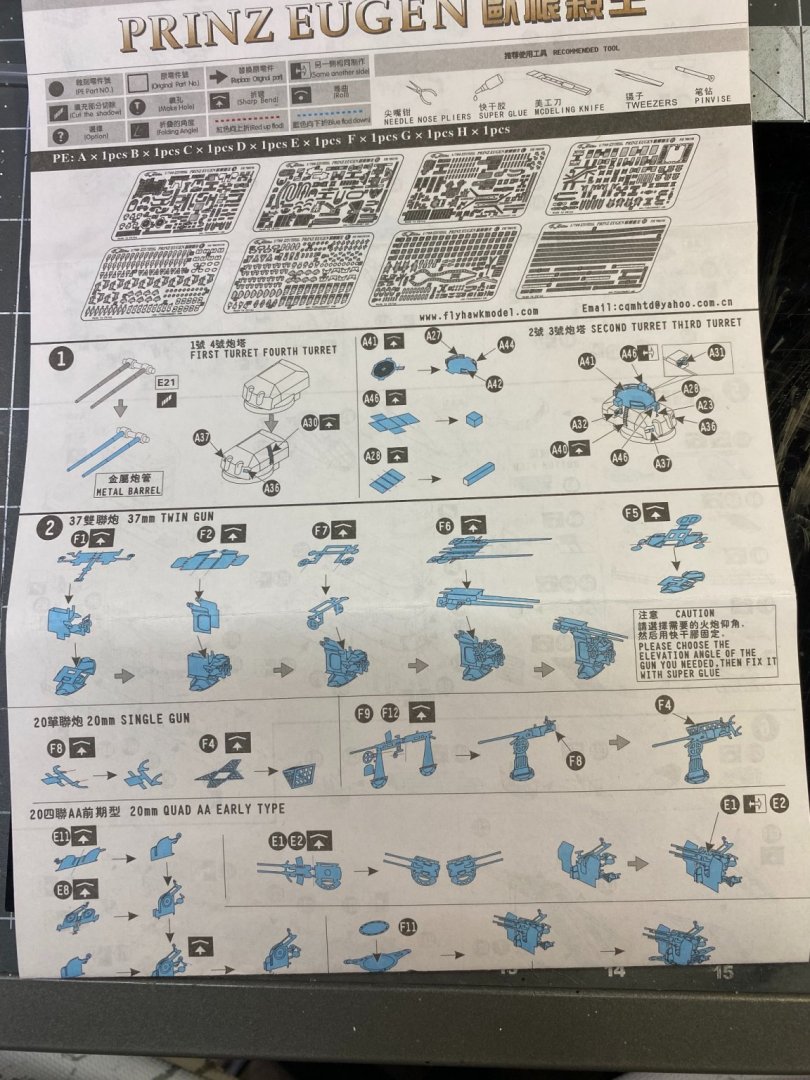

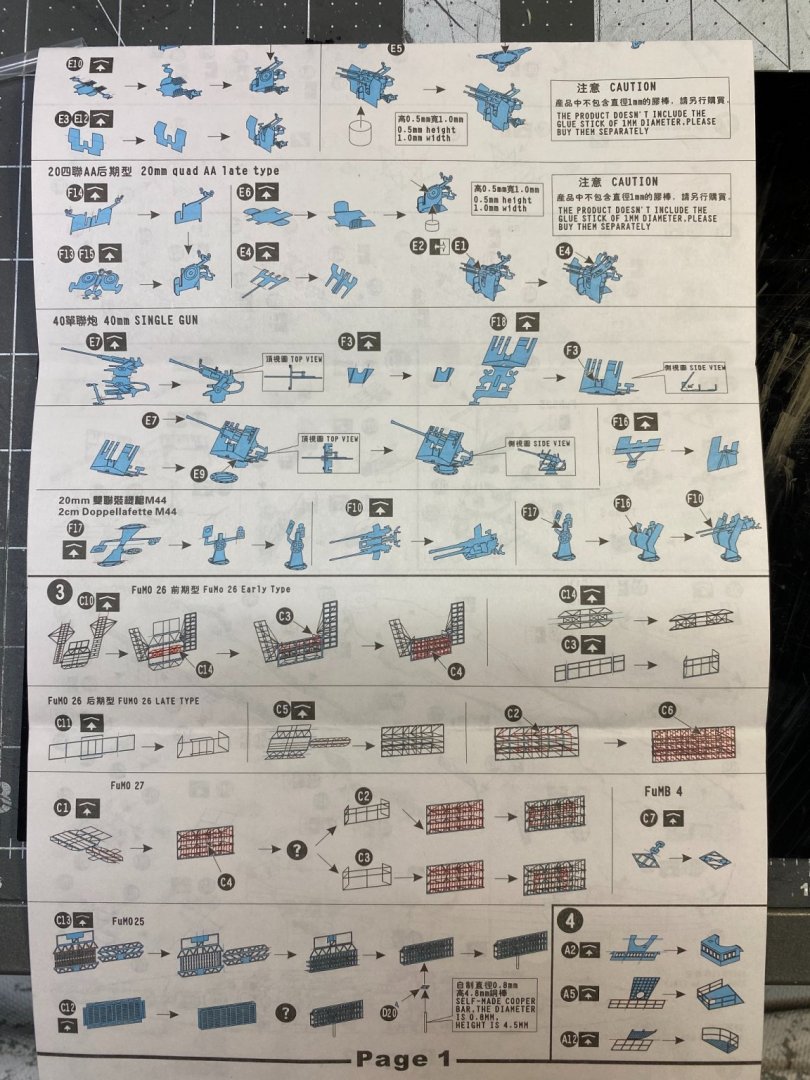

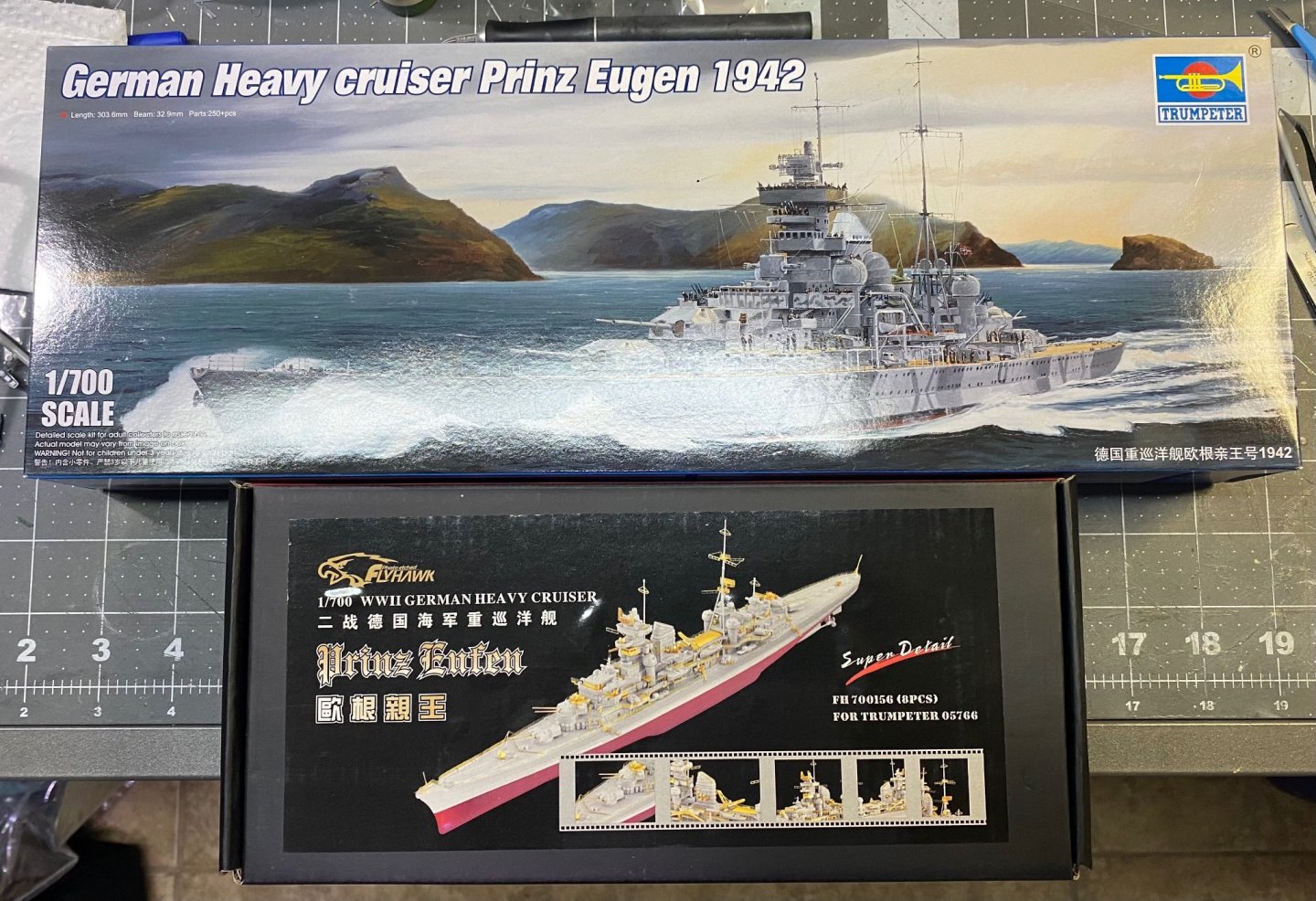

A portion of the Flyhawk update set is devoted to the ship guns. Not so desirable to me is the fact the replacement guns are 2 dimensional. Consequently I am going to explore the possibility of combining the 3 dimensional stock gun parts with the 2 dimensional photo etch enhancements. We shall soon see if this is a viable option.

- 174 replies

-

- prinz eugen

- trumpeter

-

(and 2 more)

Tagged with:

-

Thanks for the comments gentlemen. You're welcome back anytime.

