-

Posts

863 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Heronguy

-

I expect that you're right - I've been trying with the dremel but dissatisfied with what I've managed so far. May be that I need to practice more (ie throw out the attempts till I get something ok). I've looked at the carving forum to get a few beginner tips - what I seem to need is a template for the curve I want - my attempts to draw the curve freehand haven't been good. I haven't spent much time searching for a bannister rail image on the internet that I could resize and trace. That will be my next step. The problem/advantage of having more than one build on the go is that when I get stuck on one I don't have to get unstuck (until I'm stuck on all of them!)

- 99 replies

-

- essex

- cross-section

-

(and 1 more)

Tagged with:

-

I hadn't looked on YouTube. Is it worth the look?

-

Welcome. I'm a newcomer too (well I was 8 months ago). You'll find lots of helpful people here so ask questions when you need to. I just got the Occre Trinidad cross section too (a week ago!) I won't be starting on it for a while (months) but perhaps you'll be ready to work on it concurrently! Have you seen the other Trinidad section builds already?

-

Cool - I had never heard of Angelique before (thanks to Wikipedia I am now an expert ) Sounds like it will be pretty difficult to work with (hardness) but it would be awfully appropriate to include in a BNII build. I hope you'll doit!! How large a piece do you think you'd get? Will you mill it yourself?

- 107 replies

-

- brazzera

- marisstella

-

(and 1 more)

Tagged with:

-

Thanks Ian. Sometimes I feel less sociable and don't show much. Then of course are the times when I don't DO much so have nothing to show!! Right now I'm a bit stuck on carving a rounded railing - I keep fantasizing that the mill will help. However I don't want to wait the months it will take to get a level of proficiency to do that. Something simpler for Sherline and me!

- 99 replies

-

- essex

- cross-section

-

(and 1 more)

Tagged with:

-

Thanks Elijah, I think it will be more of a challenge to get good results on a complete hull! The beauty of the cross section is the straight short runs for planking and coppering

- 99 replies

-

- essex

- cross-section

-

(and 1 more)

Tagged with:

-

Space the final frontier! I can relate to that Mike. It'll likely be there when you have the room to bring back to the workbench.

- 99 replies

-

- essex

- cross-section

-

(and 1 more)

Tagged with:

-

I'll let you know what my experiences are. I'll be keen to figure out how to make best use of it for ship modelling. Drilling a straight line of holes for a pin rail sounds so very pedestrian but I've thought that having an x-y table for that would be handy. Now I can probably spend an hour setting up the mill and have the computer turn out a matched pair! Oh boy!

-

The mill arrived home last night! I went to inspect it the previous week and found it was as described - the mill was in pristine condition - never cut into material - and a nice collection of accessories. The gentleman selling it had hoped to use it to learn CNC programming but had trouble even turning on the computer so it just wasn't the thing for him. He has a Sherline lathe (not CNC) in his shop that does look well used so it was the programming aspect that thwarted him. I've got a programming background (though no machining background) so I imagine I'll be OK. My main concern is that learning machine may impact time in the shipyard itself - I think it will be a while before this new tool plays a useful role in my modelling efforts There are gems out there - I think I found one!

-

Small disaster tonight. Walking away from my work desk my sweater caught the bowsprit and the Bluenose II followed its predecessor and sank (i.e hit the floor. Damage wasn't too bad - the keel broke off along the glue joint (easy fix), the main mast and the bowsprit likewise can be easily reglued. The anchor chains can be straightened out. I thought I got off really really easily until I noticed that the hull had been holed. Hopefully once filled, sanded and painted it will not be too noticeable a blemish. Lesson learned? - naked modelling?????

-

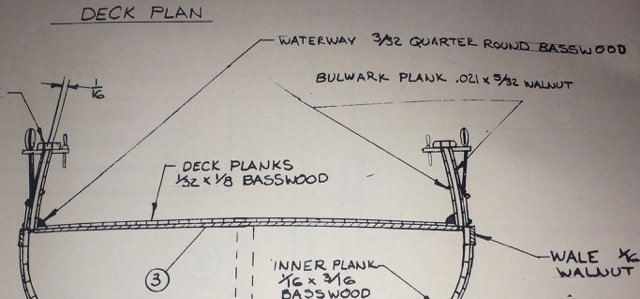

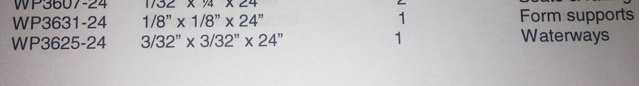

Small issue with the waterways. Kit provides 1 strip of 3/32"x3/32" basswood. Plan calls for 3/32"quarter round I can't really imagine how to turn 1 piece of square stock into 2 pieces of quarter round at this dimension 3/32". The kerf on any blade I've got would use up most of the material. I can imagine workarounds that I can use to make the waterways but I was surprised to see this in the kit. Anyone dealt with a similar request inter kits?

-

Dremel Drill pess adapter

Heronguy replied to Derek C's topic in Modeling tools and Workshop Equipment

I have one of the dremel presses. I'm satisfied with it for the purposes I have for it. I do really like the 90º turn for using it as a "lathe" for sanding down small spars (limited by the 1/8" collet size). Its also useful with the sanding drum on it giving hands free for the piece being sanded. -

Well the plot thickens. The mill itself was shipped to a distributor in 2008 so it is a bit older than the 7 years. It must have been subsequently upgraded to CNC. So far I don't know if it used Sherline sourced parts or 3rd party. Sherline updated their drivers in 2009 so it is really important for me to determine if the CNC electronics are the newer ones. I also have to check that the stepper motors have compatible plugs if I ever need to upgrade the driver box. I'm preparing myself with spec sheets so I can look at the system carefully when I get down to see it. Turns out the mill is the 8-direction version which offers more adjustments than I expect I'll ever need. Bit bigger bed though and since bench space isn't a constraint I can be happy about that. I must compliment Sherline rep for their friendly advice.

-

Loads of useful info Don. Thanks. I've been researching Sherline CNC since this opportunity came up and am aware of the parallel port vs USB issue. Standard Sherline CNC packages do support manual feed through dual axis stepper motors. One significant difference with your Taig mill would be the max spindle speed. Sherline quotes 70-2,800 rpm whereas Taig offers 1,100 to 10,000. I wonder what the advantage of the low spindle speed might be (you've already stated what the advantage of the high spindle speed is) The folks from Shoreline also think there is no problem upgrading to more recent LinuxCNC software. I'm hoping to drive down to see the equipment this weekend - with luck it will be suitable.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.