-

Posts

628 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Worldway

-

Test of Byrnes table saw

Worldway replied to michael101's topic in Modeling tools and Workshop Equipment

If I remember correctly, the fence tapers 0.005" from the blade to the back of the saw. -

Well, after a bunch of sanding, I still have more to do but I'm getting closer. I bought an electric hand held belt sander with a 1/2" wide belt. It helps and removes a lot of wood fast although it's butchering the plywood bulkheads. I will do more hand sanding to achieve the final results. I'may be at this for a while longer.

-

So here is the sorta final assembly. I still have to taper the edges and put a finish on it. I'm thinking of a wipe on poly. I have also decided not to paint at all. I'm not into historically completely accurate ships, honestly I hate painting and I think a natural wood finish looks better. I figure I will enjoy this more if I don't have to worry about painting.

-

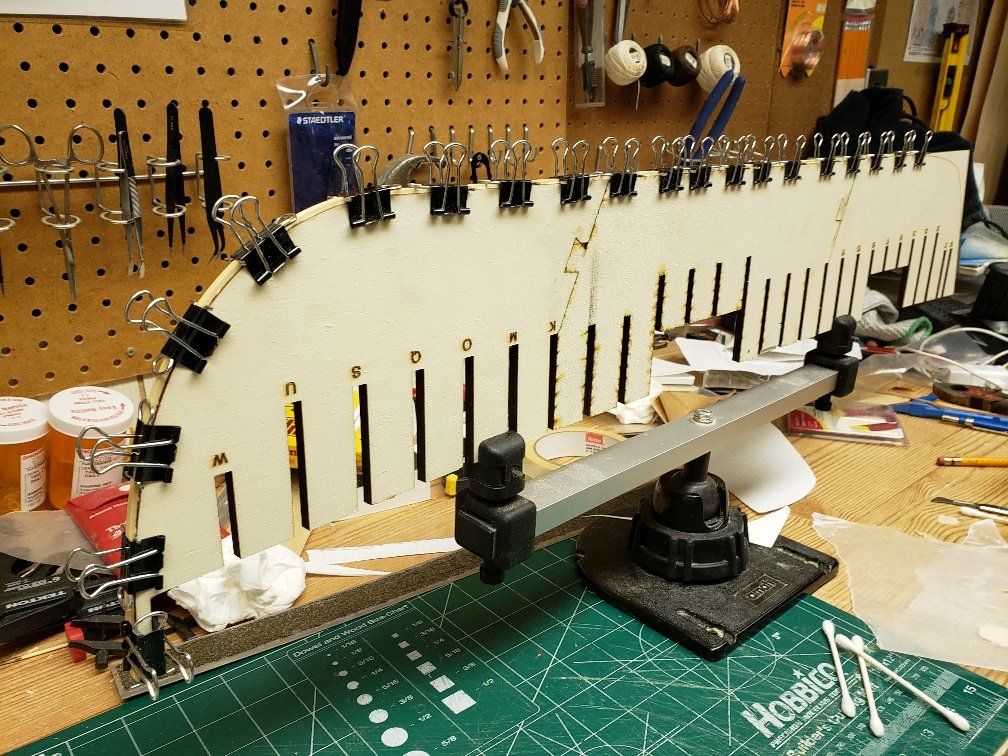

I started the head knee assembly and thought I would break it down to a few sub assemblies. I figured this would give me a tighter joint. The practicum recommends the use of Titebond II glue and no removal of the laser char. I ended up getting Titebond III and have not removed any char. I hope I end up with a good tight strong joint. (BTW, I've had problems finding Titebond II at the usual places. But my wife found Titebond III tonight at another hardware store. It's supposed to be better and stronger.)

-

I finally got my order from Syren. And when I say "finally", that is not a slight against Syren or Chuck. I have been off work since before Christmas enjoying a 2 week staycation. I asked a colleague of mine to let me know if any packages shows up for me at work. I have a lot of my stuff shipped to work to avoid porch divers in case I'm out. I don't hear from my colleague at all. I walk into my office this morning and there is this noticeably large box on the table behind my desk from Syren. I approached my colleague and asked why he didn't call me when it showed up. His answer was, he never noticed it plus my office was locked the entire time. I have no idea how long the package was sitting there. So it's in my shop now. I plan on starting very shortly. Wow, this is going to be big.