- 225 replies

-

- I Love Kit

- Hood

-

(and 2 more)

Tagged with:

-

Thanks for your comments Roger, and particularly for the link to the 3D Hood video. Lack of good reference was the primary reason I chose not to do a little bit of rigging. With this video, I think I will go back and add a little rigging along with a flag.

- 225 replies

-

- I Love Kit

- Hood

-

(and 2 more)

Tagged with:

-

The Flyhawk HMS Hood came with the mail today. Includes some of what appears to be 3D printed parts. Extensive photo etch and metal barrels. This is the deluxe kit and will sit on the shelf until ready to build another Hood. Gonna watch a couple other guys build it first. 😄

- 225 replies

-

- I Love Kit

- Hood

-

(and 2 more)

Tagged with:

-

- 174 replies

-

- prinz eugen

- trumpeter

-

(and 2 more)

Tagged with:

-

I read that the ship did not fly a national flag in 1941 when she was sunk, but I wanted to fly one anyway just because I like the way it looks, historical accuracy aside. Any thoughts on that? Final photos.

- 225 replies

-

- I Love Kit

- Hood

-

(and 2 more)

Tagged with:

-

Thanks for the comments gentlemen. My Flyhawk HMS Hood kit is out for delivery today, so I should be taking a first peek into the box later this afternoon after the postman arrives. However, I probably won't start another Hood model right now. Will be making a decision on the next project real soon.

- 225 replies

-

- I Love Kit

- Hood

-

(and 2 more)

Tagged with:

-

- 225 replies

-

- I Love Kit

- Hood

-

(and 2 more)

Tagged with:

-

Looks great! The cranes are slightly different than the Scharnhorst ones. Impressive that Flyhawk captures those small details rather than using a single mold.

-

There are a number of ways one could tackle the construction sequence of these models. I chose to paint much of it before I assembled it, then touched up where I needed to. It was in the process of assembling after the paint when I smashed mine. You are going about yours in a different way and I am interested to see how you finish it. You are building yours first, then painting afterward. You might avoid some of the destruction I did when assembling mine. I am enjoying your approach to it.

-

After I got mine in place, I managed to smash one of them...almost flat. There was no hope saving it, just left it "battle damaged". 😄

-

Came through some torrential rain on the car ride back home after the fishing trip. It was beautiful all day out in the Gulf. Could not have asked for a nicer day. Fishing was real good, too. Gag Grouper must be 24 inches or longer, I caught three that were fractions of an inch too short. But man, it was a good fight. Caught five smaller keepers called Grunts. Between us all, we caught about 25 fish so the kids all took some home for supper.

-

Alan I am slipping....Just now found your Gneisenau build thread, so I have some catching up to do! Looks great! One little thing I see that's different from the Scharnhorst kit is the handrails on the main turrets. Scharnhorst has none. Other than that, I have not see a difference.

-

My new 1:700 Flyhawk Hood Deluxe kit should arrive here by the end of this week. I'll post screen shots of the parts when it gets here.

- 225 replies

-

- I Love Kit

- Hood

-

(and 2 more)

Tagged with:

-

I have bought items from Cornwall in the past and can report very good service at competitive prices. even when including the shipping from across the pond they were less expensive than Ages of Sail on model ship items I bought.

- 321 replies

-

- Finished

- Flower-class

-

(and 1 more)

Tagged with:

-

Yves Is everything provided in the shape files you purchased represented in the model, or is there more? I wonder if someone else will take up on the production of other components that will marry to this model? I can see where there could be interest in other details that are perhaps not included.

- 321 replies

-

- Finished

- Flower-class

-

(and 1 more)

Tagged with:

-

I really like the texture and finish on your hull. It looks very much like a 1:1 hull. Excellent! Oh, and by the way, the paper "decals" came out very nice as well.

- 321 replies

-

- Finished

- Flower-class

-

(and 1 more)

Tagged with:

-

- 225 replies

-

- I Love Kit

- Hood

-

(and 2 more)

Tagged with:

-

Early tomorrow morning, am going with my son and three grandsons on this deep sea charter fishing boat. The captain says the past couple of days have been fantastic fishing. Wish us luck and I hope to bring back some great photos of the kid's fishing prowess. All of them are real anglers as men on my Mom and Dad's sides of the family have done for generations. Deep Sea Fishing - Tarpon Springs, FL - Dolphin Deep (twogeorgesdeepseafishing.com)

- 225 replies

-

- I Love Kit

- Hood

-

(and 2 more)

Tagged with:

-

Thanks OC. The chain came with the kit and accessories. A great value for the money spent IMO. All these things purchased separately would have cost a LOT more than the $60 USD I spent on Amazon for it all.

- 225 replies

-

- I Love Kit

- Hood

-

(and 2 more)

Tagged with:

-

Welcome to Florida. Insects are everywhere and the rain makes them even more active.

- 460 replies

-

- Finished

- Flower-class

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.jpg.7e80607770d9078b2f0b470e8c9c33ac.jpg)