-

Posts

125 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by petehay

-

I logged in and the links to the last pics disappeared. I can look to see if I still have them on an old iPad.

- 41 replies

-

- lifeboat

- model shipways

-

(and 1 more)

Tagged with:

-

Here is my build:

-

When I finally built this I soaked the wood in isopropyl alcohol and taped them to a form. Worked very well, especially on the ribs.

-

What did you use to simulate the tree nails? Pete in Portland

- 95 replies

-

- virginia

- artesania latina

-

(and 1 more)

Tagged with:

-

Alot of the previous images are missing for me?

- 153 replies

-

- musongus bay

- sloop

-

(and 1 more)

Tagged with:

-

Welcome to the Smack Club.

- 60 replies

-

- muscongus bay lobster smack

- first build

-

(and 2 more)

Tagged with:

-

Could you post a close up of the cleat on the bowsprit? Pete in Portland

- 209 replies

-

- muscongus bay lobster smack

- midwest products

-

(and 1 more)

Tagged with:

-

How are you doing the cleats? I, too, dislike those supplied with the kit. Pete in Portland

- 209 replies

-

- muscongus bay lobster smack

- midwest products

-

(and 1 more)

Tagged with:

-

I had great luck at coming close to this finish by using thinned acrylic gesso as my sanding sealer. Pete

- 209 replies

-

- muscongus bay lobster smack

- midwest products

-

(and 1 more)

Tagged with:

-

Very impressive job on the scratch build. Did you cut all of the wood patterns by hand or did you use power tools? Pete in Portland

- 209 replies

-

- muscongus bay lobster smack

- midwest products

-

(and 1 more)

Tagged with:

-

This is looking very good. Giving me some good ideas for my second smack. Pete in Portland.

- 209 replies

-

- muscongus bay lobster smack

- midwest products

-

(and 1 more)

Tagged with:

-

Wayne, Thank you so much for that link. I visited the Apprenticeshop in Rockland this past summer and often dream of taking their courses to become a real wooden shipwright but at 62 and living on the west coast it will probably remain just a dream. Pete48, I hope to do a kit-bashed version of the smack (with a planked hull) that is in the same well worn condition as the image of the boat in hexnut's post above. A real example of a work boat with rust and wear and weather. When I see some of the stuff that the model car guys do to make a rusted beater and the weathering that the model railroad folks display - that's what I aspire to produce with my next attempt at the smack. Pete

-

Shawn - I have not used Testors paint on anything other than plastic. I have used Tamiya acrylic model paint and they do have a "Hull Red" color. On the Lobster Smack I have used "Americana Acrylics" from Michaels. Very inexpensive and lots of colors. The smack hull is Barn Red & Deep Ultra Blue. I did have to try a couple of whites before I found one that wasn't too yellow. The trick I've found is to thin them with a couple of drops of water to a dime size blob of paint. I used the paint to seal the raw wood (no sanding sealer) Hexnut - Thanks for the photo. It's exactly the reference I needed. Rudder should go on this weekend. Casey - Yes, the 1/32" molding strips were a pain in the rear. I used a spacer block to guide the lower strip as I glued it on. I glued about 2" at a time to keep things lined up. Pete

-

Now that the weather here in Portland is starting to turn it's time to get back to the model boatyard. Over the rainy weekend I installed the toe rails, trail boards and the upper & lower molding. The stars on the trail boards are little sequins that I picked up at Michaels. I found the moldings to be particularly tedious to get right (and not get glue all over everything). Pete

-

After 15 min or so in the ammonia solution the balsa just gets "bendy" not limp. What I mean is when you form it to the curve of the bulkhead it does not have the tendency to split along the grain that unsoaked balsa does. Pete

- 60 replies

-

- muscongus bay lobster smack

- midwest products

-

(and 1 more)

Tagged with:

-

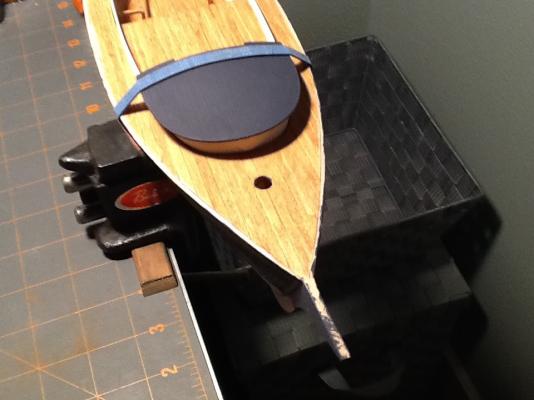

Inspired and encouraged by Mario, DeeDee and Hexnut I have started my Muscongus Bay Lobster Smack phase 1. Right before MSW went from v1 to v2 I went out and bought this kit along with the Midwest Sakonnet Daysailer. The Daysailer was my first wood boat kit and I learned a lot. I have since purchased a second Smack kit hence the phase 1/phase 2 reference. Following Mario's build as a primer I am currently building Smack #1 pretty much straight out of the box. I did plank the deck and floor with HO scale 2x10's from Northeastern Scale Lumber Co. and was very pleased with the results. I started the build over the Fourth of July weekend and thought the red, white, and blue color scheme was called for. I hope to follow this build with a totally bashed version a'la DeeDee but let's get this one built first. I have attached iPad Picts of where I am now with the build. Glad to join the Smack club. Pete

-

I'm building a Smack right now. Here's how I did it: Soak the balsa in a 50/50 mix of amonia and water (15 min). The side of the balsa that goes against the keel does not need trimming. Use the 1/16th strip that you glued along the keel in a previous step as your foundation. Fit the balsa against this strip snugged up to the keel (it should be quite pliable after being soaked). Play around with it until you find the correct placement then glue it to the keel strip (rabbet), the bulwarks and the batten strip -in that order. Carefully place some rubber bands around the model to keep the curve while it dries. Now you can trim the other 3 sides. Pete

- 60 replies

-

- muscongus bay lobster smack

- midwest products

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.