-

Posts

863 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Heronguy

-

Mark and Cliff, Thank you - just the kind of insight and advice I was looking for. I will be a complete novice on milling but the idea of precise control over operations made CNC interesting. As well that CNC can control multiple axes simultaneously seems to increase the range of milling that I would be able to do.(arcs, diagonal cuts). i will check on the dual shafts. I've read the Sherline site and it certainly looks promising that it will be dual shaft steppers - apparently the system was bought as a unit rather than assembled through upgrade parts. I'm also slightly off put by the computers age although since this is a dedicate machine and it appears Sherline hasn't upgraded software significantly since 2014 then it might be fine as long as the hardware keeps running and it sounds like this system hasn't been used much if at all). Vintage hardware running vintage Linux doesn't sound like too bad a combo. I wonder about CNC systems in general. The mill part should be good for many years. Computer and software less longevity. I'd hate to end up with a machine that couldn't be maintained!

-

Nicely done Alan. I wouldn't have thought of that way to use the insulin needles. I couldn't imagine drilling .03mm then glueing them in! Maybe I can try out your technique. I'm sure you're right that if I use the jig for a while I'll get more proficient with it. With your density of rivets I'm impressed that you made 2 different impressions - it would be for yourself not the viewer I think!

-

Nice job on the nameplate - I like the font!

- 1,135 replies

-

- model shipways

- syren

-

(and 2 more)

Tagged with:

-

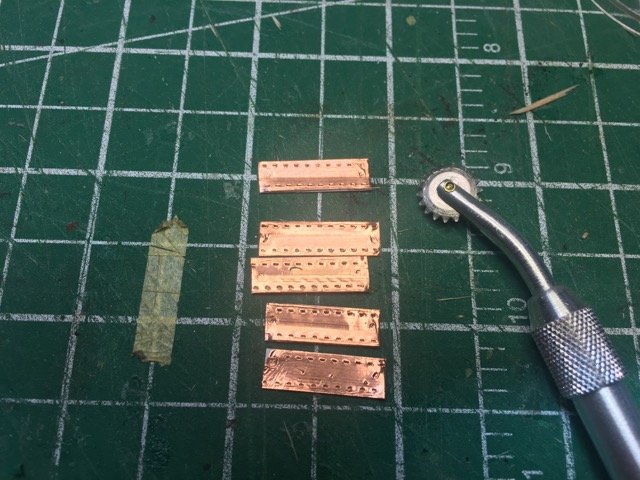

I have taken a short diversion from planking to play with coppering alternatives. I plan to copper both the Prince de Neufchatel and the Syren. I'm at the stage to do the PdN. Using the Syren instructions in chapter 8 to build a jig for applying rivets, I thought to use it for the PdN copper plates as well. I have struggled a bit to build the jig. The main problem was getting the size of the rivet heads reasonable. Th brass nails that come with most of my kits are .08mm in diameter. Given that the spacing of the rivets in Chuck's rivet pattern is 2mm I felt the rivet heads were too large. I found some .06mm brass nails - still a bit large but much better. I have some very small syringes with .03mm needles but the metal is quite bendy - I didn't do an experiment with them. Here's my jig, and the port and starboard pattern blocks - one finished the other ready for grinding down the nails. Some plates with the .6mm heads (the copper is NOT discoloured - artifact of the photo) The alternative was the use of a pounce wheel and a side-by-side comparison of the plates I found the pounce wheel process fast and easy. The Syren jig is slower, and I had some problems with the nails puncturing the foil so that it pulled up when I tried to remove the patten block to move the foil for the next impression. To be fair I haven't used the jig much yet and I may improve my technique with practice. Now to decide which way to proceed.

-

I have been considering a sherline mill (and lathe) and have come across a CNC mill that is claimed to be unused but 7 years old. Price is pretty good. I wasn't necessarily planning on CNC but was thinking DRO was a nice-to-have and CNC-ready was perhaps smart for future upgrade. I will admit that I don't have any experience with machining so I will have a learning curve in any event! I'm several hours away from the vendor so I'm asking him email questions before I plan t trip this weekend that would let me see the system. I don't yet have model numbers but have asked for them and hope to hear back today. I also don't know a complete set of accessories included but notably there is the rotary table. One of my concerns is the vintage of the computer and software for the system. A 7 year old EMC2 system has likely been significantly updated and a 7 year old linux box may limiting. I am going to call Sherline today when its morning in CA and ask them a few questions. I'm seeking advice from the forum on - any gotcha's I should be aware of in getting a 7 year old cnc system (e.g. change of interfaces to the stepper motors ...) - any configuration/accessory issues I might want to check on with the vendor. - any limitations created by having a CNC version - i.e. can I still use it completely manually? - general advice concerning value of CNC for our hobby Thanks all!

-

Since I am temporarily stalled on the coppering until I get around to making a rivet jig, I decided there was little harm in planking the deck. I decide to go with a 4-plank butt shift pattern as described in Simple Butt-Shift Deck Planking Ulises Victoria in our articles database. The caulking betweenn planks is using a Prismacolor Premier art marker. I really prefer it to pencil caulking. Progress to date: The Syren is in the background.

-

I read Piotr's comment as wanting to build the ship not the cross section.

-

I was hoping to do the trenails (treenail, also trenail, trennel, or trunnel). Right now I'm so focussed on the bulwarks and the little flaws I think the trenails would be an improvement. Also I've never done them, and this is a learning build, I kinda owe it to the build to try them out. I will watch how you approach the process! I don't feel like I have a particularly well developed aesthetic sense so it always a dither process for me to decide on colours and finishes! Your mention of green sounds pretty good!

-

Hi David, I've driven by Gibbard's but had never been inside. Would have been a good experience. I've been going over the side with light sanding and things are improving. I'll just keep at it with a light hand on the stain and steel wool until results are satisfactory. I'm glad I vented about the problem as I've got some encouragement and good ideas for fixes. Thanks all!

-

Very nice Rich. Your Argus is going to be beautiful broken nose and all!

- 1,135 replies

-

- model shipways

- syren

-

(and 2 more)

Tagged with:

-

Yes David, this is basswood. I've been painting (other than decking) on previous models and it didn't bother me as much. However my standards are increasing (always higher that my skill level unfortunately!) and I had high expectations when I woke up this morning. I was so disappointed. I've started a light sanding (Steve's suggestion) and it has helped already. I'm treating this as a learning experience - seems there's lots of those in my builds! As for your head-on 25 feet comment? - sorry I'd take your results any day - they're good.

-

I finished the starboard upper bulwark and I was OK with the result. The caulking marker I used between planks was good on the edges but there was serious bleeding at the butt joints. I wanted to see how ir would look after staining with Golden Oak. Now I'm NOT OK. I don't like the appearance at all. I have to do something to make this better. I wonder what?

-

Hello Ian, Thanks for dropping by. I'm following your Brazerra build with interest - I have a Marisstella kit on the shelf and I think the exercise in understanding plans will likely test me! The Bluenose and Bluenose II are such important symbols to those who grew up here that I think all Canadian ship modeller's should build one at least once! I think you'd enjoy the ship.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.