-

Posts

7,746 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by CDW

-

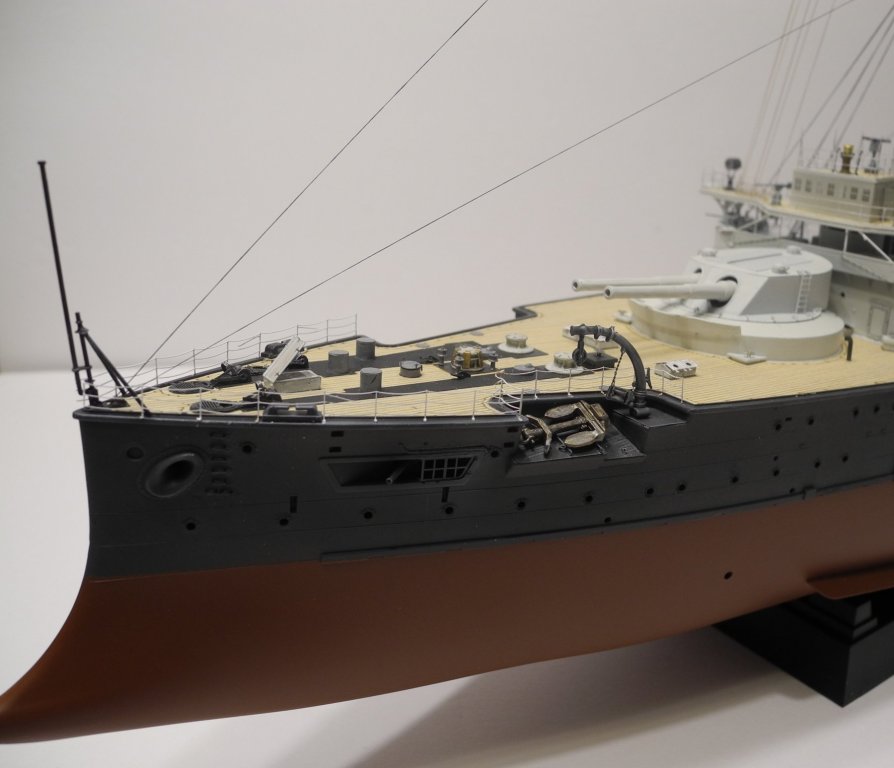

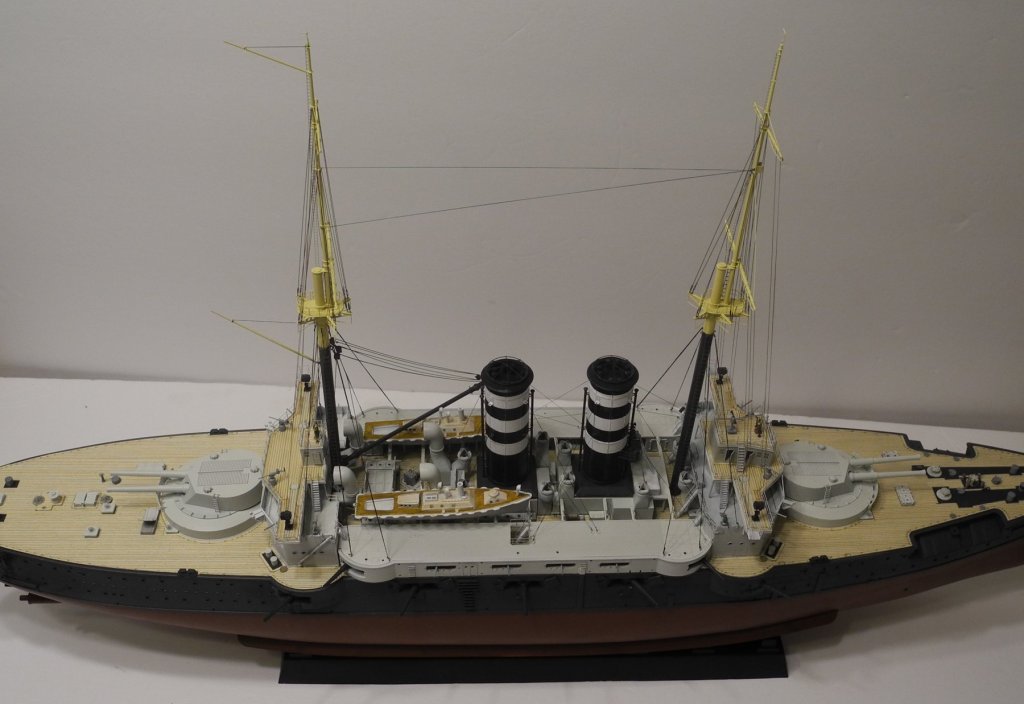

Thanks for the kind comment Cog, but she's not finished. Only meant to imply that the bow section was nearly finished. Still have quite a bit to do before I can call it finished. I just ordered some IJN flags for it yesterday from a shop in England. Hope they are what I'm expecting or else I'll have to print some out with my ink jet printer.