-

Well said Hubert

-

Unfortunately I've had some financial setbacks so had to cancel my order for the disc sander today. As I politely said to them, they have not heard the last from me. My wish is that Jim develops a band saw / re saw. Maybe someday.

-

Byrne's Table Saw additions/add ons

Worldway replied to blackjack40's topic in Modeling tools and Workshop Equipment

Just being a new owner of the Byrnes saw myself I realized a couple of things. Because shipping to Canada can add up, I wished I added a few more blades and a couple more zero clearance inserts. 4" blades are difficult to find in Canada. I also wish I had ordered more of the miter bars. It's the piece of machined aluminum that fits in the guide slots on the table. That way I would have a few spares if I wanted to make jigs that run in the slots. -

It's usually found right under your nose, in plain sight or slightly buried.

-

I am notoriously bad for grabbing a tool, using it then throwing it on the bench. Eventually I can't find anything and end up with a bench to cluttered to use. To make matters worse, I have two workshops and it gets to a point where I can't use either. That's when I have to spend a weekend cleaning up both shops, returning tools from one shop to the other and putting things away. I promise myself I'll put tools away after use, which lasts for about a week then the mess begins again. It literally gets to a point where I'll use a tool, set it down, need it again and spend the next 10 minutes trying to locate it. Having said that, in the house we have a place for everything and everything is in its place. So I get used to where everything is until one day I can't find anything. Reason being, the admiral will decide, maybe twice a year, that she wants to rearrange everything. She doesn't tell me that she has done it. So now, I have to ask her where everything is. In 6 months time I'll learn all the new locations and then she'll rearrange again. Maybe that's her way of ensuring that she will always be needed. 😍

-

I'm wondering where I can purchase 4" table saw blades in Canada, or more specifically in Ontario. I won't need any soon but have been doing some research. The normal box stores don't stock them and I've tried a few specialty woodworking stores websites. It's for the Byrnes saw and although he sells good blades with his saw I figured now is time to save a buck or two and try to find something locally.

-

Thanks Kurt and Derek, a couple of fantastic ideas.

-

Thanks for the pics Jim, this helps a ton. I noticed that the kit includes two templates to help you shape the filler blocks. I'm not sure how useful they are but I'll soon find out. I did notice that the bulkheads did not go all the way to the bearding line so I thought I should add filler pieces before I start the bulk of the fairing. I have a lot of Maple veneer so I thought I would cut and glue a couple of pieces together to use as filler pieces. I then added the filler pieces to go from the bulkhead to the bearding line.

-

Hi Jim, Can you tell me who you got your boxwood carvings from. I'm not sure who Jack is. Or you might tell me and I'll have a face plant, knowing exactly who he was and didn't realize.

- 105 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks Chuck and Tim. I was working on my Fair American today and was thinking that it's a tough but doable kit. I have a practicum plus this site to help me through that build. I know I will get 100% support from all the great builders at MSW while working on the Winchelsea. I also believe the scale will be a help because everything is just a little bit bigger.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Wow, I think I'm in over my head.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I just purchased a disc sander from Byrnes and thought I would include the draw plate in my purchase. I know that it's good for making fake nails but I'm wondering what other uses it could have, if any.

-

I purchased something similar and it was garbage. I would have to say that if they are re-purposing a part (exacto,or similar blade) then it's not that good. By the looks of it, you could make your own quite easily.

-

You have to add a stern filler block. The practicum tells you to set it in place, mark the outline of the bulkhead, then remove all the material past that point. I didn't do that, so I was left with removing a good 1" bit of the filler piece after it was glued in place. The only thing I could think of using was a carving knife.. This was after the first hour or so. I just dug my heals in and decided to go for it. I was getting to a spot where I thought I was close to being done. But then I realized.... You had to get down to the bearding line. So perseverance, a couple of beers plus 3 hours finally got me to a point where I can continue. Sorry I don't have pictures of the bulkhead installation or the bow filler blocks. But on and upward.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.jpg.4b9546914df2c235b4fe82d7c03670bd.jpg)