- 467 replies

-

- mikasa

- wave models

-

(and 1 more)

Tagged with:

-

Once again, thank you so much fellows for your nice comments. @Imagna...If I build a Russian ship from the same time period of the same scale, 1:200, it will have to be a paper model. That's the only other 1:200 pre dreadnoughts I have seen available.

- 467 replies

-

- mikasa

- wave models

-

(and 1 more)

Tagged with:

-

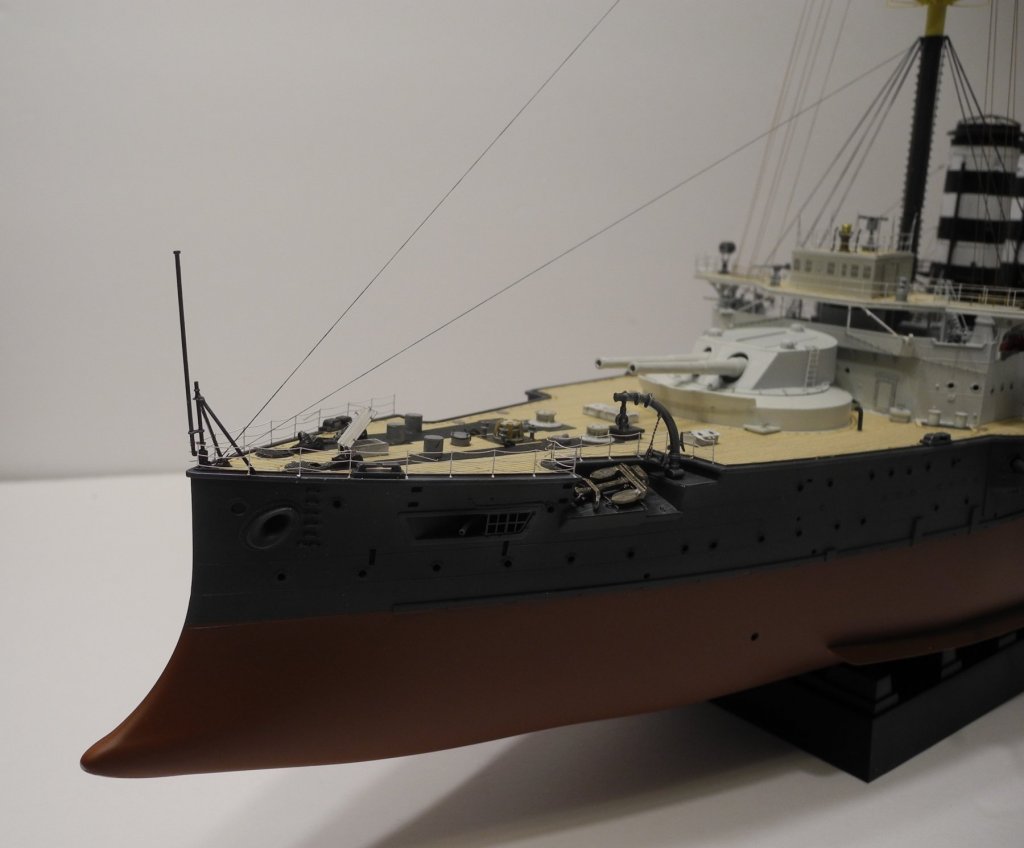

Thank you for the kind words, Denis. All three anchors and chains now installed. Except for the prominent Chrysanthemum emblem and IJN flag, the bow section is nearly completed now.

- 467 replies

-

- mikasa

- wave models

-

(and 1 more)

Tagged with:

-

A little trick I learned while building RC aircraft models...use the old formula Titebond as it is not water resistant as is the new formula. Why? If you make a mistake (as I often do), I can easily "disassemble" a glued part by moistening it with water. Of course, this is okay for static models or models that will not otherwise be exposed to water.

- 209 replies

-

- constitution

- revell

-

(and 1 more)

Tagged with:

-

Mike You are doing a 1st class job on this model. One of the best looking models of this type I have seen. Keep up the great work, am enjoying your progress photos and am encouraged to jump on some of the old Revell kits I've had sitting in wait for a long time.

- 209 replies

-

- constitution

- revell

-

(and 1 more)

Tagged with:

-

Is she darker than it appears in the pictures? Sometimes, my camera makes it look much lighter than it really is in real life. You are making swift progress. I'll bet you are really enjoying this build.

-

Richmond I was just on the Freetime Hobbies Ukraine website. I am not sure they are still in business. They once offered payment by Paypal, but the only method they show now is Western Union. That doesn't seem a good omen to me. I tried to contact them by email, so I will let you know if I get a response back from them. CDW

-

Richmond The name of the shop in Ukraine is Freetime Hobbies. This is their url: http://www.freetime.co.ua/en/ They were very prompt with their shipping as well.

-

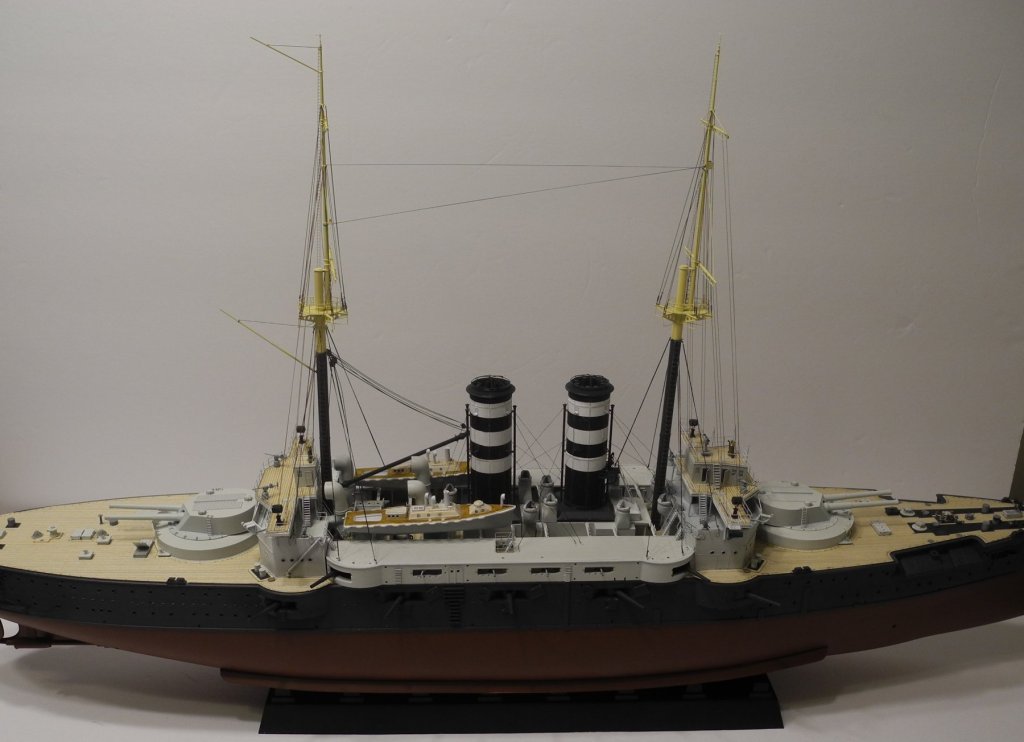

Thank you Phil and Paul. Your kind comments are motivation to continue and finish this project.

- 467 replies

-

- mikasa

- wave models

-

(and 1 more)

Tagged with:

-

Similar happened to me last time I wanted to order from GPM. I just emptied my cart and ended up buying the same items from a shop in Ukraine. Postage there was very reasonable as was the cost of the parts.

-

- 467 replies

-

- mikasa

- wave models

-

(and 1 more)

Tagged with:

-

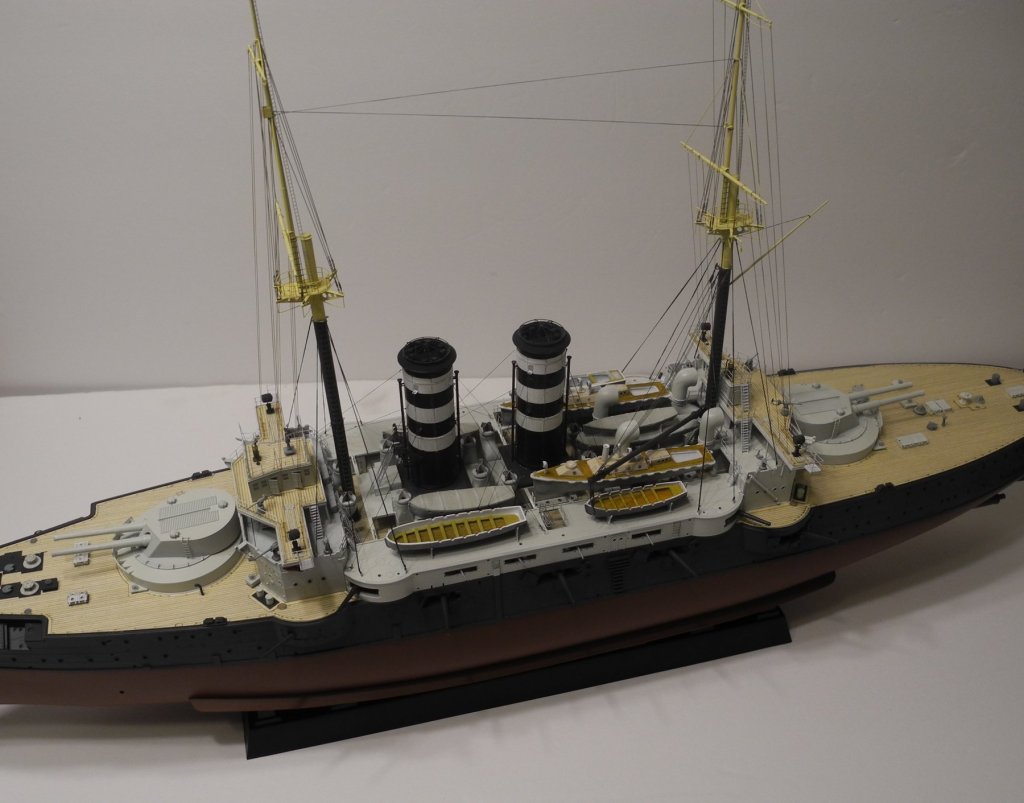

I agree with your observation of how well Tamiya rattle can primer sticks to photo etch. It's a nice leveling primer for plastic, too. What frustrates me with the Tamiya rattle can paint is how frequently the can of paint becomes unusable long before all the paint is used up, due to clogs. I've tried everything I know to do to prevent this, but it happens way too often. Besides being expensive, I often am able to use about half the paint in the can before it clogs up to an extent that I cannot clear the clog, and/or the propellant gas inside the can is expired.

-

Another word of advice to anyone building a model with the Pontos update sets, whether it be the Bismarck or any other model, try to pay close attention early on to all the photo etch parts on the frets. I have learned that the Pontos photo etch sets contain a lot of useful parts that are not mentioned in any way on the instruction sheets. I have learned this only after I searched out and purchased other aftermarket parts, then once I used all the instruction-identified Pontos photo etch parts, discovered they were included but not mentioned in the instructions. The most recent example of this for me was when I had to find and buy tie down points for my rigging, and then learned the Pontos photo etch sheets actually included them, but they were not mentioned on the instructions. There are other relevant parts included that are unidentified as well.

-

I have been battling that "funky" Trumpeter plastic with my current build. Tamiya rattle can primer seems to go on without problems, but there are lots of problems with acrylics, even after the Tamiya primer has been applied. One would think perhaps the cause is unwashed plastic and residual mold release agent, but that's not it. I scrub these plastic parts down very well with a mild detergent before ever applying any paint. There is (I think) some odd additive in the plastic itself that's causing the problem. Weird and frustrating.

-

- 467 replies

-

- mikasa

- wave models

-

(and 1 more)

Tagged with:

-

Look great, but that has to be a painful process to work through. So many of the things that look really great are like that. In the end, it's worth the effort.

-

- 467 replies

-

- mikasa

- wave models

-

(and 1 more)

Tagged with:

-

You come a long way very quickly with the Black Pearl. What is the 2nd ship? Looks great!

-

I think you nailed it on the stained deck, OC. Looks very Black Pearl authentic to me. Excellent job, just excellent.

-

Every year, I go to an RC aircraft event called Top Gun. Contestants from all over the world come to compete for the title of, Top Gun. They are judged for static scale fidelity as well as a choreographed solo flight performance. The event is not limited to, but consists mainly of jet fuel powered turbine engine aircraft. Now when I go to this event, I always leave feeling very good about how little I spend on my plastic modeling hobby compared to these modelers. They literally have tens of thousands of dollars wrapped up in each model aircraft....and in an instant, they shatter into a gazillion pieces when they crash. And they do crash from time to time.

-

I know a big Florida hobby dealer who specializes in buying large hobby collections/estates. They pay 10 cents on the dollar and sometimes less for collections. He's bought tons of hobby items that way and has large warehouses he stores it inside.

- 209 replies

-

- constitution

- revell

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.jpg.7e80607770d9078b2f0b470e8c9c33ac.jpg)